Connecting piece feeding equipment

A connecting sheet and equipment technology, which is applied in the field of connecting sheet feeding equipment, can solve the problems of increasing the occupied area, reducing the efficiency of cell assembly, and reducing the feeding efficiency, so as to achieve the effect of ensuring the feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

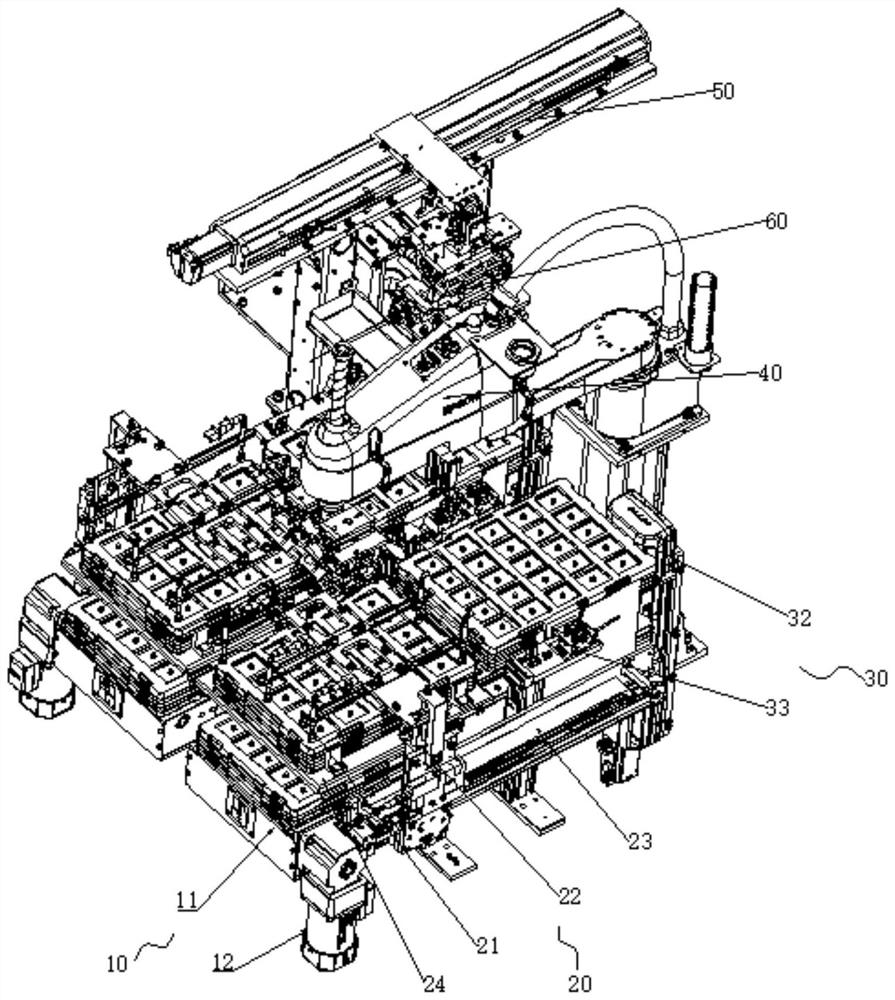

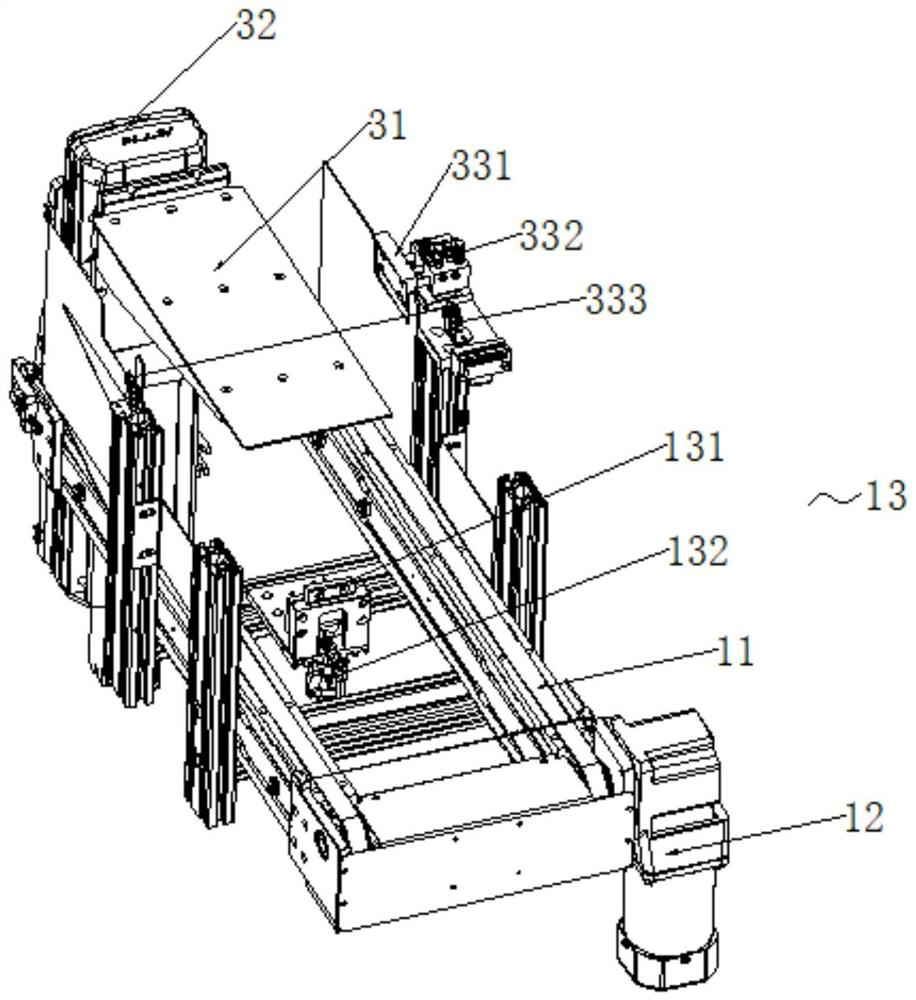

[0034] In order to solve the above technical problems, this embodiment provides a connecting piece feeding device, such as figure 1 As shown, it includes a conveying mechanism 10 for transporting stacked trays, and a lifting mechanism 30 is provided on the conveying path of the trays. The lifting mechanism 30 is used to lift the trays to a certain height, and is suspended above the lifting mechanism 30. There is a transport mechanism 40, which absorbs the connecting piece in the uppermost tray, and then loads the connecting piece, and a transfer mechanism 20 is suspended on the conveying mechanism 10, and the transferring mechanism 20 moves back and forth along the conveying direction of the conveying mechanism 10 , when the connecting piece in the uppermost material tray on the lifting mechanism 30 is loaded, the empty material tray on the lifting mechanism 30 is transferred away by the transfer mechanism 20, and then the lifting mechanism 30 continues to lift the lower layer ...

