Return line type self-calibration camera assembly equipment

A technology for assembling equipment and cameras, which is applied in metal processing equipment, devices for coating liquid on the surface, metal processing, etc. It can solve problems such as waste, difficult to guarantee accuracy, and non-repairable products with poor assembly, so as to achieve simple structure and precision The effect of image quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

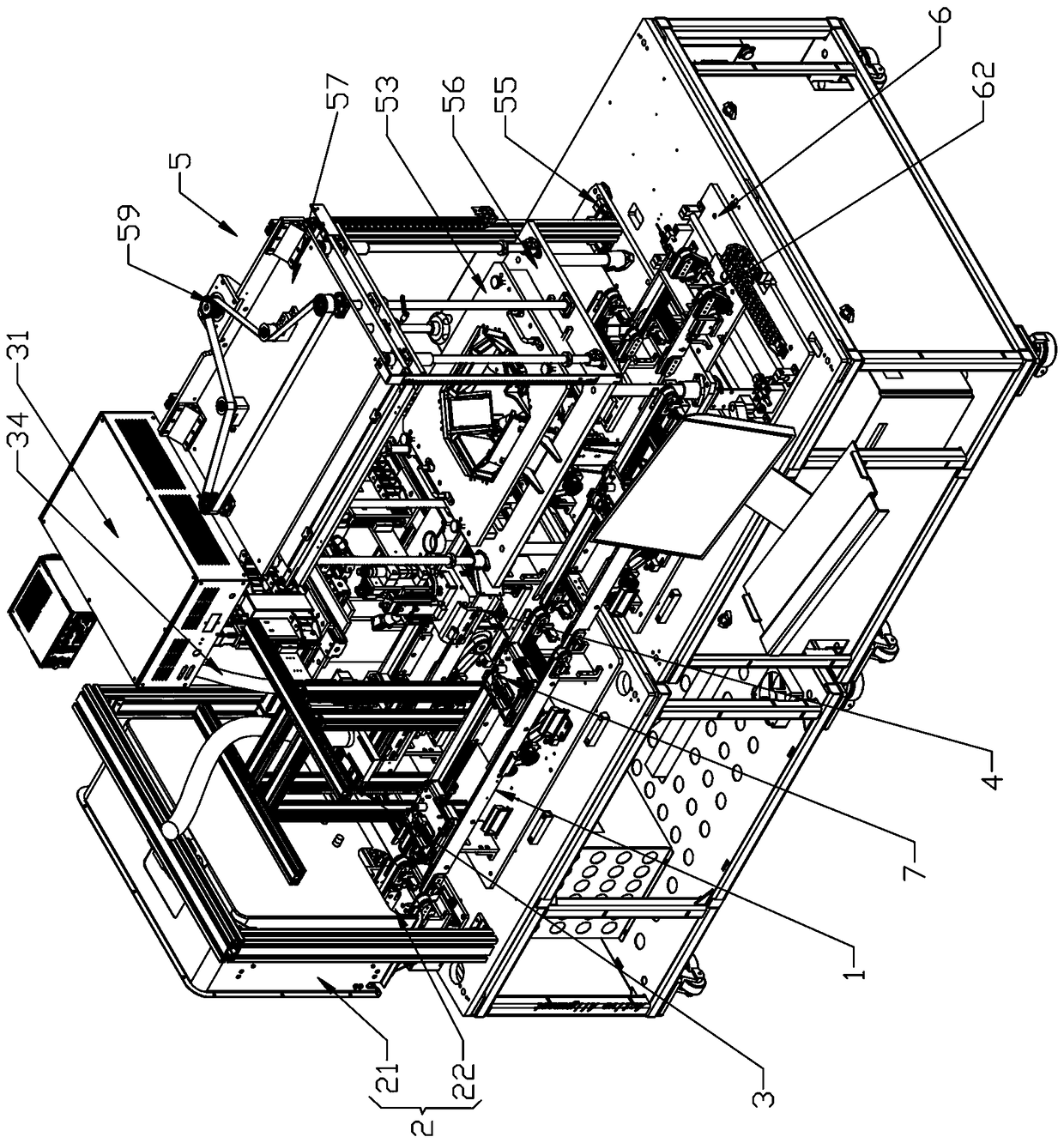

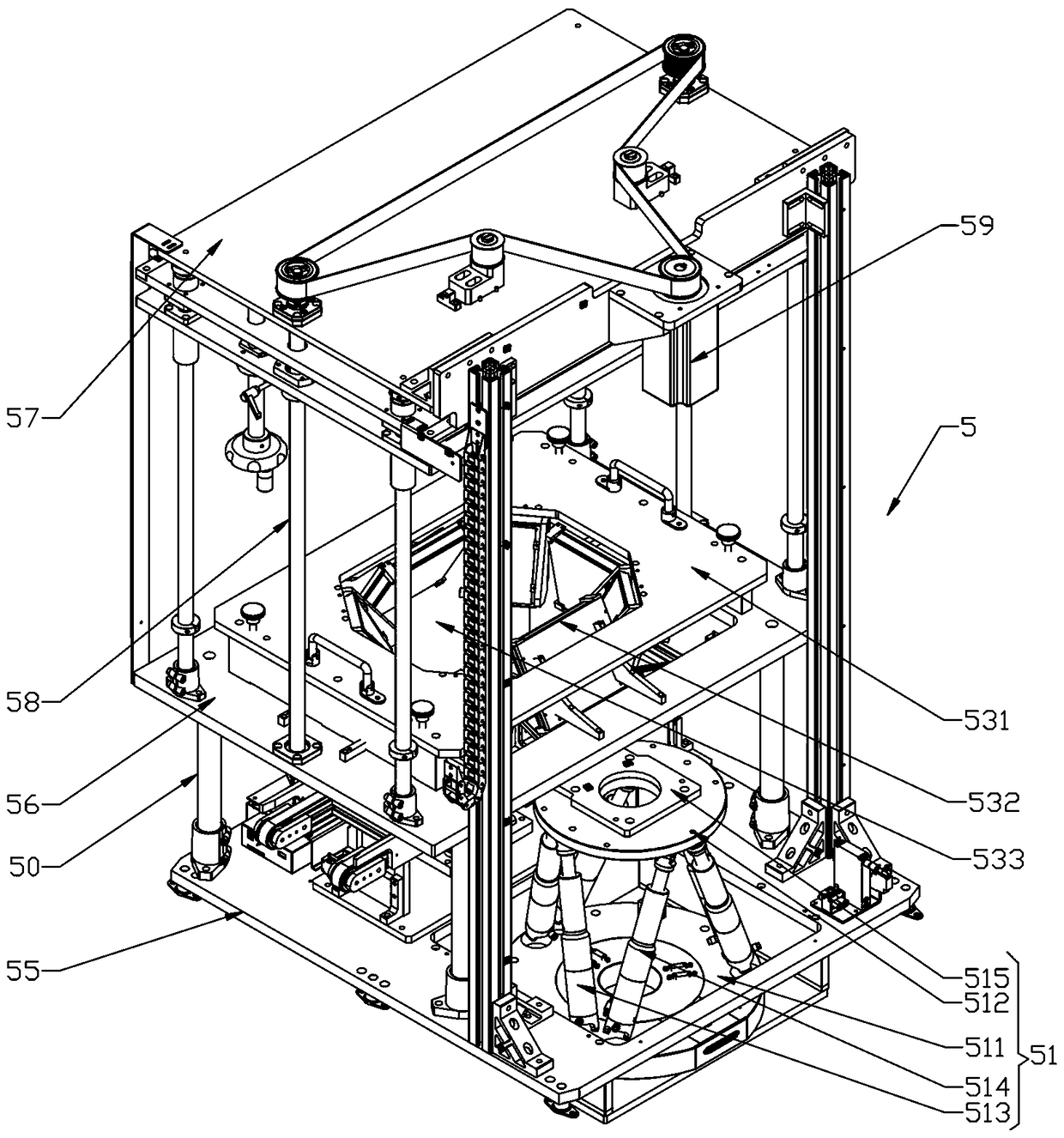

