Front filter device of vacuum pump

A pre-filter and vacuum pump technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of time-consuming and labor-intensive, increased filter cost, etc., and achieve low failure rate, low manufacturing cost, and easy assembly easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention is described below with specific examples, and those skilled in the art can easily understand the advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented in other different ways, that is, various modifications and changes can be made without departing from the disclosed scope of the present invention.

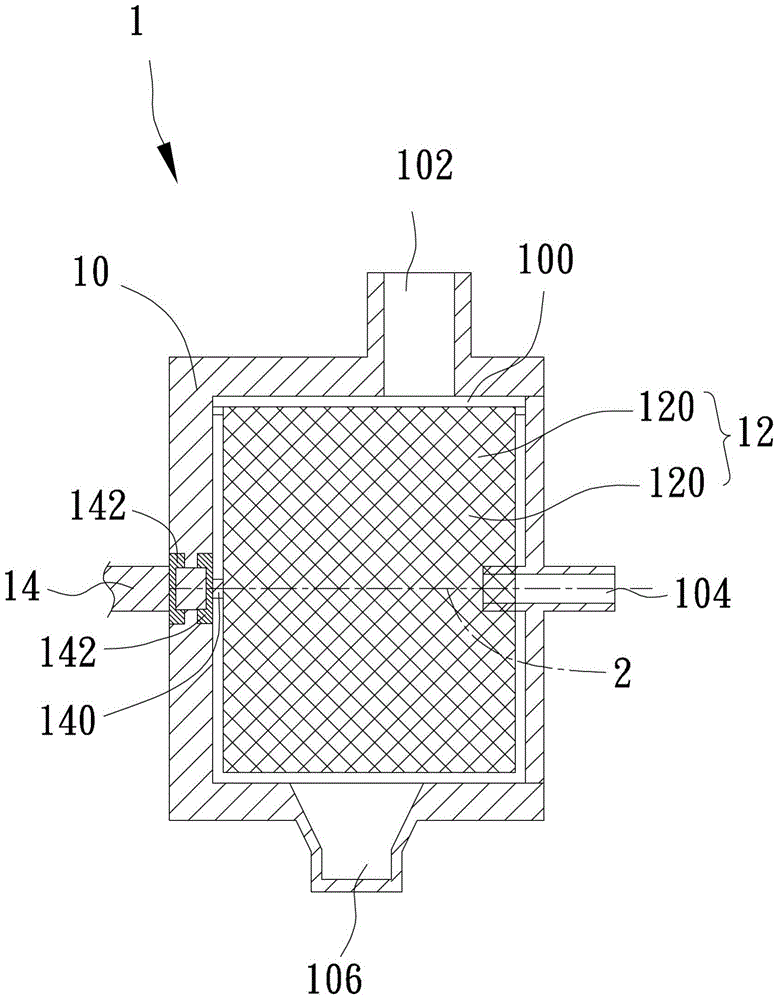

