Dry ice cleaning equipment for semiconductor element

A dry ice cleaning and semiconductor technology, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve problems affecting geometric features, waste of resources, failure of integrated circuits, etc., to ensure cleanliness, High cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

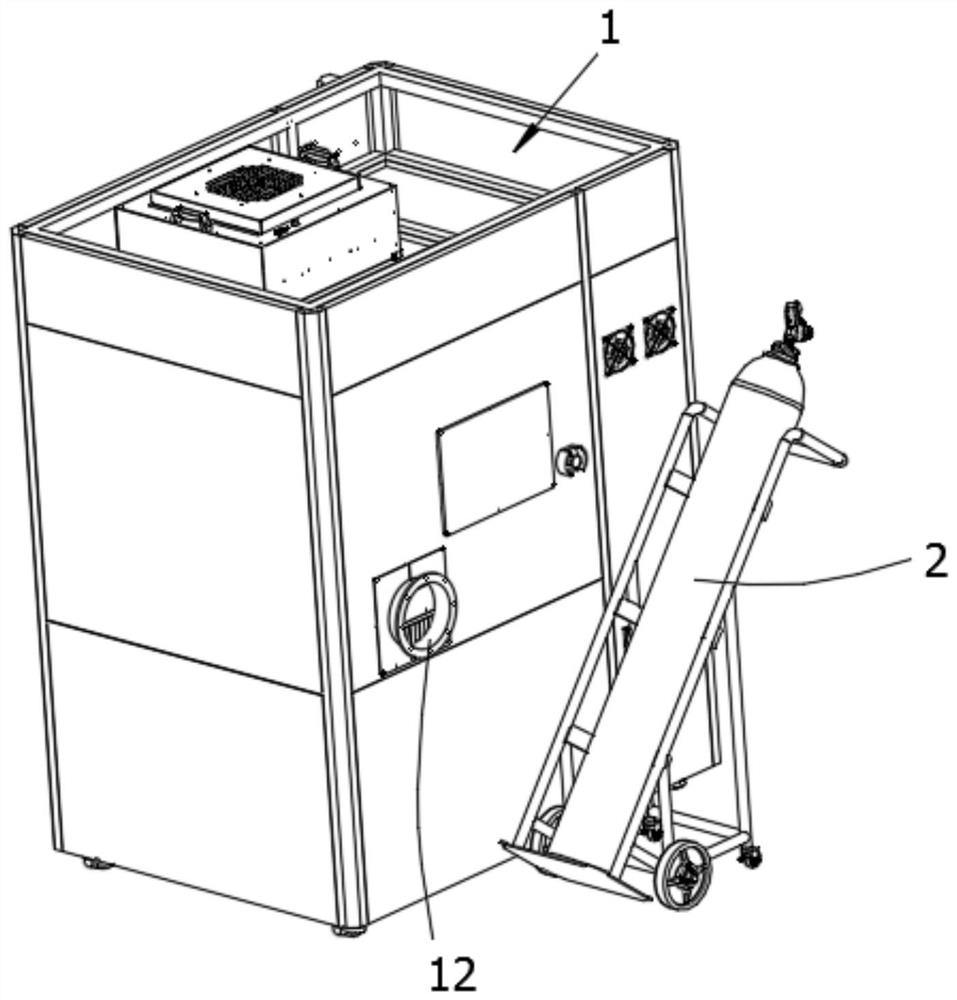

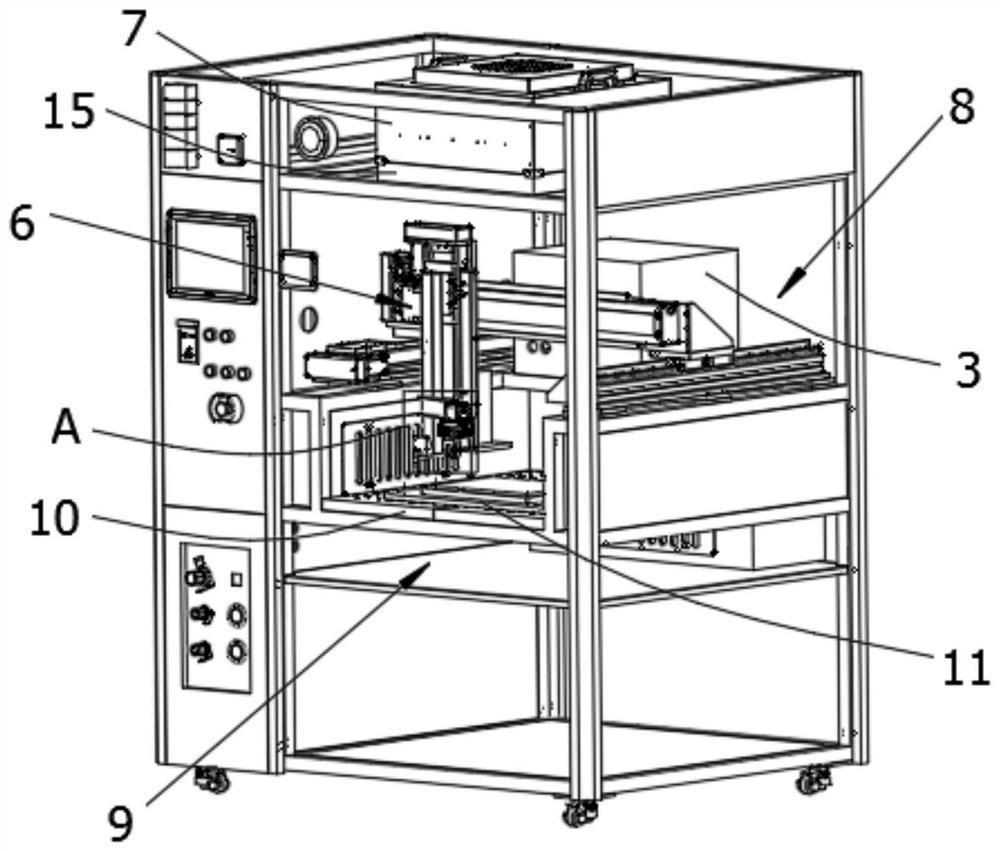

[0026] Embodiment: a kind of semiconductor element is cleaned equipment with dry ice, as Figure 1-Figure 3 As shown, it includes an equipment rack body 1, a dry ice generating mechanism, a dry ice blasting mechanism, a dry ice purification mechanism and a cleaning room installed on the equipment rack body;