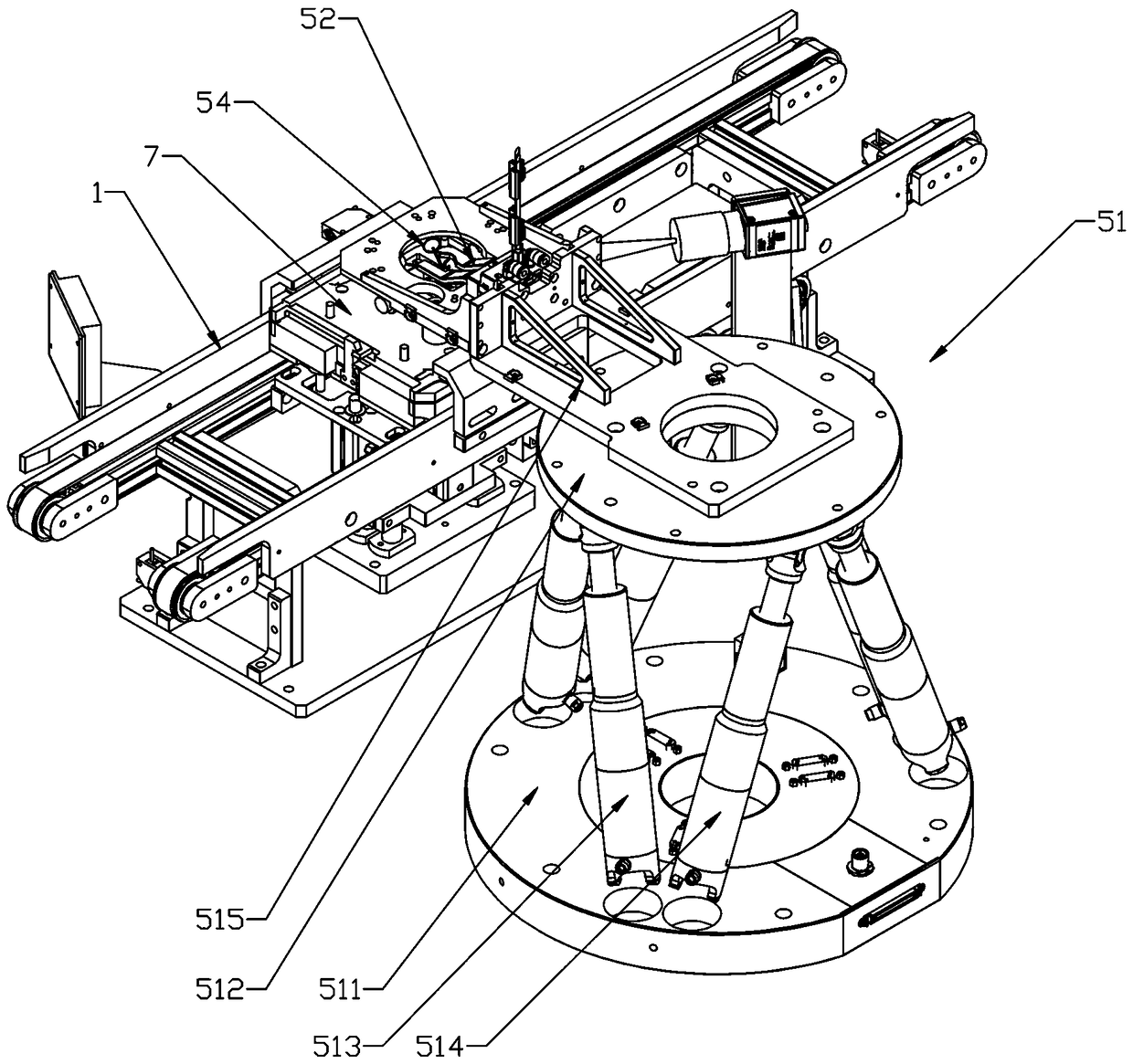

[0030] Such as Figure 1 to Figure 6 As shown, the specific embodiment of the present invention is: the present invention comprises a belt assembly line 1 and a feeding module 2, a plasma cleaning module 3, a glue dispensing module 4, a camera automatic calibration module 5, and a lower The material return module 6, the belt assembly line 1 is provided with a carrier 7, the camera automatic calibration module 5 includes a six-axis platform manipulator 51, and the gripper 52 of the six-axis platform manipulator 51 is located above the carrier 7 , the top of the jaw 52 is provided with a folding mirror module 53, the folding mirror module 53 includes a folding mirror fixing plate 531 and a number of folding mirrors 532, the middle part of the folding mirror fixing plate 531 is provided with a through groove 533, Several folding mirrors 532 are evenly arranged on the lower part of the side wall of the through groove 533 . In the present invention, the present invention adopts a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com