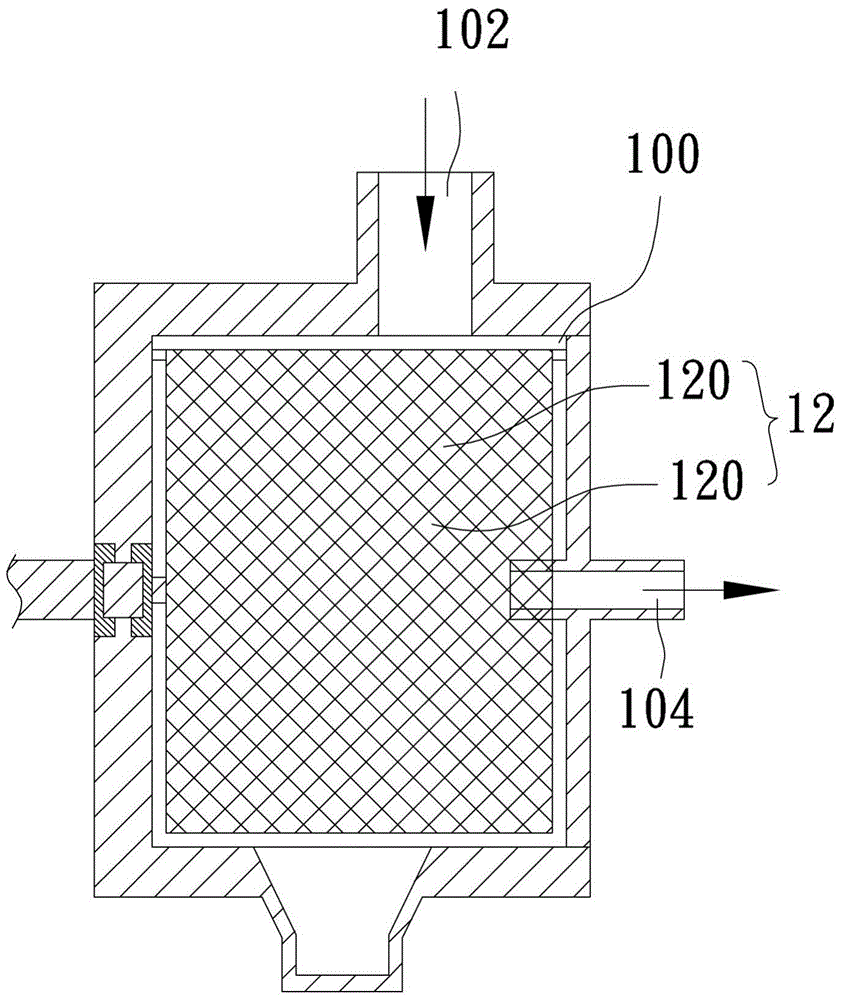

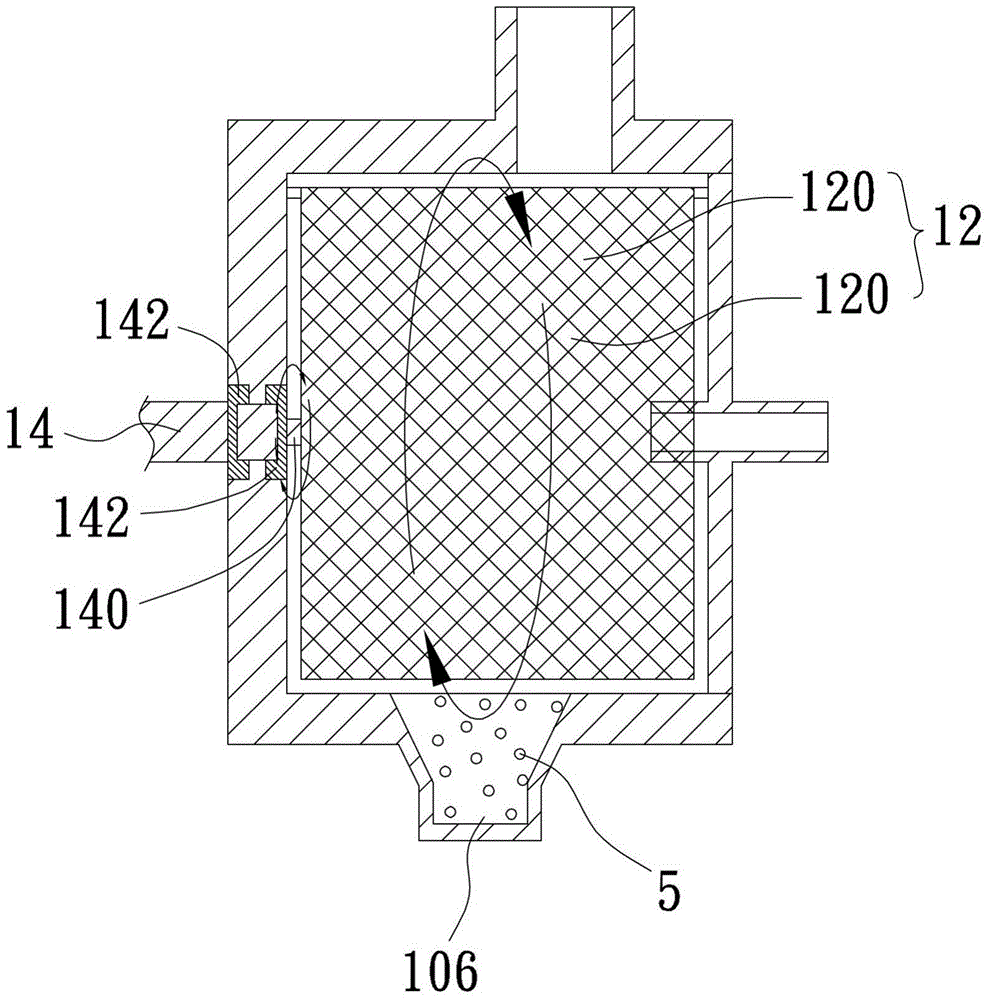

[0033] see figure 1 Shown is a schematic diagram of a preferred embodiment of the present invention. The present invention is a vacuum pump pre-filter device 1, which is mainly composed of a filter barrel 10, a filter screen 12 and an actuator 14, wherein the filter barrel 10 forms a chamber 100, and an air inlet communicating with the chamber 100 102 and air outlet 104 and a dust collection area 106 located below the filter barrel 10 and communicated with the chamber 100, while the filter screen 12 is surrounded by an axial direction 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com