Ultrahigh-pressure supercritical carbon dioxide current-carrying dry ice cutting device and method

A carbon dioxide and cutting device technology, applied in the field of decommissioning of nuclear facilities, can solve the problems of increased secondary waste, low cutting efficiency, and increased decommissioning funds, achieving significant economic and social benefits, reducing the amount of secondary waste, The effect of saving disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] An ultra-high pressure supercritical carbon dioxide streaming dry ice cutting device and method provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

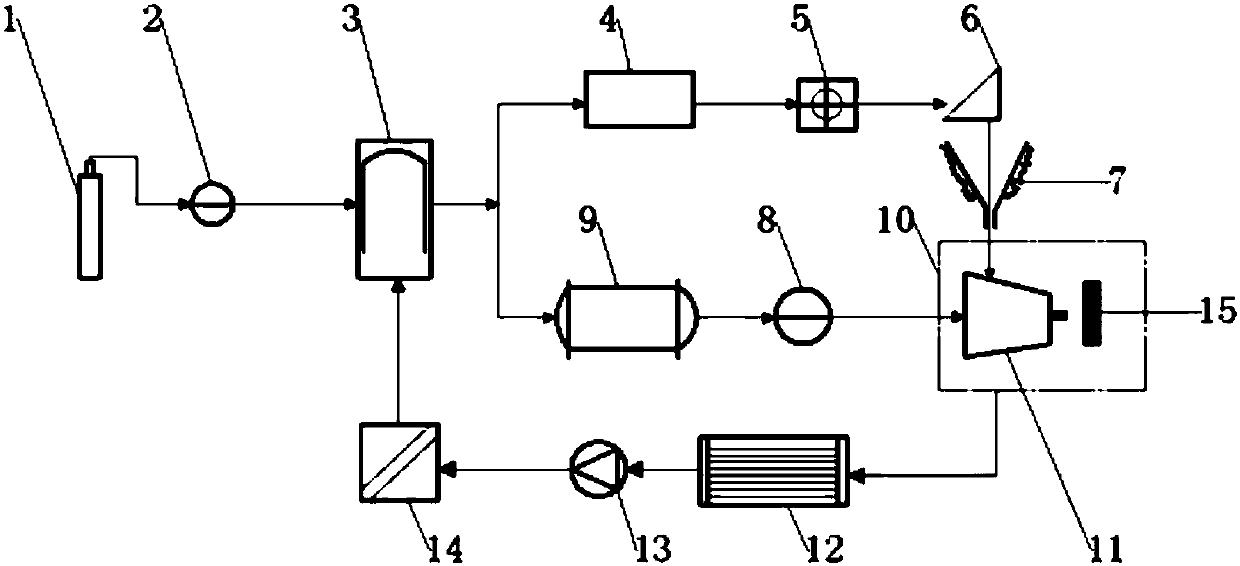

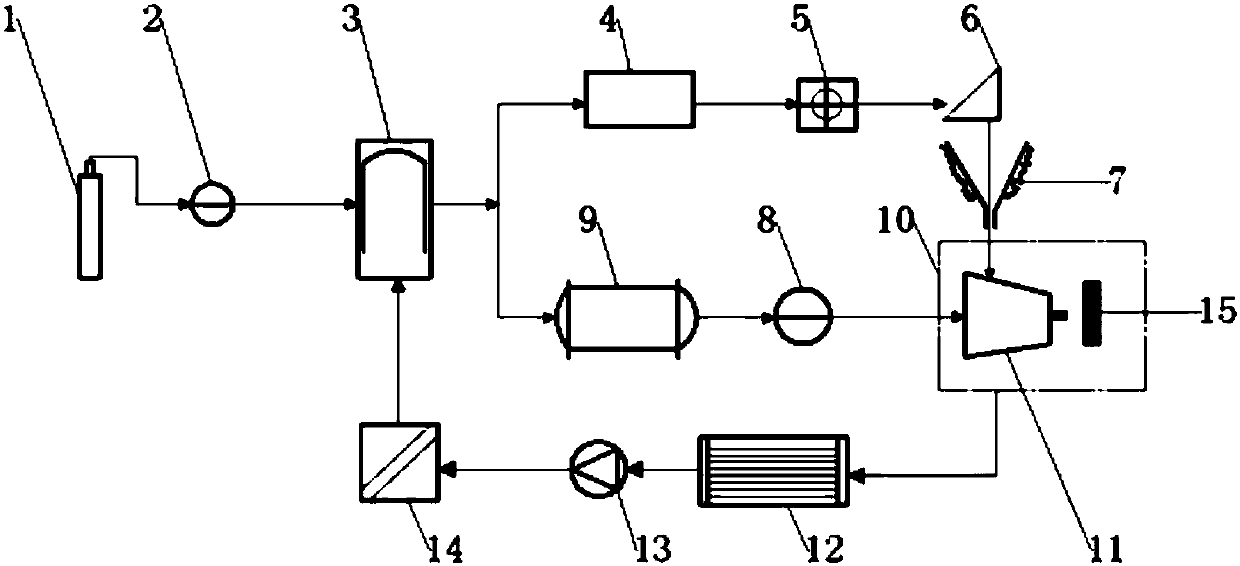

[0037] Such as figure 1 As shown, a cutting device for ultra-high pressure supercritical carbon dioxide streaming dry ice provided by the present invention includes an industrial gas cylinder 1, a supplementary pump 2, a storage tank 3, a dry ice granulator 4, a dry ice crusher 5, a vibrating screen 6, Funnel 7, booster pump 8, heater 9, negative pressure shroud 10, jet cutting device 11, dryer 12, recovery pump 13, two-stage filter 14, cutting and dismantling parts 15;

[0038] The industrial gas cylinder 1 is connected to the storage tank 3 through the supplementary pump 2, the storage tank 3 is connected to the dry ice granulator 4 and the booster pump 8 at the same time, the dry ice granulator 4 is connected to the dry ice c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com