Complex cleaning system for heat exchanger

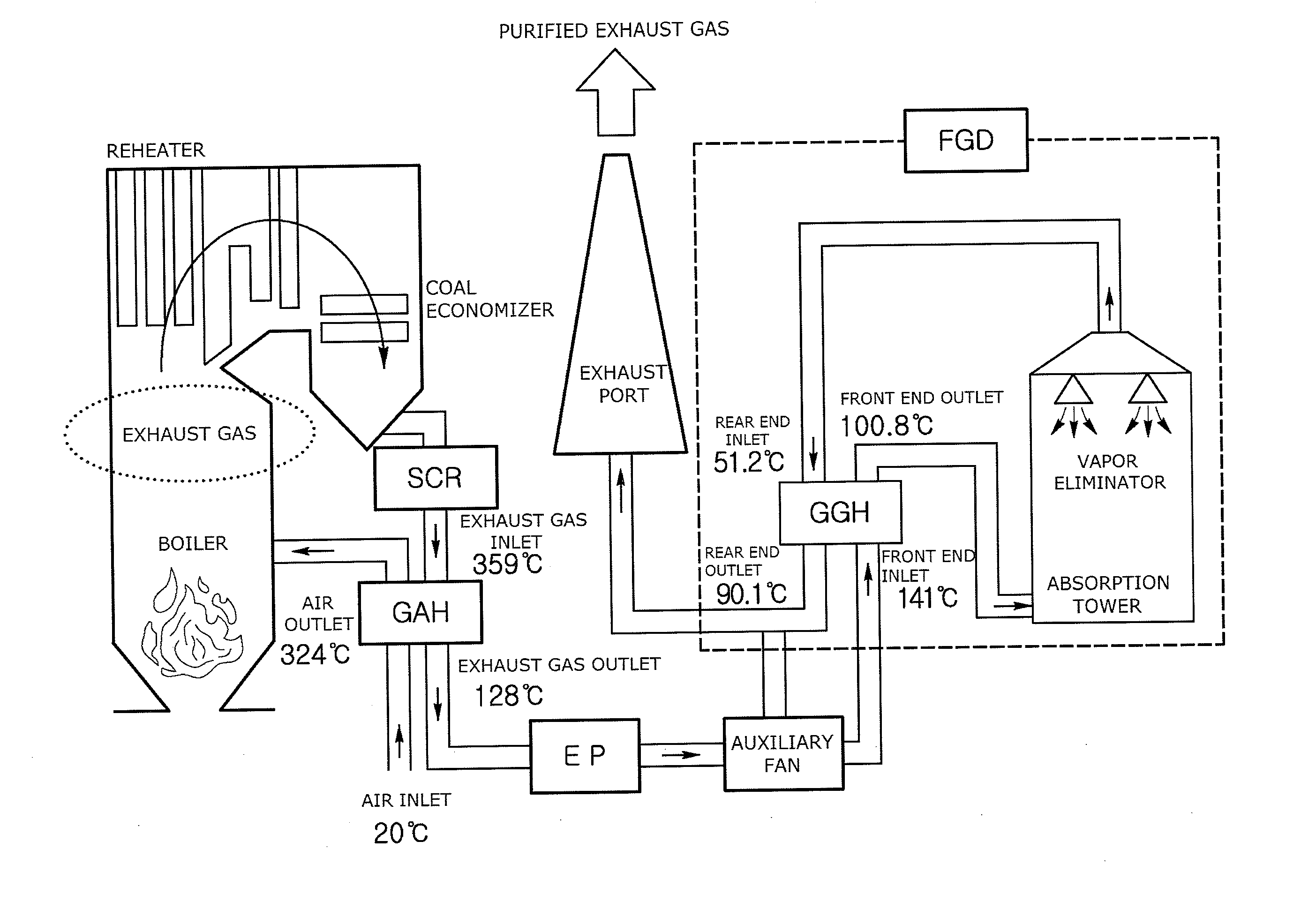

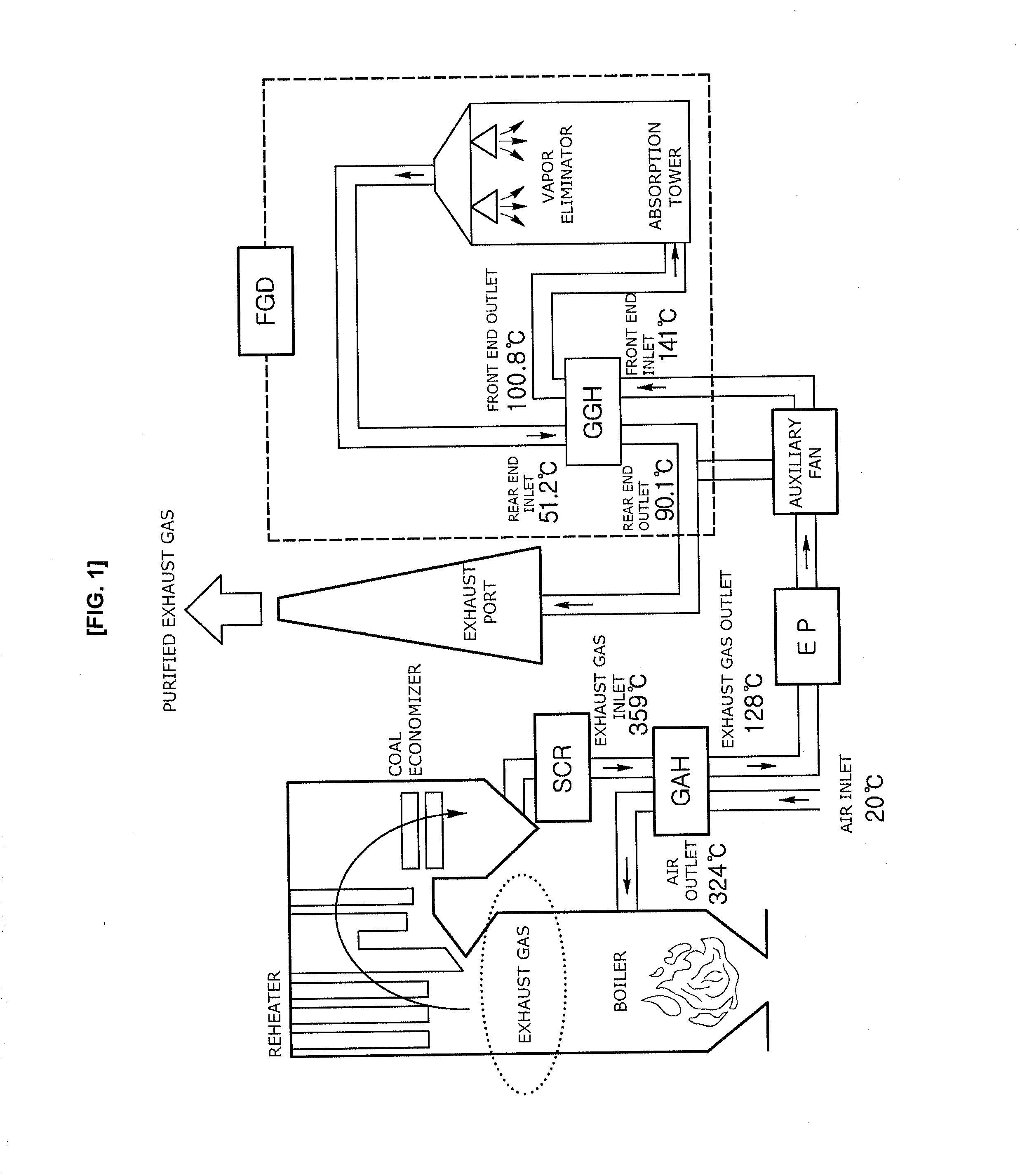

a heat exchanger and complex technology, applied in the direction of indirect heat exchangers, flush cleaning, lighting and heating apparatus, etc., can solve the problems of corroding the rear facilities of the scr device, low denitrification efficiency of the sncr method, and reducing the activity of bisulfate, so as to achieve low pressure, reduce the amount of high-temperature steam, and reduce the effect of water content in the exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

