Automatic flat plate box boxing machine

An automatic cartoning machine, flat box technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of poor stability and narrow range of contents, and achieve continuous cutting, improve the pass rate, and ensure the quality of cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

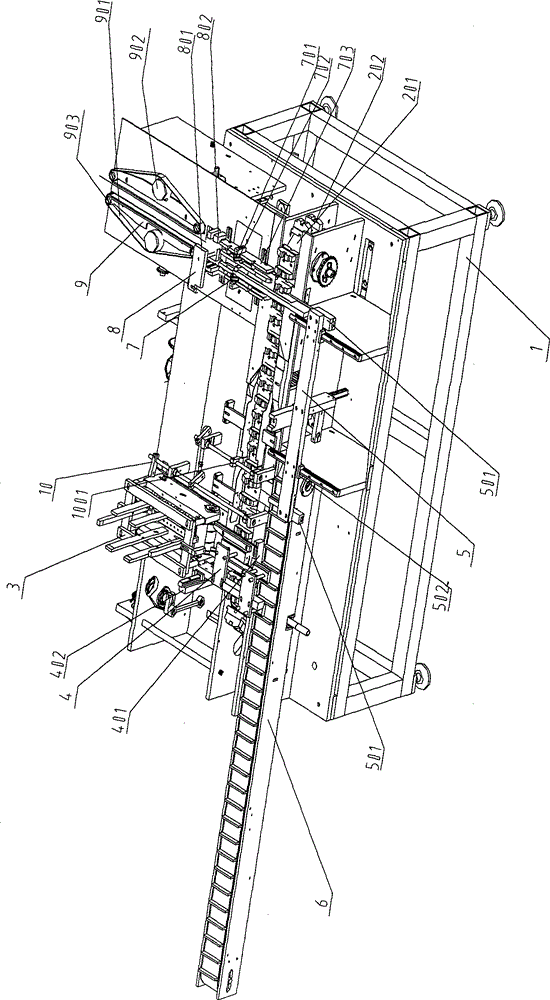

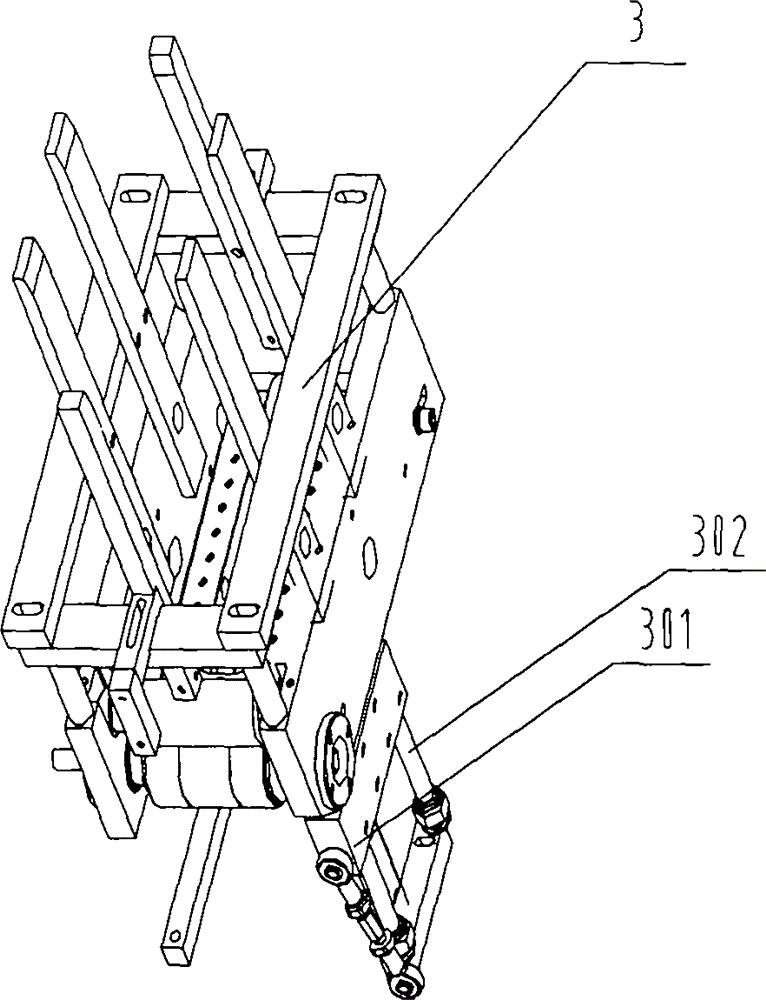

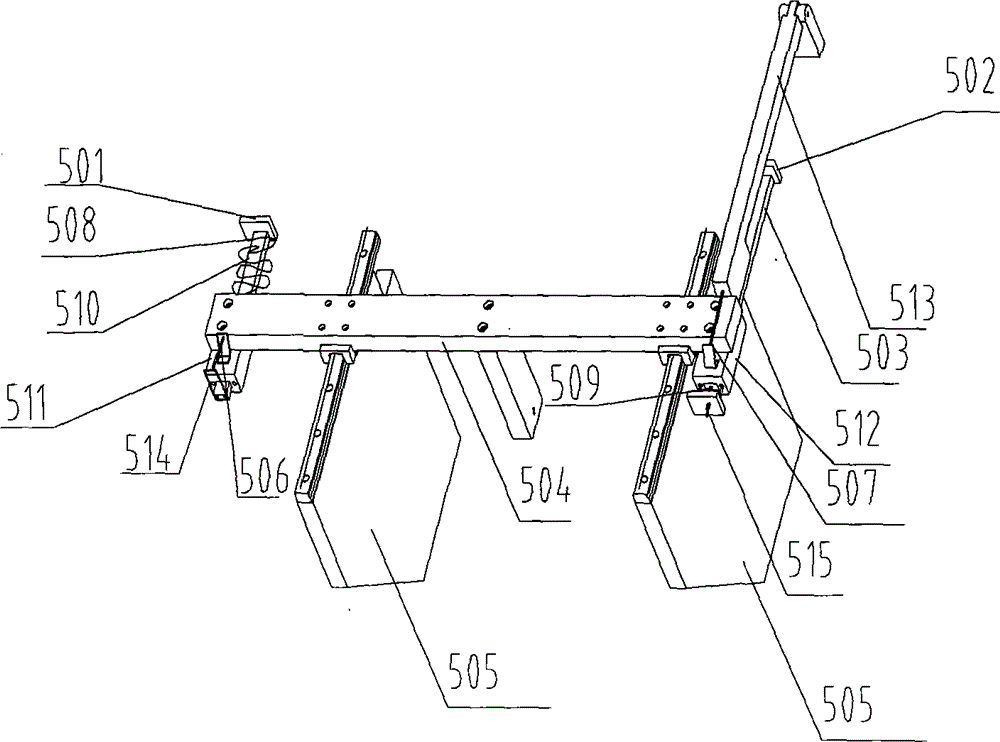

[0032] refer to Figure 1 to Figure 8 , a flat box automatic cartoning machine, comprising a frame 1, the frame 1 is provided with a feeding mechanism 6, a pushing material into the warehouse and a box pushing out mechanism 5, a carton hopper 3, a carton forming mechanism, a folding Ear mechanism 10, hemming and tongue folding mechanism, plastic box mechanism 7, side wing hemming device 8 and out-of-box conveying mechanism 9;

[0033] The carton forming mechanism includes a carton pressing block assembly 4, a carton forming module 202 and a carton forming module timing belt 201, and the feeding mechanism 6 includes a feeding timing belt, and the feeding timing belt and the carton forming module Synchronous belts 201 are arranged side by side;

[0034]The carton magazine 3 is located on the side overlapping with the feeding synchronous belt and close to the synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com