Determination method for plate incremental forming limit diagram

A technology of incremental forming and measuring method, applied in software testing/debugging, instrument, calculation, etc., can solve the problems of low accuracy of measurement results, cumbersome and complicated methods, etc., and achieve the effect of high accuracy, reasonable method, simple and fast method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] refer to Figure 1-Figure 6 , the measuring method of the progressive forming limit diagram of sheet metal of the present embodiment, concrete method is as follows:

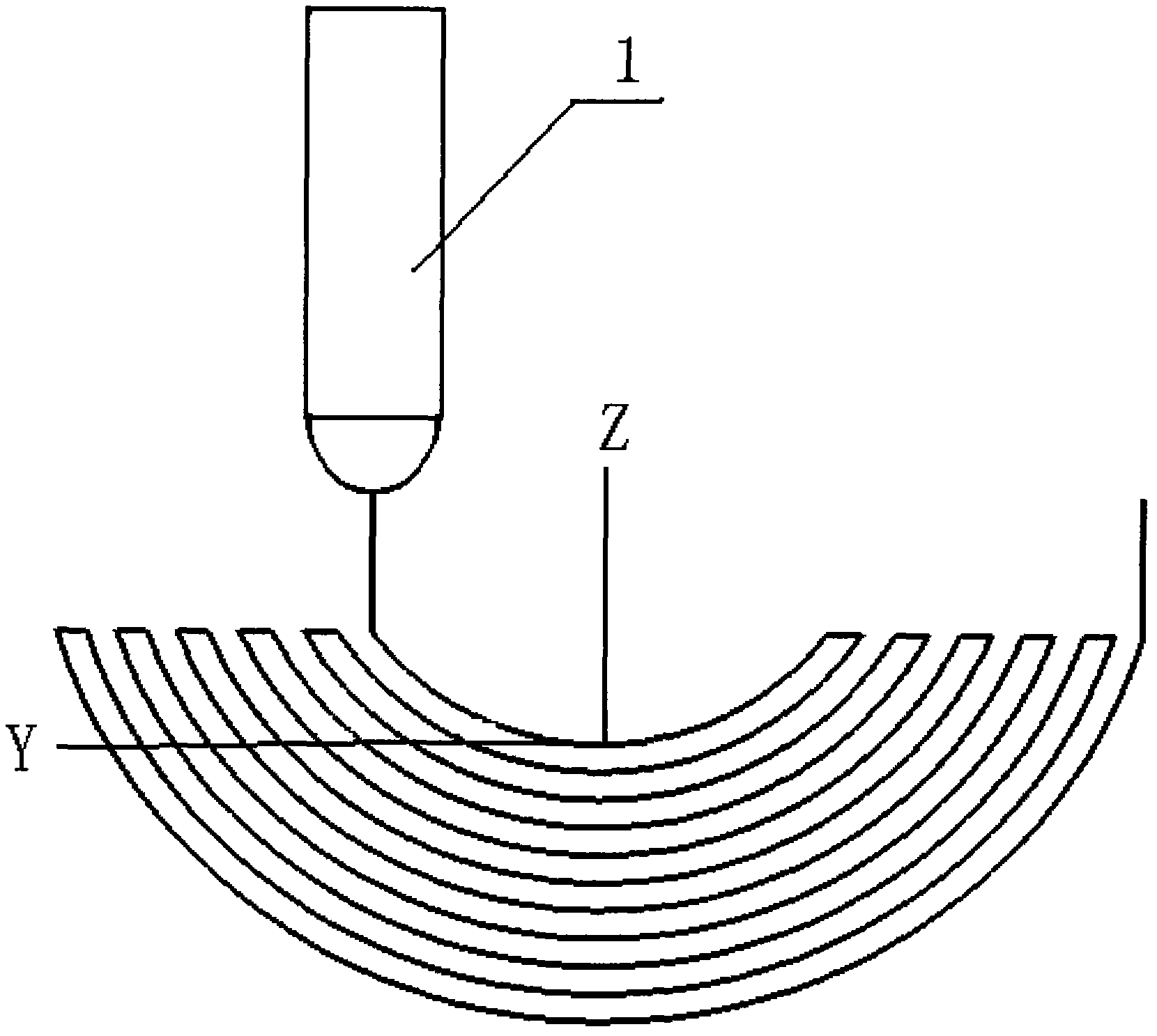

[0026] (1) if figure 1 , using UG NX8.0 drawing software, sketch the reciprocating arc curve in the Y-Z plane, the initial arc diameter is 120mm, the adjacent arc diameter is increased by 0.2mm, and the final arc diameter is 150mm, using the "processing" module " Fixed "curve / point" drive in "Contour Milling", specifying the drawn arc curve as the machining track of the processing tool, and generating a one-way arc groove machining program;

