Copper-coated iron powder and preparation method thereof

A copper-clad iron and iron powder technology, applied in transportation and packaging, metal processing equipment, coating, etc., can solve environmental pollution and other problems, and achieve the effects of excellent performance indicators, good fluidity, and reasonable particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] One aspect of the present invention provides a method for preparing copper-clad iron powder.

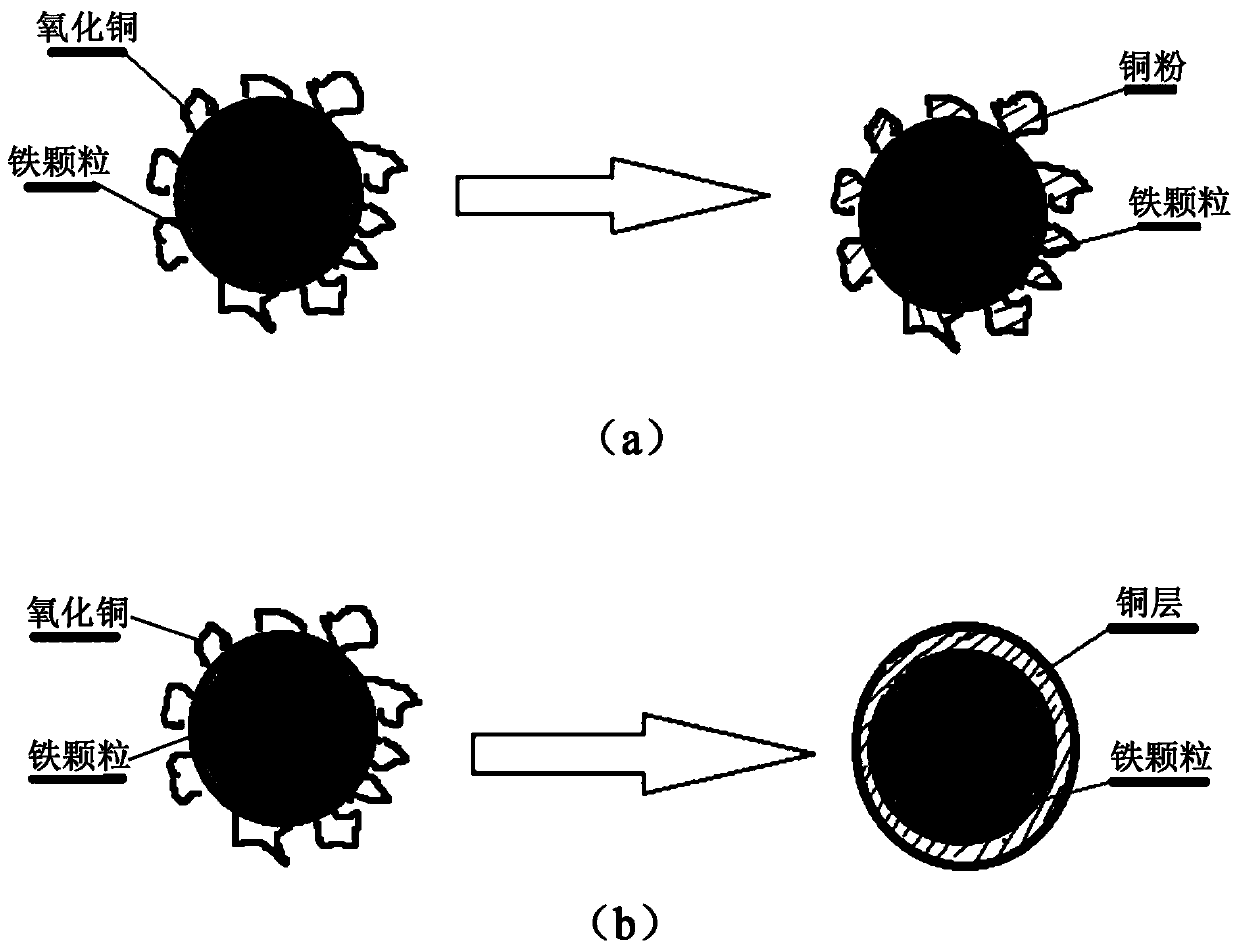

[0029] figure 1 It shows the comparison schematic diagram of the copper-clad iron powder preparation method of the present invention and the existing reduction method, wherein, (a) diagram shows the schematic diagram of the copper-clad iron powder prepared by the common reduction method, and the product prepared by this method has copper powder Can not fully coat the problem of iron particles; (b) figure shows the schematic diagram of the reduction method of the present invention to prepare copper-clad iron powder, the metal copper of the present invention can be completely coated on the iron powder particle surface, and is made of metal copper The coating layer is uniform and dense.

PUM

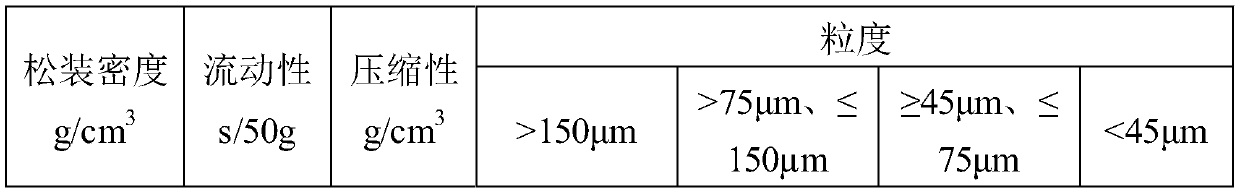

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com