Tunnel wall cleaning device

A technology for cleaning devices and tunnel walls, which can be used in road cleaning, cleaning methods, construction, etc., and can solve problems that cannot be used to clean electrical equipment installation areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

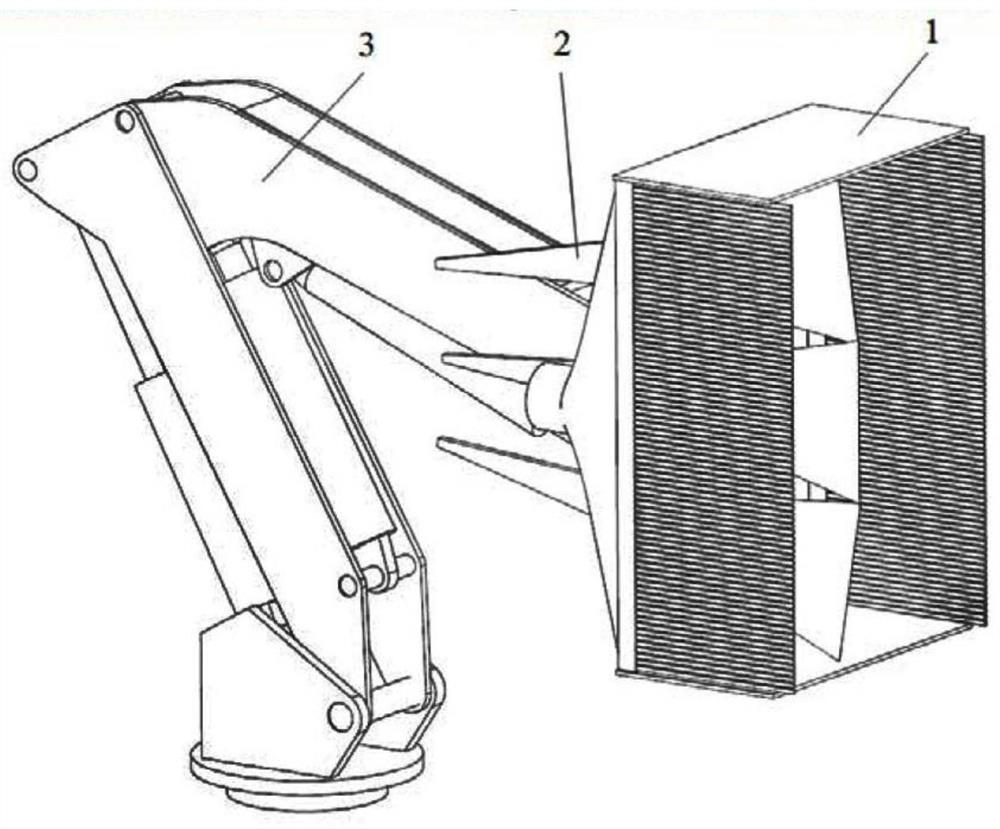

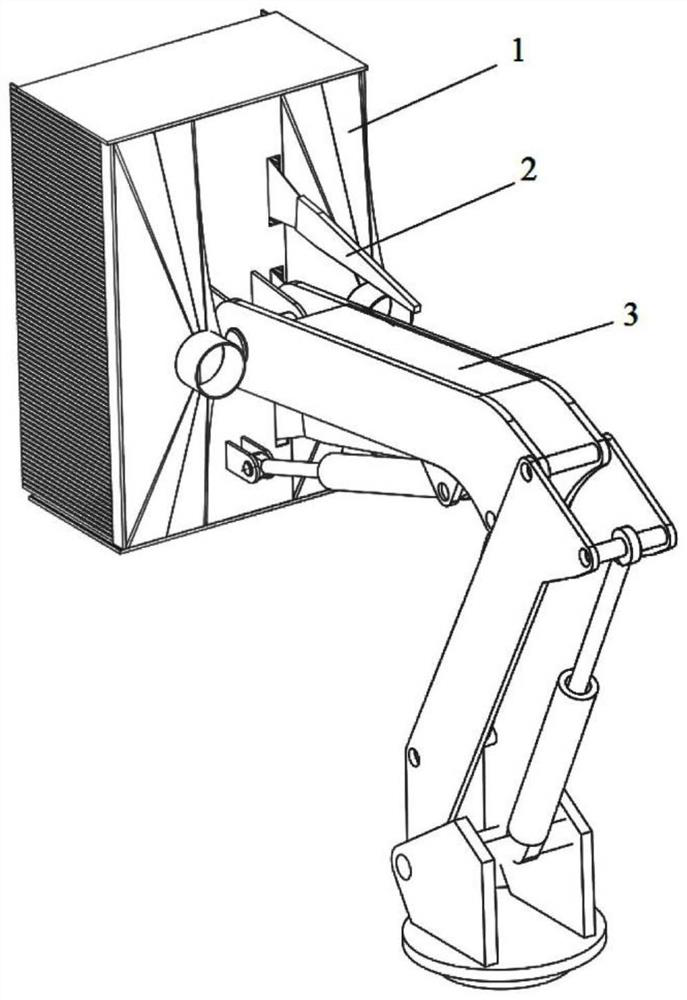

[0036] Such as figure 1Shown is a schematic structural view of the tunnel wall cleaning device according to the present invention. The tunnel wall cleaning device of the present invention includes a dry ice blasting assembly 2 , the dry ice blasting assembly 2 is fixedly connected to a cover body 1 , and a mechanical arm 3 is connected to the back of the cover body. Setting the cover body 1 can prevent dust from being raised in the cleaning area during cleaning; the cover body 1 is provided with a brush discharge plate 12 when cleaning the electrical equipment installation area on the tunnel wall, the bristles on the brush discharge plate 12 can realize the cleaning function on the one hand, On the other hand, it can avoid obstacles. This design enables the cover body 1 to be as close to the tunnel wall as possible through the mechanical arm 3 during cleaning operations to prevent dust, which solves the problem of high-pressure wind cleaning in the prior art. No matter what t...

