Control method for dry ice cleaning of chip packaging mold

A dry ice cleaning and chip packaging technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of packaging plastic residues, reduce the quality of chip packaging products, etc., and achieve the effect of improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

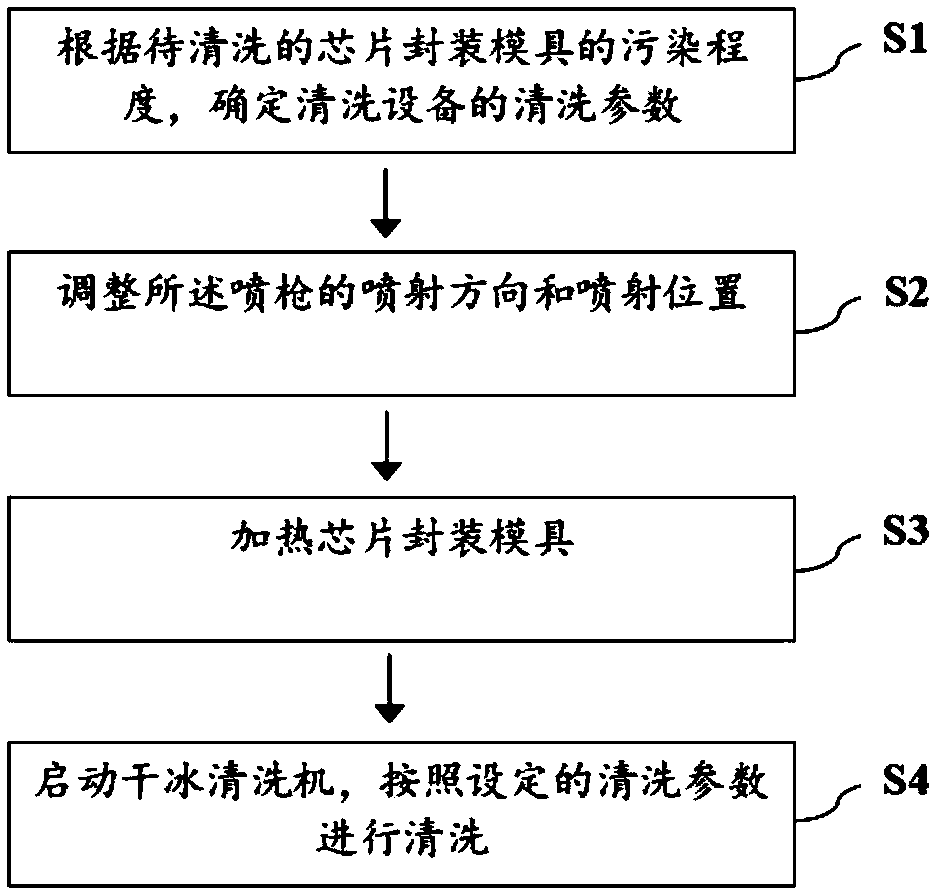

[0042] Depend on figure 1 As shown, the present embodiment provides a control method for chip packaging mold dry ice cleaning, including the following steps:

[0043] S1. Determine the cleaning parameters of the cleaning equipment according to the degree of contamination of the chip packaging mold to be cleaned, wherein the cleaning equipment includes a dry ice blasting machine, a spray gun for spraying dry ice, and an air compressor that provides compressed air for the dry ice blasting machine The air compressor is connected to the air inlet pipe 60 of the dry ice blasting machine, the spray gun is connected to the air outlet pipe 70 of the dry ice blasting machine, and the dry ice blasting machine provides solid dry ice particles for the spray gun. Wherein, the chip packaging mold is a mold that protects semiconductor chips, gold wires and lead frames together with thermosetting plastics in industry, one of which is as Figure 10 As shown, grooves adapted to the size of the...

