Automatic straightening production line of T-shaped guide rail

An assembly line and automatic technology, applied in the field of automatic straightening of T-type guide rails, can solve the problems of low production efficiency, difficult to meet the requirements of straightening accuracy, and long circulation lines, so as to improve production accuracy and efficiency, save manpower and occupy space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

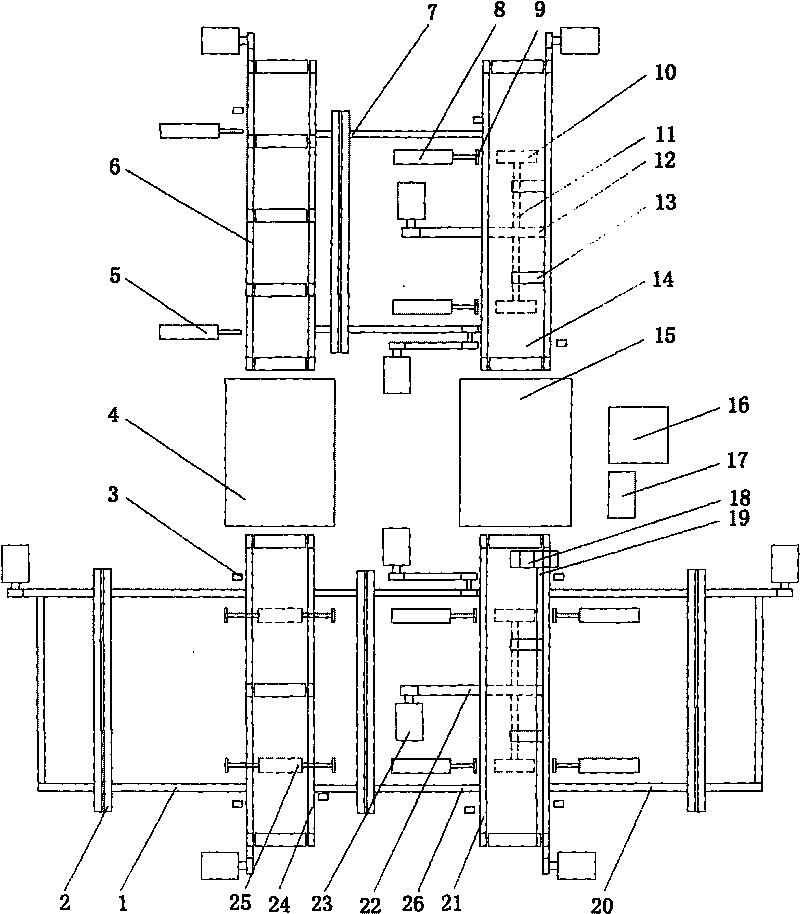

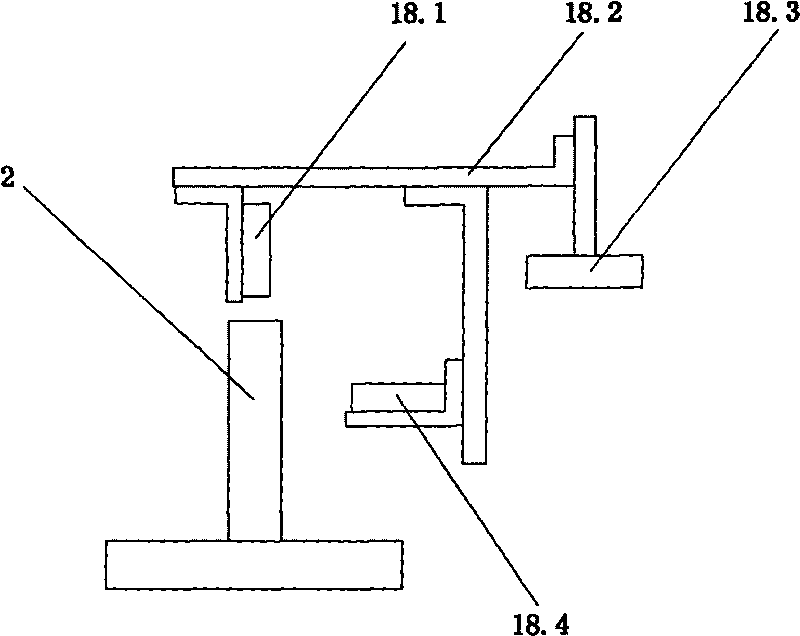

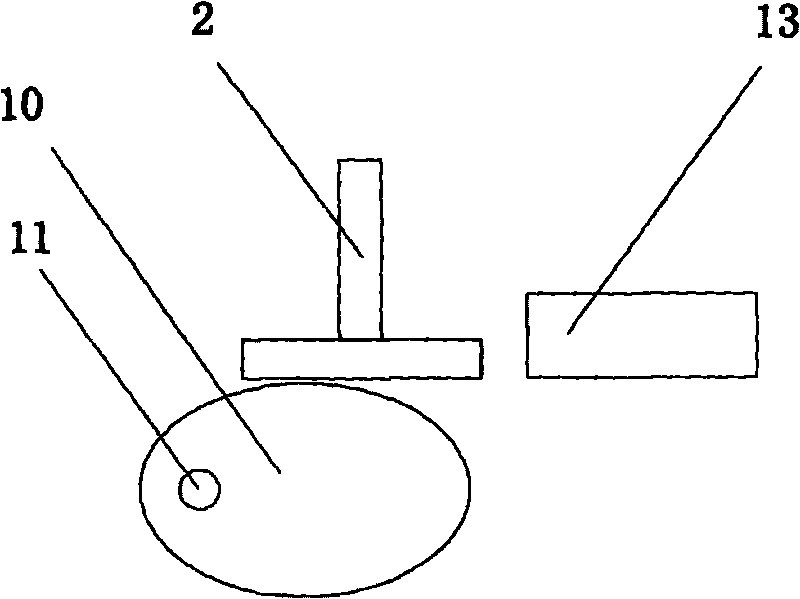

[0022] like figure 1 As shown, the present invention arranges the side automatic leveler 4 and the top surface automatic leveler 15 in parallel, and the first roller table 24 and the second roller are respectively arranged on the same axis at the inlet and outlet ends of the side automatic leveler 4. Road 6, the fourth roller table 21 and the third roller table 14 are respectively arranged on the same axis at the inlet and outlet ends of the top surface automatic leveler 15, and the second roller table 24 and the third roller table 21 are provided with a second chain The transmission frame 26, the first chain transmission frame 7 is arranged between the second roller table 6 and the fourth roller table 14, and the chain transmission vertical to the respective roller table is respectively provided on the first roller table 24 and the third roller table 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com