Heating dust suction and dry ice cleaning surface depainting treatment equipment and method

A technology for processing equipment and dry ice, applied to cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., can solve problems such as inapplicability of chemical paint removers, corrosion of composite materials, etc., and achieve efficiency improvement and dosage The effect of reducing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

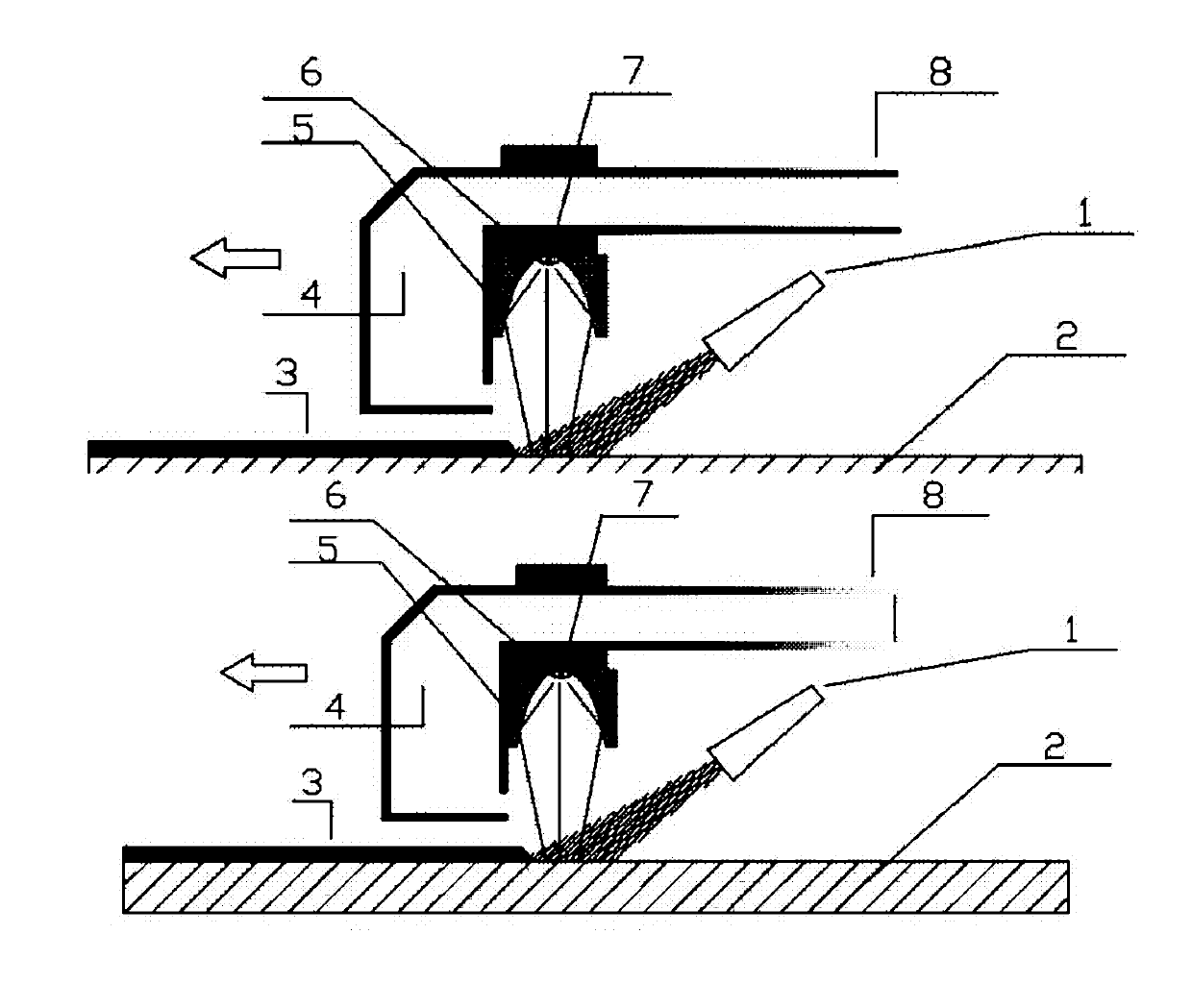

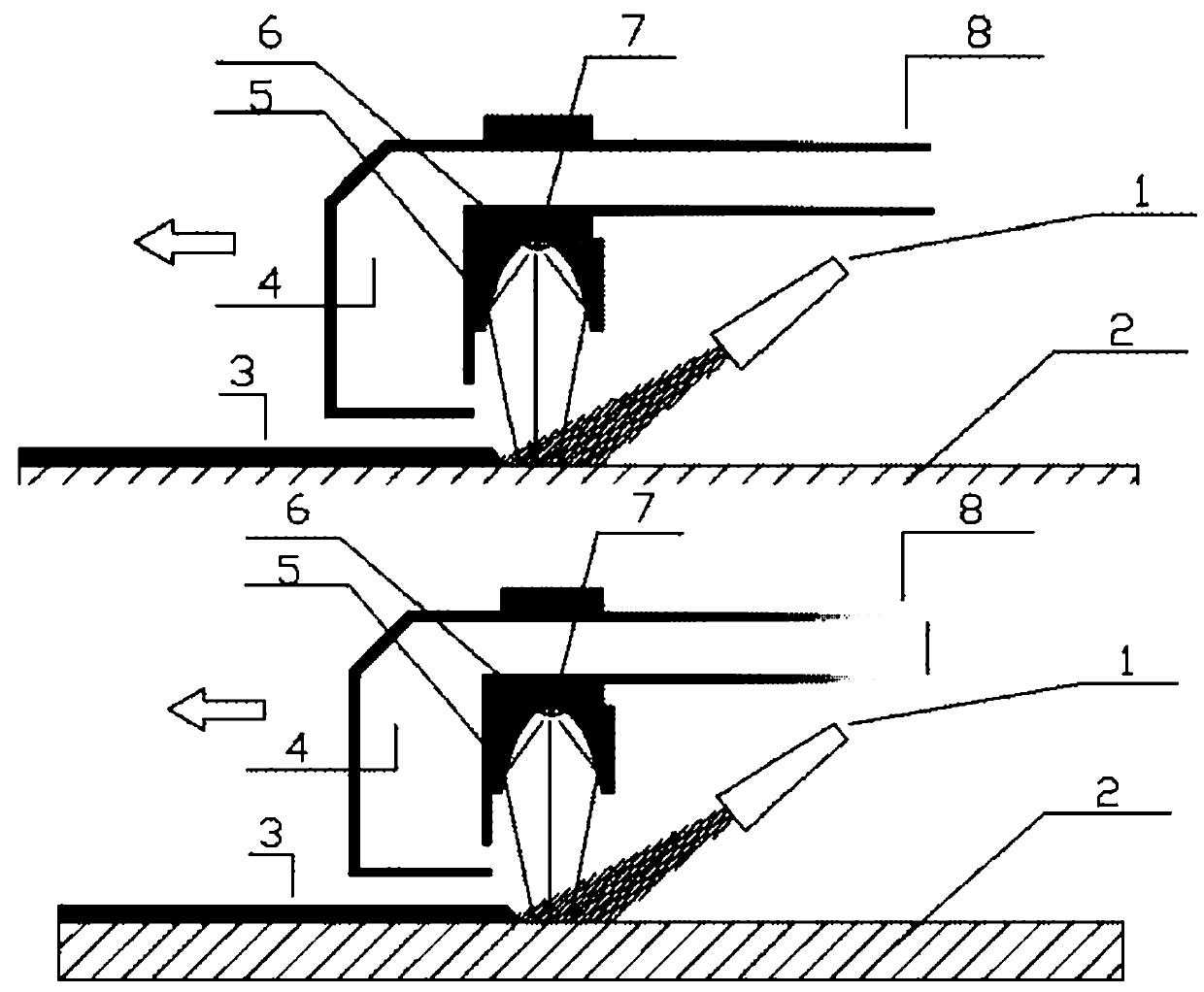

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0021] The advancing direction of the port of the paint stripping system of the present invention is shown by the arrow. In the accompanying drawings, the point light source adopts a xenon pulse lamp 7, and uses the reflector 5 to reflect the light emitted by the light source, and then irradiates the surface of the paint stripping object through the irradiation port, and the light energy is instantly converted into heat energy, so that the surface paint layer 3 is softened . The xenon pulse lamp tube 7 is covered with a pure water circulation cooling tube 6 to cool the lamp tube.

[0022] While the laser pulse xenon lamp is irradiating the surface of the object to be depainted, the dry ice blasting device uses the low-temperature dry ice particles in the high-speed airflow to depaint the area at -78°C. The dry ice particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com