Microcrystal ceramic composite board as well as blank and preparation method of microcrystal ceramic composite board

A technology for microcrystalline ceramics and composite slabs is applied in the field of microcrystalline ceramic composite slab blanks to achieve the effects of improving the process, increasing the rate of superior products, and alleviating the mismatch of expansion/contraction coefficients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

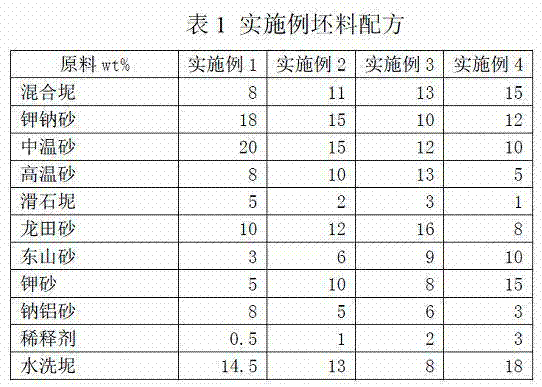

[0060] (1) According to the formula given in Table 1, the raw materials are batched into the ball mill by a forklift.

[0061] (2) According to the ratio of powder: water: grinding medium = 1:0.4:3, add water and grinding balls for grinding. When grinding, the slurry flow rate is 30m / s; 1.0%, stop ball milling when the slurry specific gravity is 1.72g / ml, discharge.

[0062] (3) The ground slurry is sieved through three times to ensure that unground raw materials and impurity iron are removed.

[0063] (4) Stir and mix the slurry after sieving, and then spray granulate. The powder obtained by spray granulation is stale for 24 hours, and the moisture content in the powder is detected to be 7.2%.

[0064] (5) Grading the granulated particles according to 0.5% for more than 20 mesh; 40% for 40 mesh; 58% for 80 mesh; dry.

[0065] (6) Spread frit on the surface of the dried green body, then fire at 1200-1250°C for 70 minutes, and polish to obtain a microcrystalline ceramic comp...

Embodiment 2

[0067] (1) According to the formula given in Table 1, the raw materials are batched into the ball mill by a forklift.

[0068] (2) According to the ratio of powder: water: grinding medium = 1:0.4:2, add water and grinding balls for grinding. When grinding, the slurry flow rate is 50m / s; 0.9%, stop ball milling when the slurry specific gravity is 1.74g / ml, discharge.

[0069] (3) The ground slurry is sieved through three times to ensure that unground raw materials and impurity iron are removed.

[0070] (4) Stir and mix the slurry evenly after sieving, and then spray granulate. The powder obtained by spray granulation is stale for 28 hours, and the moisture content in the powder is detected to be 6.8%.

[0071] (5) Grading the granulated particles according to 0.8% for more than 20 mesh; 45% for 40 mesh; 52% for 80 mesh; dry.

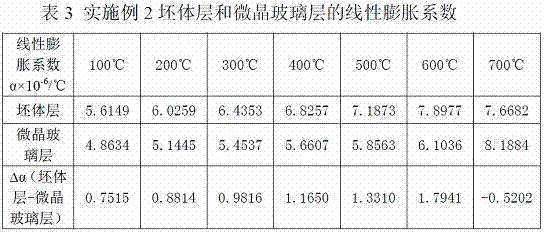

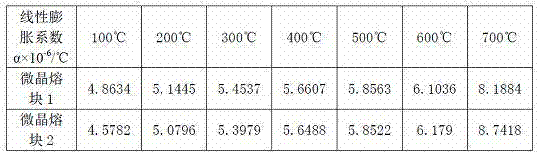

[0072] (6) Spread frit on the surface of the dried green body, then fire at 1100-1200°C for 120 minutes, and polish to obtain a microcrystalline cera...

Embodiment 3

[0074] (1) According to the formula given in Table 1, the raw materials are batched into the ball mill by a forklift.

[0075] (2) According to the ratio of powder: water: grinding medium = 1:0.6:3, add water and grinding balls for grinding. When grinding, the slurry flow rate is 70m / s; 1.1%, when the specific gravity of the slurry is 1.69g / ml, the ball milling is stopped and the material is discharged.

[0076] (3) The ground slurry is sieved through three times to ensure that unground raw materials and impurity iron are removed.

[0077] (4) Stir and mix the slurry evenly after sieving, and then spray granulate. The powder obtained by spray granulation is stale for 40 hours, and the moisture content in the powder is detected to be 7.4%.

[0078] (5) Grading the granulated particles according to 0.3% for more than 20 mesh; 45% for 40 mesh; 54% for 80 mesh; dry.

[0079] (6) Spread frit on the surface of the dried green body, then fire at 1050-1150°C for 180min, and polish ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com