Novel pretreatment method for anodic oxidation process

An anodic oxidation and pretreatment technology, which is applied in the field of surface pretreatment before anodic oxidation of titanium and titanium alloys, can solve the problems of reducing the interface bonding strength between the substrate and the film layer, failing to reach product roughness, and small surface roughness. , to achieve the effect of reducing secondary interface pollution, improving interface quality, and eliminating interface pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0051] This embodiment discloses a process for anodic oxidation pretreatment, the general steps are as follows:

[0052] 1) Degrease and degrease the surface of the test piece substrate to be anodized;

[0053] 2) Roughen the test piece with dry ice blasting;

[0054] 3) Perform specific solution activation treatment on the test piece;

[0055] 4) Carry out specific anodizing treatment on the test piece.

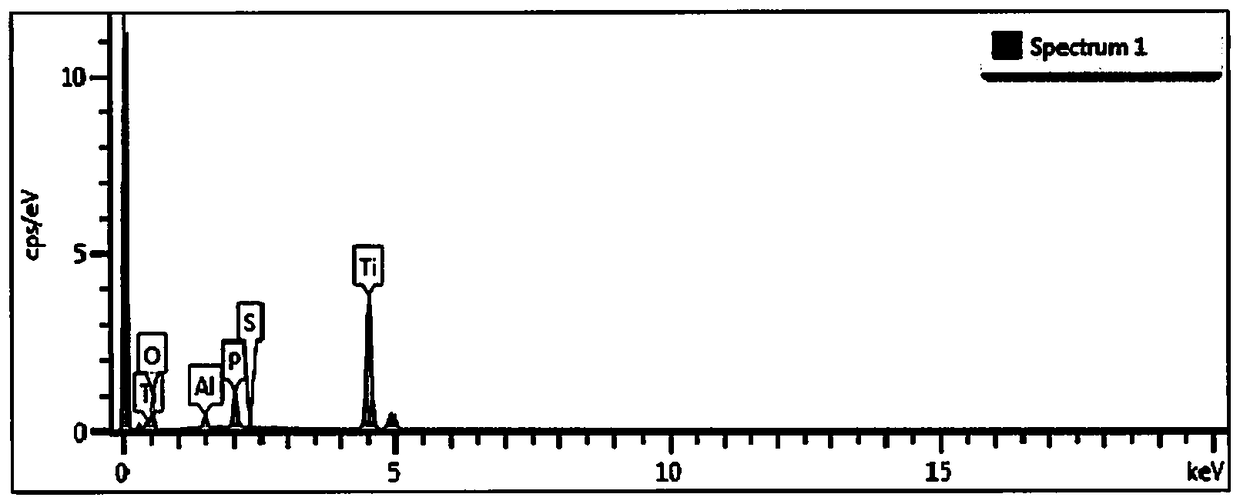

[0056] Dry blasting roughening leads to the attachment and embedding of residual abrasive fragments on the surface of the substrate, resulting in interface contamination. In order to understand the purification and roughening effect of dry ice particle blasting on the test piece, this embodiment uses the traditional dry sandblasting method for comparison.

[0057] The general steps of traditional method processing are as follows:

[0058] 1) Degrease and degrease the surface of the test piece substrate to be anodized;

[0059] 2) Perform dry sandblasting roughening on t...

specific Embodiment 2

[0075] This embodiment discloses a process for anodic oxidation pretreatment, the general steps are as follows:

[0076] 1) Degrease and degrease the surface of the test piece substrate to be anodized;

[0077] 2) Roughen the test piece with dry ice blasting;

[0078] 3) Supersonic flame spraying treatment is carried out on the test piece.

[0079] Dry blasting roughening leads to the attachment and embedding of residual abrasive fragments on the surface of the substrate, resulting in interface contamination. In order to understand the purification and roughening effect of dry ice particle blasting on the test piece, this embodiment uses the traditional dry sandblasting method for comparison.

[0080] The general steps of the traditional dry sandblasting method are as follows:

[0081] 1) Degrease and degrease the surface of the test piece substrate to be anodized;

[0082] 2) Perform dry sandblasting on the test piece;

[0083] 3) Supersonic flame spraying treatment is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com