FLC (forming limit curve) testing method based on variation of strain rate

A technology of strain rate and test method, applied in the direction of testing the ductility of materials, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. FLC online test

[0030] 1.1 Test method

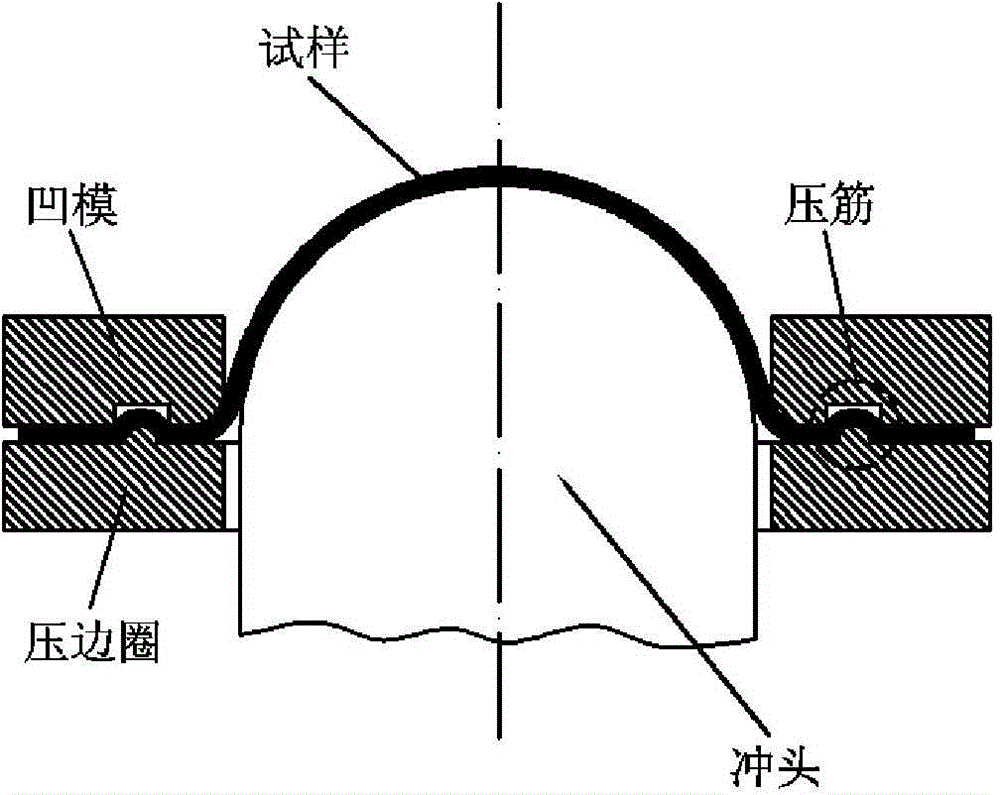

[0031] see image 3 , using the Nakajima curved surface bulging test method for the forming limit test of the material, the punch diameter is 100mm, the punch speed is 40-60mm / min, and the blank holder compresses the sample so that the material at the edge of the sample will not flow into it during the test In the die, the sample mainly deforms and flows at the contact part with the punch. By changing the geometry of the sample, different strain paths can be obtained at the part where the sample contacts the top of the punch.

[0032] 1.2 Preparation of samples

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com