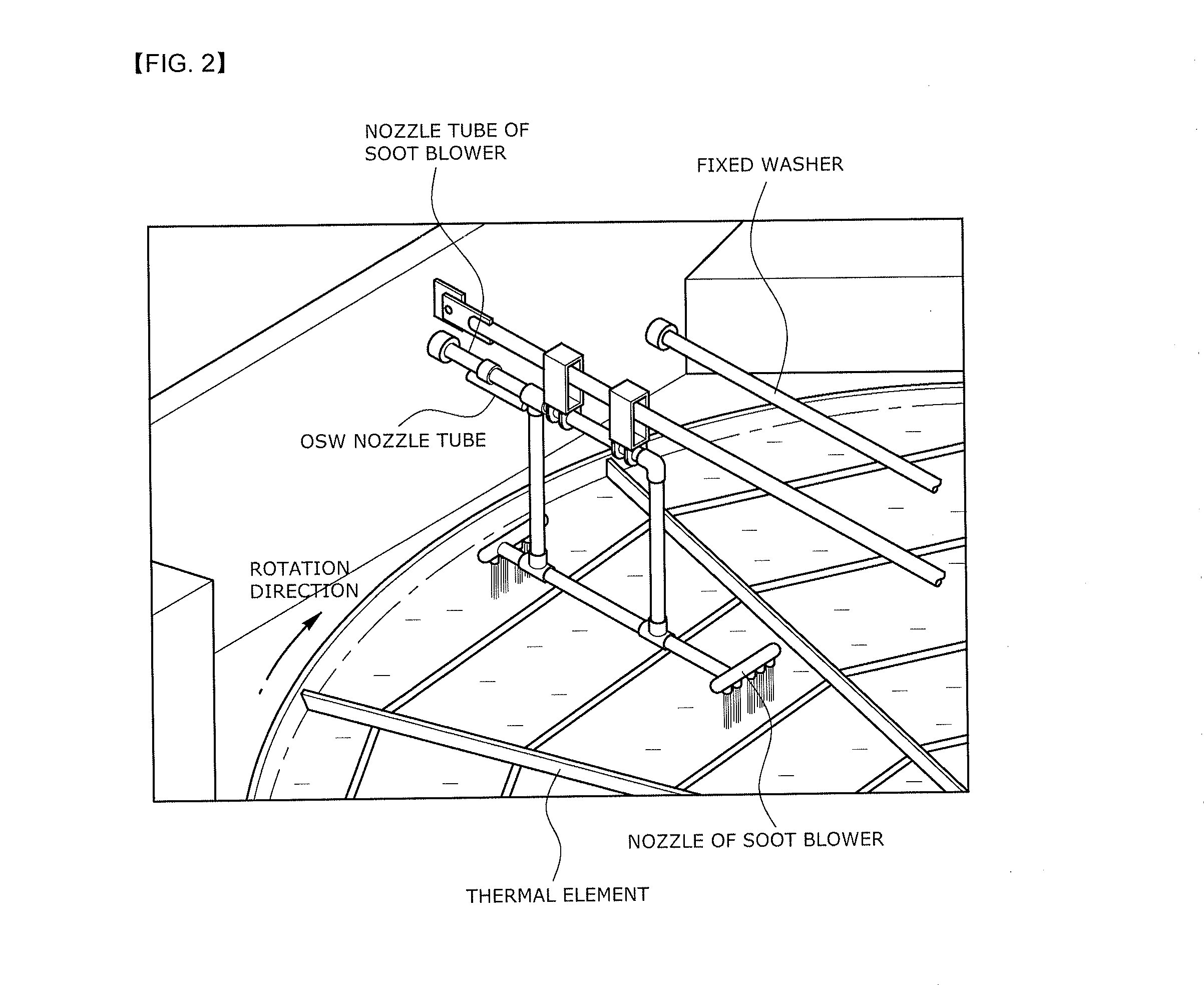

[0035]1: rotation direction of air preheater, 2: air preheater, 3: dry ice pellet spraying nozzle, 4: dry ice pellet spraying device, 5: dry ice pellet sizer, 6: high-temperature steam spraying device, 7: supply air outlet, 8: exhaust gas inlet, 9: supply air inlet, 10: exhaust gas outlet

BEST MODE

[0036]Hereinafter, the embodiments of the present disclosure will be described in detail with reference to accompanying drawings.

[0037]As shown in FIG. 5, dry ice pellets are sprayed from a cleaning device by air having a high-pressure or low-pressure to hit a surface of a thermal element of an air preheater. The dry ice pellets causes ammonium bisulfate to be rapidly frozen at ultralow temperature (−78° C.), such that ammonium bisulfate contracts due to a temperature difference with ambient temperature, thereby a number of cracks are occurred. The dry ice pellets penetrate into ammonium bisulfate through the cracks while sublimating to expand equal to or greater than 800 times in its volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com