Patents

Literature

30results about How to "Avoid mixing together" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

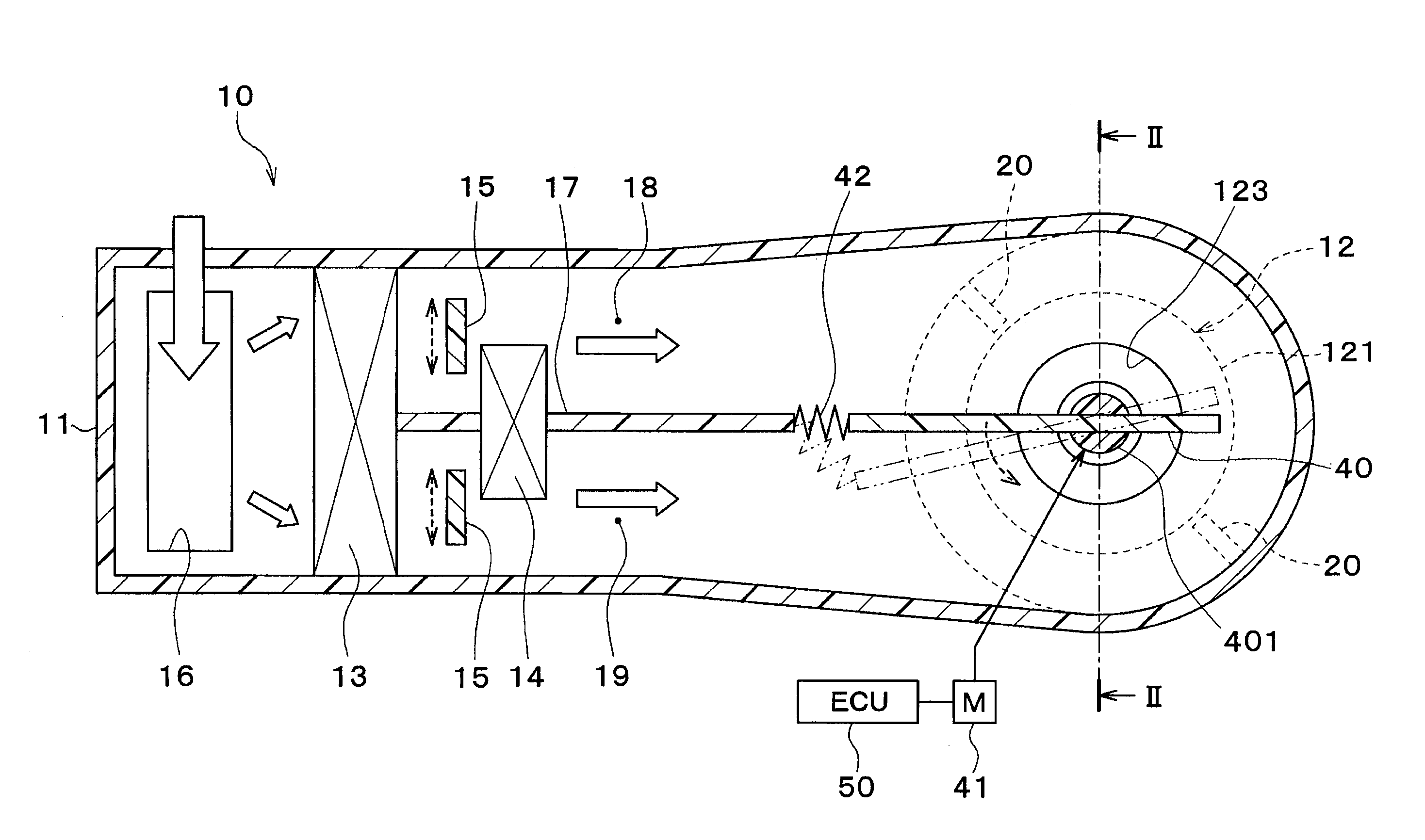

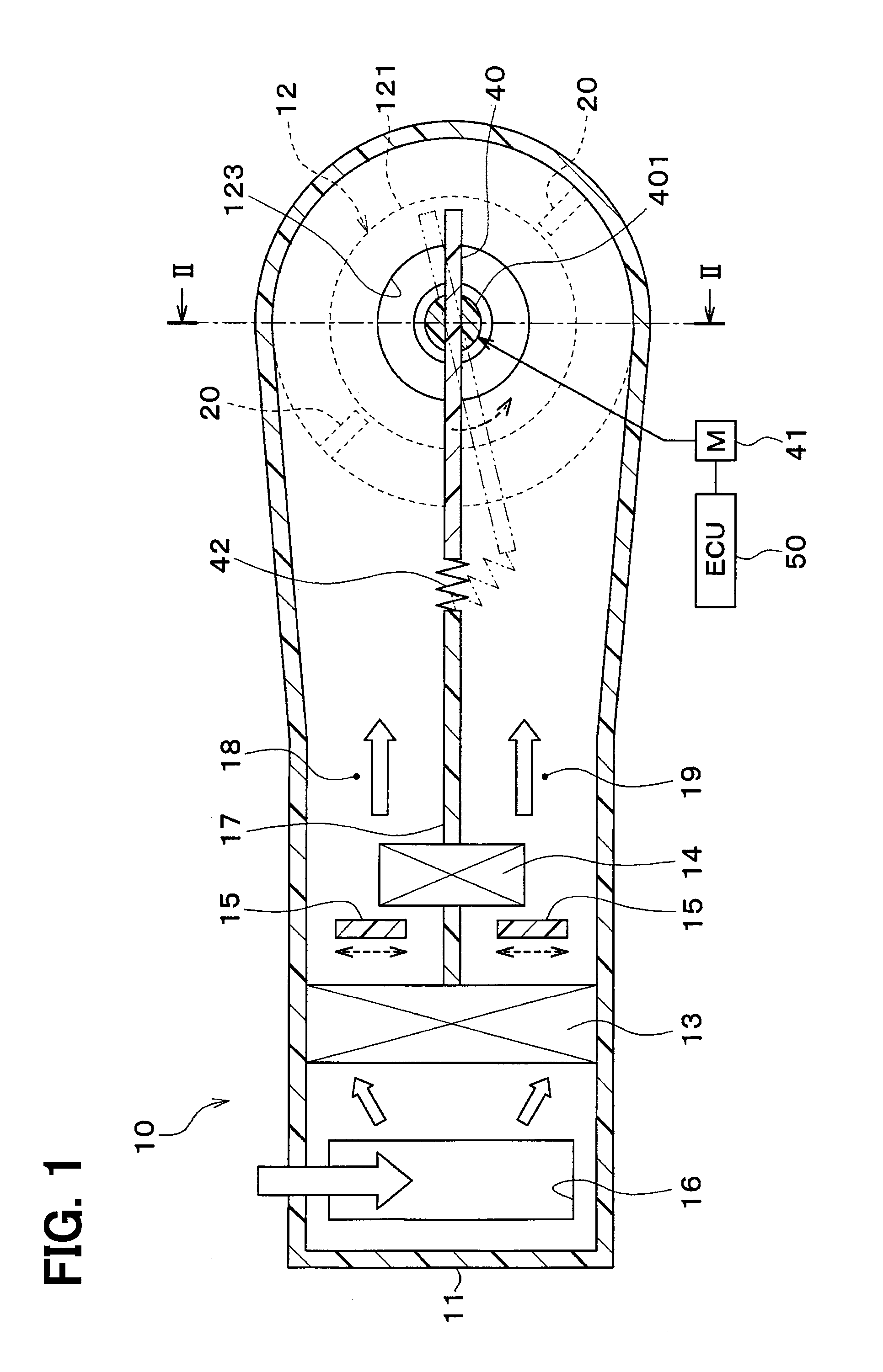

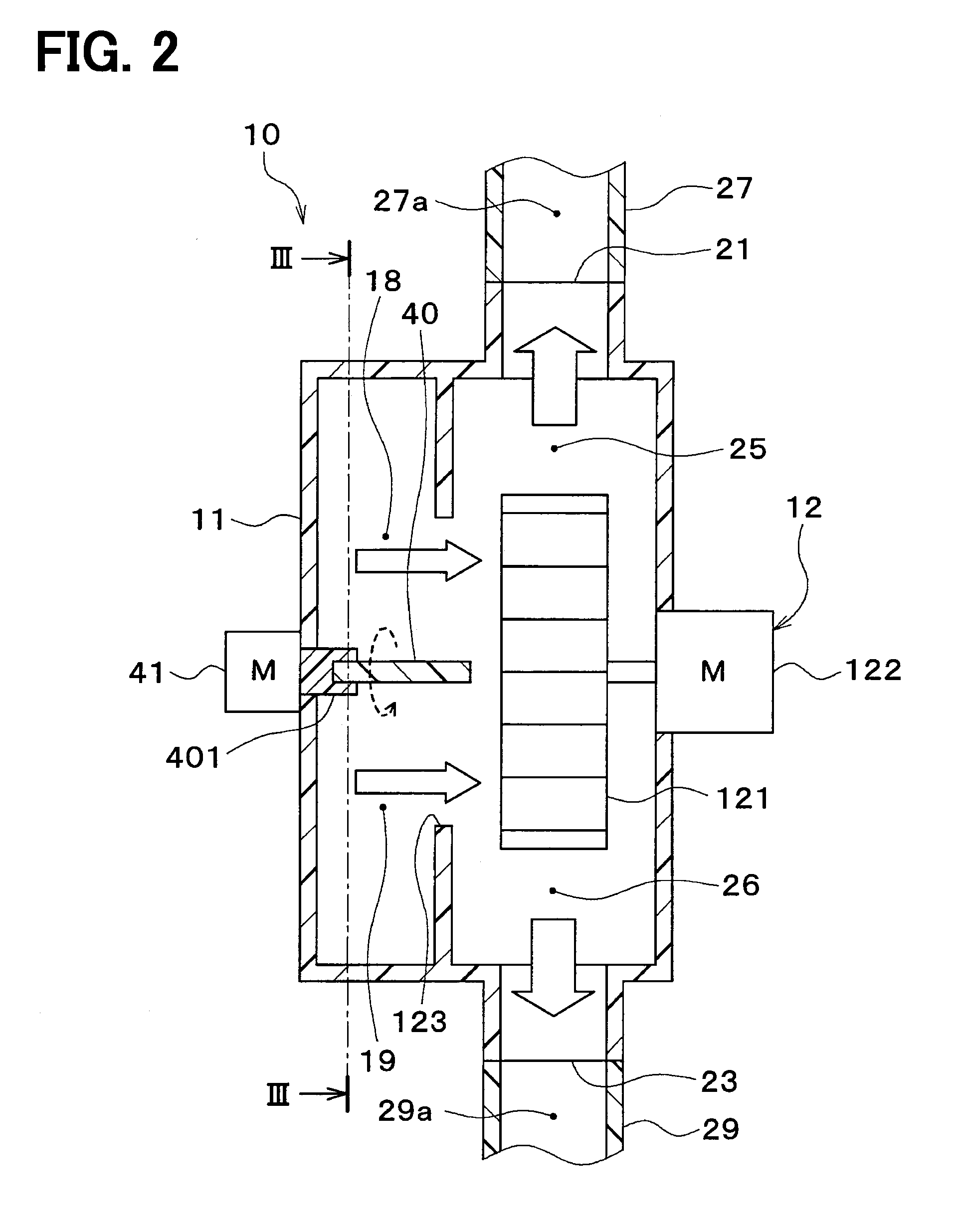

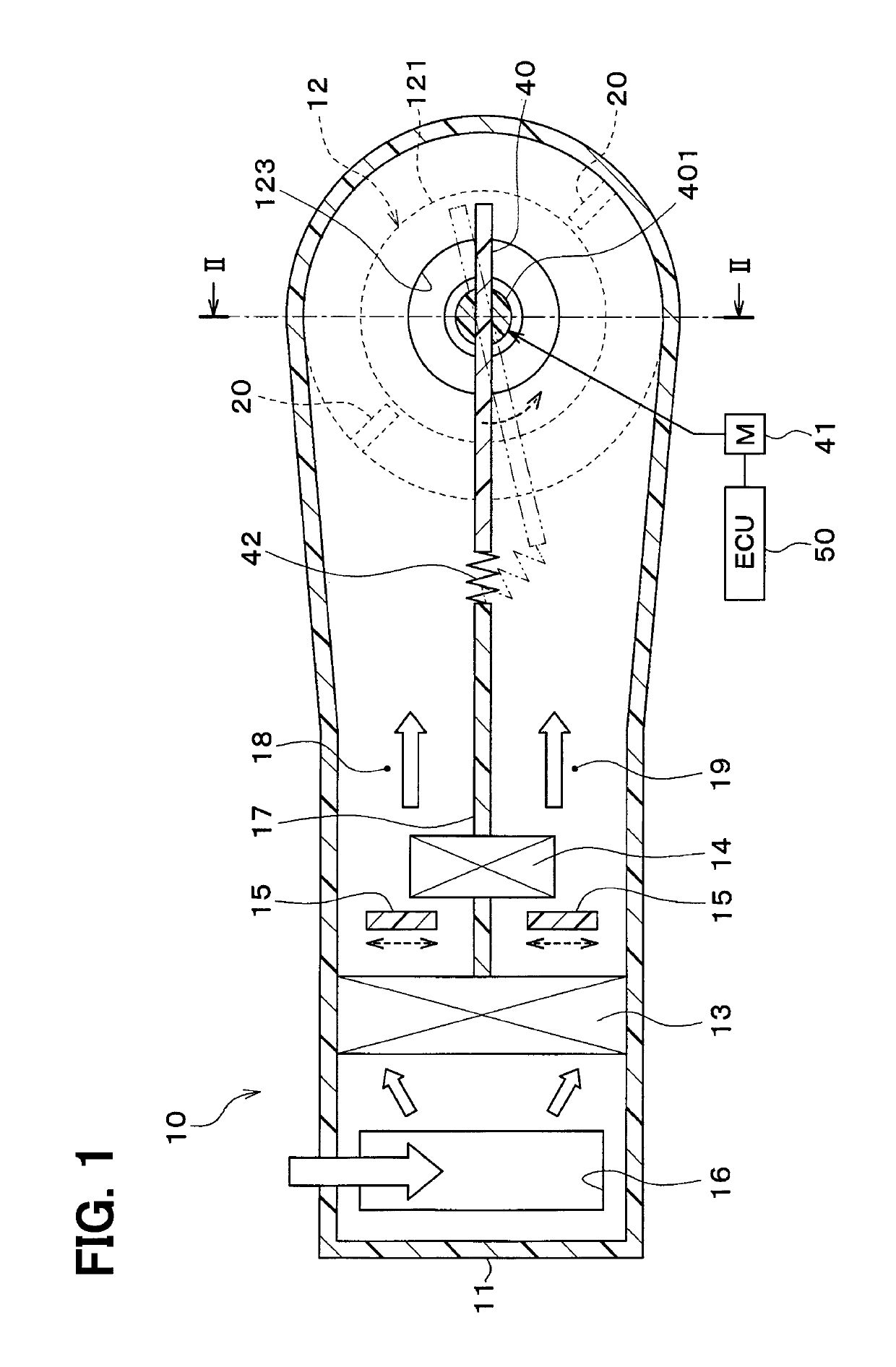

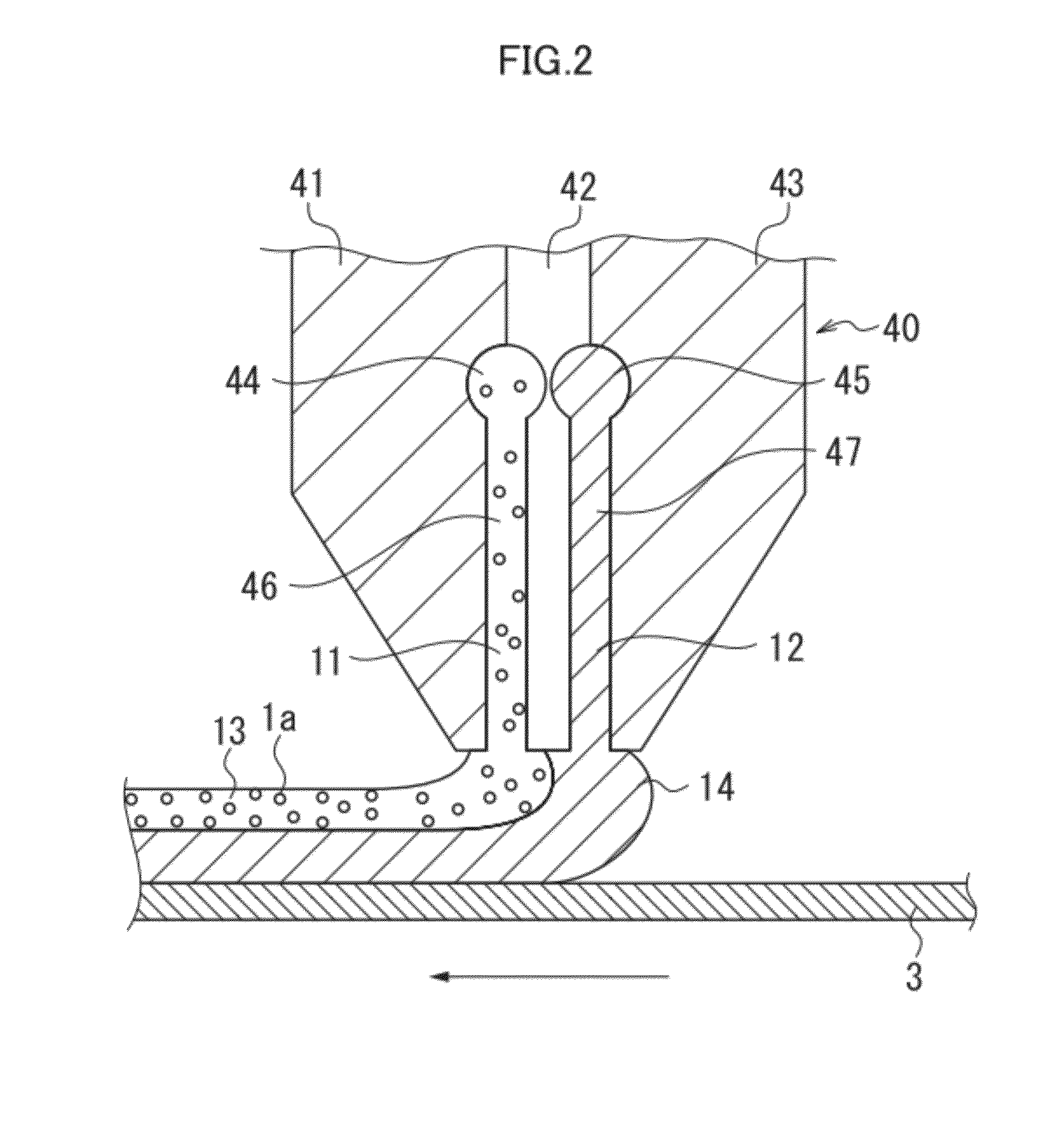

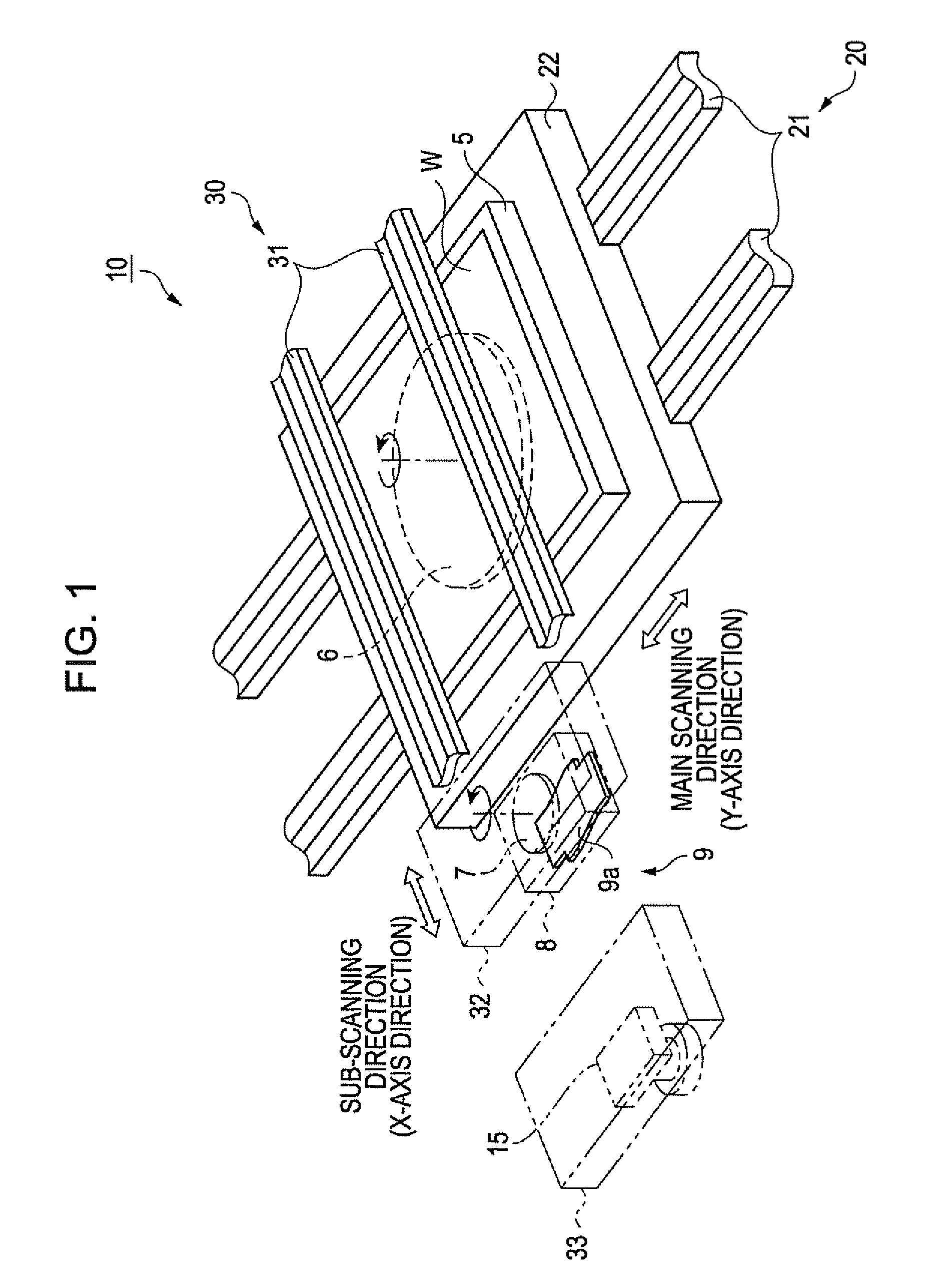

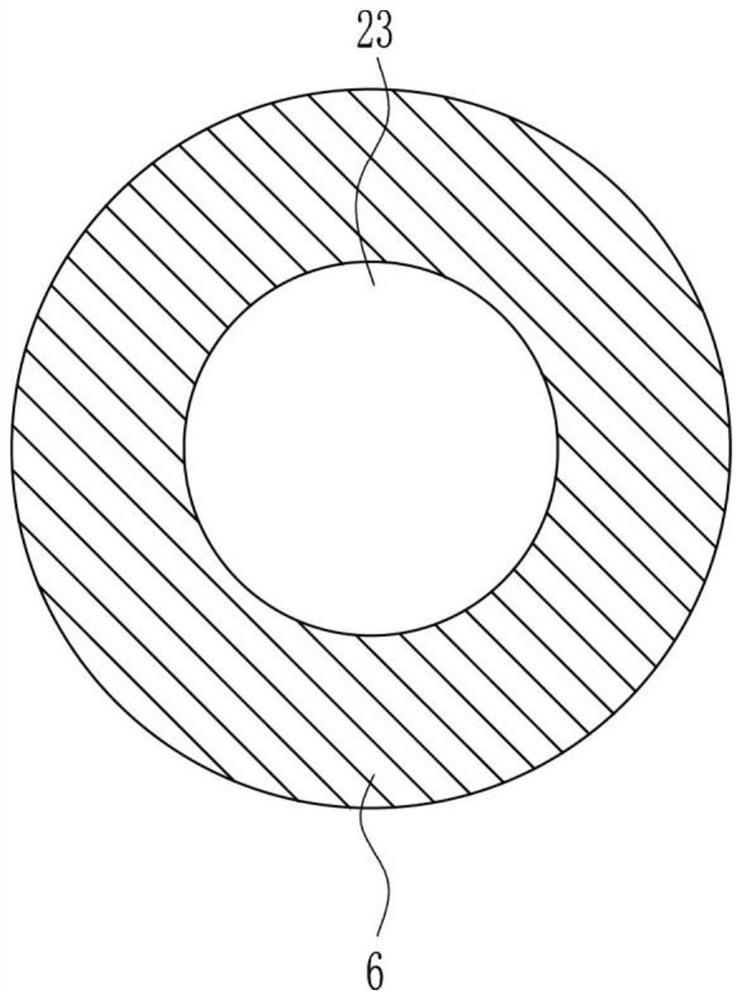

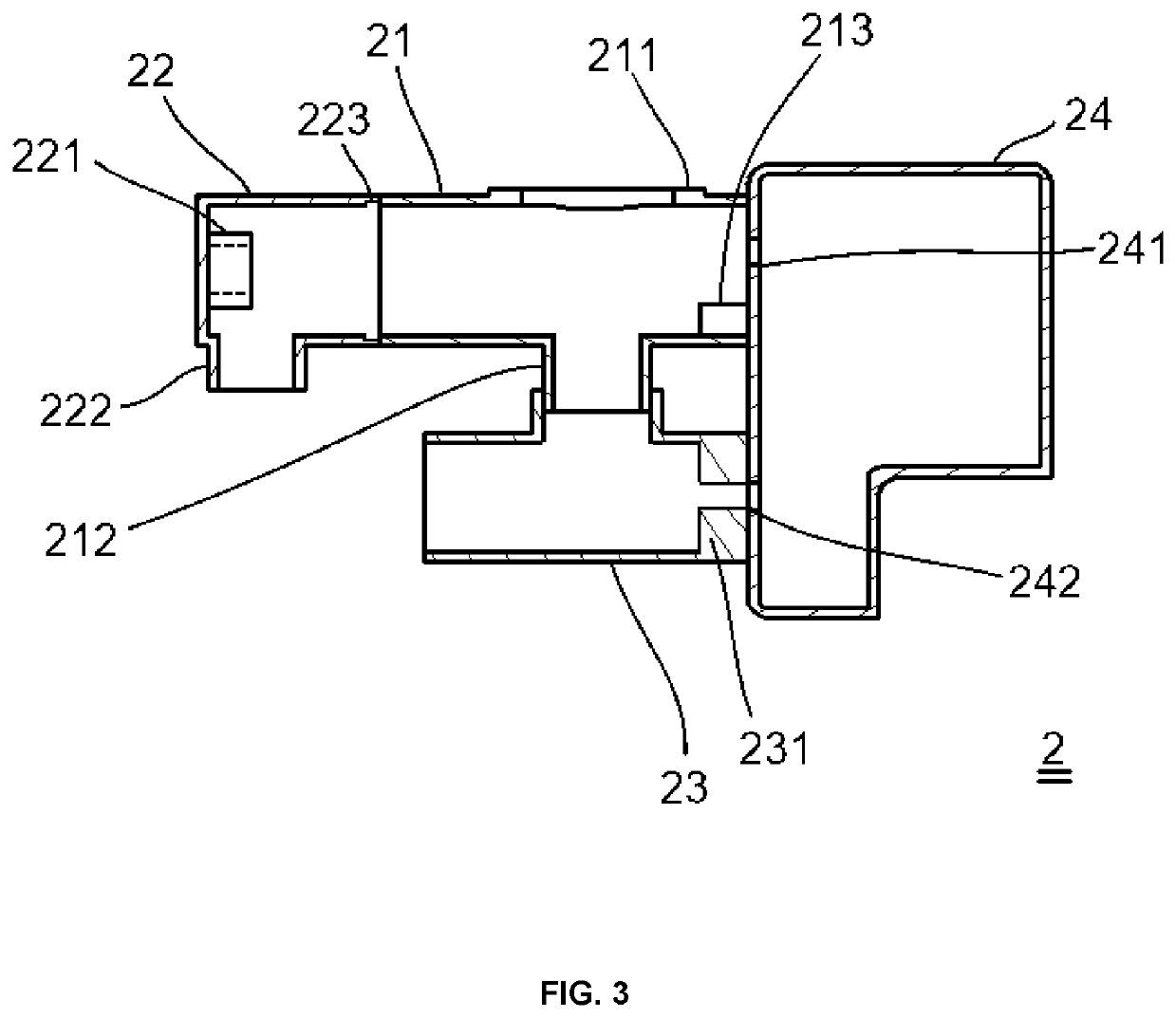

Air conditioning device

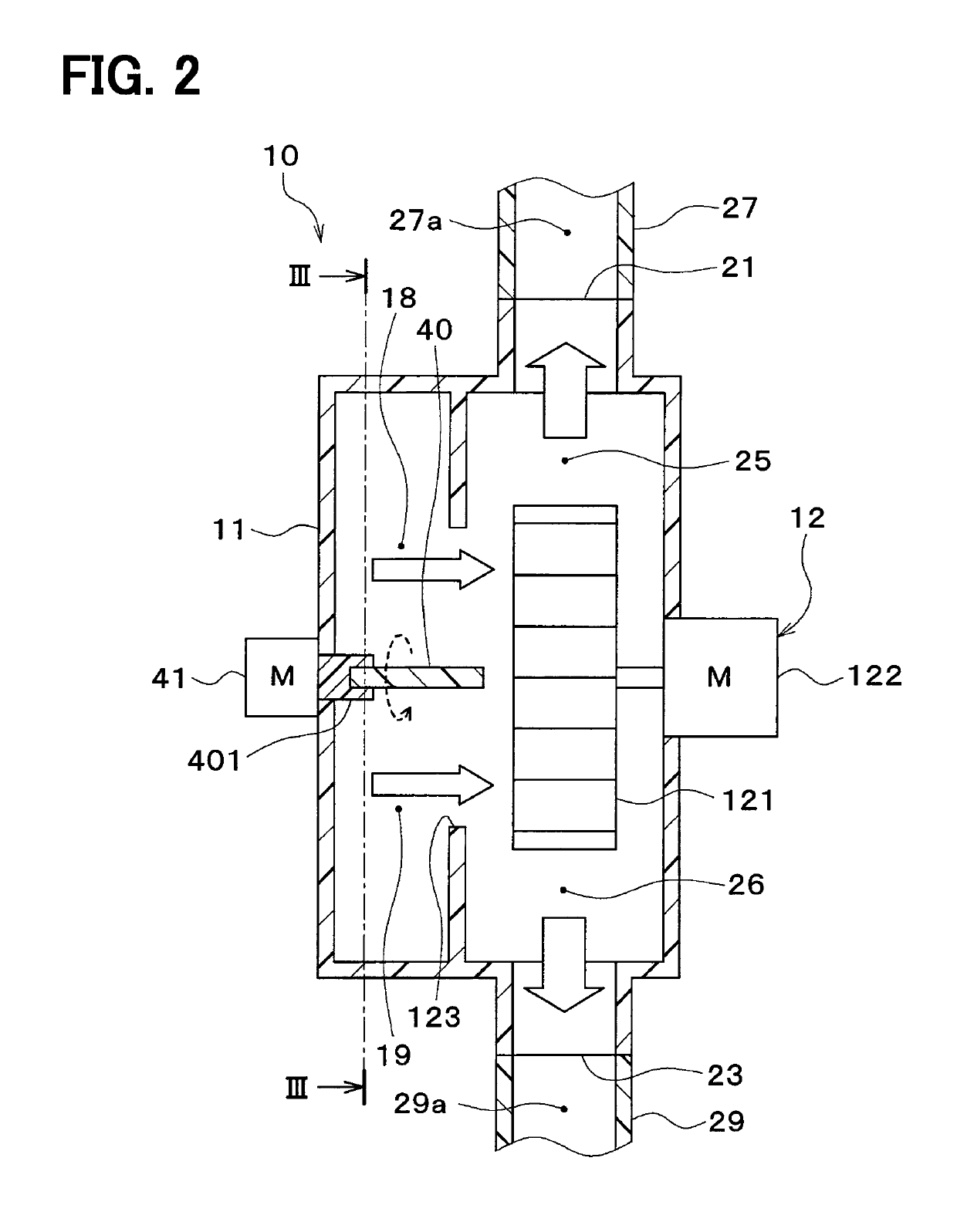

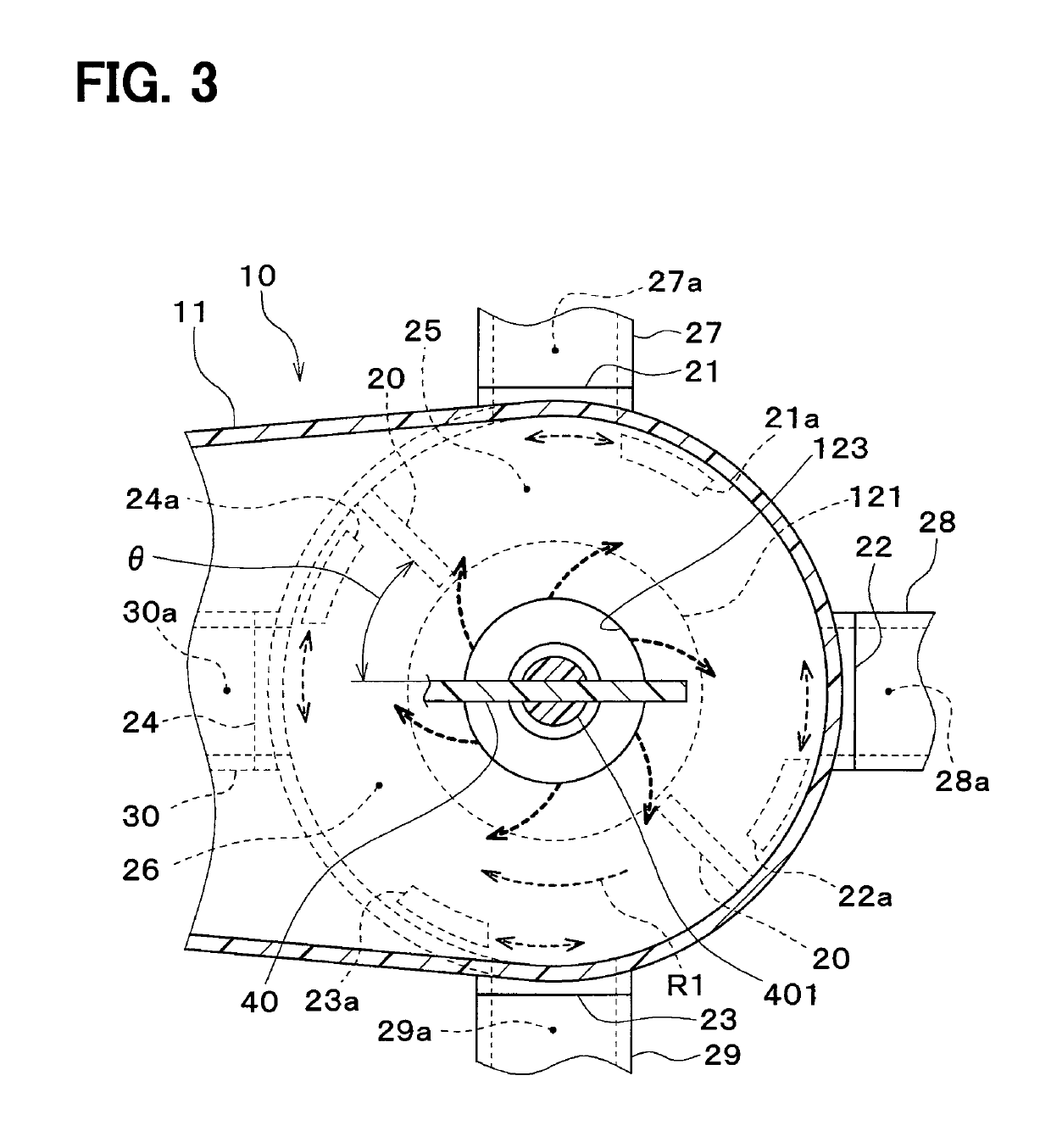

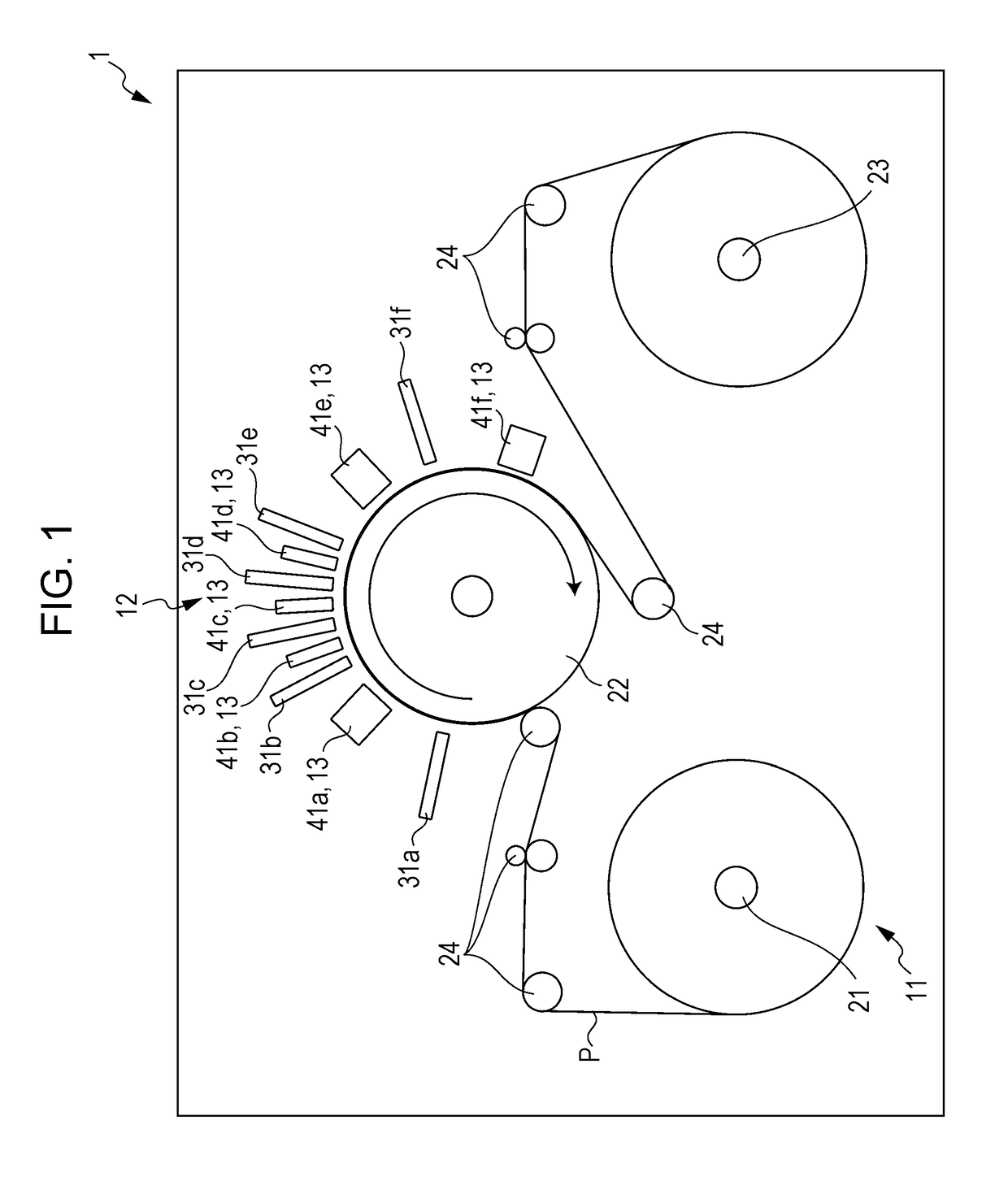

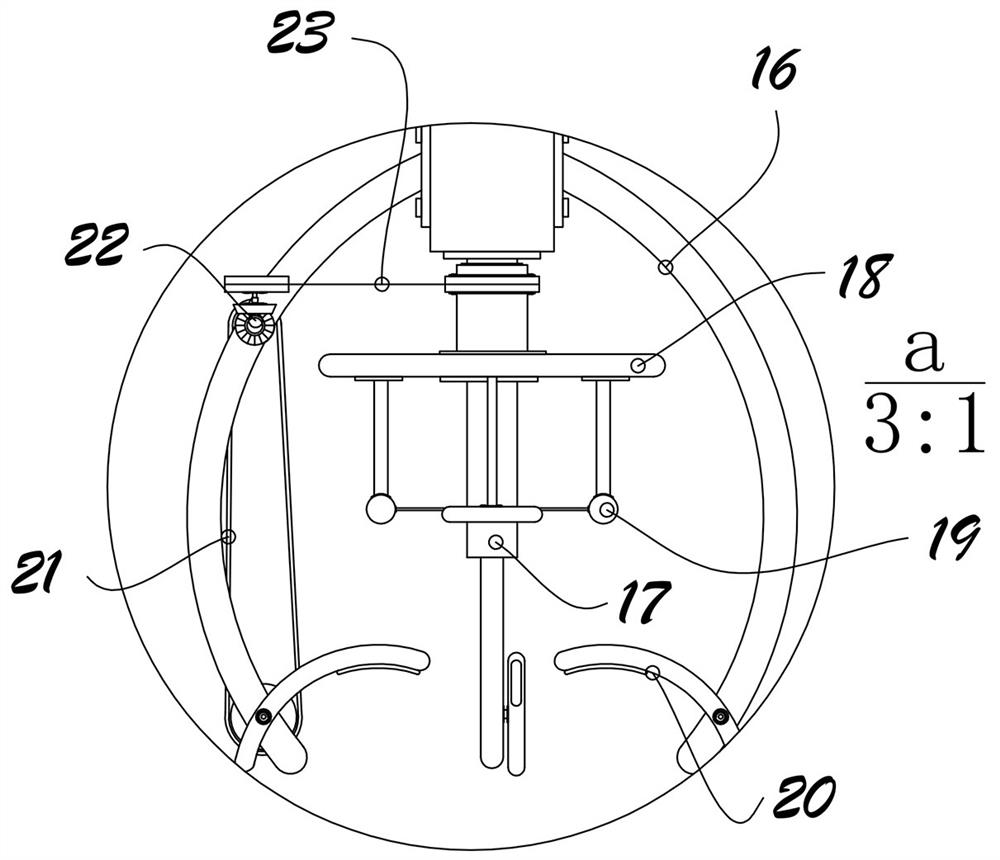

ActiveUS20160288609A1Reduce pressure lossAvoid mixing togetherAir-treating devicesLighting and heating apparatusEngineeringInhaled air

An air conditioning device includes a casing that provides multiple air passages, a blower fan that suctions an air from the multiple air passages and blows out the air in the casing, a suction side partitioning member that is disposed on a suction side of the blower fan in the casing and separates air flows from the multiple air passages from each other, and a blowing side partitioning member that is disposed on a blowing side of the blower fan in the casing and separates the air flows from the multiple air passages from each other. The suction side partitioning member and the blowing side partitioning member are disposed so that a relative position of the blowing side partitioning member to the suction side partitioning member is deviated in a rotation direction of the blower fan.

