Automatic cleaning device of insulator for artificial contamination test

A technology of automatic cleaning and artificial contamination, applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., can solve the problems of unfavorable personal safety, time-consuming and labor-consuming, low reliability, etc., and achieve improvement Test efficiency, time-consuming and labor-intensive solution, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

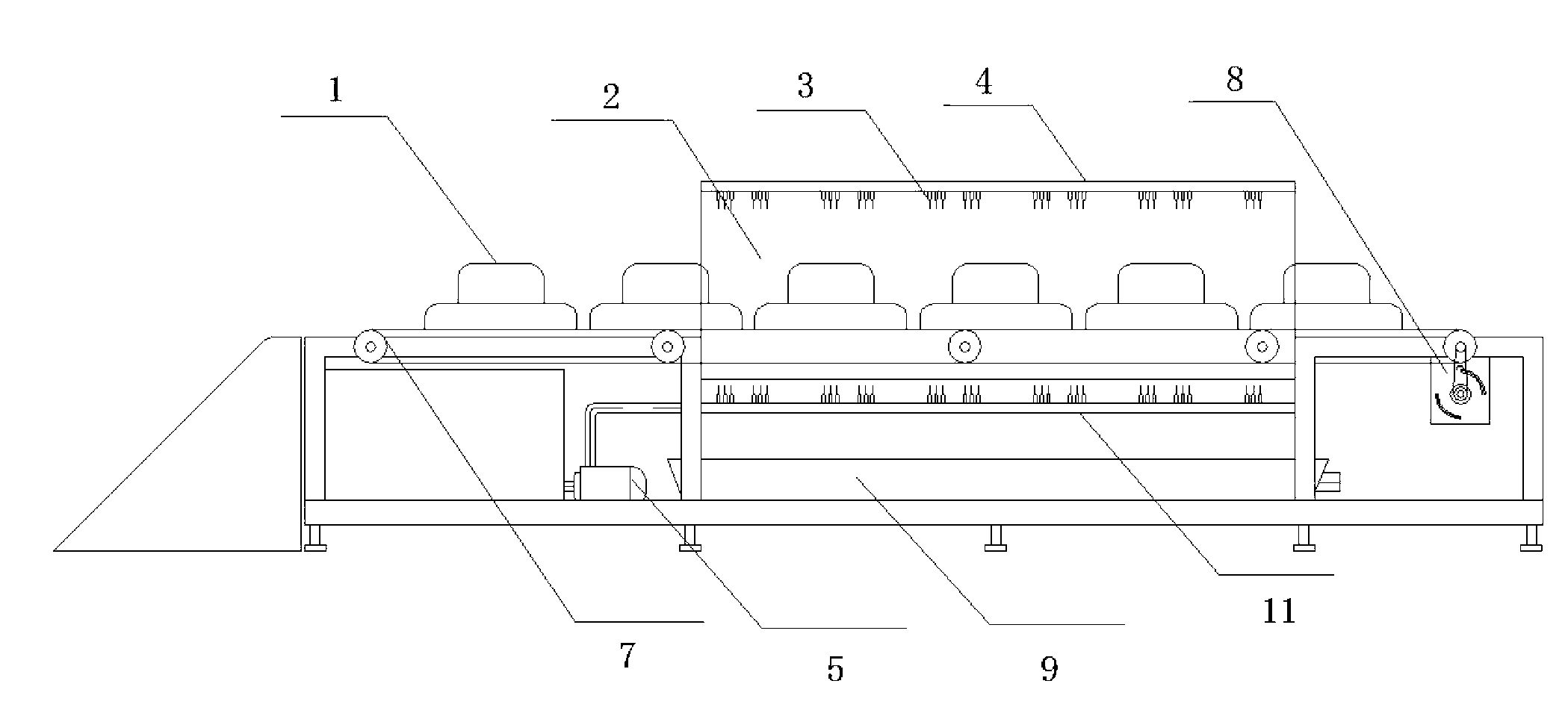

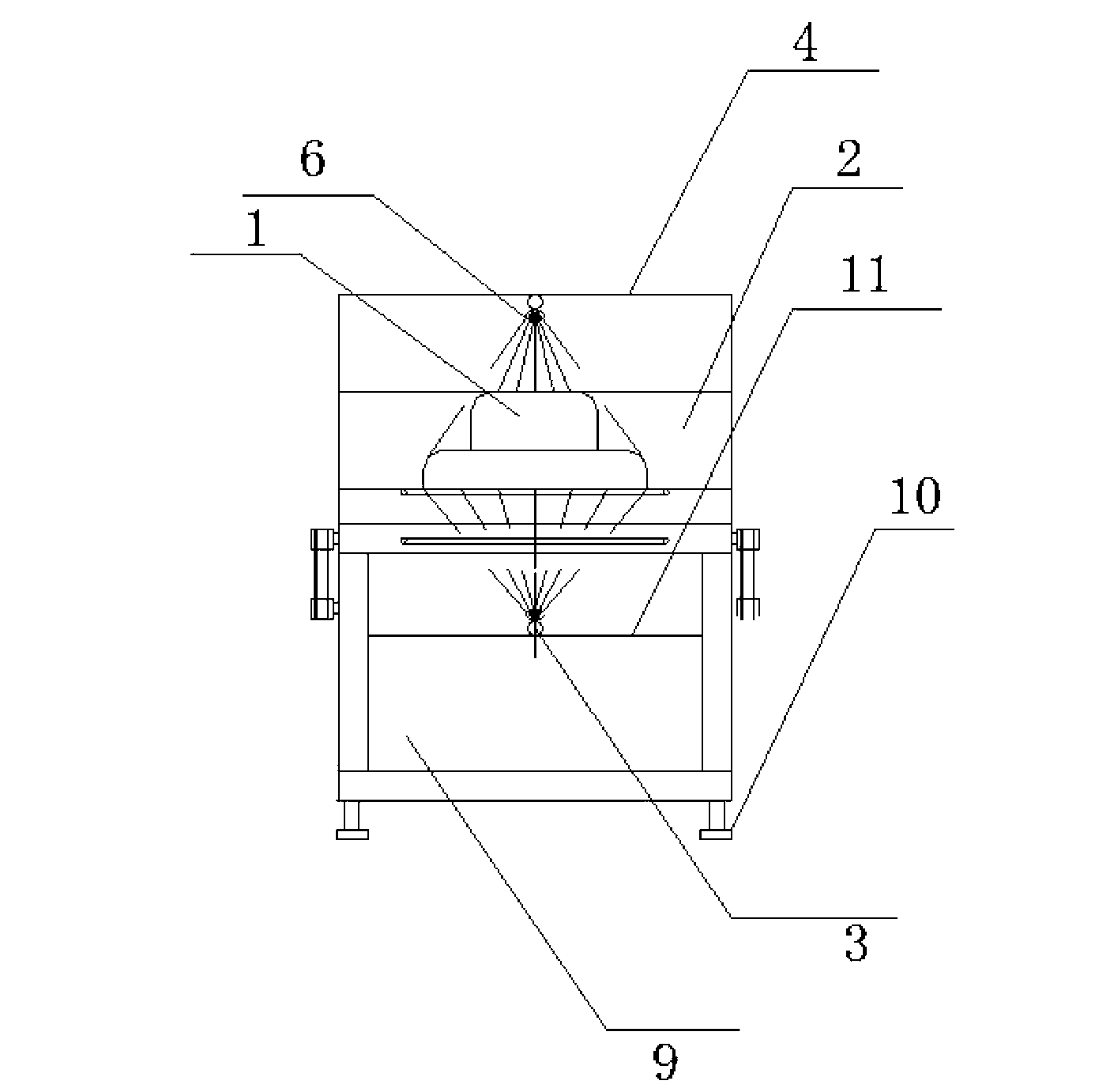

[0025] Such as Figure 1-Figure 3 , to provide an insulator automatic cleaning device for artificial pollution test, the device includes a conveying mechanism with cleaning mechanisms on both sides, a drainage mechanism and a moving mechanism located below the cleaning mechanism.

