Tide wave and stream wave type ,esh-cage underwater automatic cleaning method and device

An automatic cleaning and wandering technology, applied in the field of floating raft net cage culture and agriculture, can solve the problems of increasing labor costs, high consumption, pollution of sea areas, etc., and achieve the effect of improving production level, promoting healthy growth and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

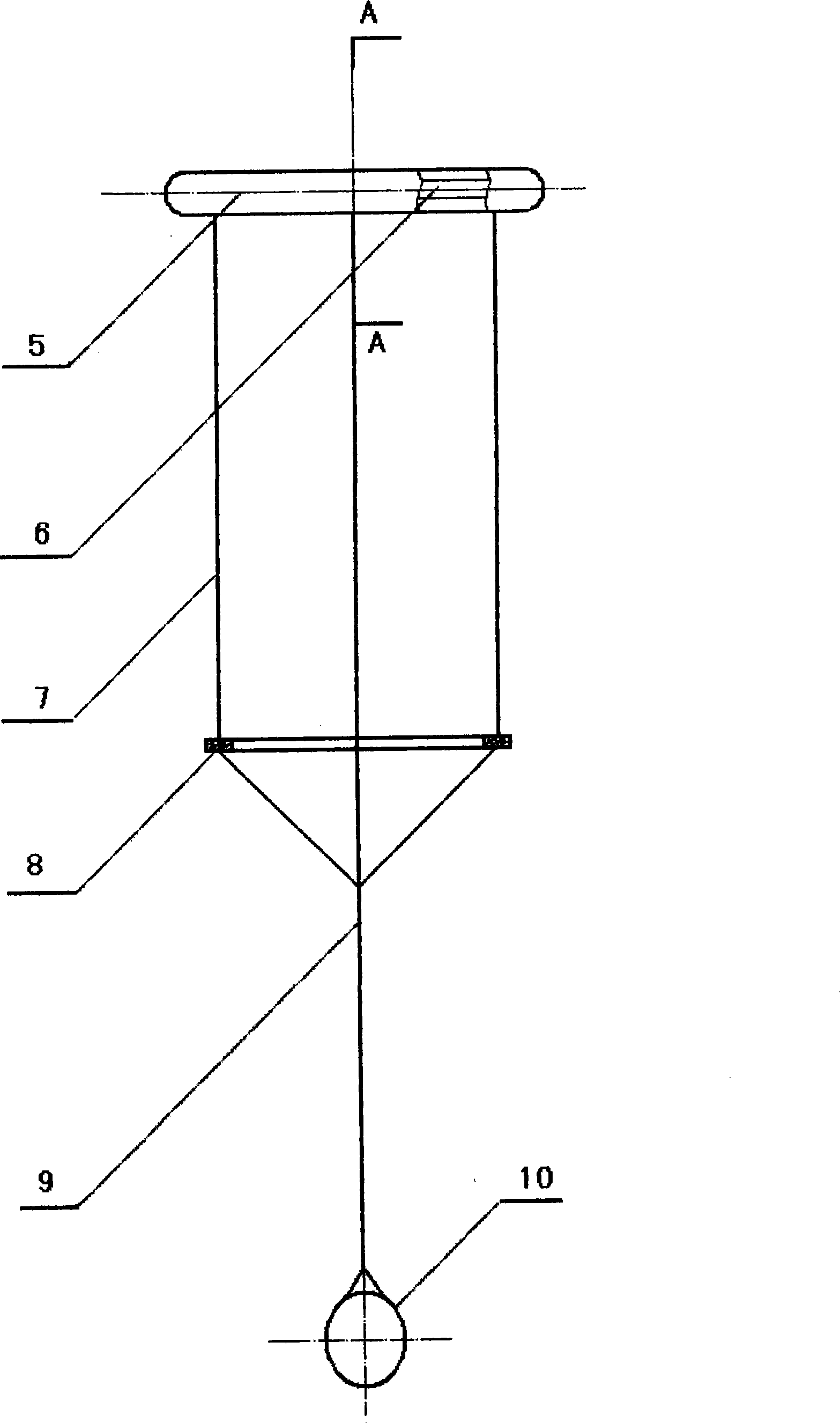

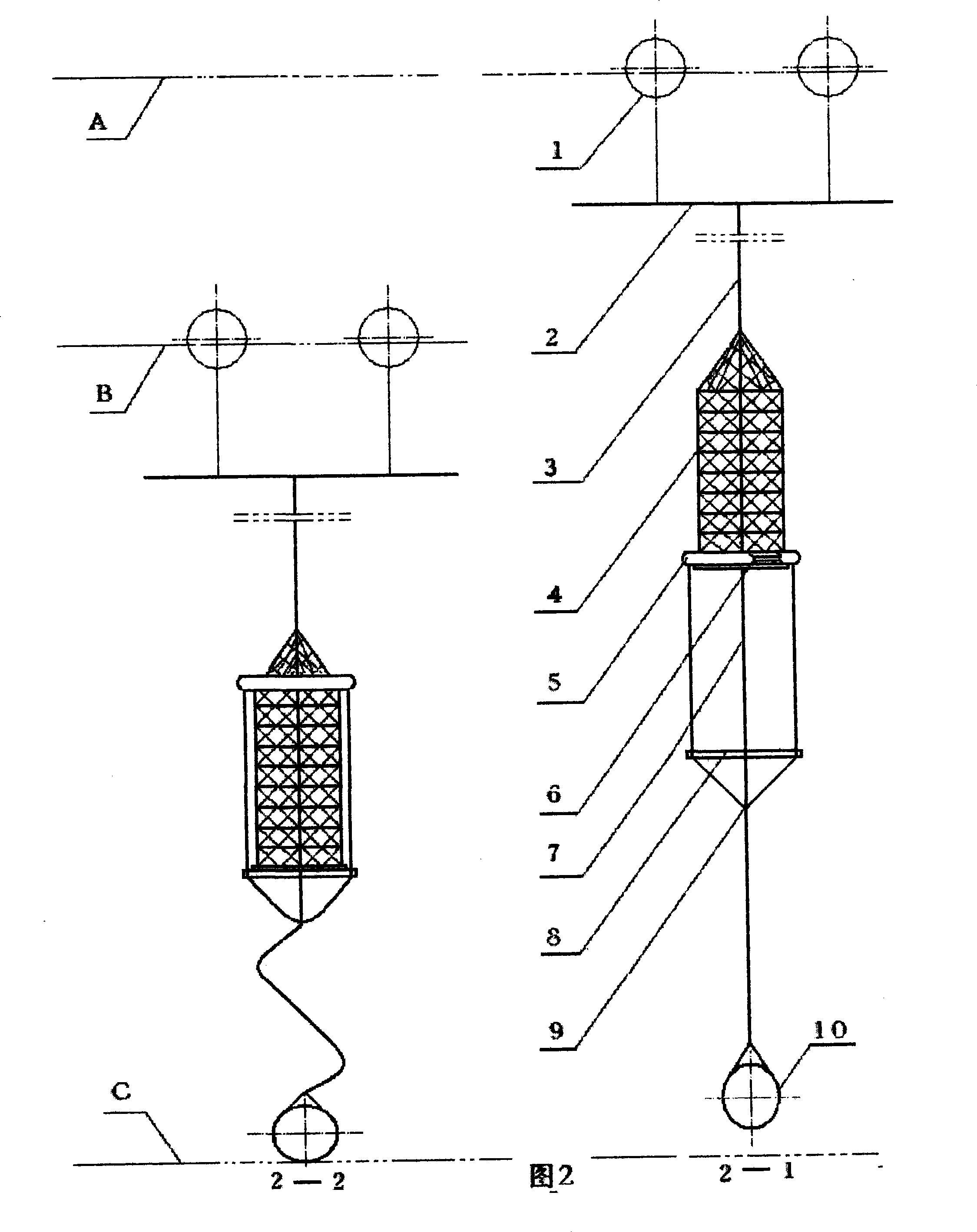