Owner:DENSO CORP

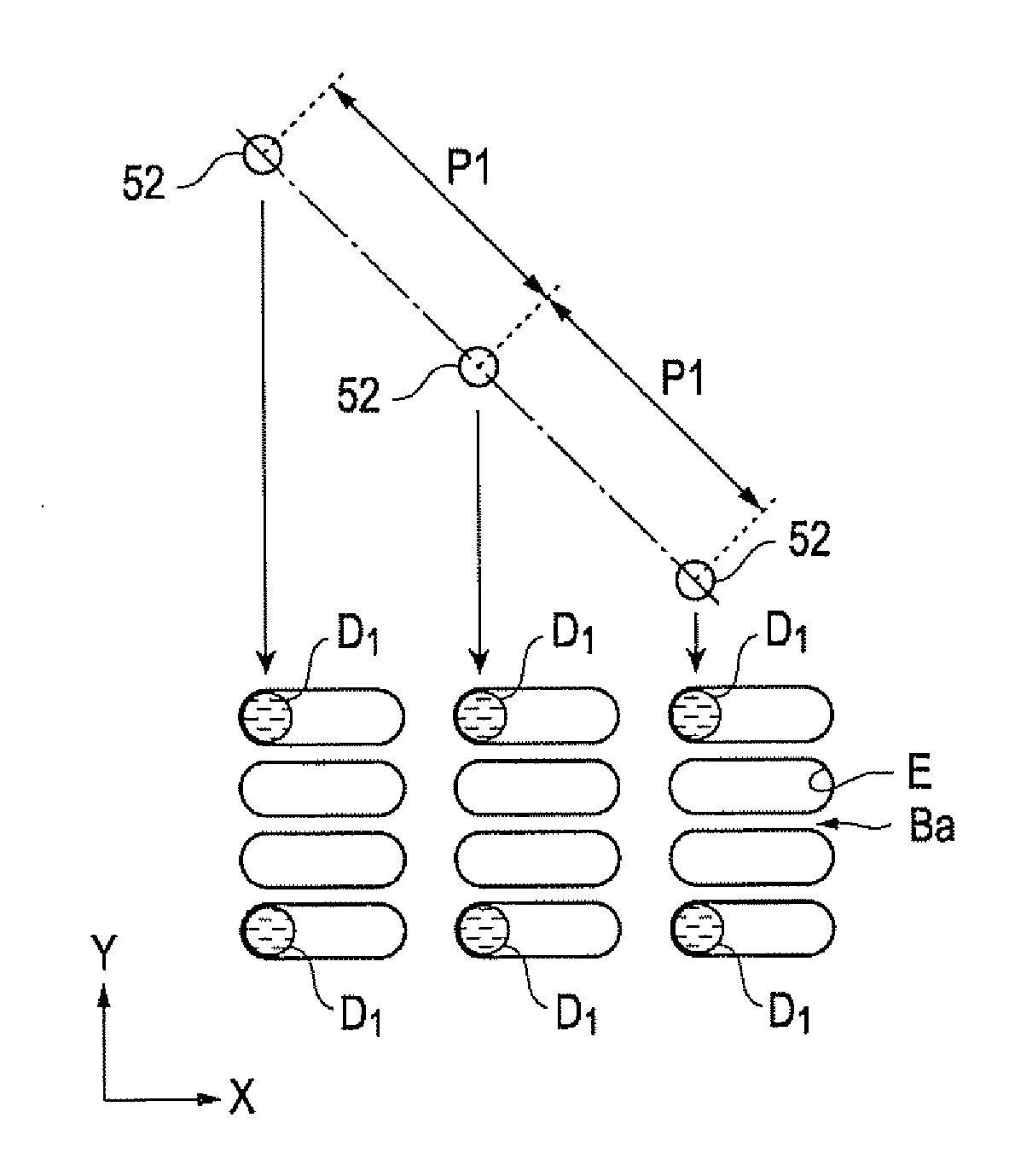

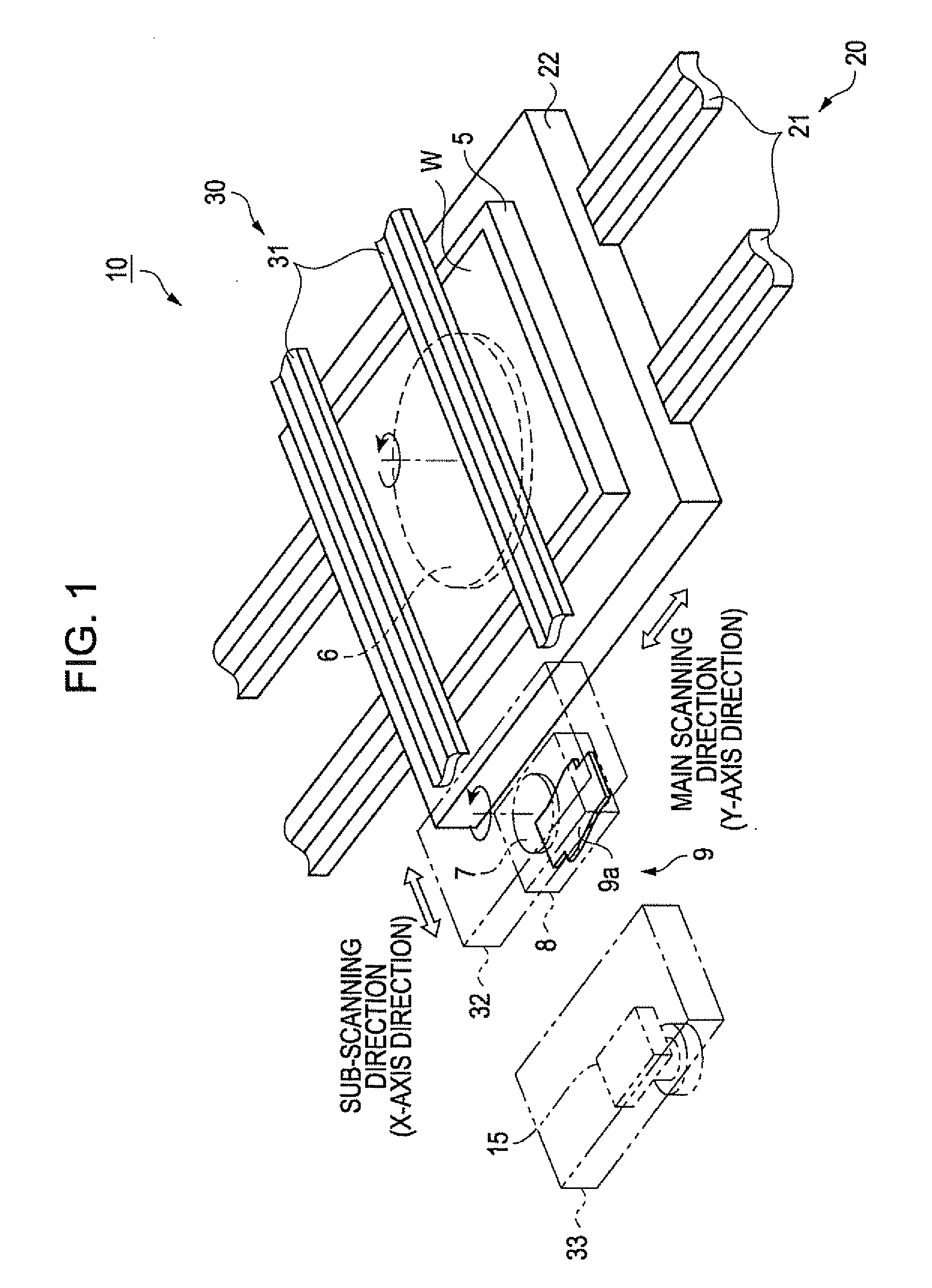

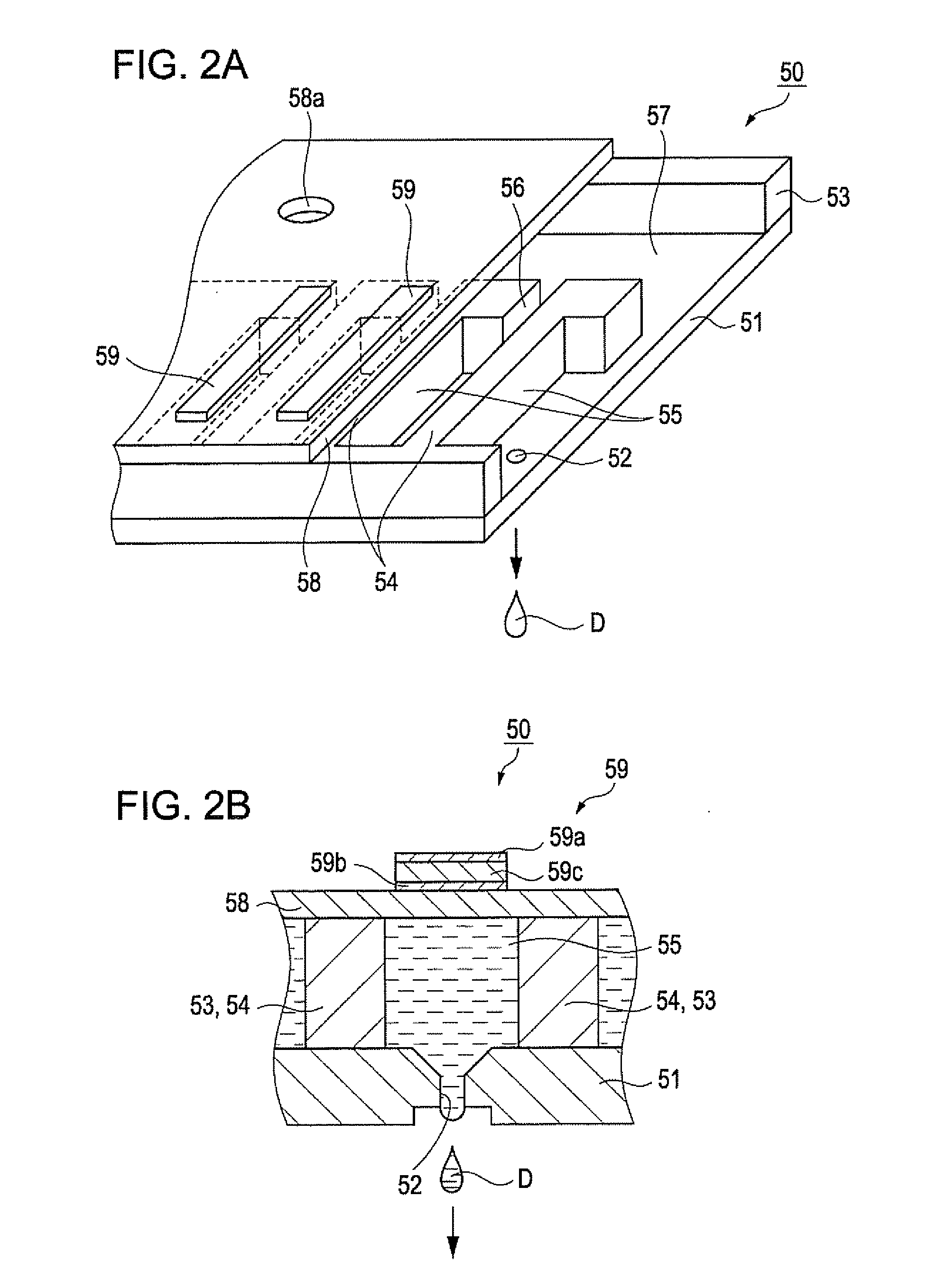

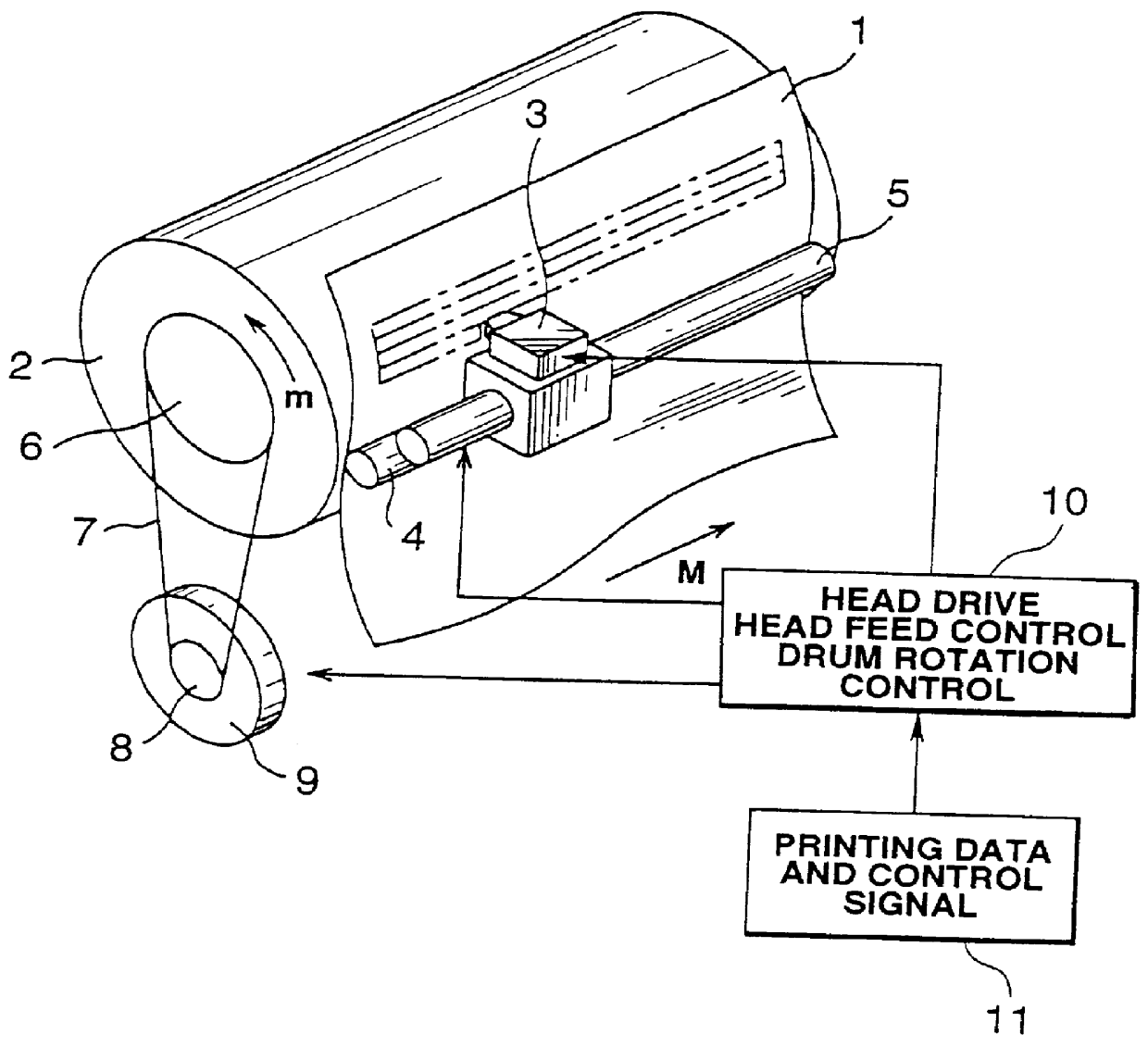

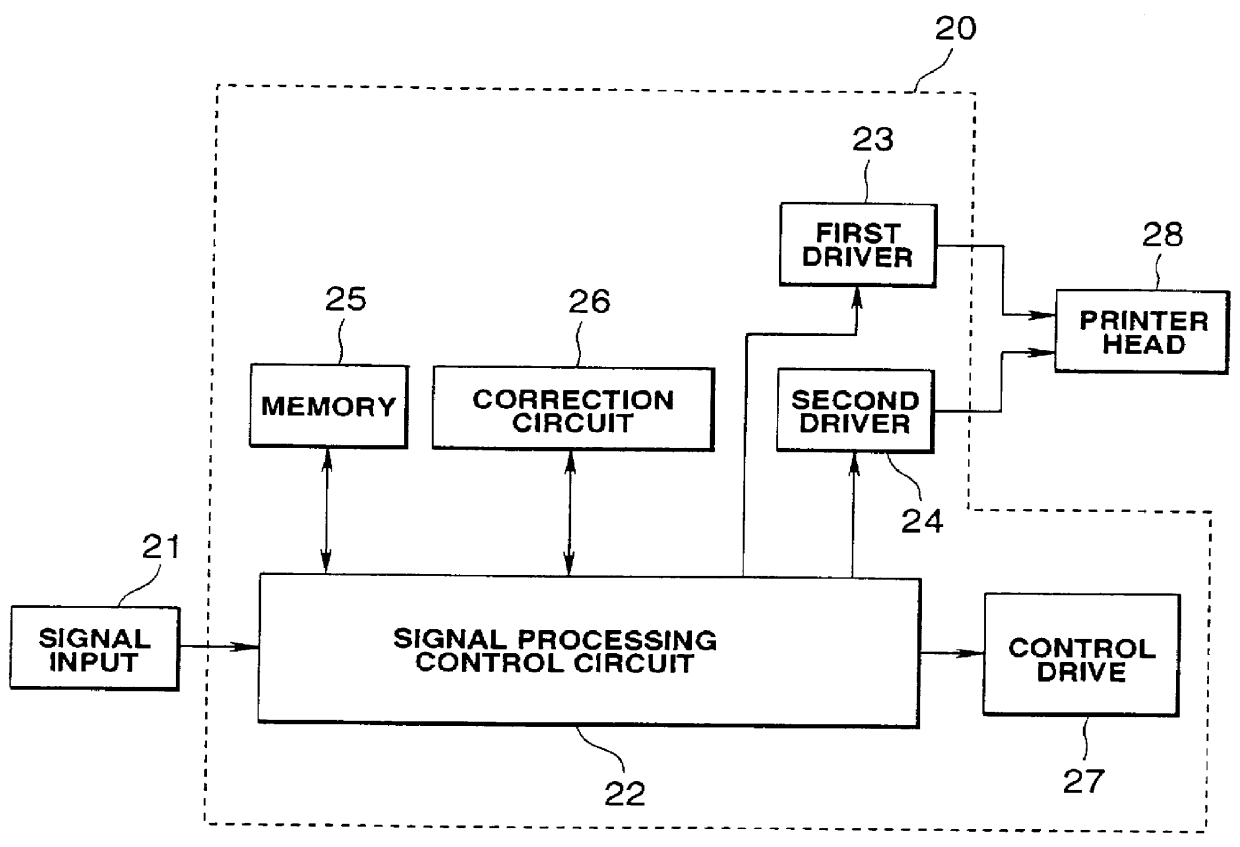

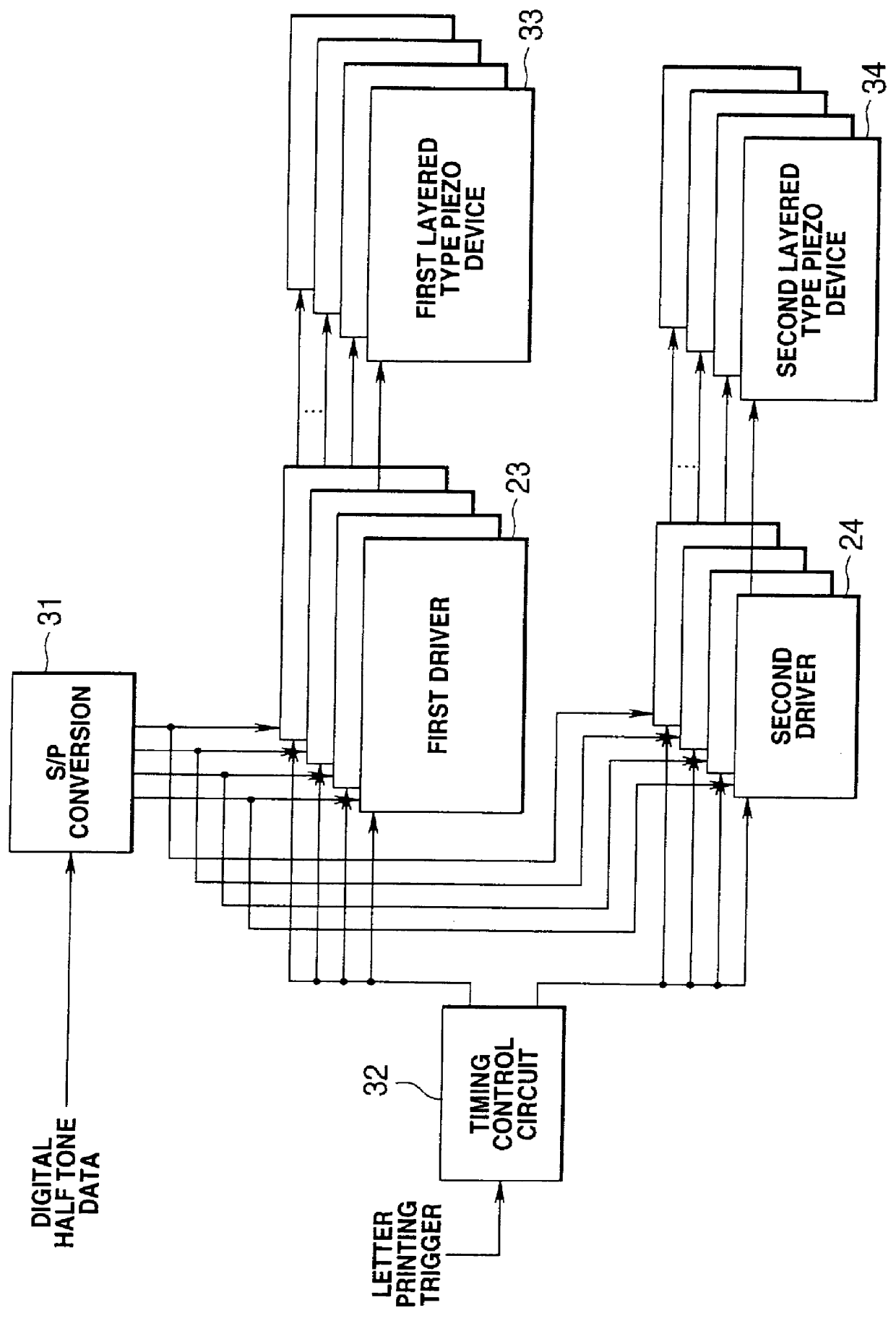

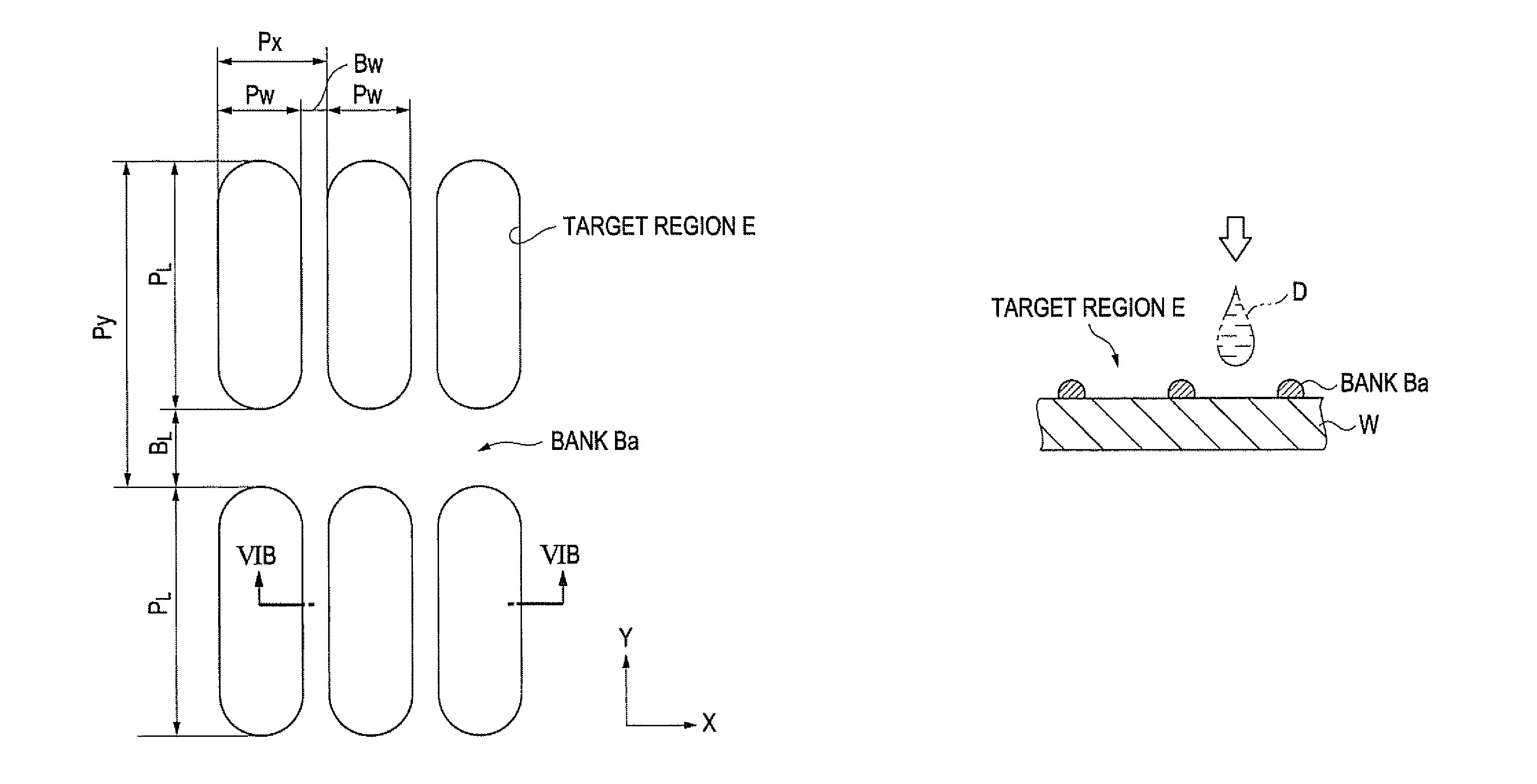

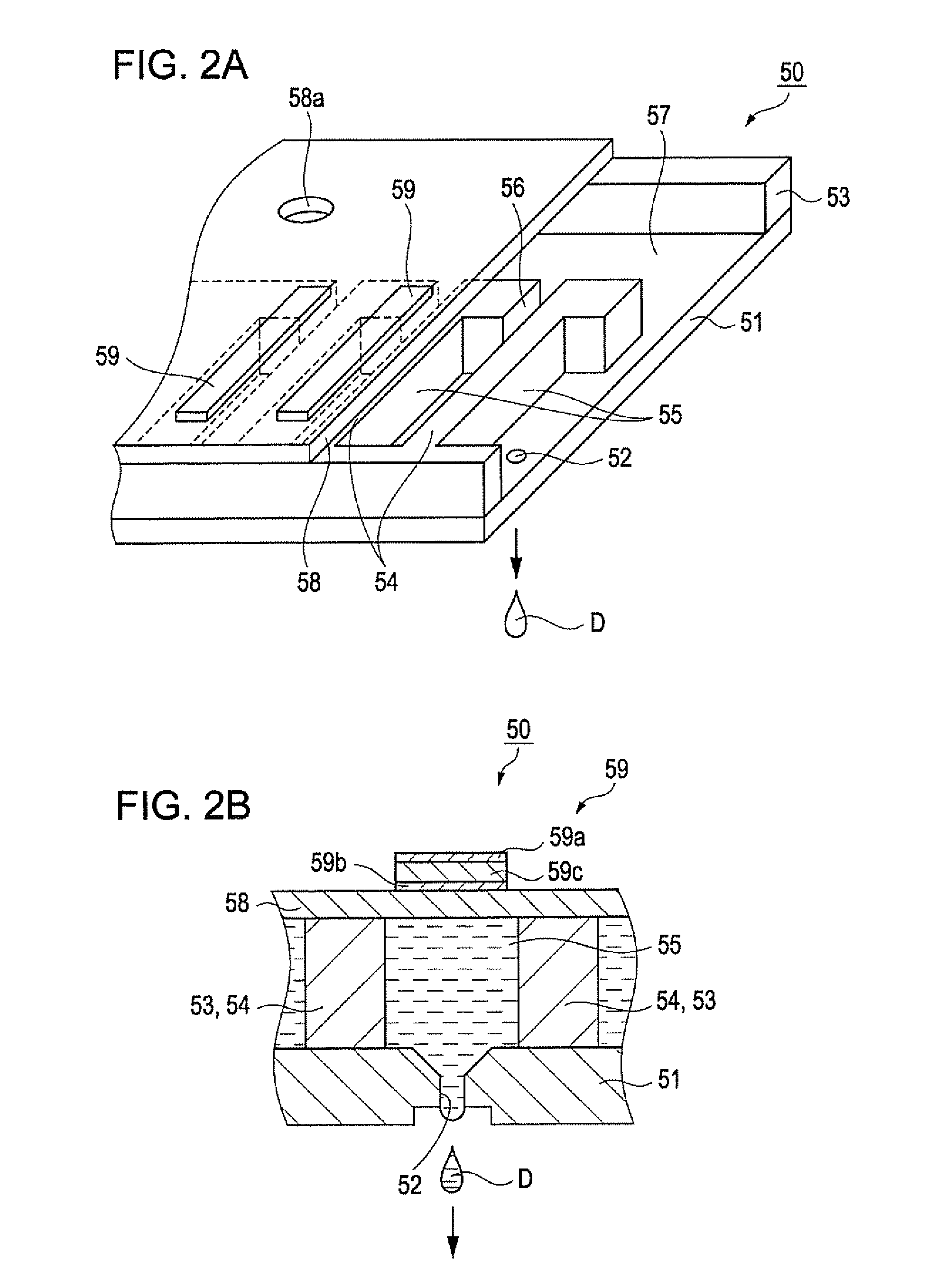

Method for ejecting liquid material, method for manufacturing organic electroluminescence device, and method for manufacturing color filter

ActiveUS20080317941A1Suppress failureHigh yieldSolid-state devicesCoatingsEngineeringOrganic electroluminescence

A method for ejecting a liquid material includes classifying the plurality of nozzles of a head into a plurality of nozzle groups having different landing position accuracies for droplets; and performing ejection includes main scanning for ejecting droplets of a liquid material through nozzles selected from the plurality of nozzles, while generating relative movement in a main-scanning direction between the head and a target substrate, and sub-scanning for generating relative movement between the head and the target substrate in a sub-scanning direction orthogonal to the main-scanning direction. The main scanning and the sub-scanning are performed separately for each of the plurality of nozzle groups. During the sub-scanning, relative movement between the head and the target substrate in the sub-scanning direction is generated in accordance with correction information for the corresponding nozzle group for correcting landing positions of the droplet. During the main scanning, a droplet is ejected through at least one nozzle selected from the corresponding nozzle group.