Embodiment 2

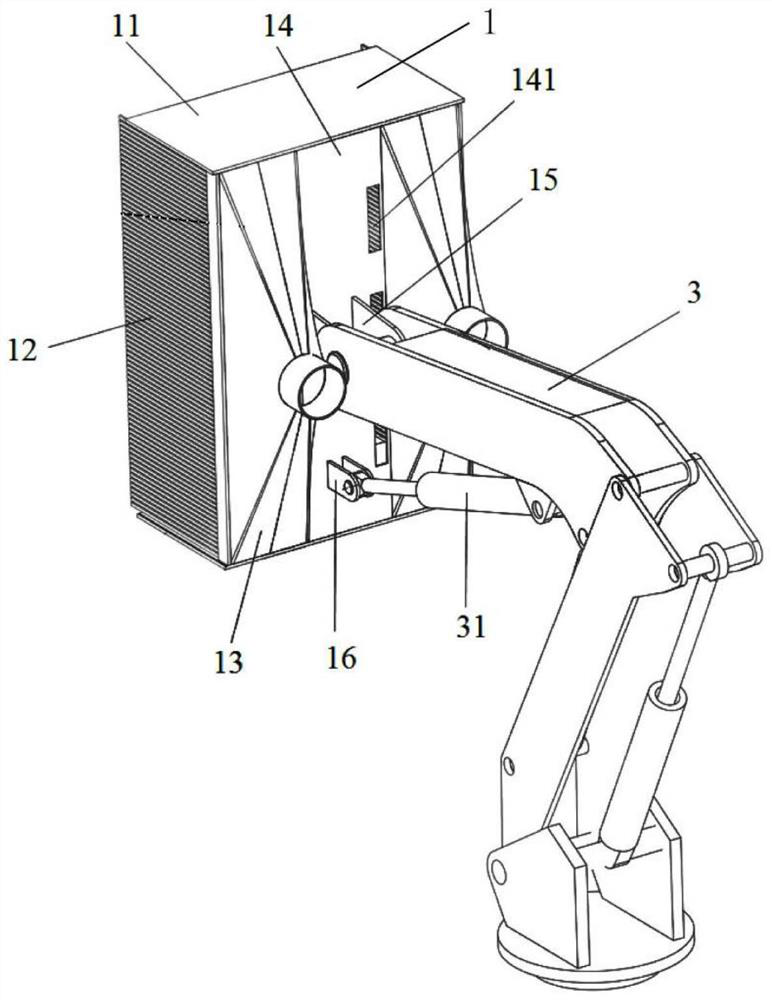

[0052] last read Figure 5 , Figure 6 Shown is a schematic structural view of the second embodiment of the tunnel wall cleaning device according to the present invention.

[0053] Implement two on the basis of embodiment one and be provided with two slide plates 17 on the outside of brush plate 12, each slide plate 17 is connected with a regulating oil cylinder 4, and the upper and lower sides of each slide plate 17 are connected with guide mechanism The baffle 11 is connected.

[0054] In this embodiment, the guide mechanism includes guide grooves 111 and rollers 112; guide grooves 111 are formed on the left and right edges of the side of the baffle plate 11 opposite to the brush discharge plate 12, and rollers are installed in the guide grooves 111. 112 , the sliding plate 17 moves back and forth along the bristle direction of the brush removal plate 12 under the action of the adjustment oil cylinder 4 and the roller 112 , thereby adjusting the length of the bristles actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com