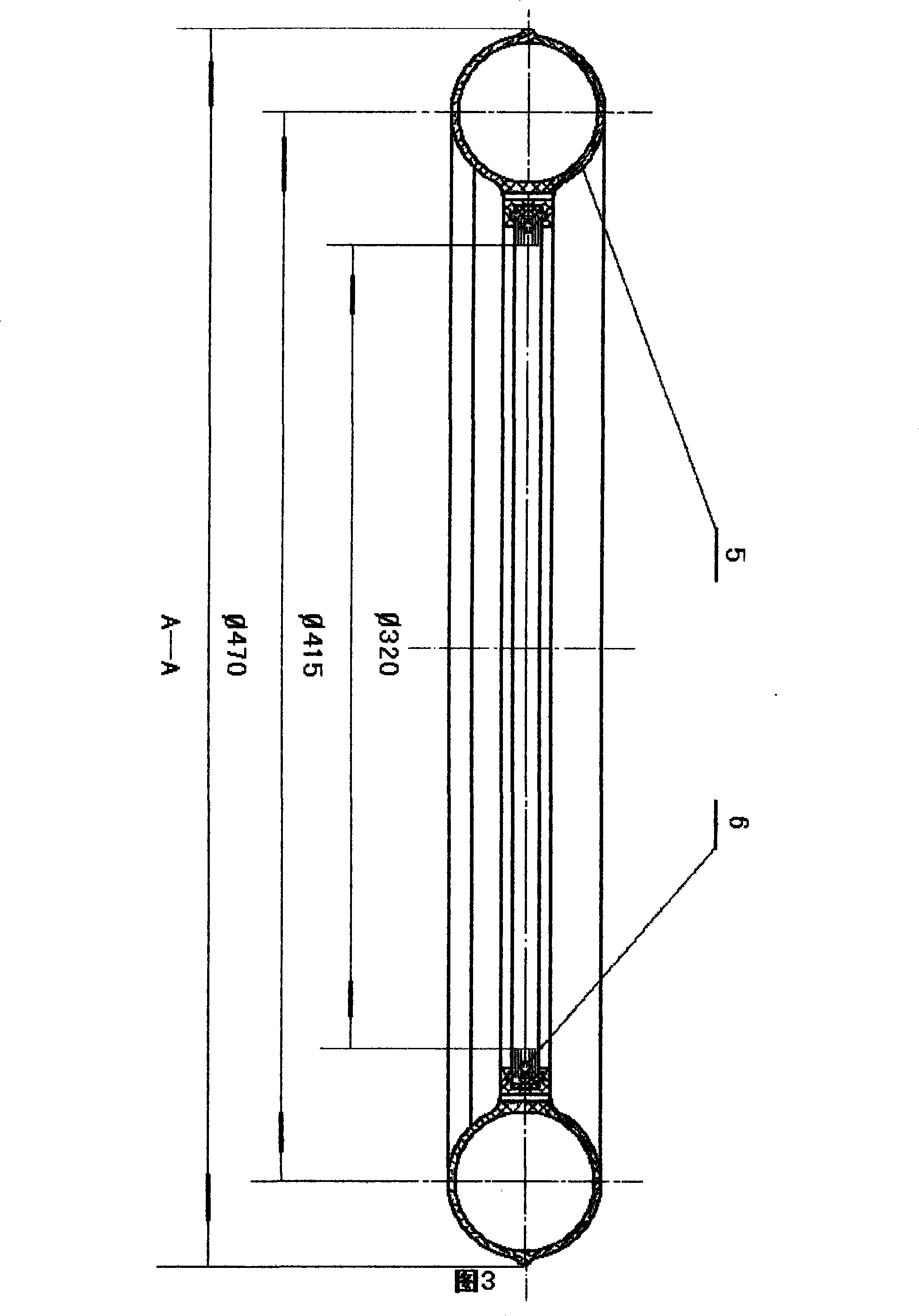

[0036]Control the specific gravity of the material used in the ring-shaped hollow float net brush to make it less than 1, and punch holes in the upper and lower parts of the hollow circle of the ring-shaped hollow float net brush, so that when the inner cavity is filled with seawater, the ring-shaped hollow The overall specific gravity of the float mesh brush is slightly less than 1, and the inner diameter of the ring-shaped hollow float mesh brush is 20-30 mm larger than the outer diameter of the middle partition of the cage, and the outer diameter of the bottom partition of the mesh cage is increased to make it larger than the inner diameter of the mesh brush , the upper end of the mesh cage is crossed by two iron bars through the upper partition of the mesh cage and fixed so that the ring-shaped hollow float mesh brush cannot be separated from the mesh cage up and down to form a device - a ring-shaped water injection float mesh brush (Such as Figure 5 ).

[0037] The tida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com