[0027] The dry ice generating mechanism includes a liquid carbon dioxide storage tank 2 and a dry ice generator 3, and the liquid carbon dioxide storage tank and the dry ice generator are connected through a hose;

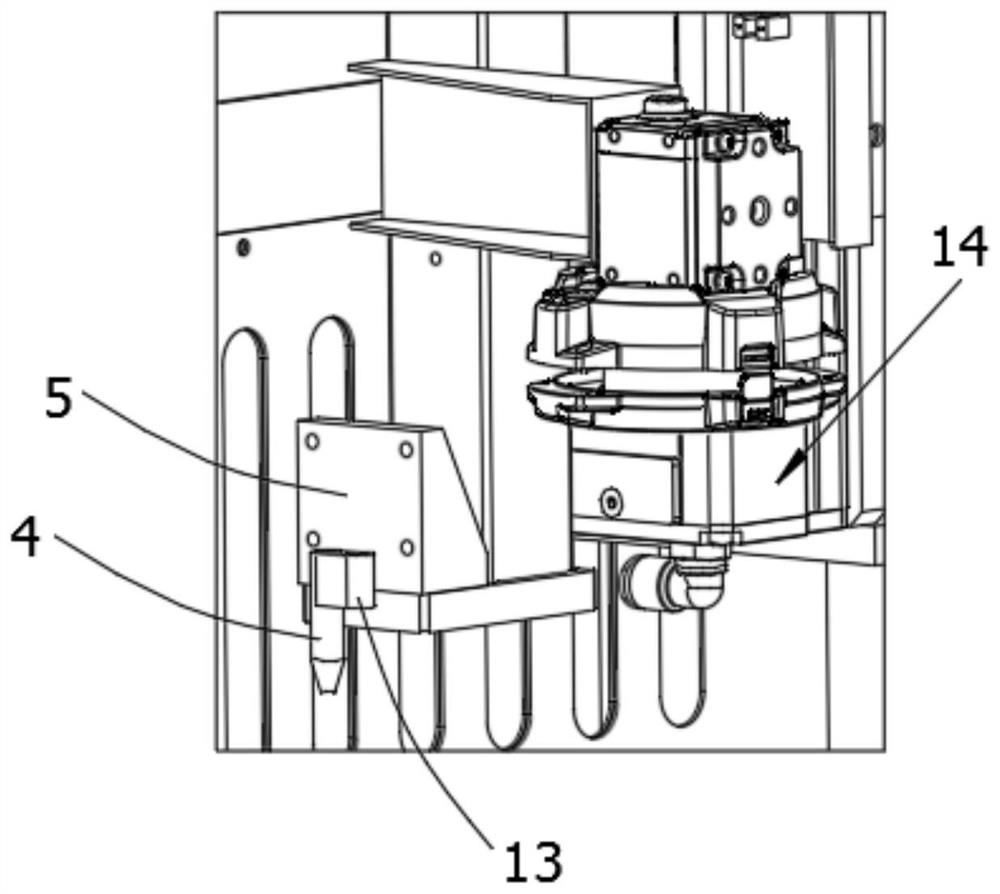

[0028] The dry ice blasting mechanism includes a dry ice nozzle base 5 for installing a dry ice nozzle 4 and a manipulator 6 that drives the dry ice nozzle base to move, the dry ice nozzle is connected to the dry ice generator through a hose, and the dry ice nozzle and the dry ice nozzle The manipulator is located in the cleaning chamber;

[0029] The dry ice purification mechanism includes an intake fan 7 and an exhaust fan, the intake fan is located above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com