Mixing and gluing device with controllable temperature and integrated chromaticity detection

A chromaticity and bucket body technology, applied in chemical instruments and methods, mixers with rotating stirring devices, dissolution, etc., can solve the problems of difficult temperature control, difficult to grasp the color of materials, etc., to achieve easy operation, ensure accuracy, The effect of mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

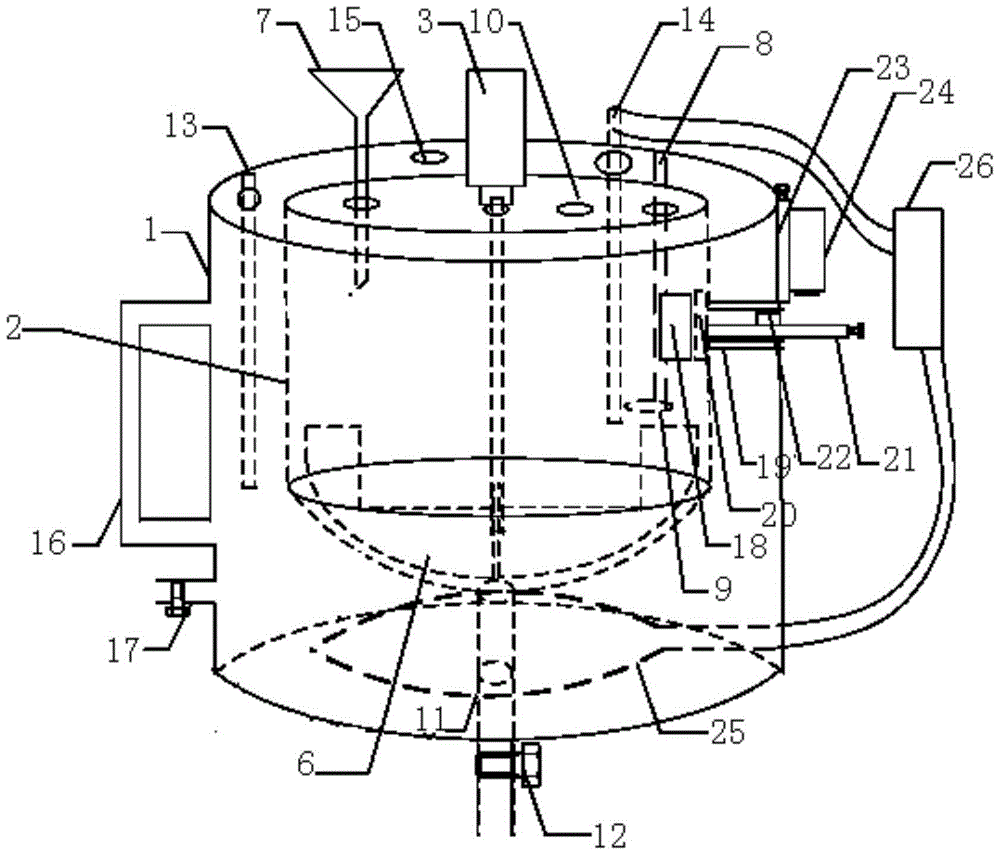

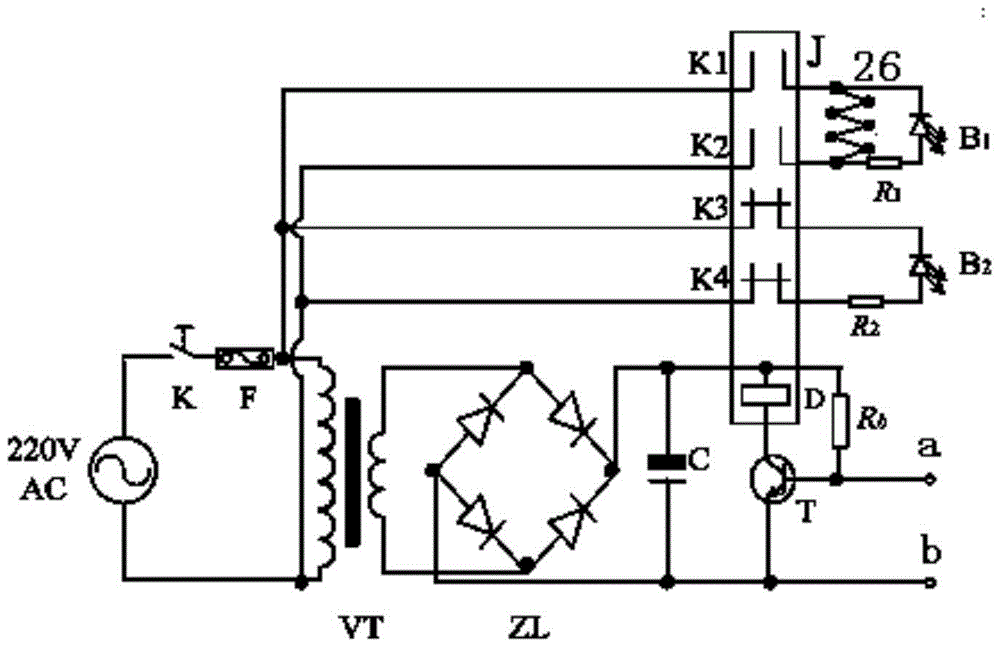

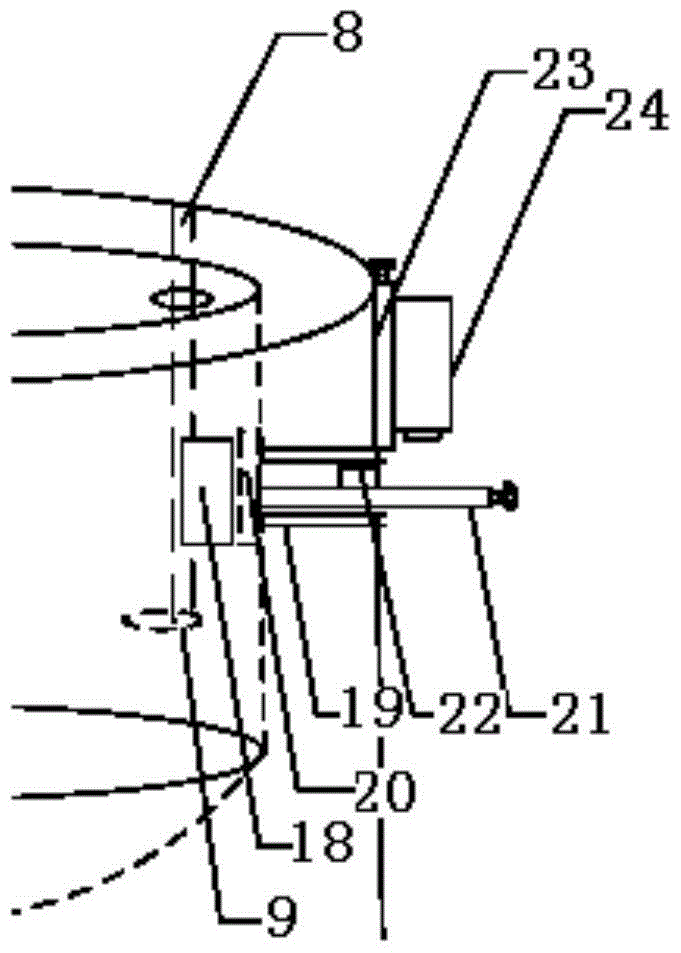

[0030] Such as figure 1 , image 3 , Figure 5 shown. The temperature-controllable and chromaticity detection integrated mixing device includes a mixing glue container, and the mixing glue container is composed of an outer container 1 and an inner container 2 with a common central axis arranged in the outer container 1, and the top of the inner container 2 is set as a bile mouth and The top surface of the inner container 2 is flush with the top surface of the outer container 1, an annular upper end wall is connected between the top of the outer container 1 and the top of the inner container 2, and the upper end of the inner container 2 is covered with a round cover for closing the inner container. 2. The bottom is set in a spherical crown shape and has a certain distance from the bottom of the outer container 1;

[0031] A stirring DC motor 3 is installed at the center of the dome cover, and a stirring shaft 4 is arranged vertically downward along the central axis in the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com