Anti-cracking mixture for cement-stabilized bases of roads in alpine high-altitude regions

A mixture and base layer technology, applied in the field of water-stabilized base layer anti-crack mixture and anti-crack mixture in alpine and high-altitude areas, can solve the problems of semi-rigid base layer cracking and reflection cracks, reduce the number of reflection cracks, and achieve suitable gradation. , the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

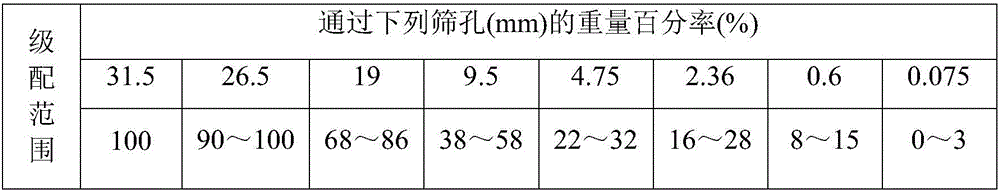

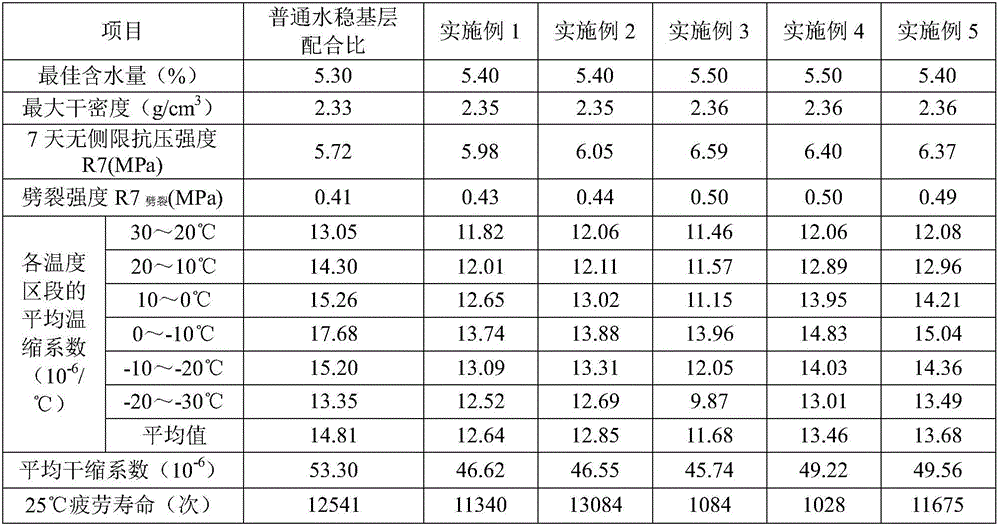

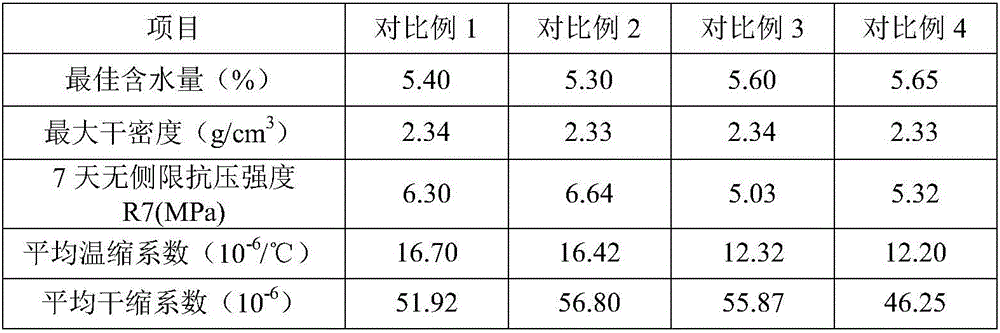

[0042] Prepare the water-stabilized base compound, wherein the weight percent range of each component is as follows: crushed stone 75%, natural sand 10%, cement 5%, sodium sulfate 6%, solid aluminum sulfate 4%, raw materials are stirred and mixed, After mixing evenly, prepare a test block for testing.

[0043] Firstly, the compaction test of cement-stabilized macadam (T 0804-1994) is carried out to determine the maximum dry density and optimal water content of cement-stabilized macadam under the material ratio. According to the results of the compaction test, a cylindrical specimen (T0843-2009) of φ150×150mm and a central beam specimen of 100mm×100mm×400mm (T 0844-2009) were formed. The 7-day unconfined compressive strength test (T 0805-1994) and the 7-day split test (T 0806-1994) were carried out using cylindrical specimens, and the temperature shrinkage test (T 0854-2009) and Dry shrinkage test (T 0855-2009), the test results are shown in Table 2.

[0044] Embodiment 1 is ...

Embodiment 2

[0046] Prepare the water-stabilized base compound, wherein the weight percent range of each component is as follows: crushed stone 85%, natural sand 5%, cement 3%, sodium sulfate 5%, solid aluminum sulfate 2%, raw materials are stirred and mixed, After mixing evenly, prepare a test block for testing.

[0047] Firstly, the compaction test of cement-stabilized macadam (T 0804-1994) is carried out to determine the maximum dry density and optimal water content of cement-stabilized macadam under the material ratio. According to the results of the compaction test, a cylindrical specimen (T0843-2009) of φ150×150mm and a central beam specimen of 100mm×100mm×400mm (T 0844-2009) were formed. The 7-day unconfined compressive strength test (T 0805-1994) and the 7-day split test (T 0806-1994) were carried out using cylindrical specimens, and the temperature shrinkage test (T 0854-2009) and Drying shrinkage test (T 0855-2009), fatigue life test, test results are shown in Table 2.

[0048]...

Embodiment 3

[0050] Prepare the water-stabilized base compound, wherein the weight percentage range of each component is as follows: 80% of crushed stone, 8% of natural sand, 3% of cement, 7% of sodium sulfate, 2% of solid aluminum sulfate, the raw materials are stirred and mixed, After mixing evenly, prepare a test block for testing.

[0051] Firstly, the compaction test of cement-stabilized macadam (T 0804-1994) is carried out to determine the maximum dry density and optimal water content of cement-stabilized macadam under the material ratio. According to the results of the compaction test, a cylindrical specimen (T0843-2009) of φ150×150mm and a central beam specimen of 100mm×100mm×400mm (T 0844-2009) were formed. The 7-day unconfined compressive strength test (T 0805-1994) and the 7-day split test (T 0806-1994) were carried out using cylindrical specimens, and the temperature shrinkage test (T 0854-2009) and Drying shrinkage test (T 0855-2009), fatigue life test, test results are shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com