Screw extrusion centrifugal acceleration dry ice pill cold jet cleaner

A centrifugal acceleration, screw extrusion technology, applied in inorganic chemistry, cleaning methods and utensils, non-metallic elements, etc., can solve the problems of low initial speed of dry ice particle spraying, small cleaning range, etc., to improve efficiency and outlet spray speed, The effect of expanding the effective area and facilitating the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

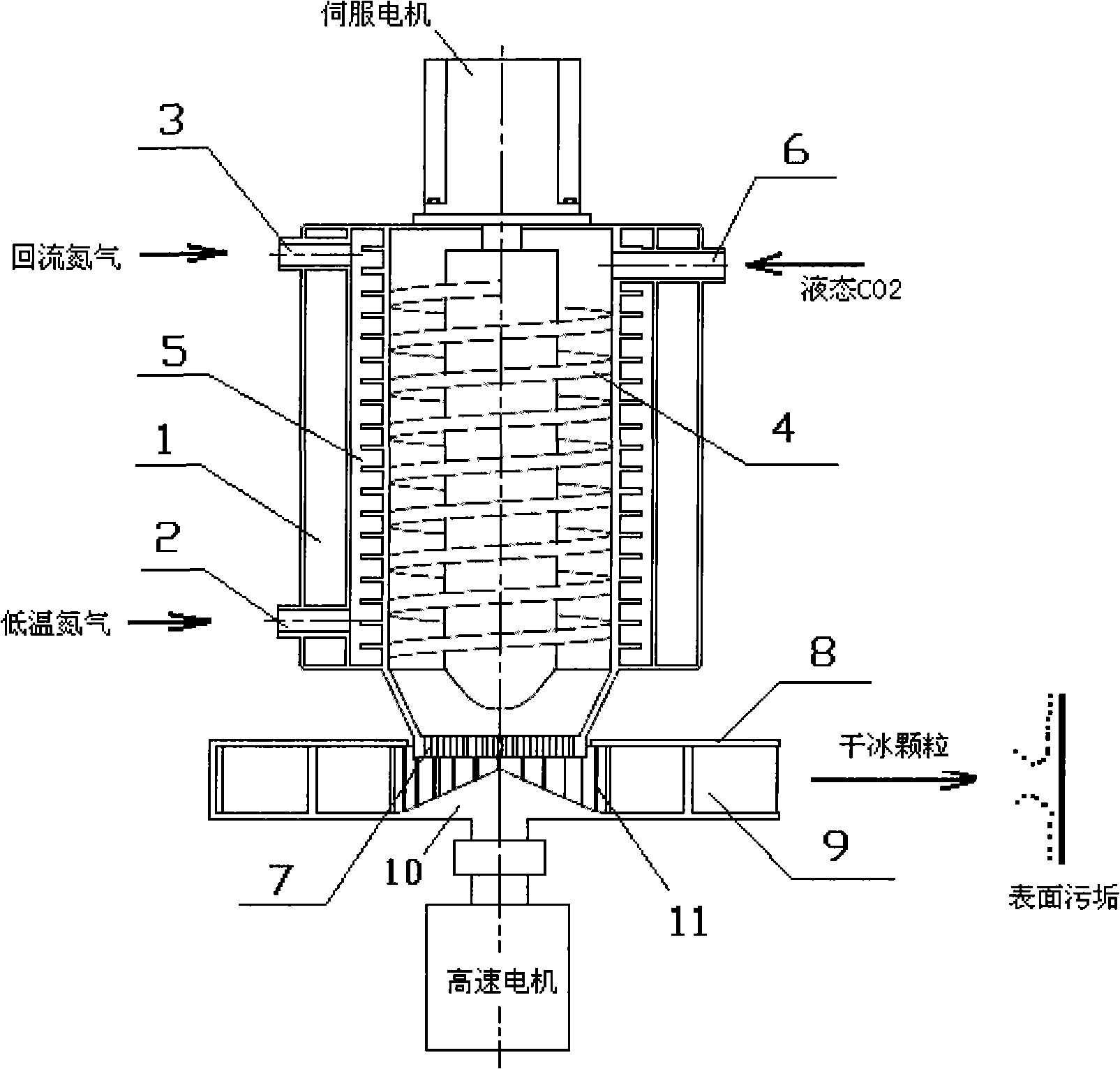

[0012] See figure 1 . Spiral squeeze centrifugal accelerated dry ice pellet cold jet cleaning machine, including a cylindrical Dewar 1 with a liquid helium inlet 2 and an outlet 3 on the cylindrical Dewar 1, and a spiral feeder is installed in the inner cavity of the cylindrical Dewar 1 The inner cavity of the cylindrical Dewar 1 is surrounded by a heat exchanger 5. The inner cavity of the cylindrical Dewar 1 and liquid CO 2 The feed port 6 is in communication, the lower end of the cylindrical Dewar 1 has a forming disc 7 at the discharge port, the forming disc 7 has one or more through holes spaced apart from each other, and the lower end of the forming disc 7 is equipped with a belt There is a bottom plate 8 with a hole. A box body 9 is installed below the bottom plate 8. The box body 9 has an opening on the side wall. A turntable 10 is horizontally installed in the box body 9 and a centrifugal fan 11 is connected to the turntable 10. The turntable 10 is tapered, the centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com