Embodiment 2

[0056] The embodiment of the present invention provides a method for controlling dry ice cleaning of a chip packaging mold, and the following dry ice cleaning machine is used:

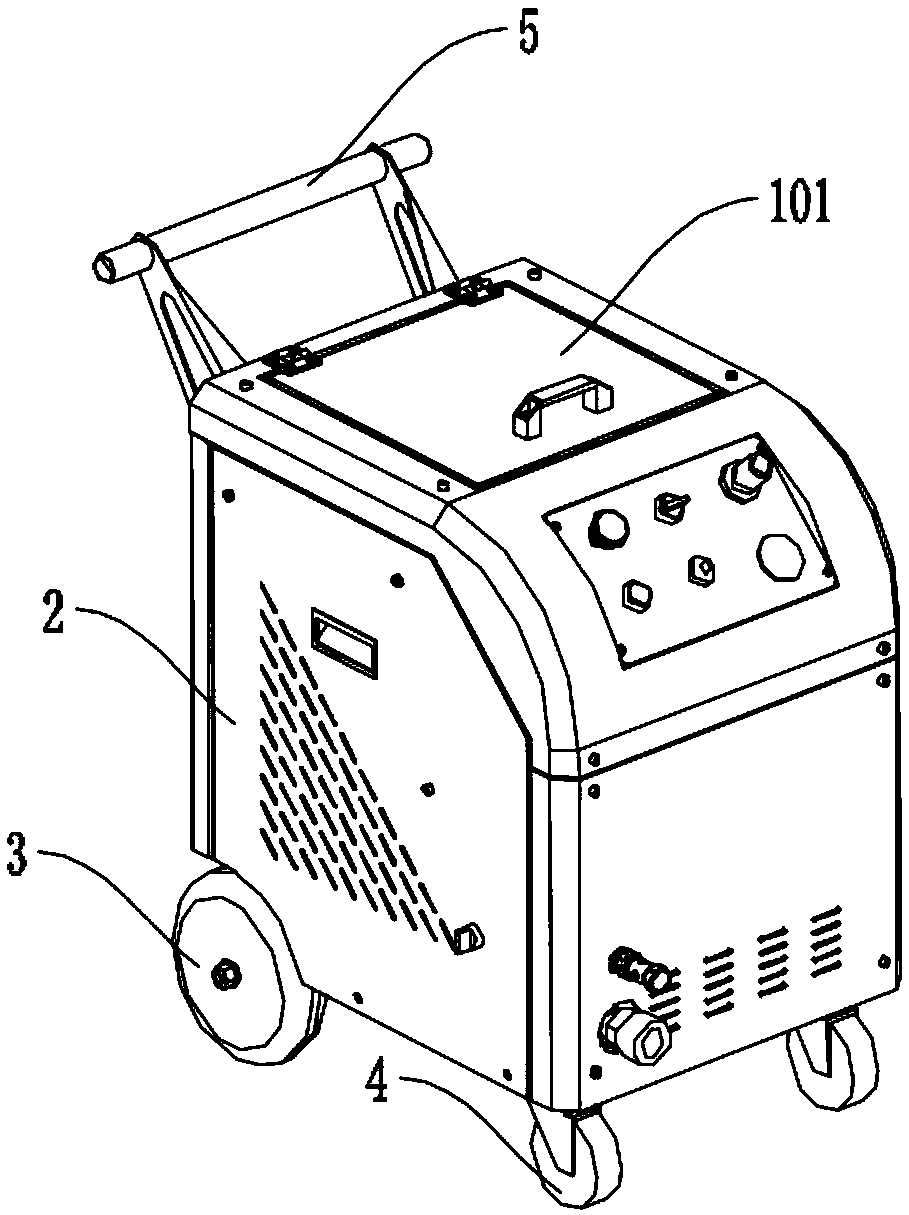

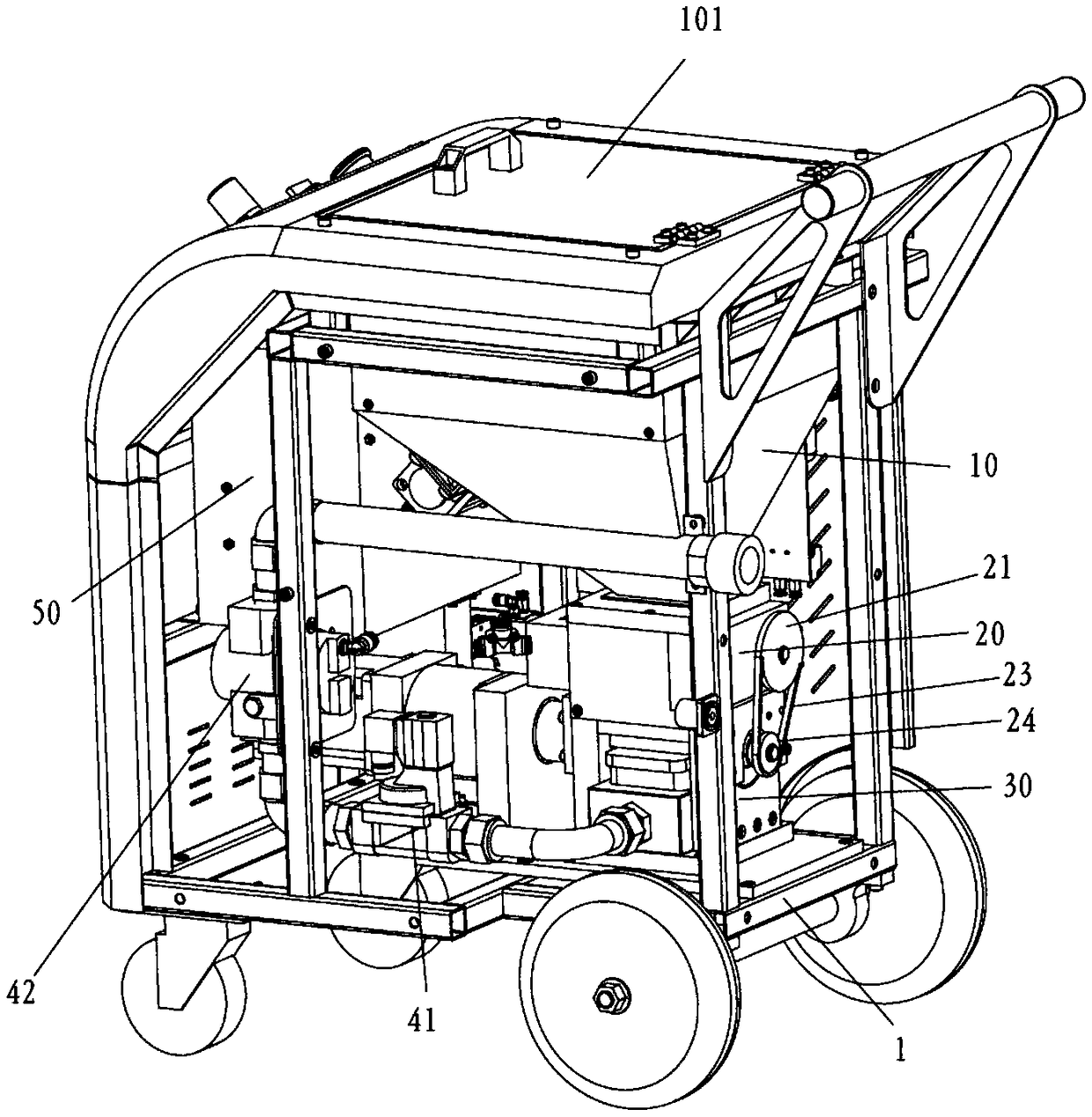

[0057] refer to Figure 2-8 As shown, this embodiment provides a dry ice blasting machine, including a frame 1 , a feeding device 10 , an ice crushing device 20 , an ice mixing device 30 and a controller 50 . The dry ice blasting machine provided in this embodiment adopts an independent modular design, so that each module is independently installed at each position of the frame 1 and can be disassembled and replaced independently.

[0058] refer to image 3 and Figure 6 As shown, the frame 1 is used to provide a working chamber and support. The frame 1 is provided with a feeding device 10 , an ice crushing device 20 , an ice mixing device 30 and a controller 50 . Detachable sheet metal parts 2 are installed around the frame 1, and each sheet metal part 2 can be disassembled independently without a...

Embodiment 3

[0080] An embodiment of the present invention provides a method for controlling dry ice cleaning of a chip packaging mold, and the following auxiliary brackets can be applied:

[0081] combine Figure 9 , this embodiment provides an auxiliary support, including: a base 81 , a workbench 82 and a lifting mechanism 83 .

[0082] Further, the bottom of the base 81 is provided with an adsorption piece 811 for fixing with external equipment. More preferably, the adsorption member 811 is a magnetic base, and a plurality of magnetic bases are adsorbed and fixed on the chip processing machine, which ensures the quick disassembly of the auxiliary support on the chip processing machine.

[0083] Further, the workbench 82 includes a bottom plate 821 , a sliding mechanism 822 and a moving seat 823 for fixing the spray gun. More preferably, the bottom plate 821 is a U-shaped flat plate. The sliding mechanism 822 is arranged on both sides of the U-shaped plate, and the U-shaped opening ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com