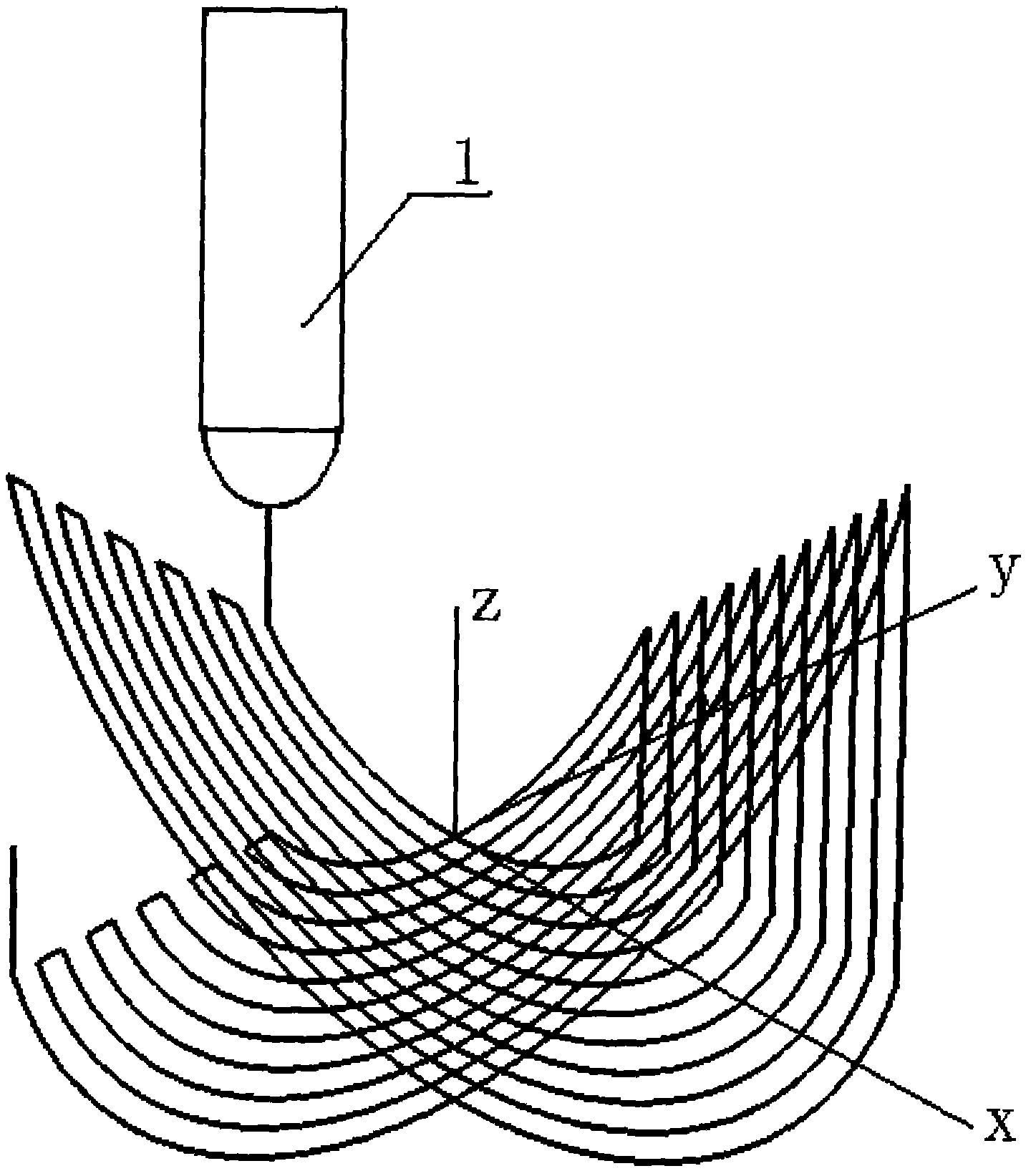

[0027] (2) if figure 2 , use UG NX8.0 graphics software to sketch arc curves in the Y-Z plane and X-Z plane, and alternately connect the arc curves in the two planes to form a single processing path, using the "fixed contour milling" in the "processing" module Driven by "curve / point" in the middle, designate the formed single processing path as the tool processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com