Owner:KATEEVA

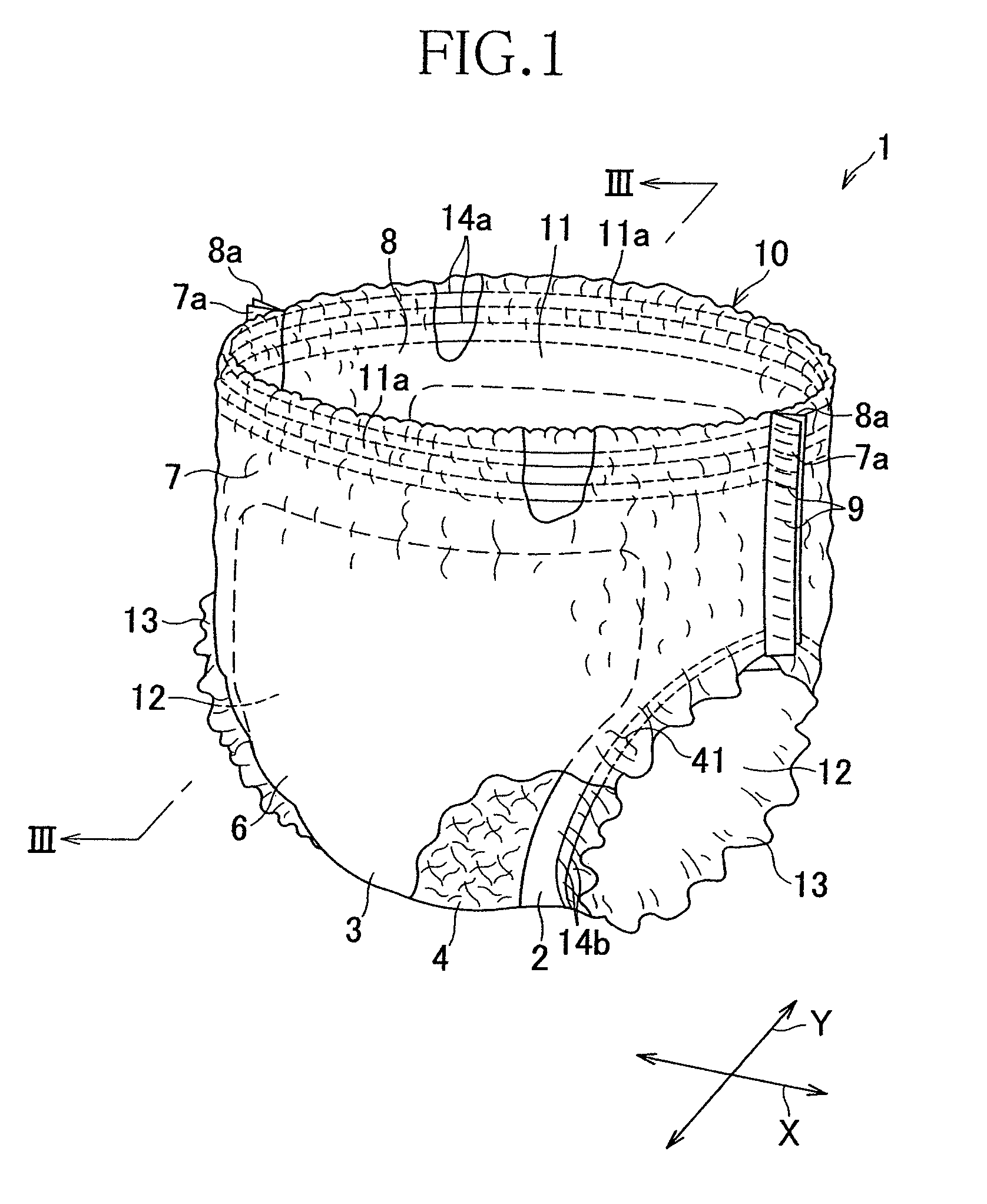

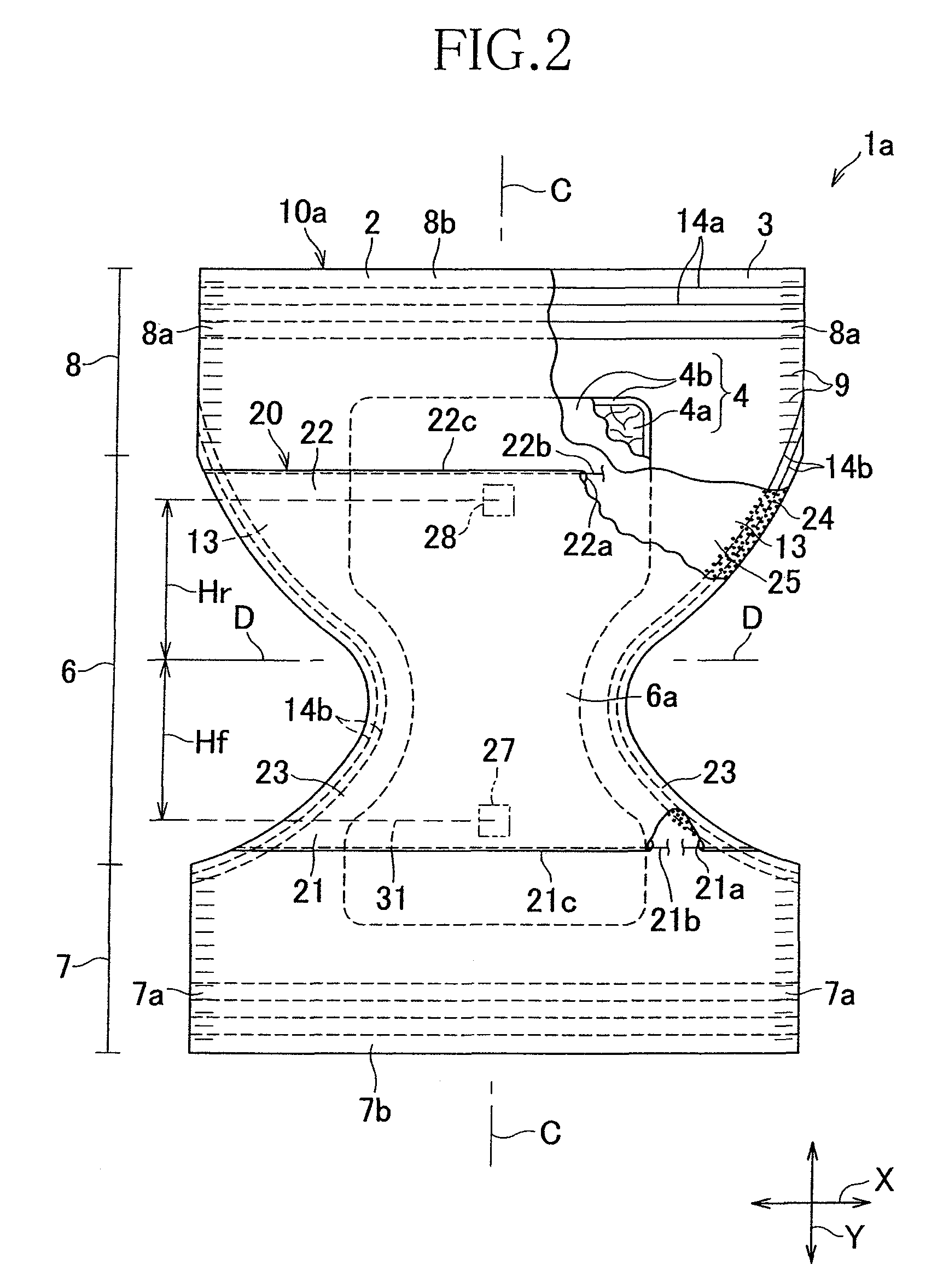

Disposable pull-on type diaper

Owner:UNI CHARM CORP

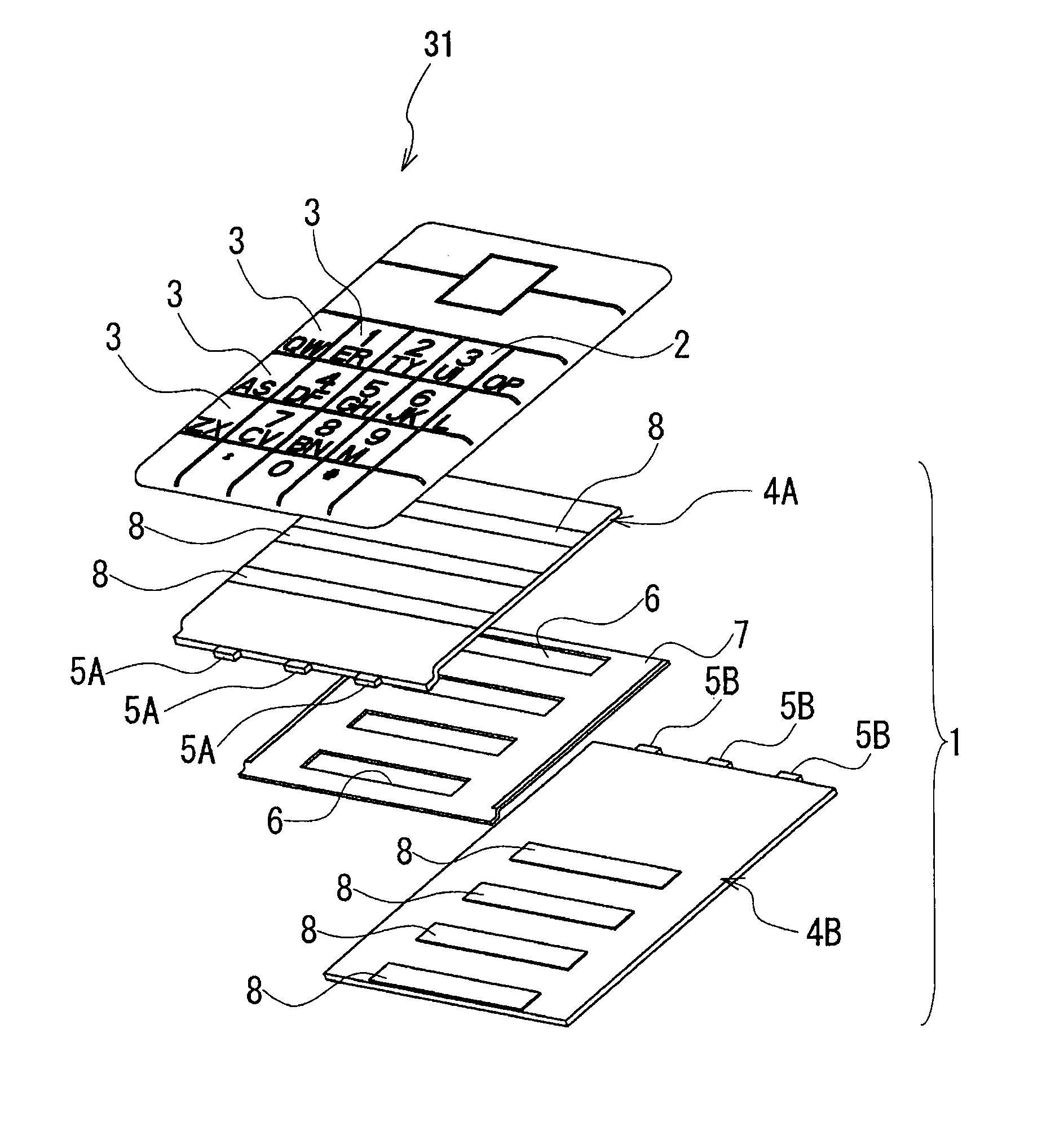

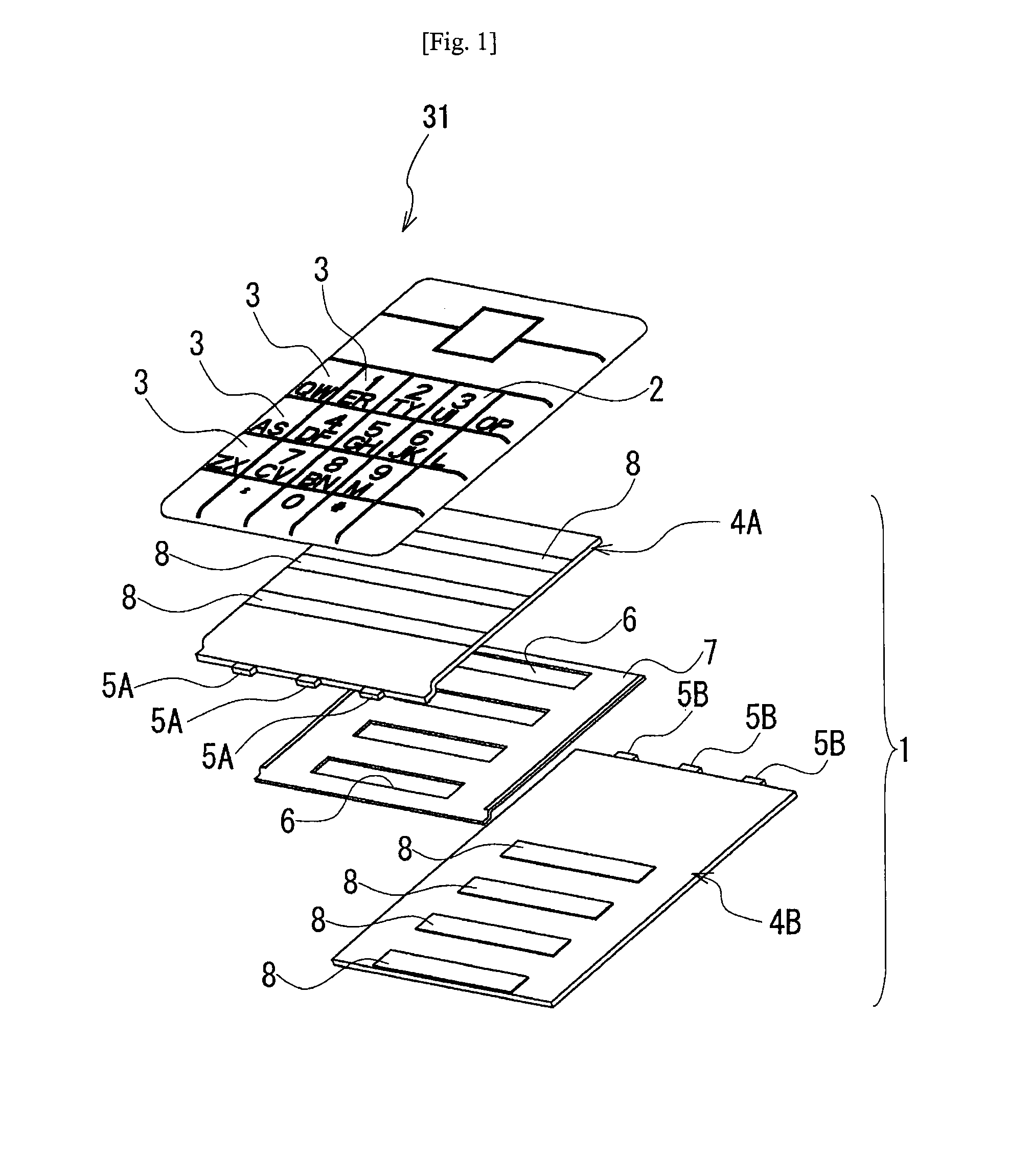

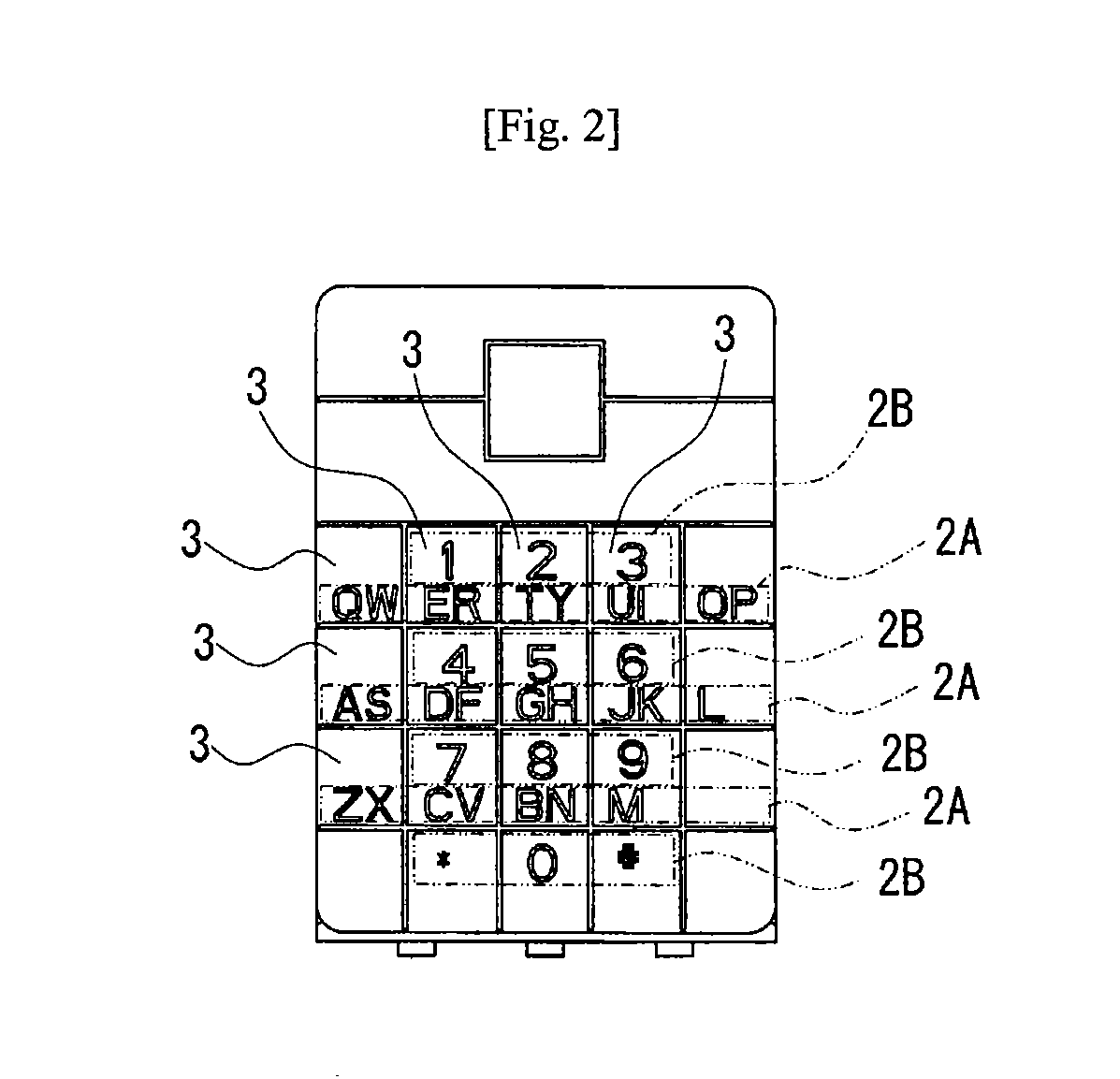

Lighting device for operation panel and electronic device

Owner:CITIZEN ELECTRONICS CO LTD

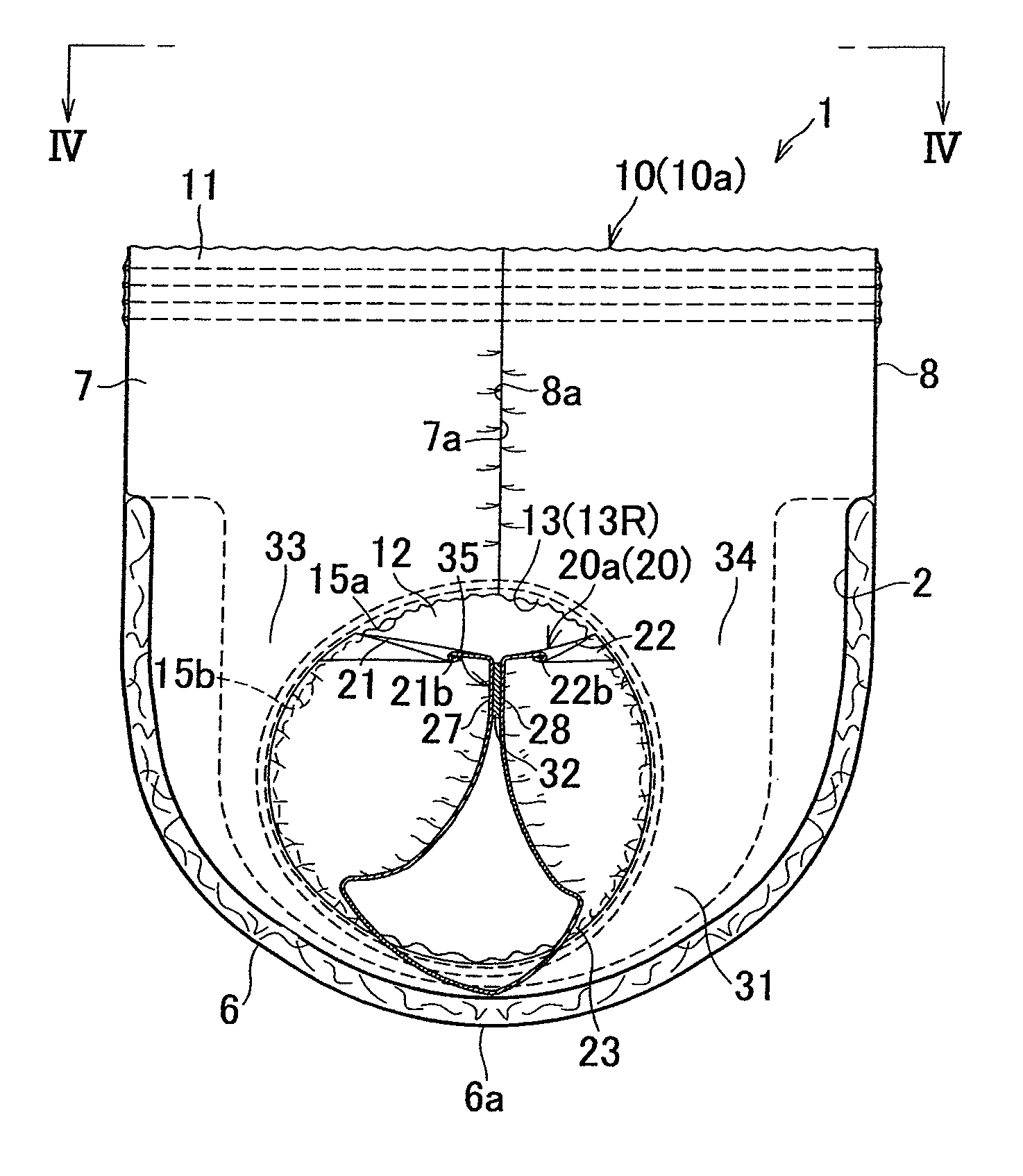

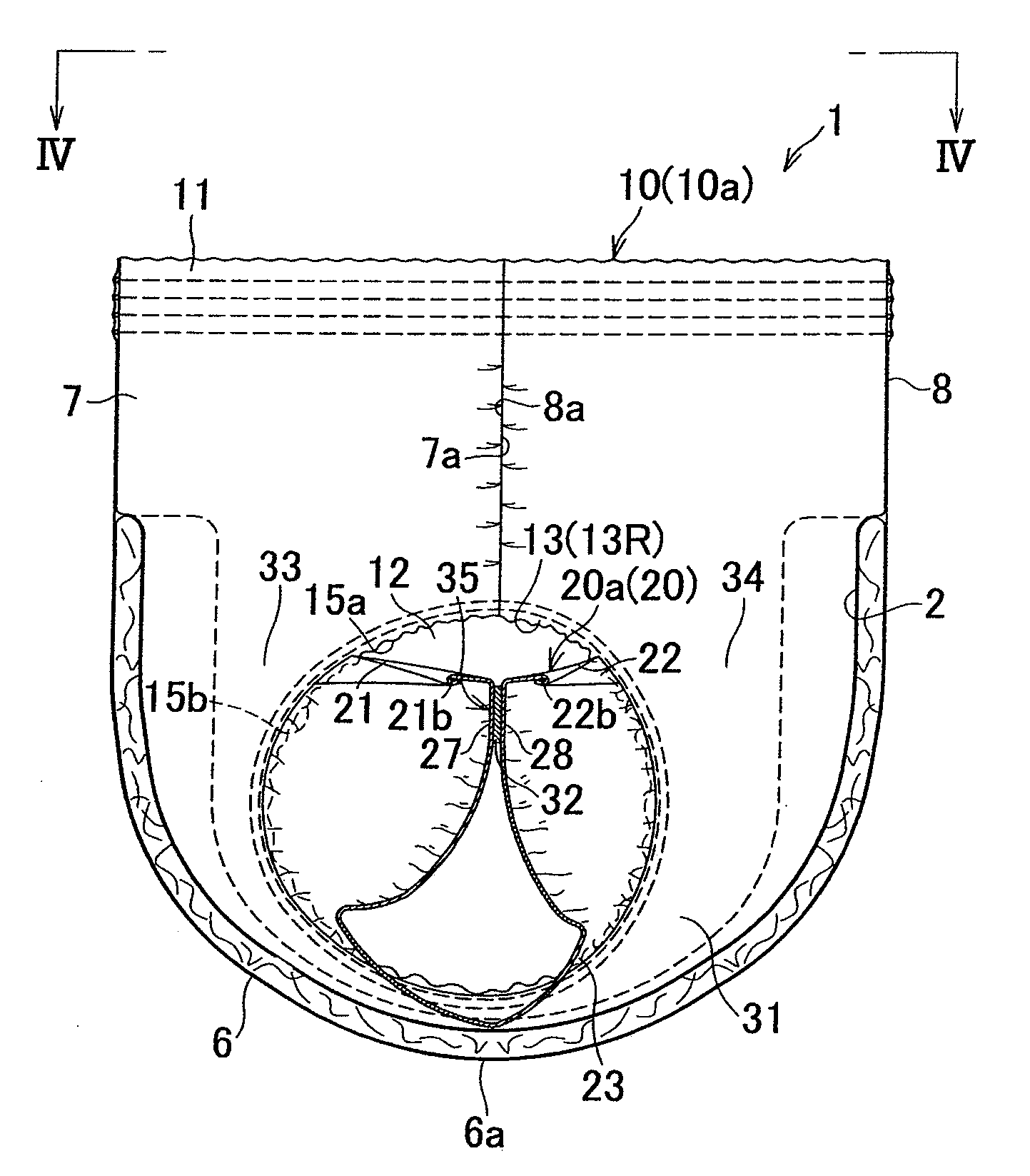

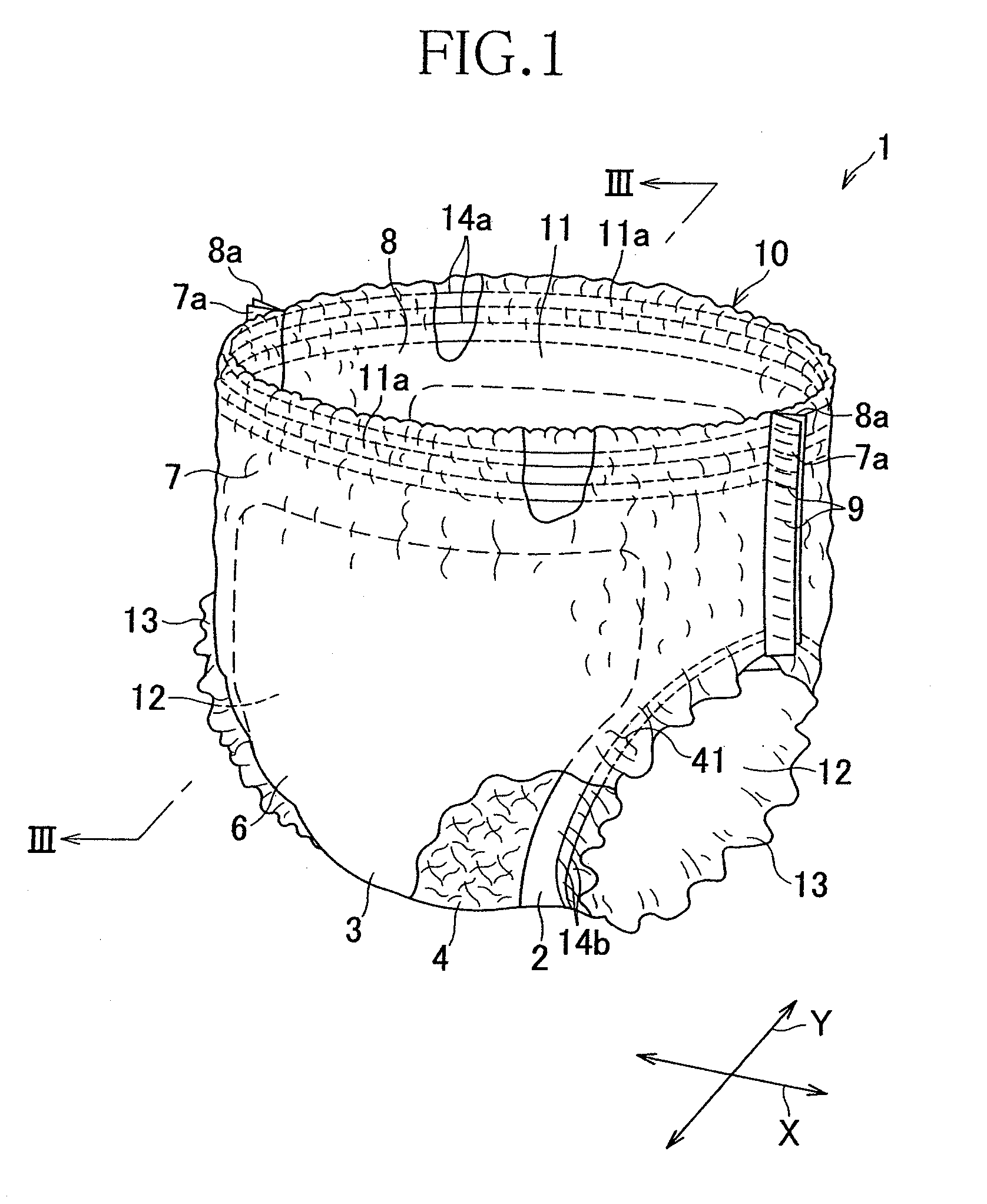

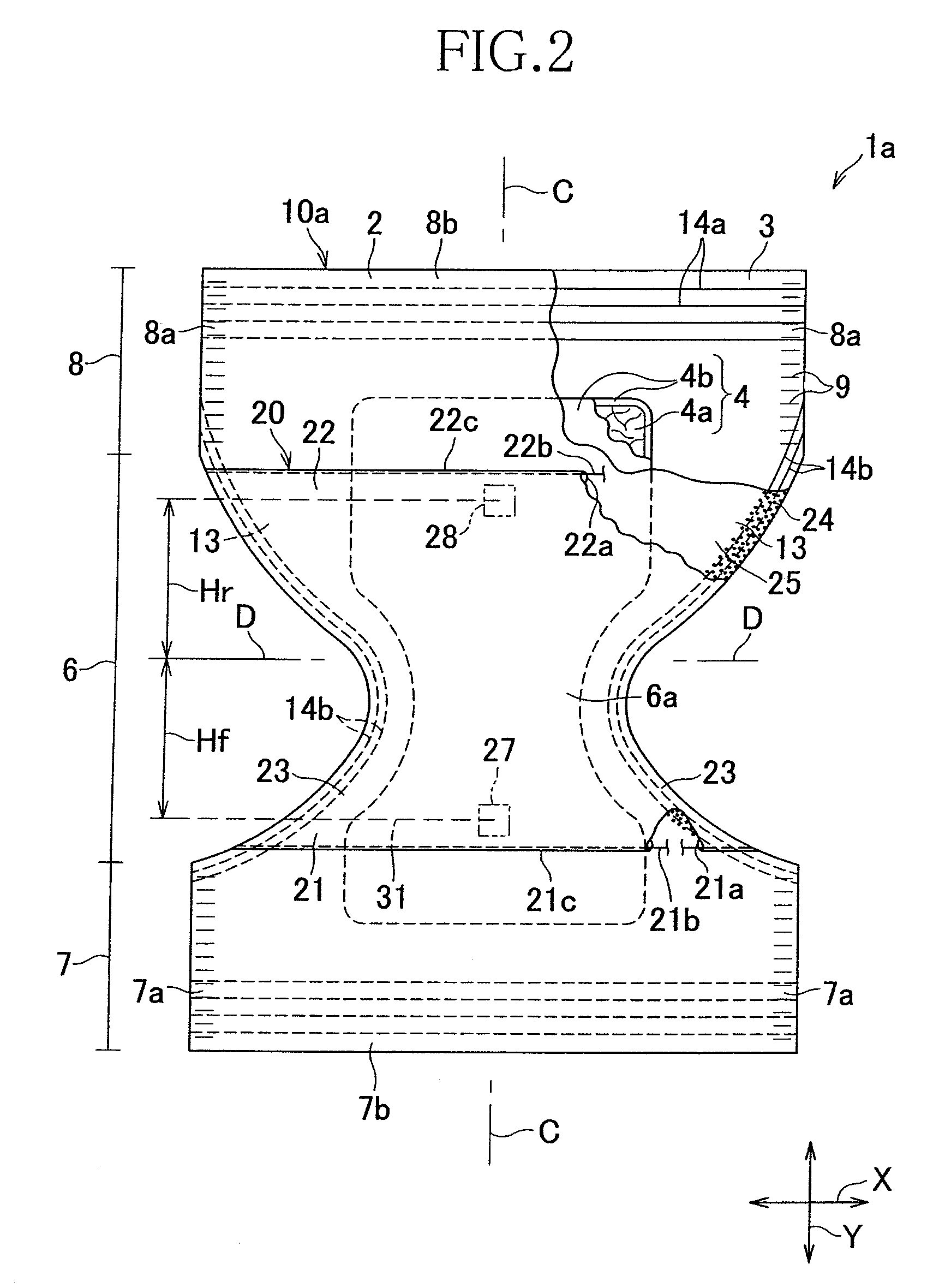

Disposable pull-on type diaper

InactiveUS20070239129A1Prevent leakageAvoid mixing togetherBaby linensTamponsCrotchFront and back ends

A disposable pull-on type diaper has a separator interposed between an inner surface of an absorbent chassis and the wearer's skin so as to protect the diaper wearer's skin from being soiled with feces. The separator is formed by a piece of sheet extending from a bottom of a crotch region of the diaper toward a front waist region and a rear waist region and fixed to lateral edges of the crotch region. The piece of sheet has a front end and a rear end both extending in a transverse direction of the crotch region. These front end and rear end are free along middle segments thereof as viewed in the transverse direction of the crotch region from an inner surface of an absorbent chassis and inseparably integrated with each other.

