Slip form construction method of large-fluidity paving concrete for subway rail base

A construction method and concrete technology, applied in the directions of tracks, roads, ballast layers, etc., can solve the problems of low construction efficiency of subway base concrete, application of high-fluidity paving concrete, poor fluidity of dry-hard concrete, etc., saving manpower and material resources. , Reduce the difficulty of transportation and improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

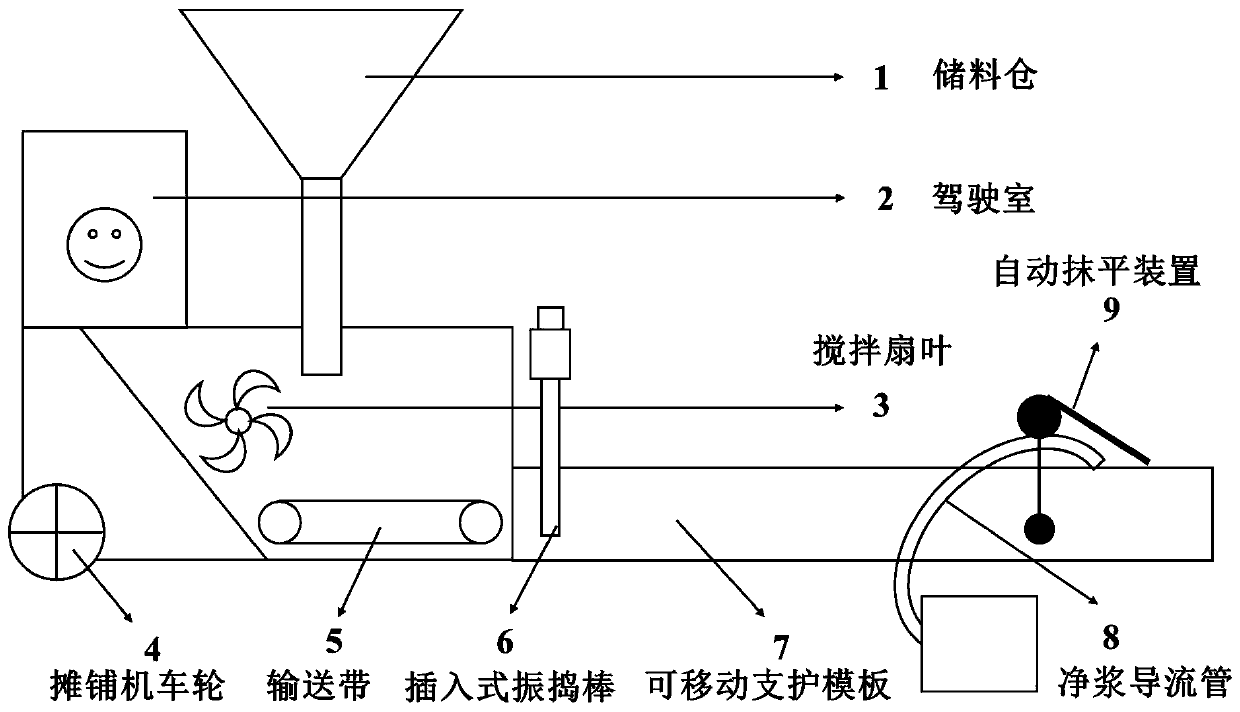

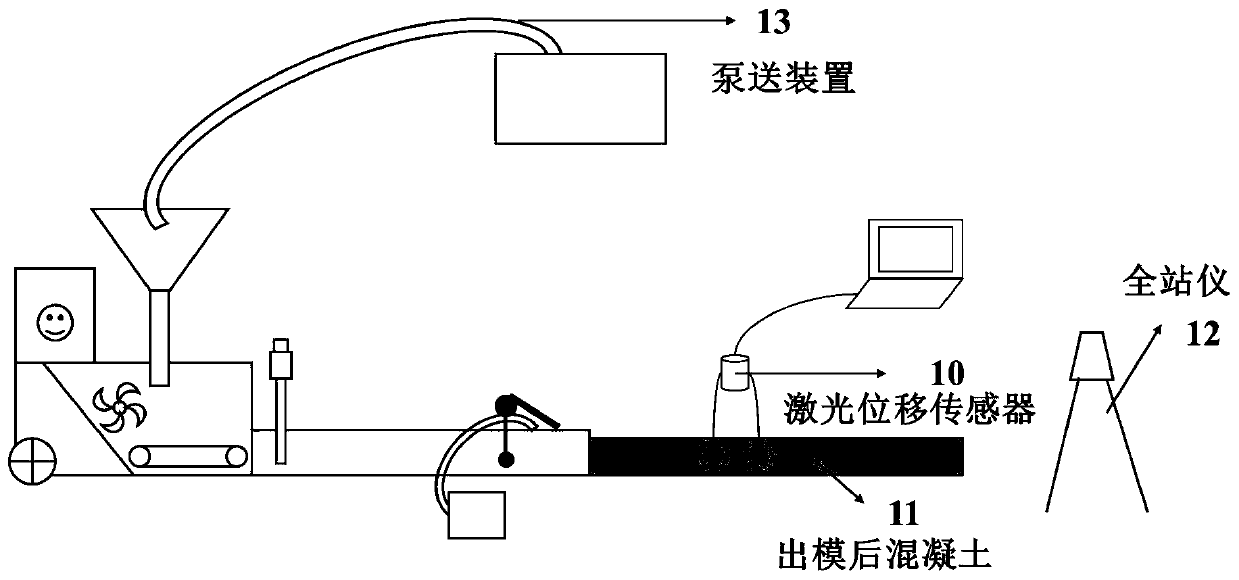

[0032] see figure 1 , figure 2 ,

[0033] (1) Placement and commissioning of the concrete slipform paver for the subway track base: figure 1 As shown, the slipform paver mainly includes a driver's cab 2, a storage bin 1, a stirring blade 3, a conveyor belt 5, a plug-in vibrating rod 6, a movable support formwork 7 and an automatic smoothing device 9. Drive the die paver to the site, debug various functions, and adjust the position accurately for standby.

[0034] (2) Preparation and transportation of high-fluidity paving concrete: the concrete mixing station produces high-fluidity paving concrete according to the predetermined mix ratio, and the single production volume is 3m 3 , transported by the concrete mixer truck to the construction site, the slum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com