Embodiment 2

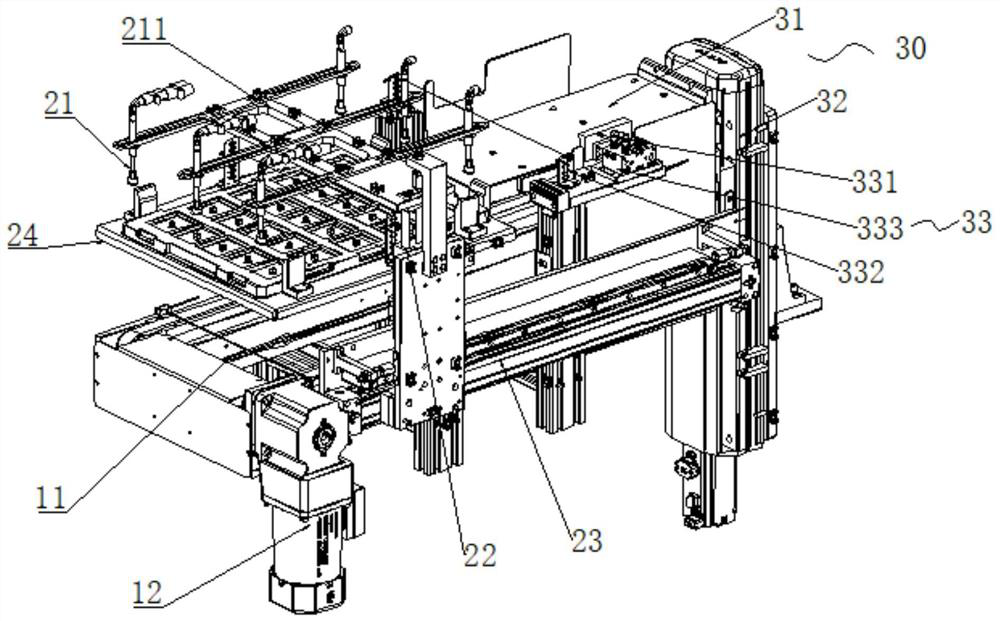

[0046] This embodiment provides a connecting sheet feeding device, such as Figure 7As shown, it also includes a conveying mechanism 10, a transfer mechanism 20, a lifting mechanism 30 and a handling mechanism 40 for conveying stacked trays, and a lifting mechanism 30 is set on the conveying path of the trays, and the lifting mechanism 30 is used to move the trays Lifting to a certain height, the connecting piece in the uppermost tray is sucked by the conveying mechanism 40, and then the connecting piece is loaded, and a transfer mechanism 20 is suspended on the conveying mechanism 10, and the transferring mechanism 20 is along the conveying direction of the conveying mechanism 10 The movement is used to transfer the feed tray on the lifting mechanism 30 .

[0047] The difference from Embodiment 1 is that the transport mechanism 40 of this embodiment includes a moving assembly 47 , a blanking assembly 46 and a transfer assembly 48 movably arranged on the moving assembly 47 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com