Tunnel wall cleaning vehicle

A technology for cleaning vehicles and tunnel walls, which can be applied to road surface cleaning, cleaning methods, construction, etc., and can solve problems that cannot be used to clean electrical equipment installation areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

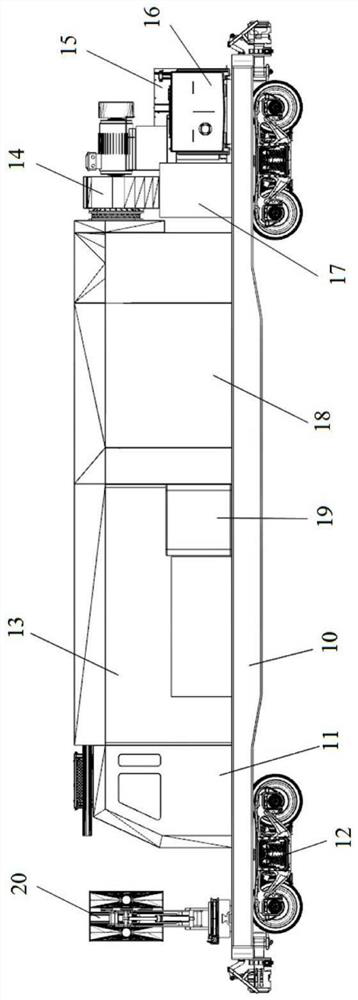

[0044] Such as figure 1 Shown, according to the structural representation of the tunnel wall cleaning vehicle of the present invention. The tunnel wall cleaning vehicle of the present invention comprises a car body 10, and bogies 12 are respectively arranged on the front and rear sides below the car body 10, and the two sets of bogies 12 on the front and rear sides can be the same or can be selected differently according to needs. The bogies 12 are The running system of the whole vehicle is representative; the top of the car body 10 is provided with a driver's cab 11, a power room 13, a fan 14, an air compressor 15, a hydraulic system 16 and an electrical system 17, and the cleaning vehicle is also provided with a dust removal system 18 and dry ice cleaning. The working device 20 ; the power room 13 is provided with power equipment required for vehicle work, and a dry ice cleaning device 19 is also provided.

