Method for manufacturing three-dimensional periodic structure metamaterial by utilizing three-dimensional printing technology

A three-dimensional periodic and three-dimensional printing technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of long time consumption and poor preparation accuracy, and achieve the effect of improving manufacturing accuracy, simplifying speed, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

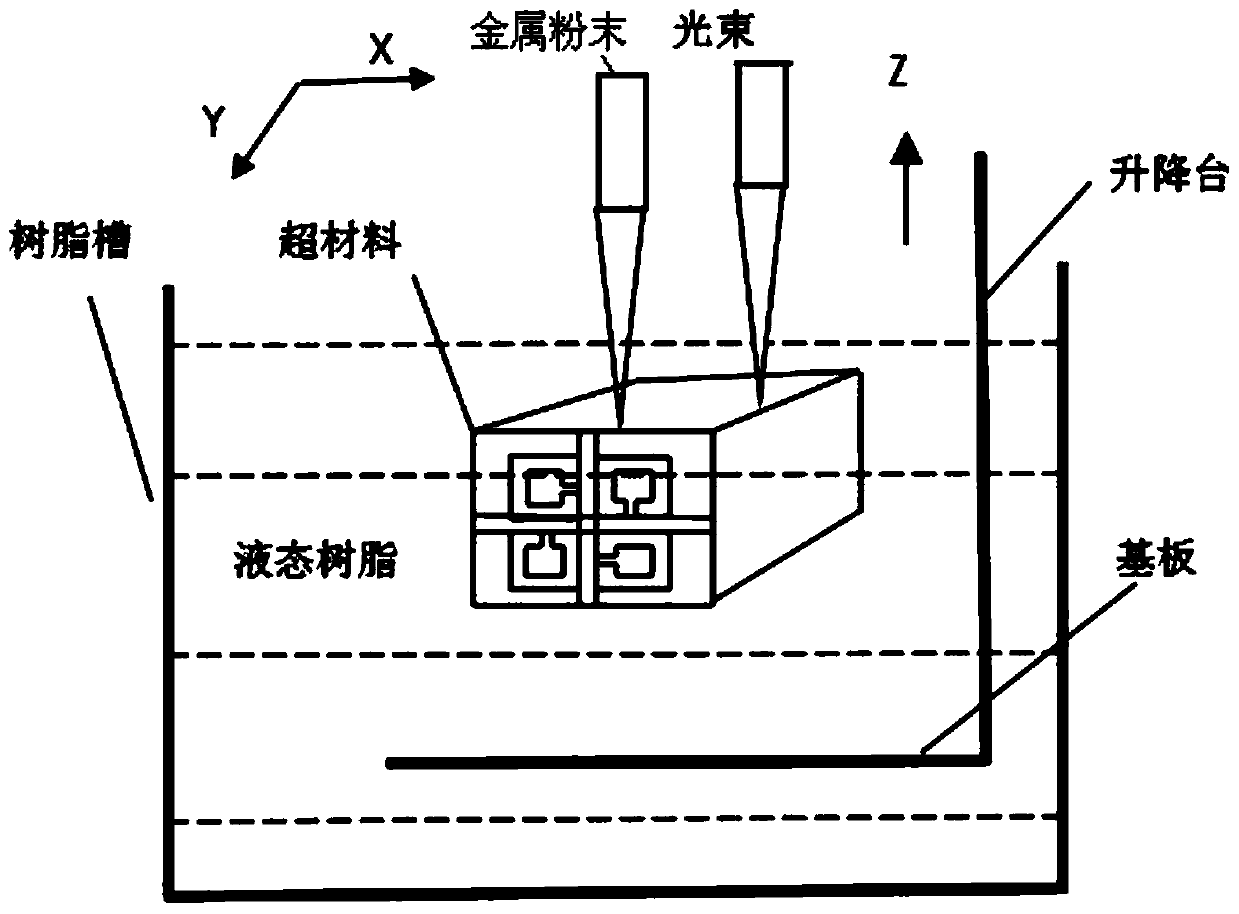

[0017] Further illustrate the present invention below in conjunction with accompanying drawing.

[0018] The method for producing three-dimensional periodic structure metamaterials by three-dimensional printing technology mainly includes the following steps:

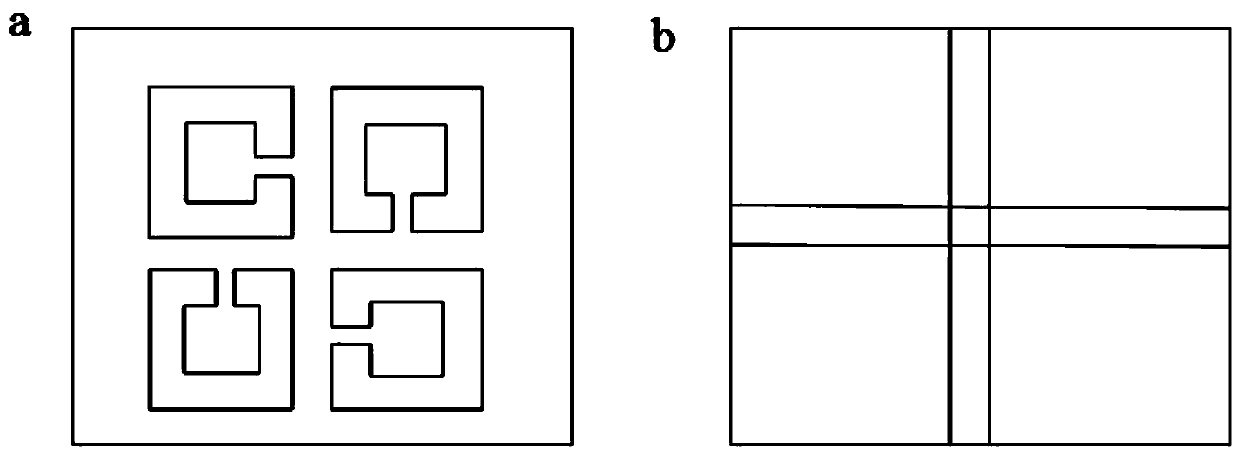

[0019] Step 1. Simulation design of 3D periodic structural metamaterials

[0020] Before making three-dimensional periodic structure metamaterials, according to the performance of the metamaterials, such as metamaterials with wave-absorbing properties, metamaterials that can change the direction of electromagnetic wave radiation, etc., the three-dimensional periodic structure metamaterials will be established in professional electromagnetic simulation software. The model of the material, after the simulation design of the three-dimensional periodic structural metamaterial is completed, the metamaterial model to be produced is obtained;

[0021] The manufacturing technology of the present invention can realize the rapid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com