Flocculation container of washing machine

A technology of flocculation container and washing machine, which is applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of easy breaking of large flocs, high impact force of water flow, easy generation of a large amount of foam flocculants, etc. The effect of uniform speed and stability, reduction of impact force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further introduced below in conjunction with the accompanying drawings.

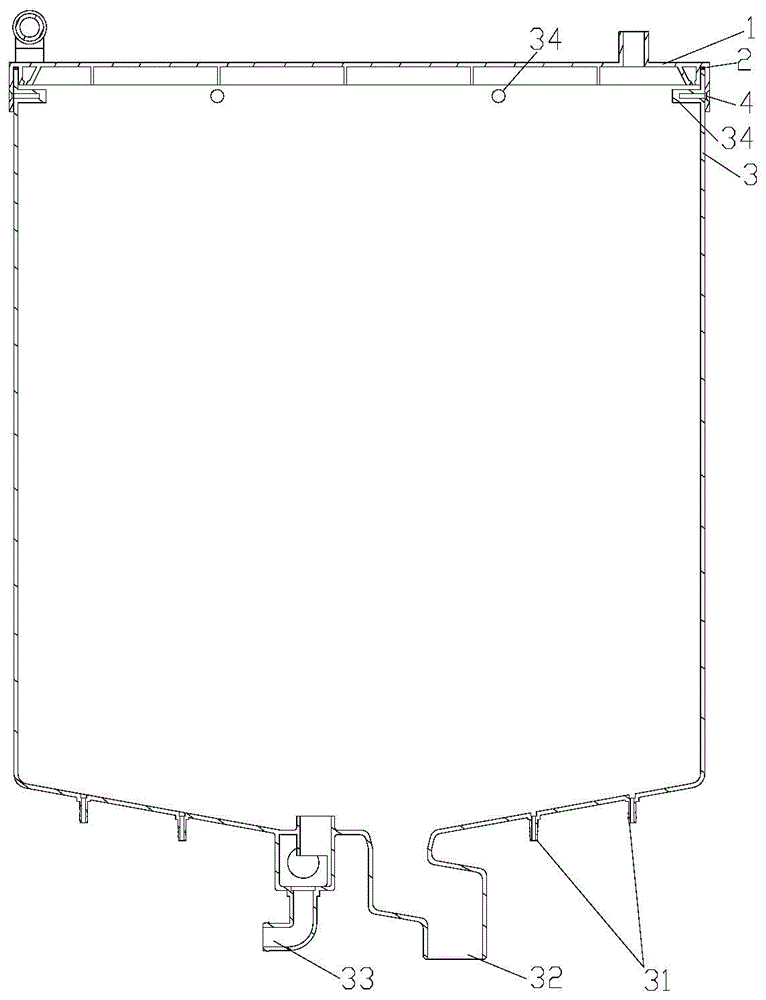

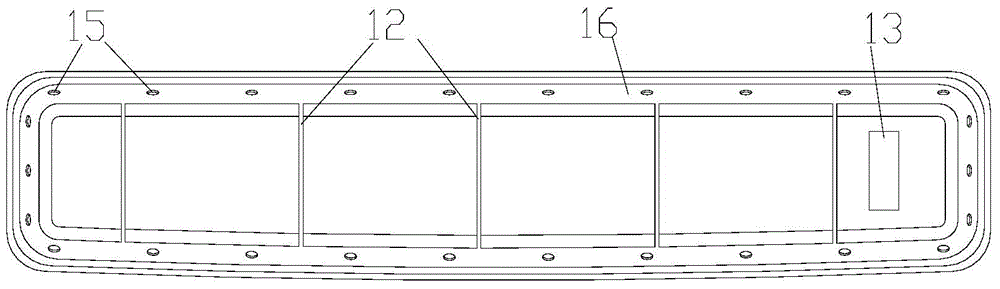

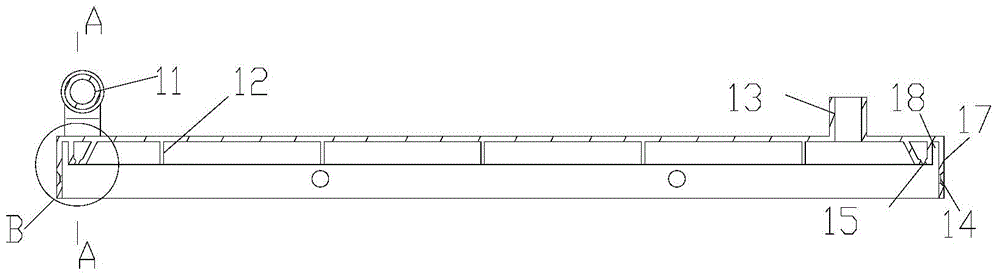

[0035] Such as figure 1 As shown, the embodiment of the present invention introduces a flocculation container of a washing machine, which includes a flocculation bucket 3 and a flocculation bucket cover 1 fastened to the upper opening of the flocculation bucket 3 . The contact between the flocculation bucket cover and the flocculation bucket is provided with a sealing strip 2 to improve the airtightness of the flocculation container and prevent the water in the flocculation bucket from overflowing. The bottom of the flocculation bucket 1 is provided with a sewage discharge port 32 for discharging sewage, a water return port 33 for returning clean water after flocculation reaction, and an air inlet 31 for air intake into the flocculation container. The flocculation bucket cover 1 is provided with a delivery port 13 for putting the flocculant into the flocculation cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com