Forming limit measuring device under bilinear strain path and testing method

A technology of forming limit and measuring device, which is applied in the field of sheet metal forming to achieve accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

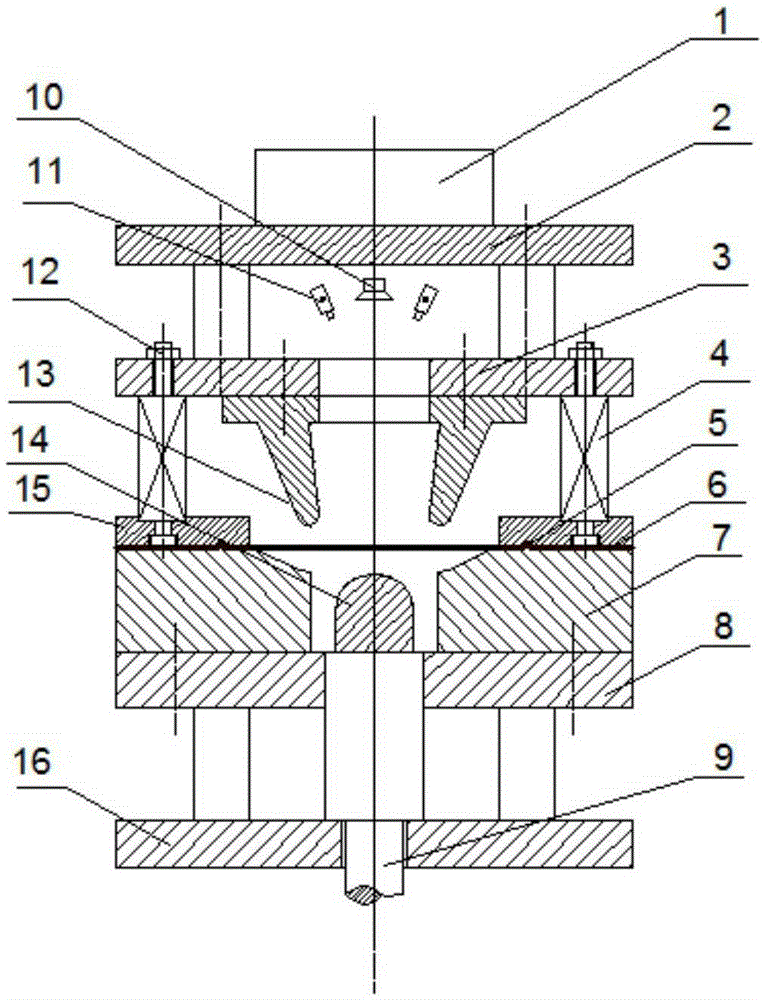

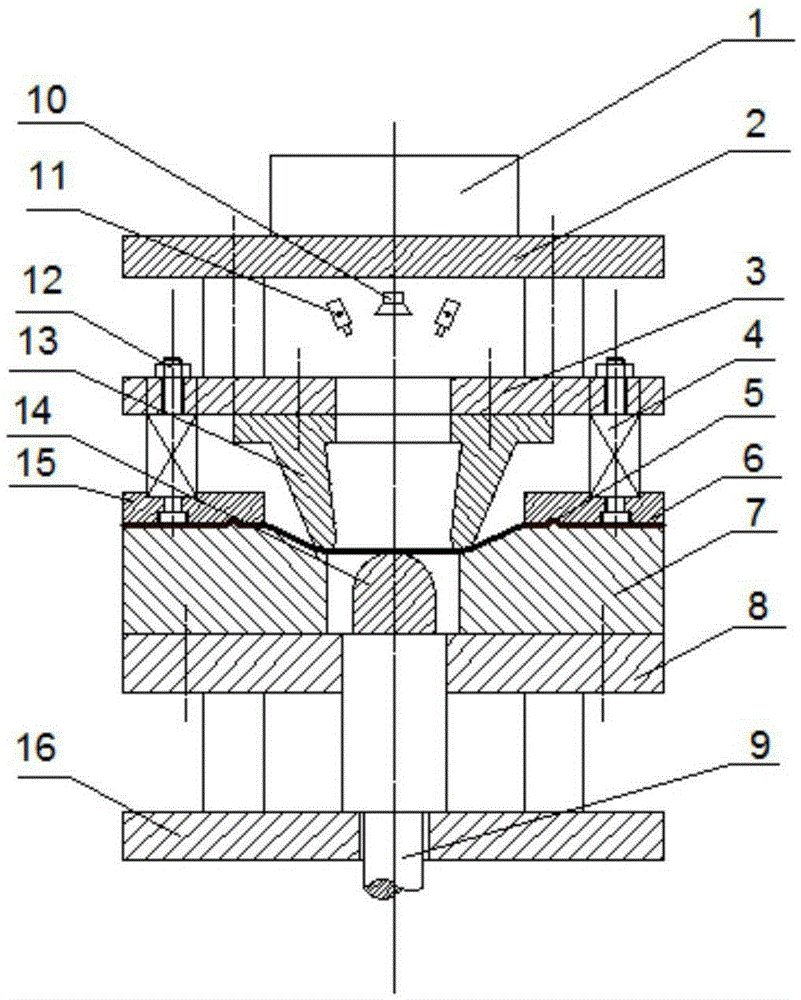

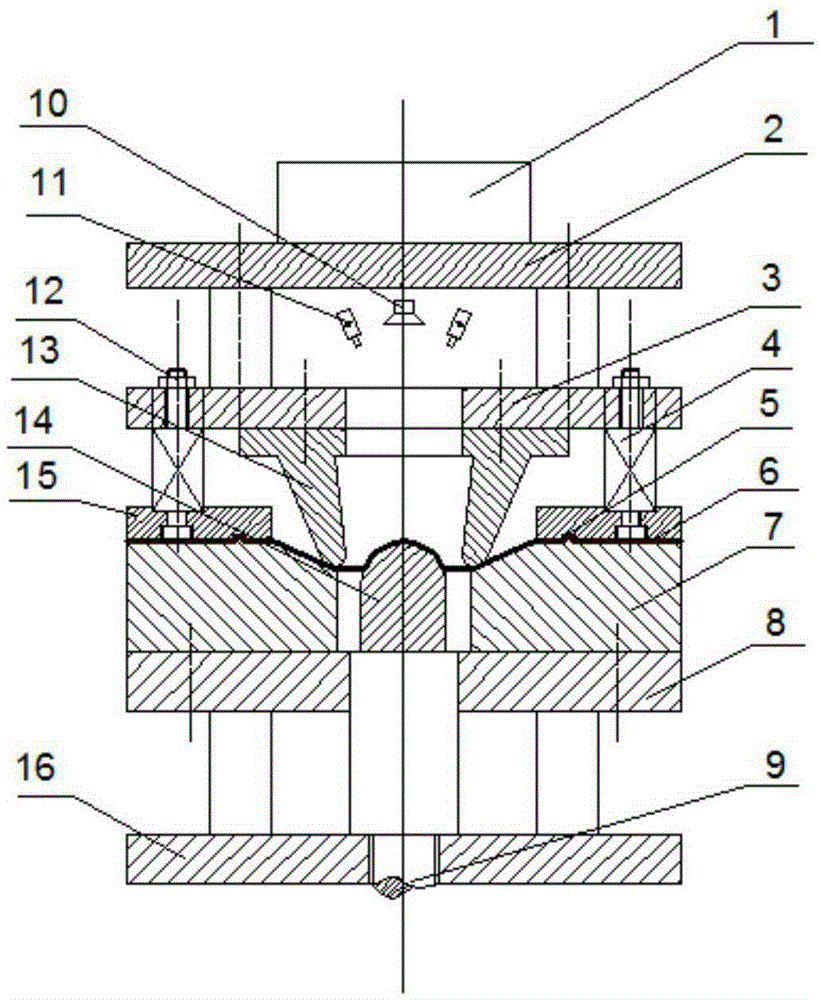

[0028] A forming limit measuring device under a dual linear strain path, comprising a master cylinder 1, an upper beam 2, a blankholder beam 3, a blankholder spring 4, a drawbead 5, a sample 6, a die 7, a lower template 8, a lower Ejection cylinder 9, lighting lamp 10, camera 11, bolt 12, upper punch 13, reverse drawing punch 14, blank holder 15 and lower beam 16; master cylinder 1 is connected with upper beam 2, camera 11, lighting 10 is fixed on the upper beam 2, the blank holder spring 4 is fixed on the blank holder beam 3 by the bolt 12, the upper punch 13 is connected with the blank holder beam 3, the die 7 is provided with a drawbead 5, the die 7 is connected with the lower The template 8 is connected, there is a lower beam 16 under the lower template 8, the reverse drawing punch 14 is located under the sample 6 and connected with the lower ejection cylinder 9, the sample 6 is fixed on the blank holder 15, and the blank holder 15 is on the blank holder Below the spring 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com