Owner:UNI CHARM CORP

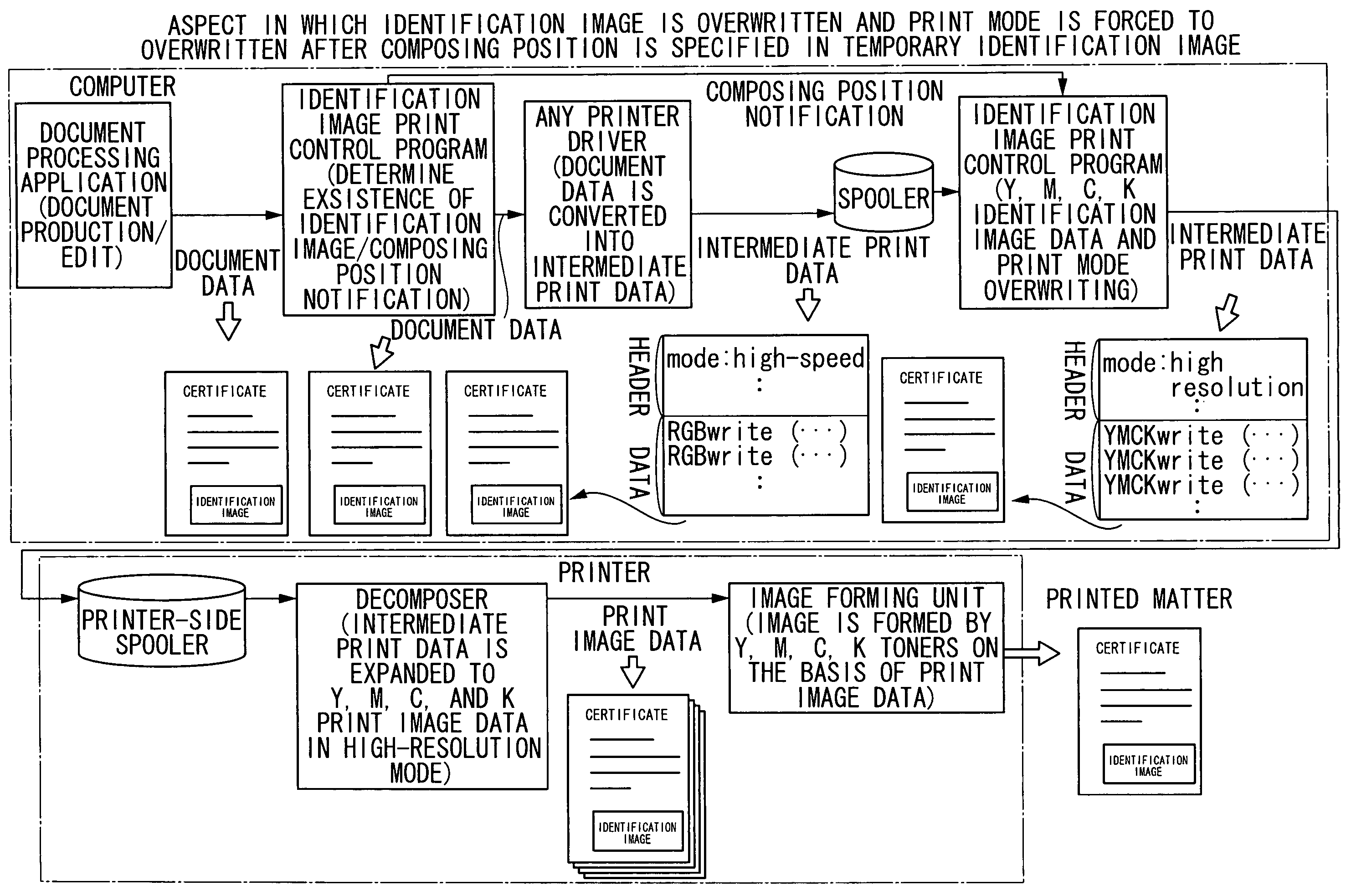

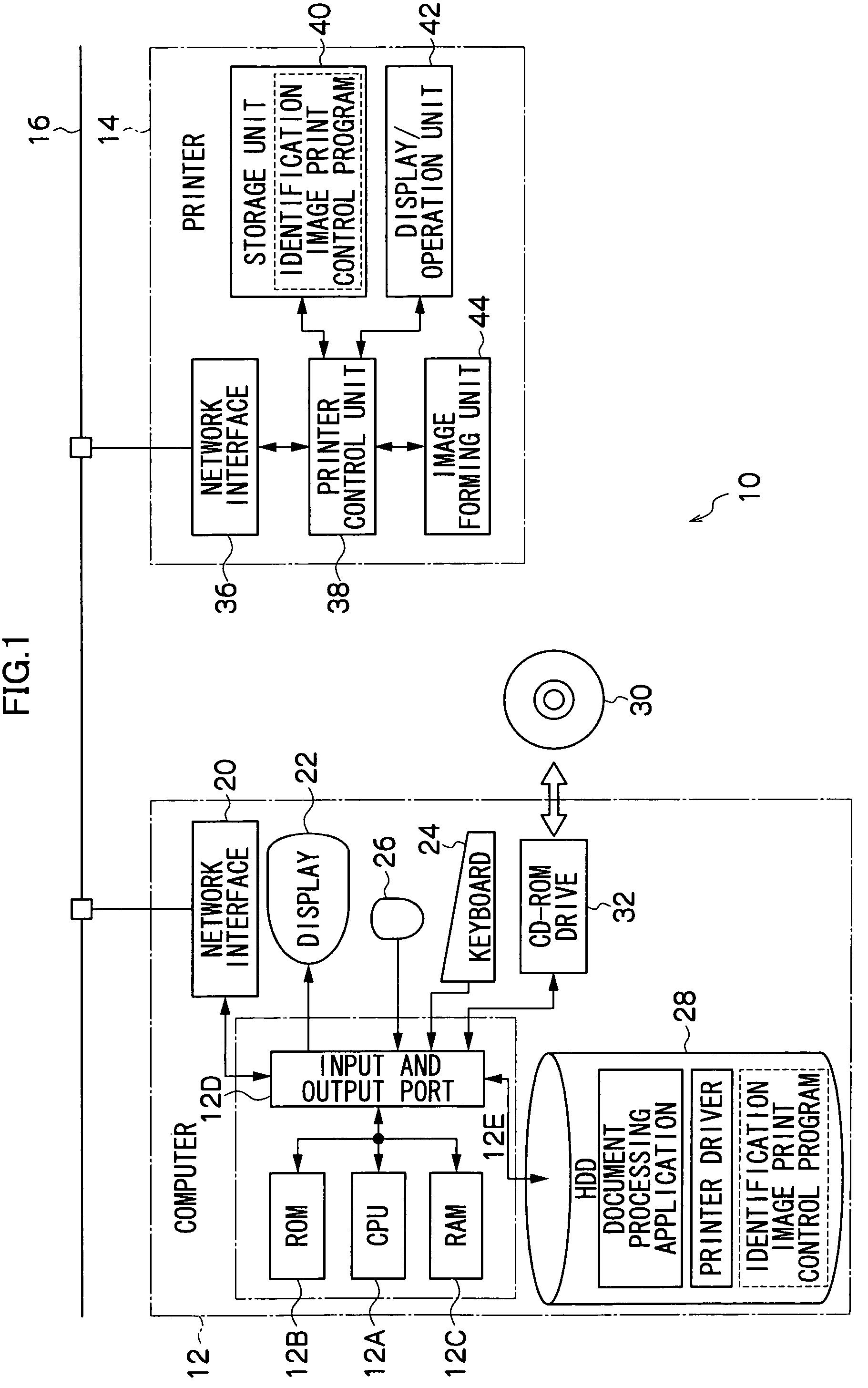

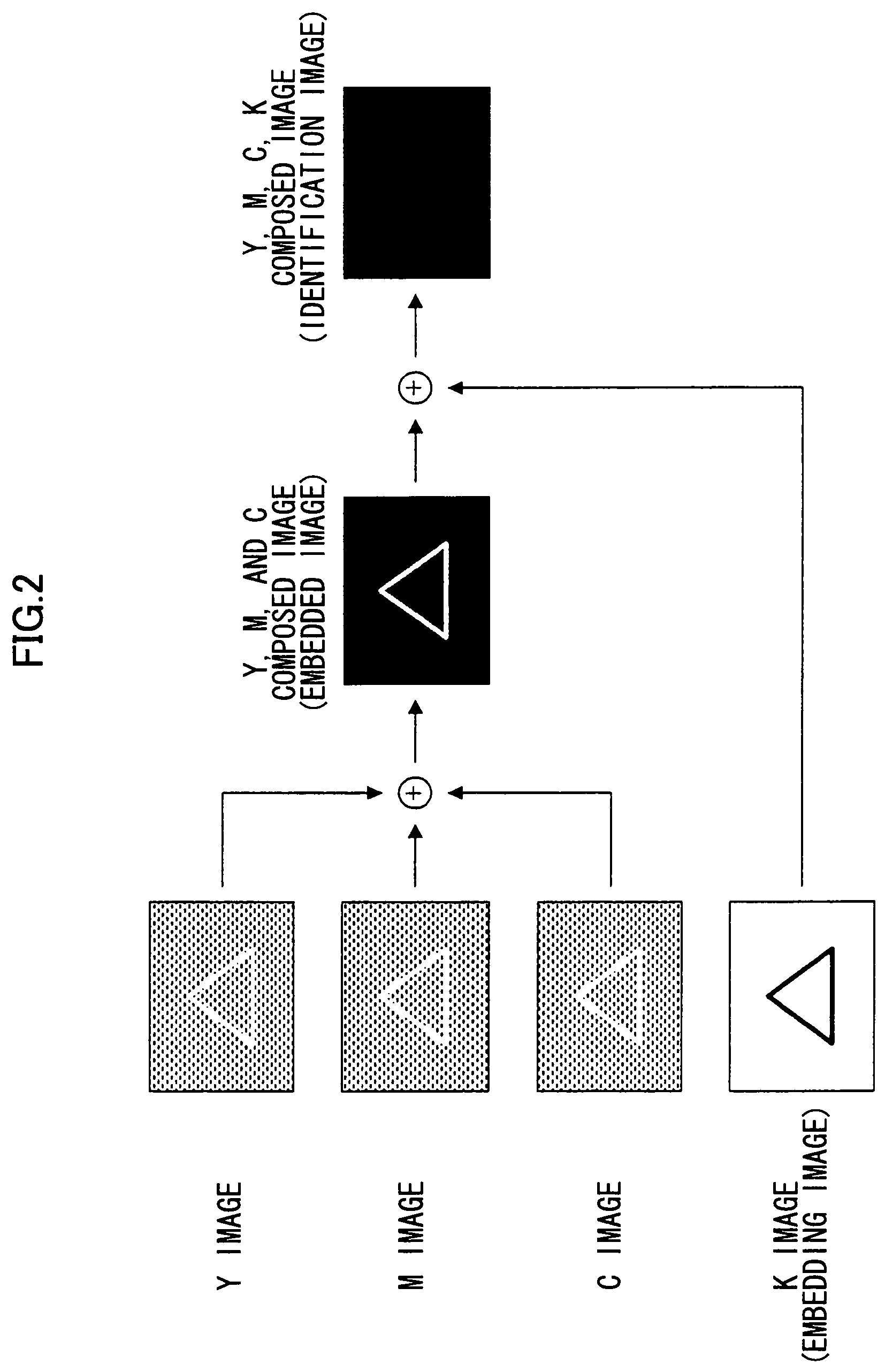

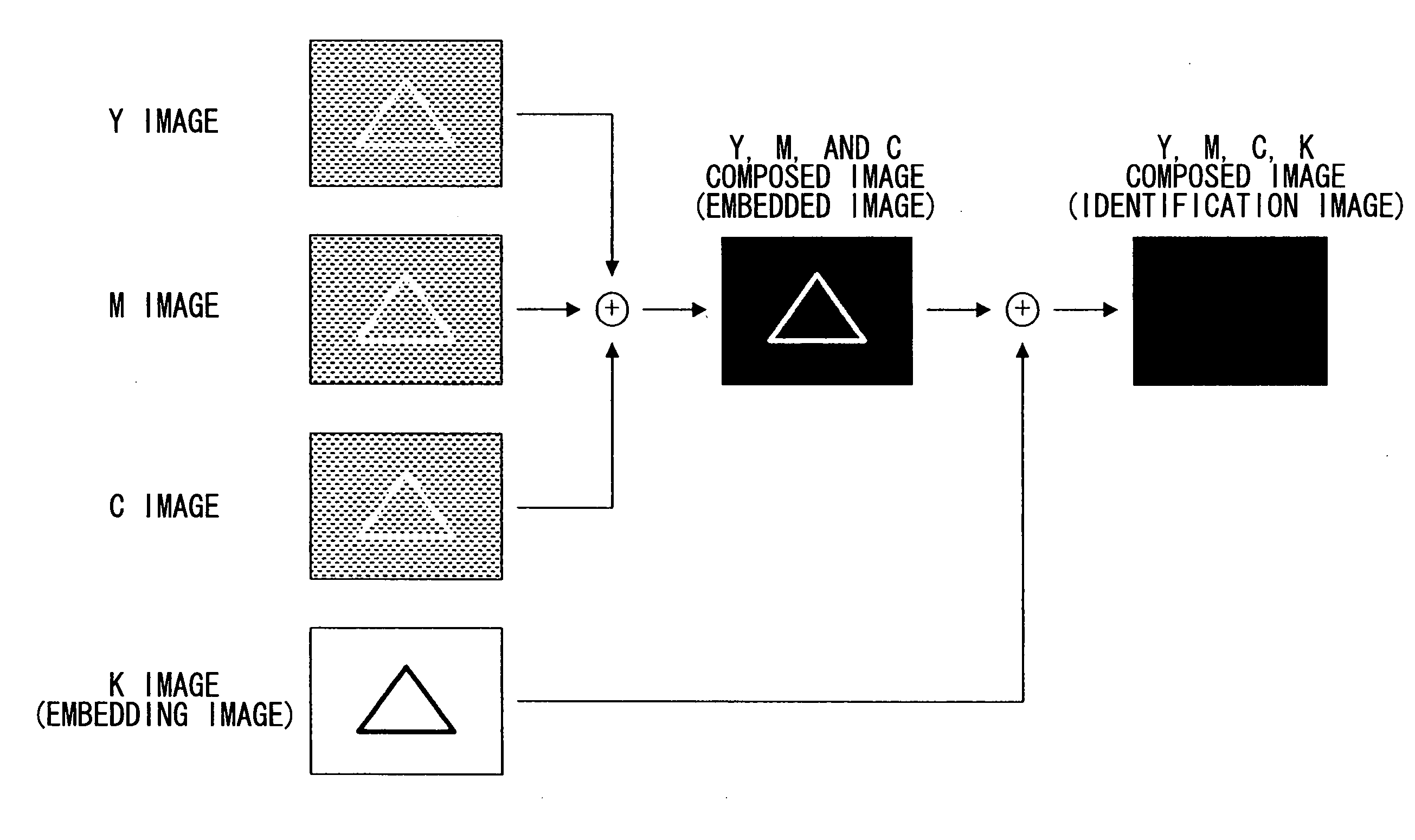

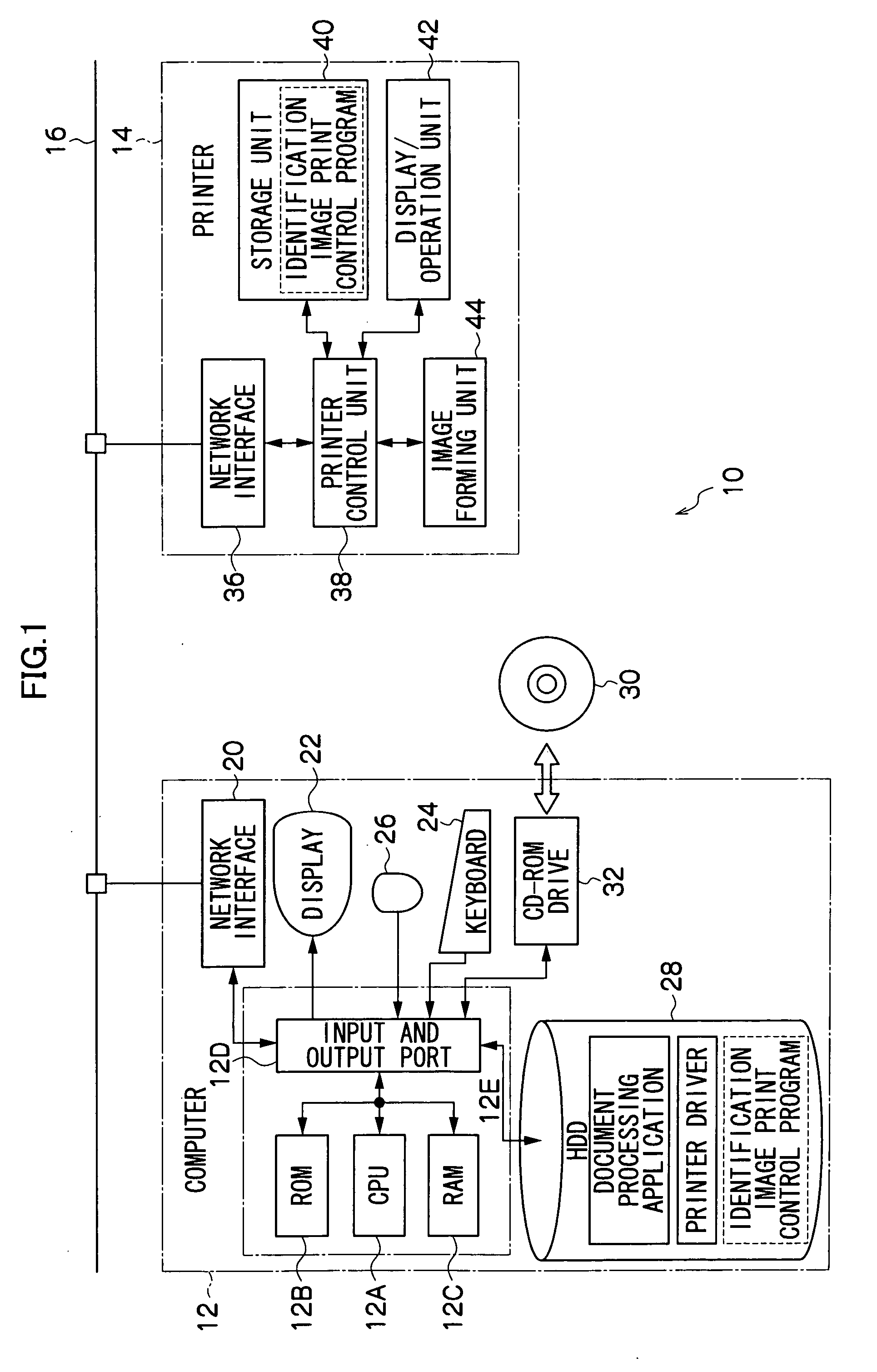

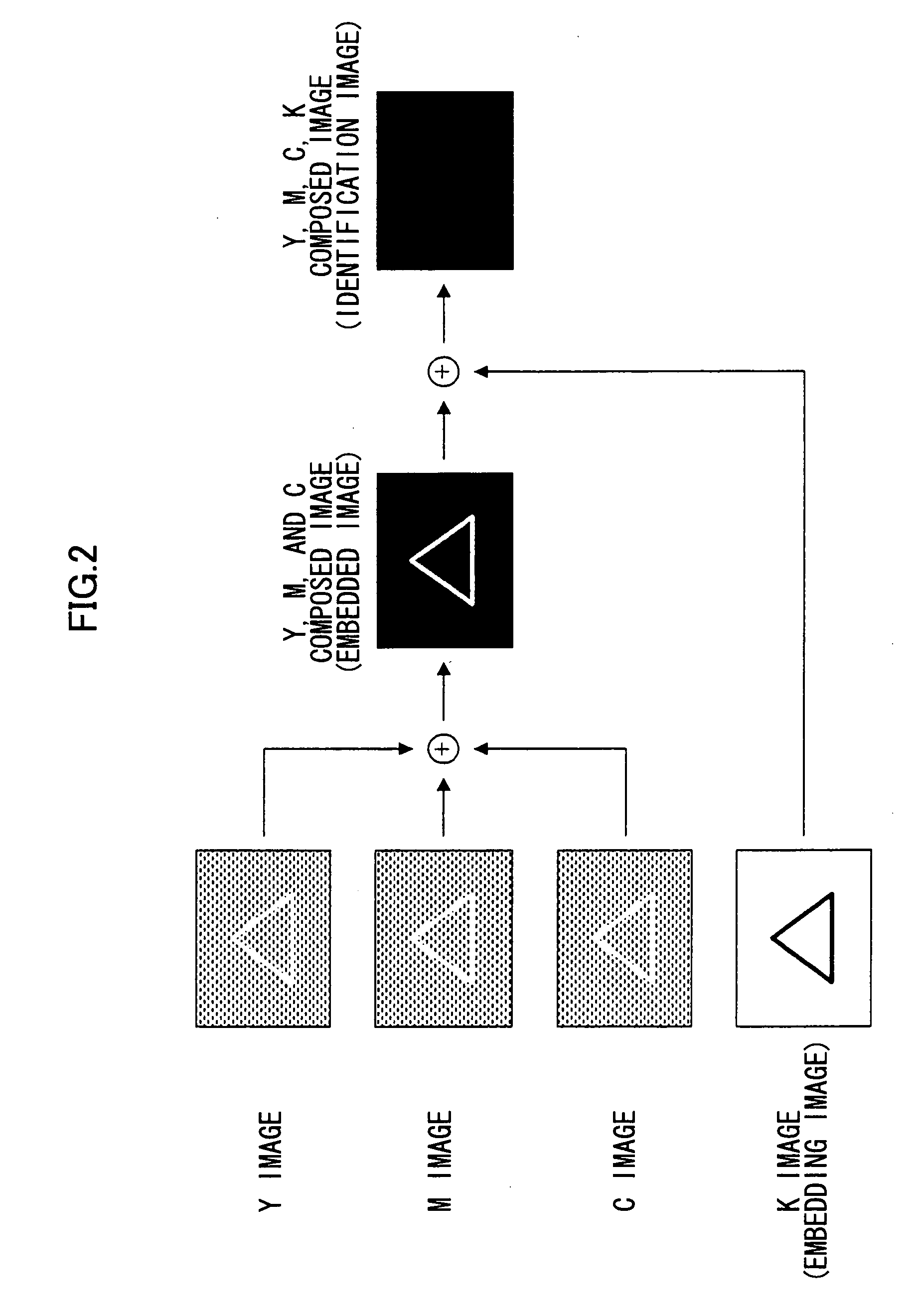

Print controlling apparatus, method, and storage medium for generating print image data of a particular color space representing a print object document in the form of a plurality of color components

InactiveUS7505179B2Avoid mixing togetherAccurate printingDigitally marking record carriersDigital computer detailsComputer graphics (images)Documentation

Owner:FUJIFILM BUSINESS INNOVATION CORP

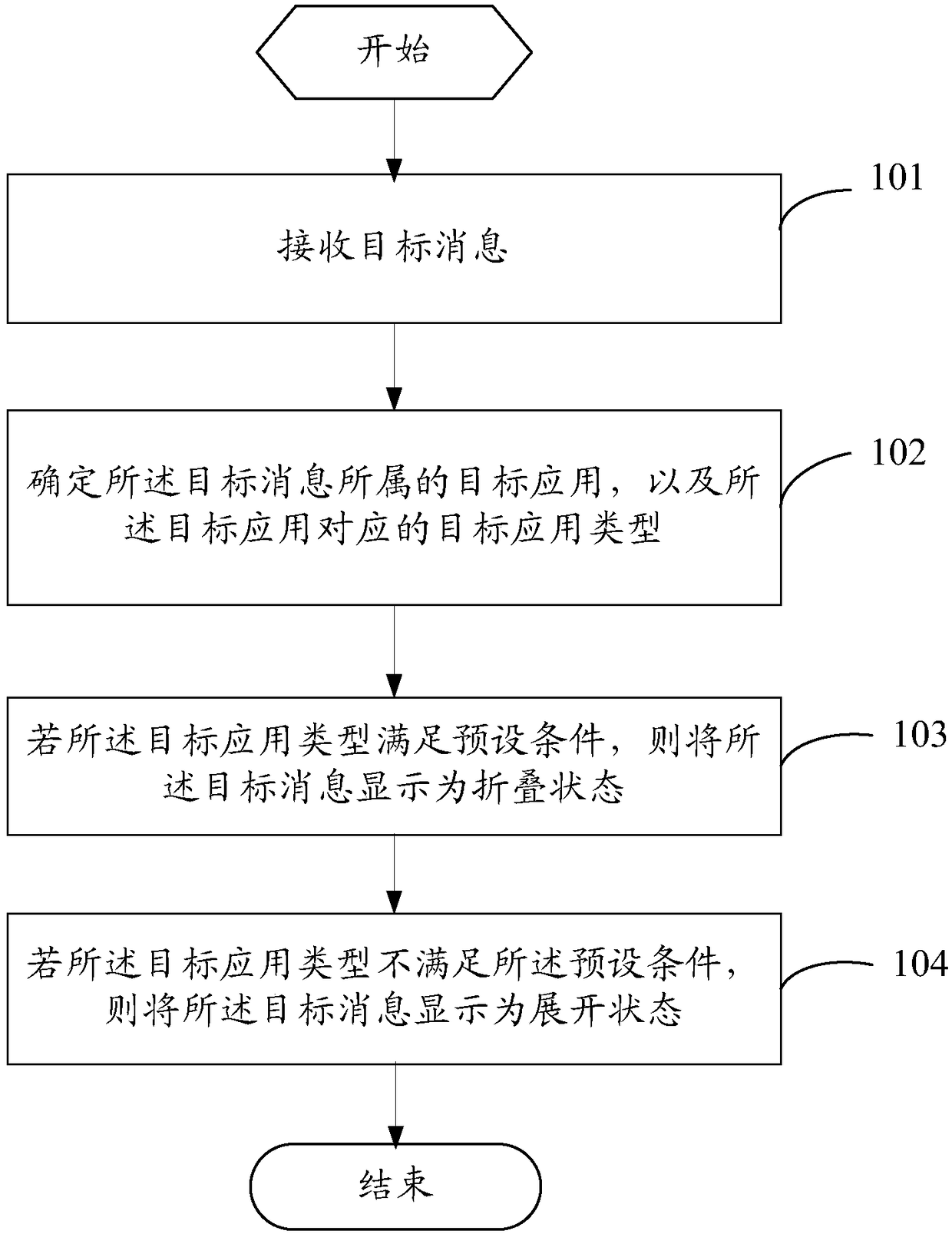

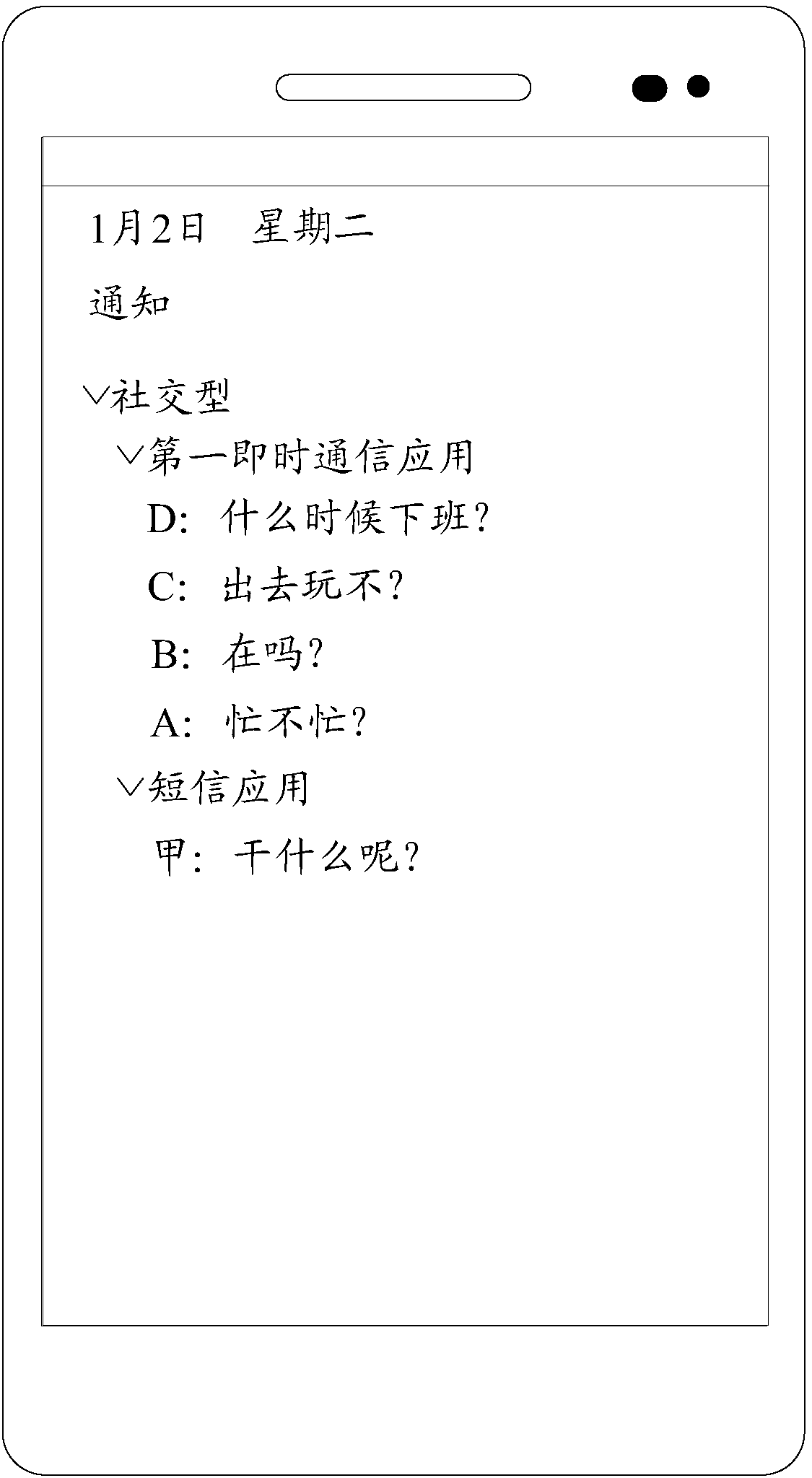

Method for displaying message and mobile terminal

InactiveCN108427593AAvoid mixing togetherSubstation equipmentExecution for user interfacesComputer terminal

Owner:VIVO MOBILE COMM CO LTD

Print controlling apparatus, method, and storage medium

InactiveUS20060033962A1Accurate printingGreat advantageDigitally marking record carriersDigital computer detailsColor spaceControl equipment

A print control apparatus which performs printing process with a printer using coloring agents of the plurality of color components includes: an identification image controller that controls to add the identification image data to the print image data without color space conversion being performed when the printer prints the document in which the identification image is composed. The identification image includes an embedding image and an embedded image. The embedding image and the embedded image are formed to be superposed on each other, and the embedded image is processed in advance so that visual identification of the embedding image is difficult under visible light when the embedding image and the embedded image are printed.

