Cement-stabilized macadam base and construction method thereof

A cement-stabilized gravel and construction method technology, applied in the direction of buildings, roads, roads, etc., can solve the problems of reducing the stiffness of the base layer, achieve the effects of improving fatigue resistance, improving shrinkage compensation ability, and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

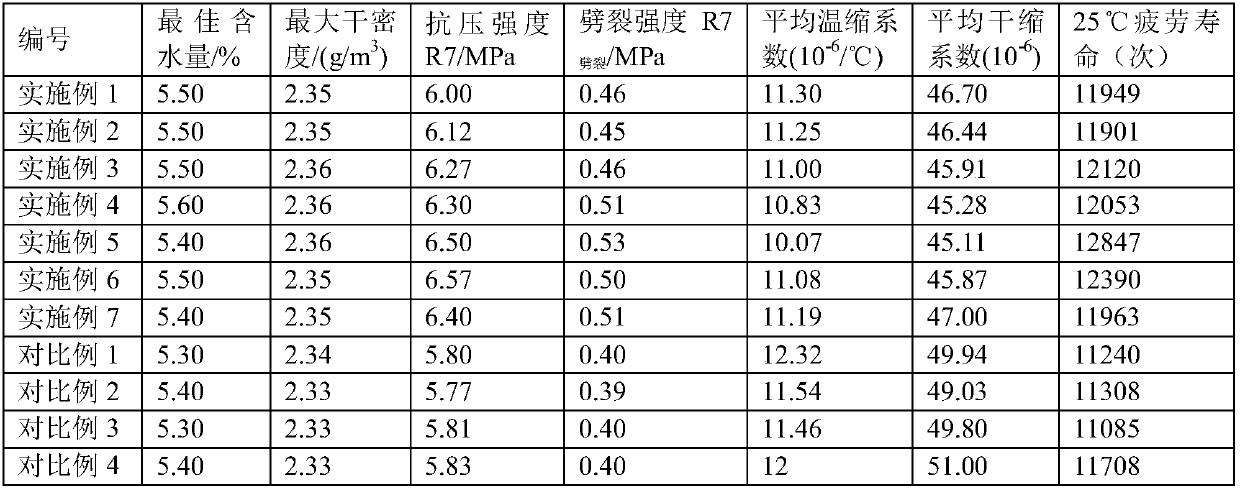

Examples

Embodiment 1

[0035] A cement-stabilized gravel base, which is constructed through the following steps:

[0036] (1) Mix 78kg coarse aggregate, 5kg fine aggregate, 4kg high belite cement, 0.2kg calcium sulfoaluminate-calcium oxide composite expansion agent and 5kg water to obtain the mixture; The crushing value is 26%, the needle flake content is 15%, the dust content below 0.075mm is 1.2%, and the soft stone content is 3%. The gradation range of the mixture formed by mixing coarse aggregate and fine aggregate is: through 31.5 100wt% through 26.5mm square hole sieve, 96.8wt% through 26.5mm square hole sieve, 79.0wt% through 19.0mm square hole sieve, 64.6wt% through 16.0mm square hole sieve, 52.9wt% through 9.5mm square hole sieve %, 32.3wt% through 4.75mm square hole sieve, 21.3wt% through 2.36mm square hole sieve, 15.2wt% through 1.18mm square hole sieve, 9.4wt% through 0.6mm square hole sieve, 9.4wt% through 0.3mm square hole sieve Hole sieve is 6.8wt%, through 0.15mm square hole sieve i...

Embodiment 2

[0040] The difference between the construction operation of embodiment 2 and embodiment 1 is: in step (2), two pavers are separated by 8m front and rear, and pave forward at the same time, with a lateral overlap of 200mm, and the rest are consistent with embodiment 1.

Embodiment 3

[0042] The construction operation steps of embodiment 3 are the same as that of embodiment 1, the difference is that each raw material is added according to the proportion in table 1, and the crushing value of limestone crushed stone is 25%, the needle flake content is 15%, and the dust below 0.075mm content of 1.0%, and soft stone content of 2.8%; the gradation range of the mixture formed by mixing coarse aggregate and fine aggregate is: 100wt% through a 31.5mm square hole sieve, 95wt% through a 26.5mm square hole sieve, 85wt% by 19.0mm square hole sieve, 77wt% by 16.0mm square hole sieve, 58wt% by 9.5mm square hole sieve, 28wt% by 4.75mm square hole sieve, 20wt% by 2.36mm square hole sieve, 11wt% by 1.18mm square hole sieve, 8wt% by 0.6mm square hole sieve, 5wt% by 0.3mm square hole sieve, 3wt% by 0.15mm square hole sieve, 3wt% by 0.075mm square hole sieve; All the other are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com