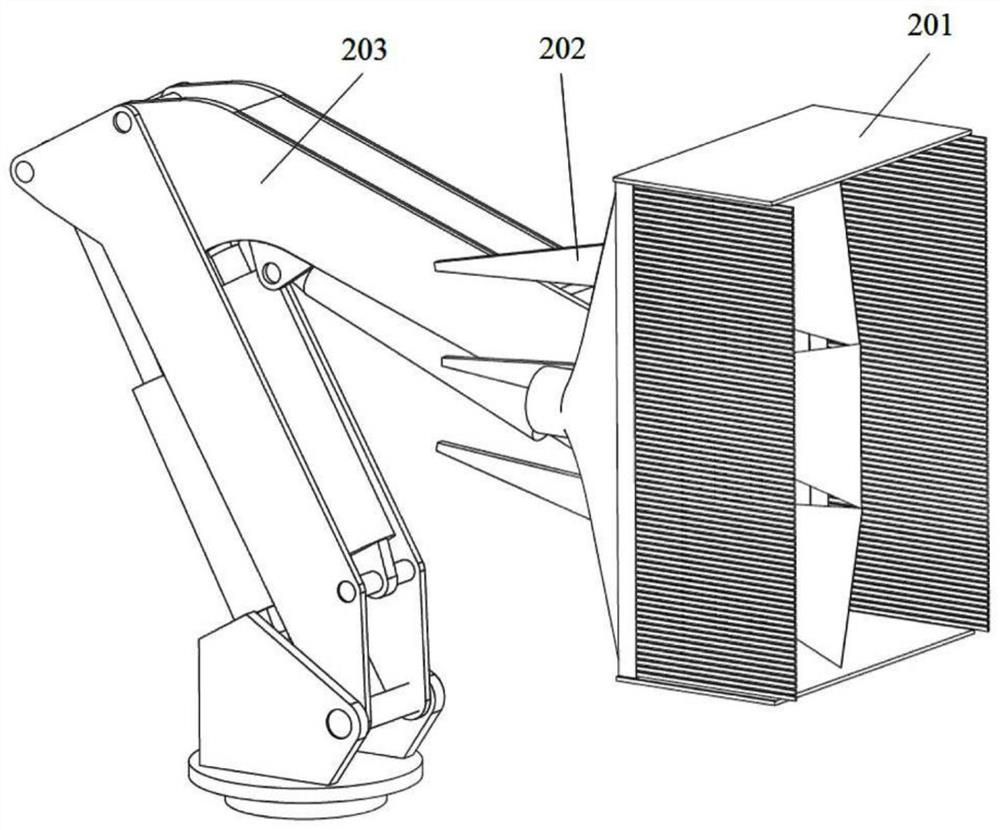

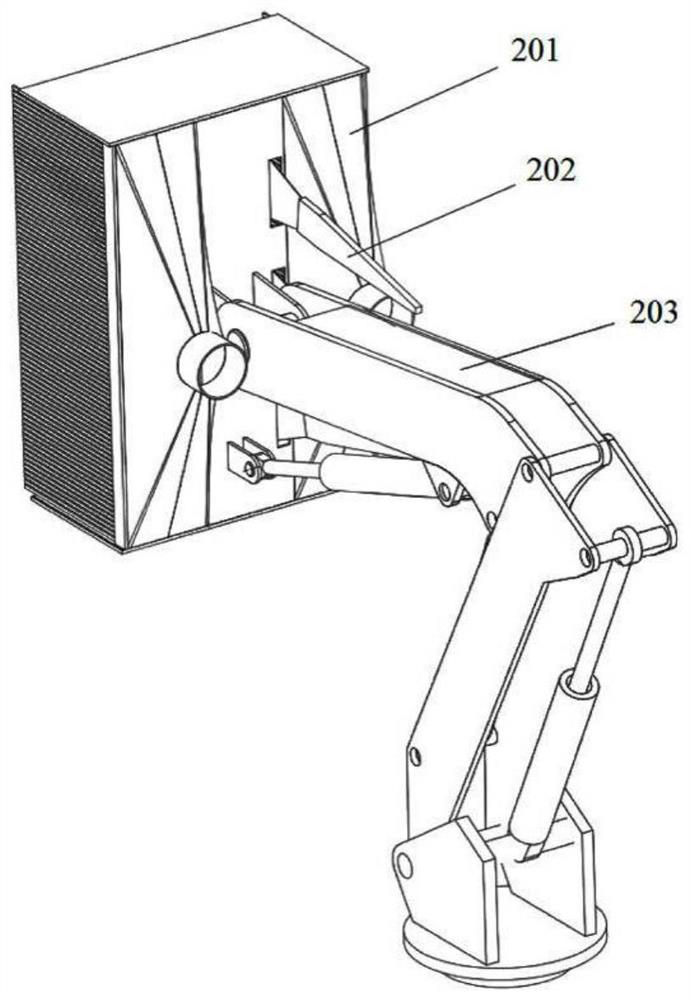

[0045] see next figure 2 , image 3 Shown, according to the tun...

Embodiment 2

[0068] see next Figure 6 , Figure 7 Shown is a schematic structural view of the second embodiment of the tunnel wall cleaning vehicle according to the present invention.

[0069] On the basis of the first embodiment, the second implementation further includes two sliding plates 37 installed on the left and right sides of the cover body 201 and outside the brush discharge plate 32 ; it also includes an adjustment cylinder 204 connected with the sliding plates 37 . A guiding mechanism is provided between the sliding plate 37 and the baffle plate 31 to enable the sliding plate 37 to move back and forth along the bristle length direction of the brush removal plate 32 .

[0070] In this embodiment, guide grooves 311 are provided on the left and right side edges of the baffle plate 31 opposite to the brush discharge plate 32, and rollers 312 are installed in the guide grooves 311, and the sliding plate 37 can be adjusted between the oil cylinder 204 and the rollers 312 Under the...

Embodiment 3

[0076] last read Figure 8 , Figure 9 Shown is a schematic structural view of the third embodiment of the tunnel wall cleaning vehicle according to the present invention.

[0077] This embodiment can be based on any structure of the tunnel cleaning vehicle provided in Embodiment 1 and Embodiment 2, and the tunnel cleaning vehicle can also include: an air knife 205 installed on the back plate 34 of the cover body 201 , the gas input end of the air knife 205 is connected with the high-pressure gas outlet of the air compressor 15 through a pipeline.

[0078] The tunnel cleaning vehicle provided in this embodiment has two cleaning methods: dry ice and air knife blowing. Considering that if dry ice cleaning is used throughout the operation, the amount of carbon dioxide emissions may be relatively large. Therefore, it can be controlled to use dry ice cleaning working device 20 to spray dry ice to clean the tunnel wall in places where local dirt is relatively serious, and wind can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com