Curvature detection device and method for drill rod

A technology of curvature detection and curvature, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high difficulty and high cost of devices, and achieve the effects of scientific structure, fast acquisition speed, and avoiding rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

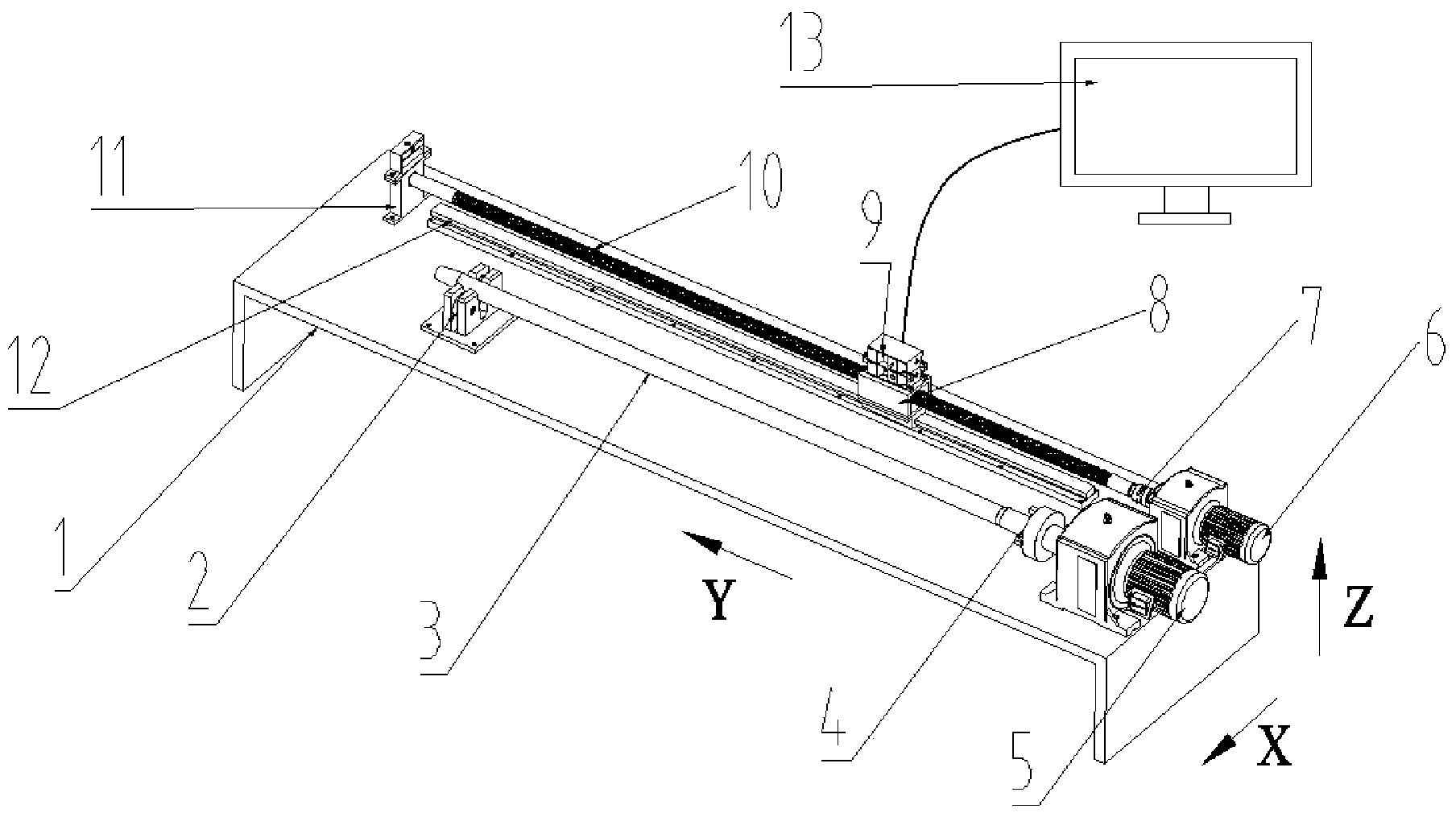

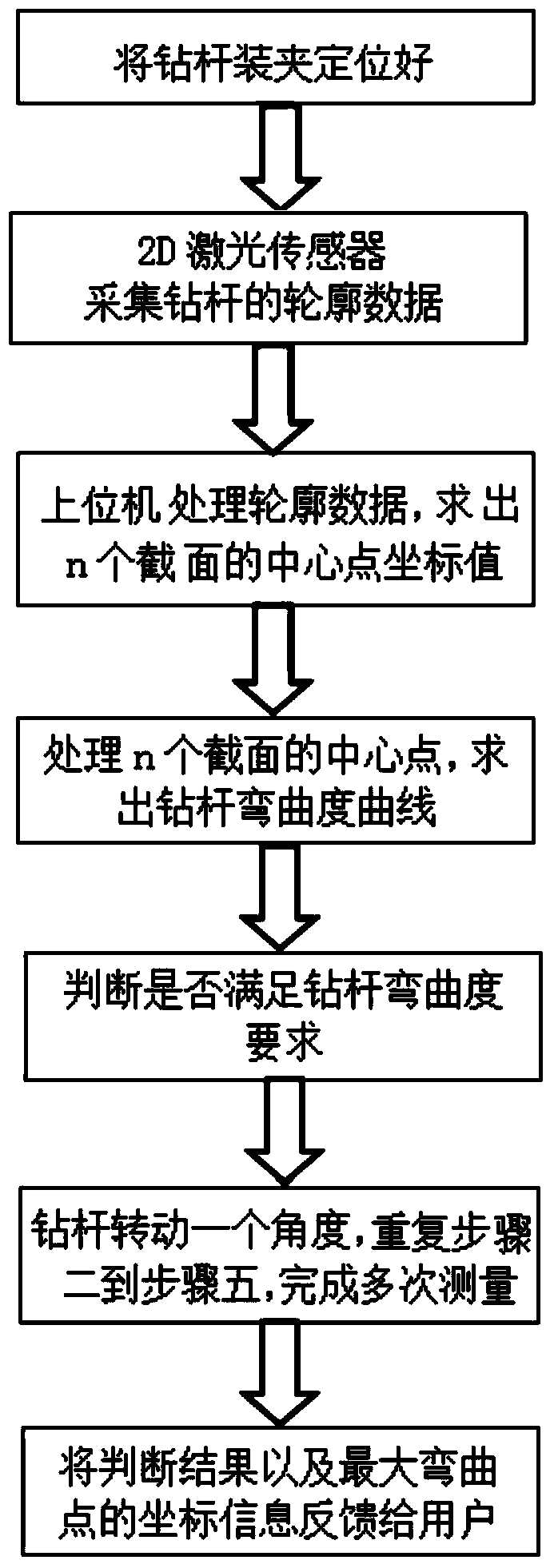

[0025] Embodiment 1: the present invention provides a kind of drill pipe curvature detection device, its structure is as follows figure 1 shown. It includes a drill pipe clamping part, a sensor transmission part and a control and calculation part; the drill pipe clamping part is provided with a working platform 1, a V-shaped block 2, a three-jaw chuck 4 and a stepping motor A5; a V-shaped block 2 1. The stepper motor A5 is fixed on the working platform 1 by bolts; the shaft of the stepper motor A5 is connected with the three-jaw chuck 4, and the three-jaw chuck 4 is used to clamp one end of the drill pipe 3, and the other end of the drill pipe 3 is placed On the V-shaped block 2; the drill rod clamping part is used to realize the positioning and clamping of the drill rod 3 and the rotation of the drill rod during multiple measurements.

[0026] The sensor transmission part is provided with a stepper motor B6, a shaft coupling 7, a ball screw 10, a linear guide rail 12, a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com