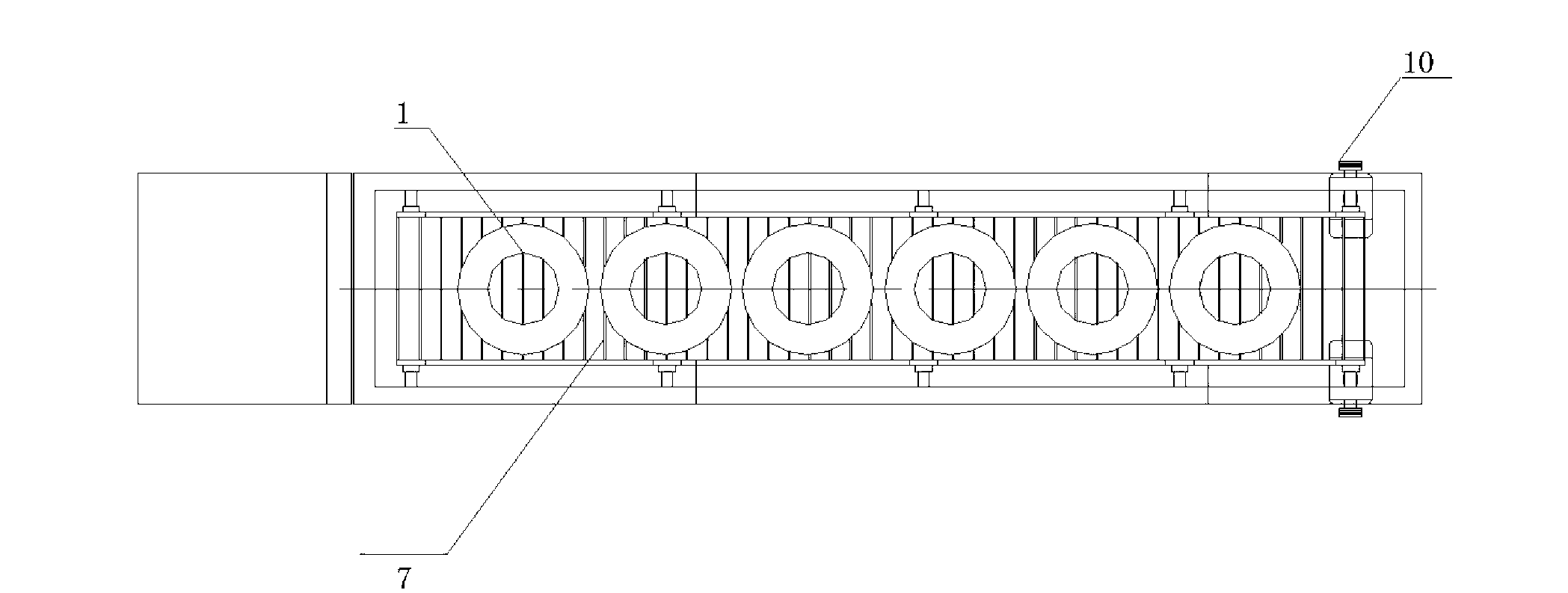

[0026] The conveying mechanism includes a motor, a conveyor belt 7 and a geared motor 8; the output speed of the motor is decelerated by the geared motor 8 to the rotational speed of the conveyor belt 7, and then drives the conveyor belt 7 to rotate.

[0027] The conveyor belt 7 is a chain conveyor belt. The rotation speed of the conveyor belt 7 is 3-5 km / h.

[0028] The cleaning mechanism includes a cleaning box 2, a nozzle 3, a water pipe A4, a water pipe B11, a cleaning brush 6 and a centrifugal pump 5; the water pipe A4 and the water pipe B11 are installed on the upper top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com