Transition-liquid-phase-assisted solid-phase connection method

A solid-phase connection and transition fluid technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of surface flatness and roughness of the connection interface, which affect the performance of joints, and improve high-temperature performance and reliability. , Improve welding efficiency, simplify the effect of surface cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

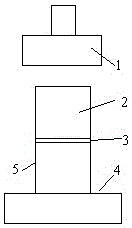

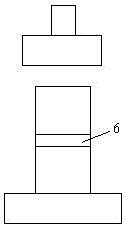

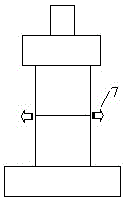

[0022] The present invention works and implements like this, as Figure 1-4 As shown, a transitional liquid-phase assisted solid-phase joining method simply grinds the joint surfaces of the materials to be welded 1 and the materials to be welded 5, and adds an intermediate layer 3 containing demelting elements between the materials to be welded 1 and 5, and assembles into a sandwich structure and placed on the lower support plate 4 of the vacuum diffusion welding furnace. Heating to between the melting point of the intermediate layer and the melting point of the material to be welded, through the interdiffusion between the demelting element and the material to be welded, the surface layer of the part to be connected is partially liquefied to form a liquefied phase 6, and then passes through the upper pressure head 2 to be welded 1 and 5 apply a certain forging pressure to extrude the liquid phase 7 to remove the physical and chemical uneven layer on the surface, and under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com