Continuous flow upright type planar liquid-phase shearing method

A planar, liquid-phase technology, applied in the direction of molybdenum sulfide, graphene, nano-carbon, etc., can solve problems such as large area, high stability requirements of power consumption devices, and inner barrel speed limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

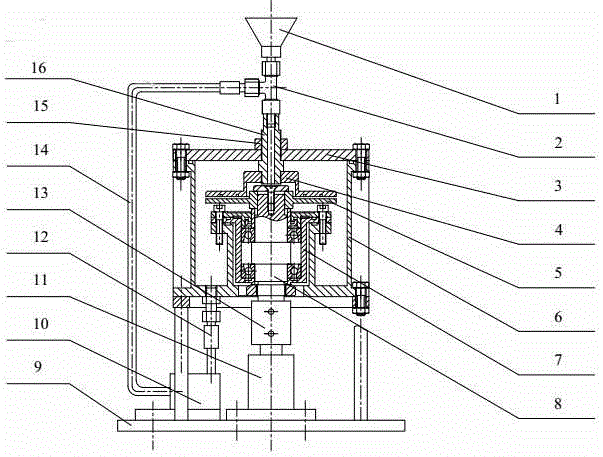

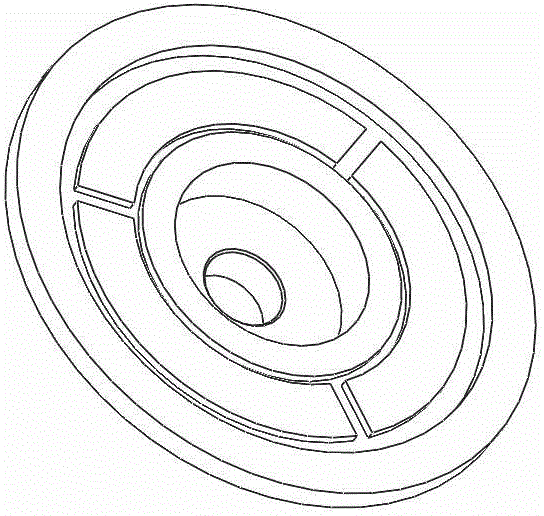

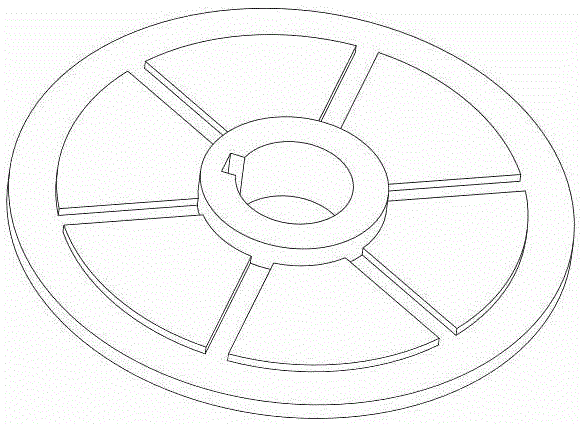

[0017] A continuous flow vertical planar liquid phase shearing method, using a continuous flow vertical planar liquid phase shearing device; the layered precursor material to be processed is mixed in the liquid, injected into the device from the feed port, and passed through the tee joint And the upper shaft enters between the upper plate and the lower plate; there is a certain gap between the upper and lower plates, and the intermittent amount can be adjusted by the thread between the upper cover plate and the upper shaft; there is relative movement between the upper and lower plates during work, and the upper plate The disc is fixed on the upper shaft and remains still during work. The lower disc and the lower shaft are connected by keys, and the lower shaft is driven by a vertical motor. When the lower disc rotates, the fluid between the two will generate laminar flow and turbulent flow at the same time. Due to the high-speed liquid phase shear force provided by the velocity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com