Method for detecting die cavity pressure in injection molding process based on ultrasonic signals

A technology of cavity pressure and injection process, used in the field of plastic injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

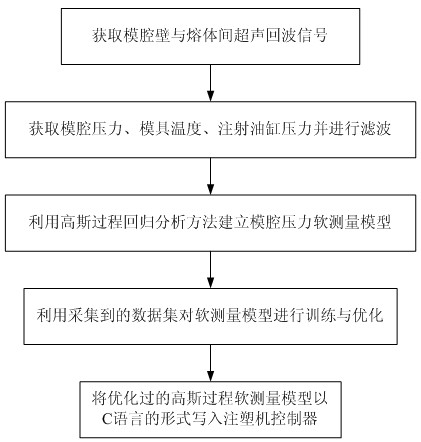

[0101] In this embodiment, polyvinyl chloride (PVC) is selected as the injection material, such as figure 1 As shown, the implementation steps of the Gaussian soft measurement method for cavity pressure in the plastic injection process based on ultrasonic signals in this example are as follows:

[0102] 1. Acquisition of ultrasonic echo signals between the cavity wall and the melt:

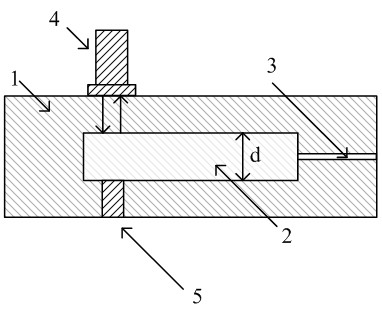

[0103] The method uses ultrasonic signals to detect the density of the melt in the mold cavity, and then establishes the relationship between the melt temperature, density and pressure through the PVT characteristics of the melt and the Gaussian soft sensor model, and realizes real-time online measurement of the pressure. For this reason, this method builds an ultrasonic detection platform for the cavity pressure. The positional relationship between the cavity, melt and ultrasonic sensors in this system is as follows: figure 2 shown. An ultrasonic probe with a frequency of 5 MHz is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com