Manufacture method for superfine hard alloy blind hole bars

A cemented carbide rod and cemented carbide technology, which is applied in the field of preparation of ultra-fine cemented carbide rods with blind holes, can solve problems such as waste of materials, low yield, thermal cracks, etc., to improve production efficiency and product quality, Improve the precision of size control and the effect of uniform and dense tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

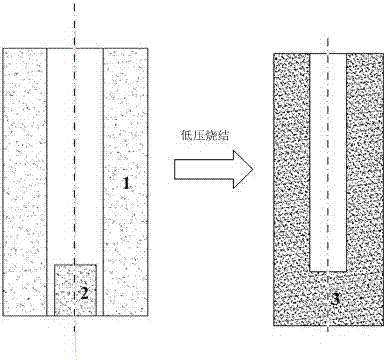

[0020] The preparation method of superfine cemented carbide blind hole bar, such as figure 1 As shown, the soft billet 1 of the straight-hole ultra-fine cemented carbide rod is prepared by vacuum piston extrusion or vacuum screw extrusion, and the shrinkage coefficient of the straight-hole ultra-fine cemented carbide rod soft billet 1 is 20~ 40%, the solid bar soft billet 2 is prepared by extrusion or molding. By adjusting the content of forming agent in the superfine mixture or the pressing pressure, the shrinkage coefficient of the solid bar soft billet is 2-11% smaller than that of the straight hole bar, and the solid bar soft billet 2 is put into the straight hole bar soft billet up to a given length. The billet 1 is fixed in a hole at one end, placed in a low-pressure sintering furnace and sintered at 1340-1420°C for 36-60 hours. During high-temperature sintering, the alloy is densified by argon pressure. The sintering pressure is 1-10 MPa, so that the solid short rod So...

Embodiment

[0024] Firstly, the vacuum piston extrusion or screw vacuum extrusion method is used to form a straight-hole ultra-fine carbide round rod soft billet with a specified size. The ultra-fine cemented carbide WC grain size is 0.2-0.8 μm, and the Co content is 6-14. %, VC content is 0~0.8%, Cr 3 C 2 The content is 0.3-1.2%, and the shrinkage coefficient of the soft billet is controlled at 20-40%. At the same time, the mixture of the same formula is used to prepare the diameter The solid bar soft billet is 1-10% smaller than the diameter of the inner hole, and the shrinkage coefficient of the soft billet is 2-11% smaller than that of the straight hole ultra-fine carbide rod soft billet. Put the solid bar soft billet into the straight hole up to the specified length The soft billet of the bar is fixed in a hole at one end, placed in a low-pressure sintering furnace, and sintered at a temperature of 1340-1420 ° C for 36-60 hours. During high-temperature sintering, the alloy is densif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com