Owner:FUJIFILM BUSINESS INNOVATION CORP

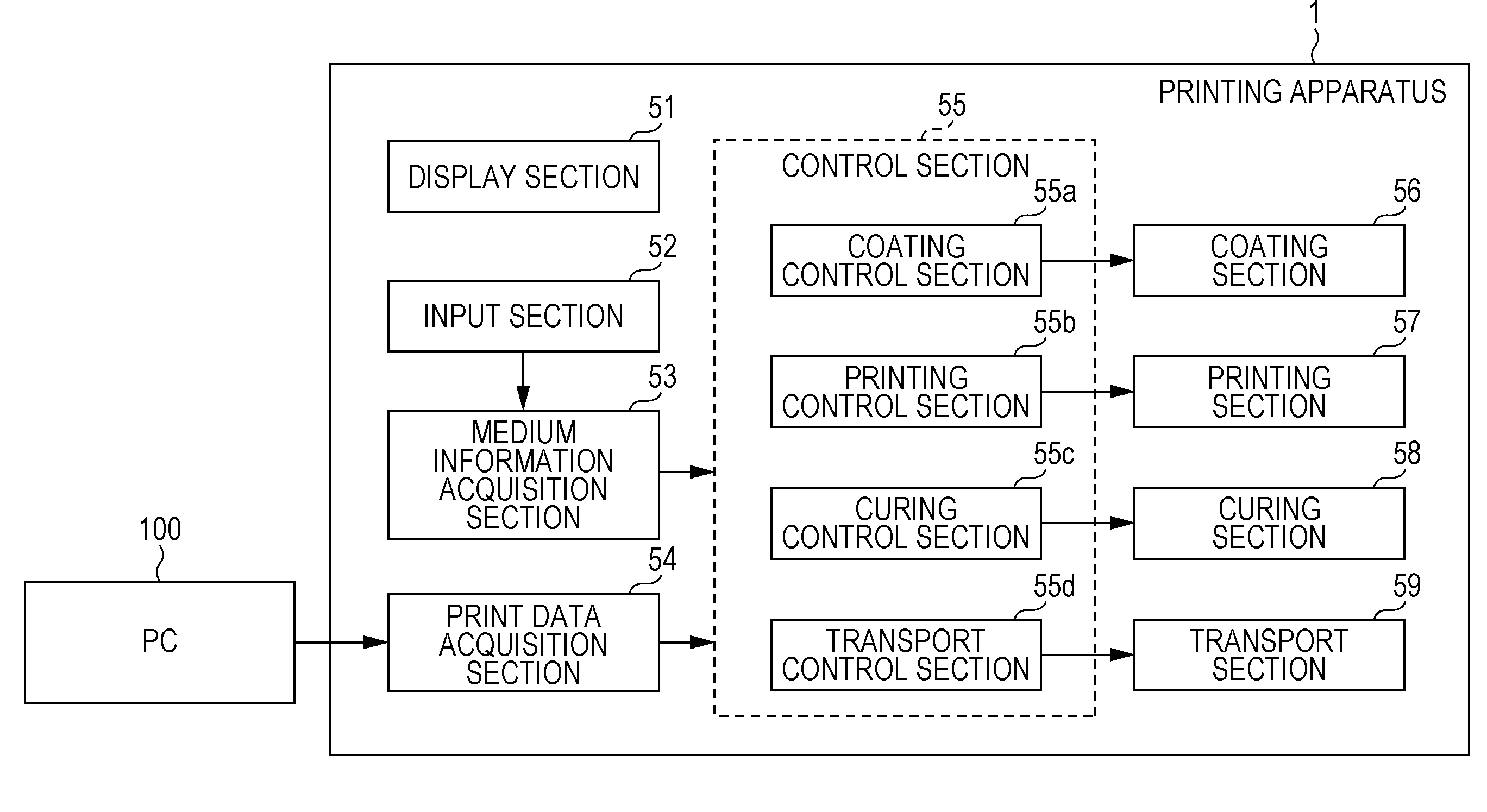

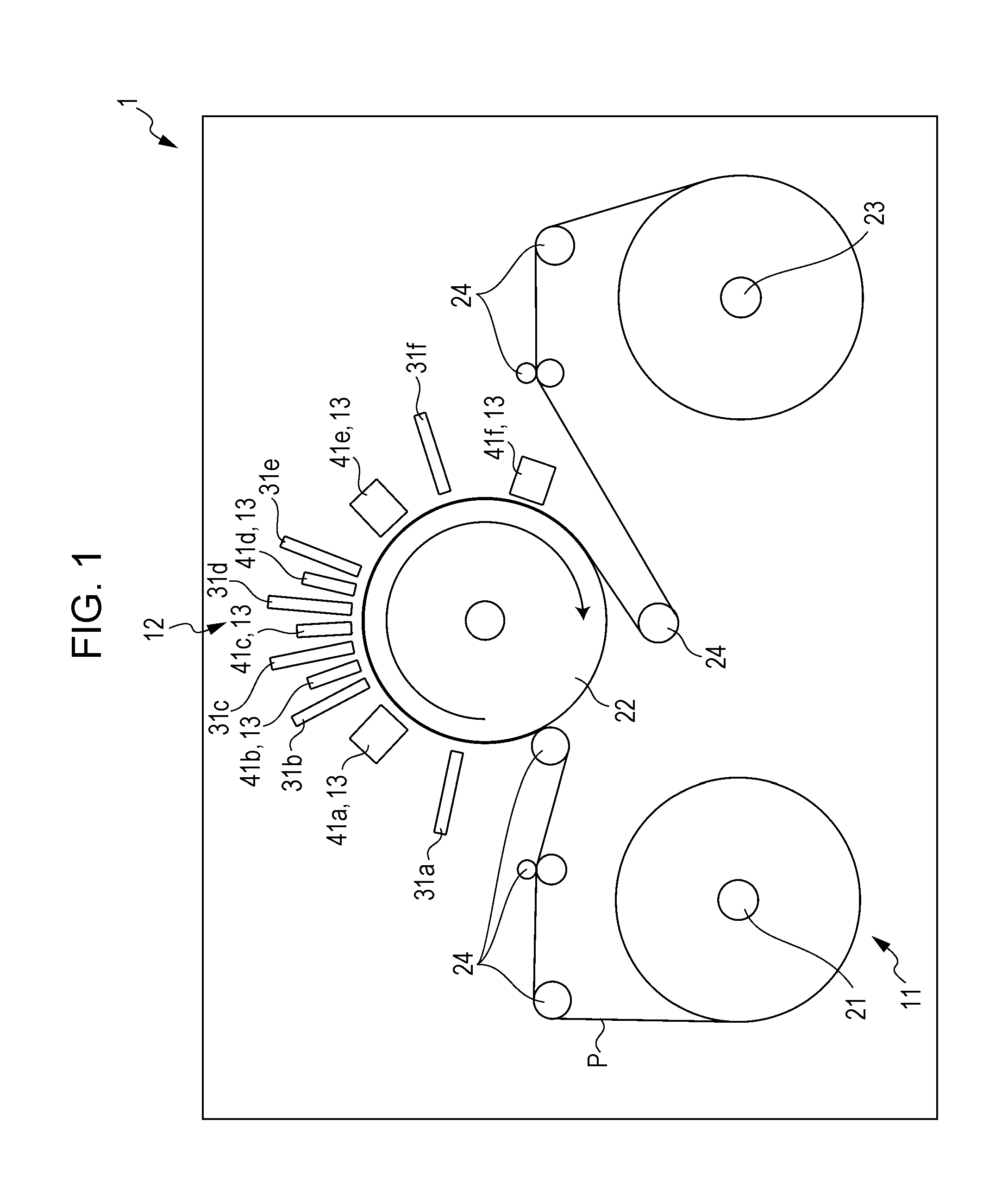

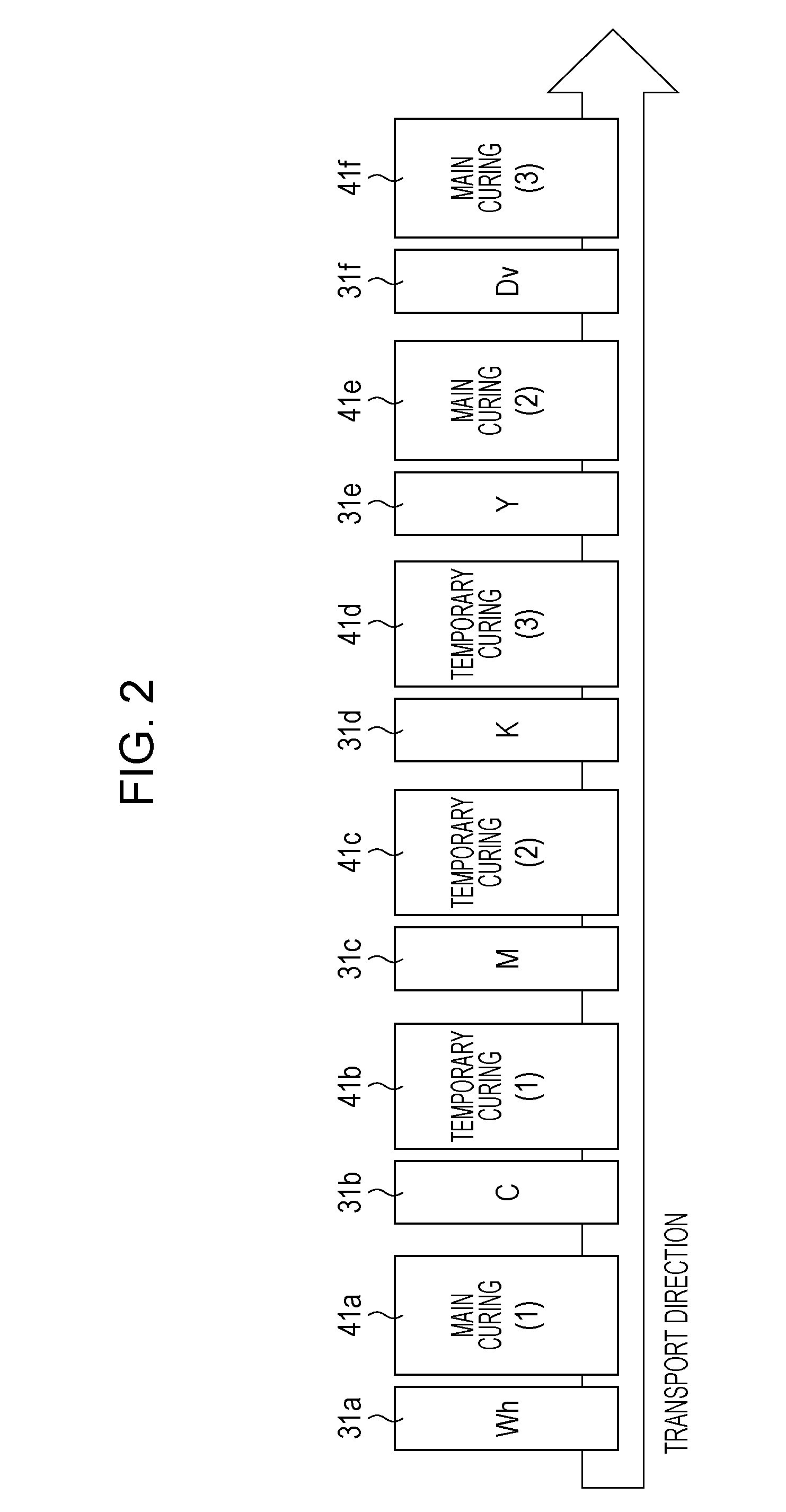

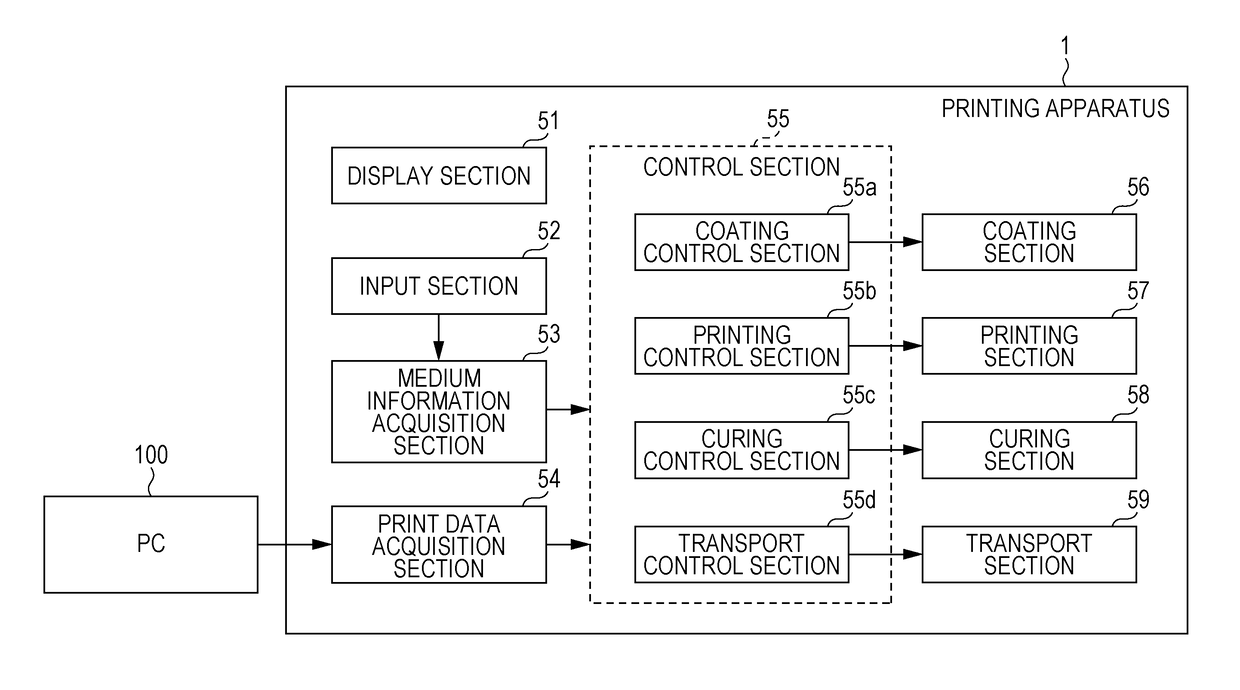

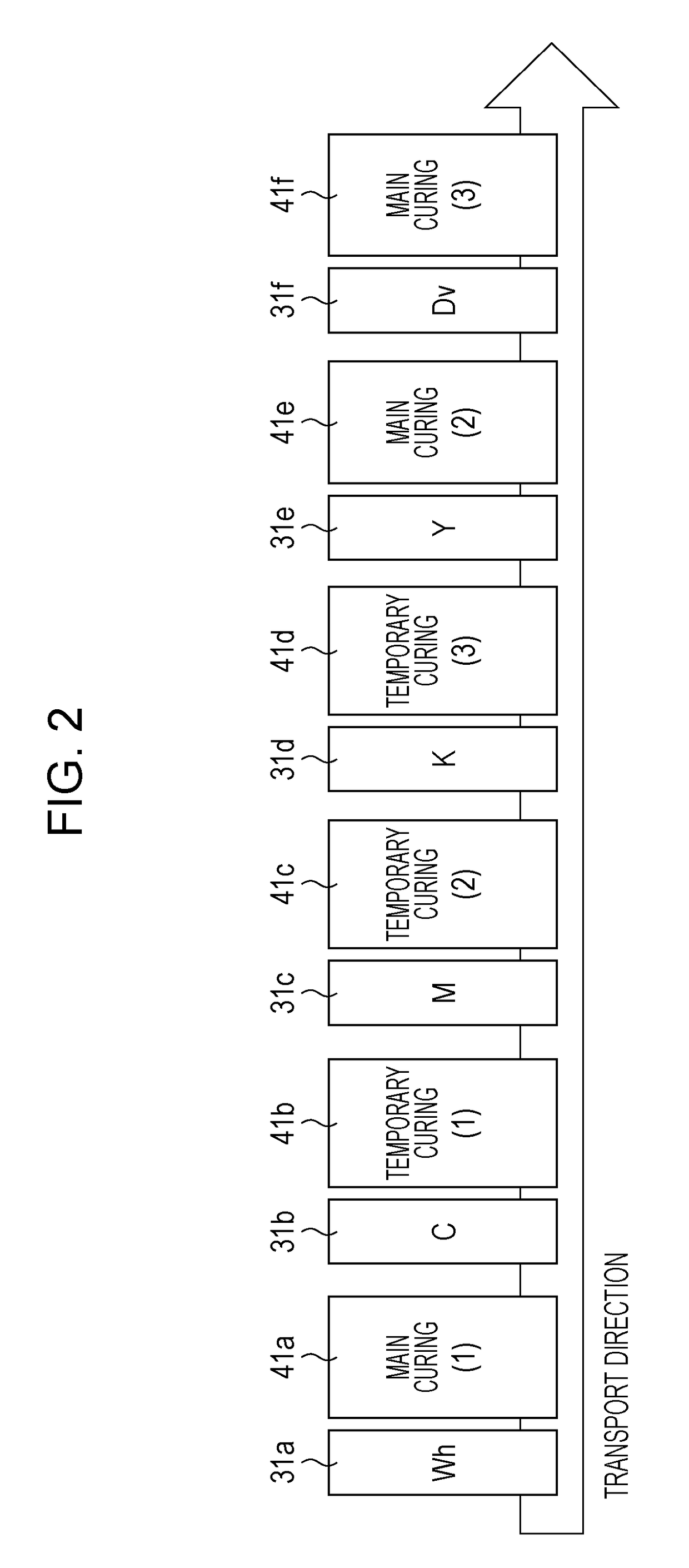

Printing apparatus and control method of printing apparatus

ActiveUS20160307078A1Prevent color developmentCurb consumptionVisual presentation using printersOther printing apparatusPrinting inkEngineering

A printing apparatus of the invention includes a medium information acquisition section that acquires medium information that can specify a type of a print medium, a printing section that discharges print ink to the print medium, a coating section that coats the print medium with precoat liquid before the printing section performs printing, and a coating control section that controls the coating section. The coating control section variably changes an amount of coating of the precoat liquid per unit area according to the acquired medium information.

Owner:SEIKO EPSON CORP

Air conditioning device

ActiveUS10369862B2Avoid mixing togetherSuppression mixingAir-treating devicesLighting and heating apparatusEngineeringAir conditioning

An air conditioning device includes a casing that provides multiple air passages, a blower fan that suctions an air from the multiple air passages and blows out the air in the casing, a suction side partitioning member that is disposed on a suction side of the blower fan in the casing and separates air flows from the multiple air passages from each other, and a blowing side partitioning member that is disposed on a blowing side of the blower fan in the casing and separates the air flows from the multiple air passages from each other. The suction side partitioning member and the blowing side partitioning member are disposed so that a relative position of the blowing side partitioning member to the suction side partitioning member is deviated in a rotation direction of the blower fan.

Owner:DENSO CORP

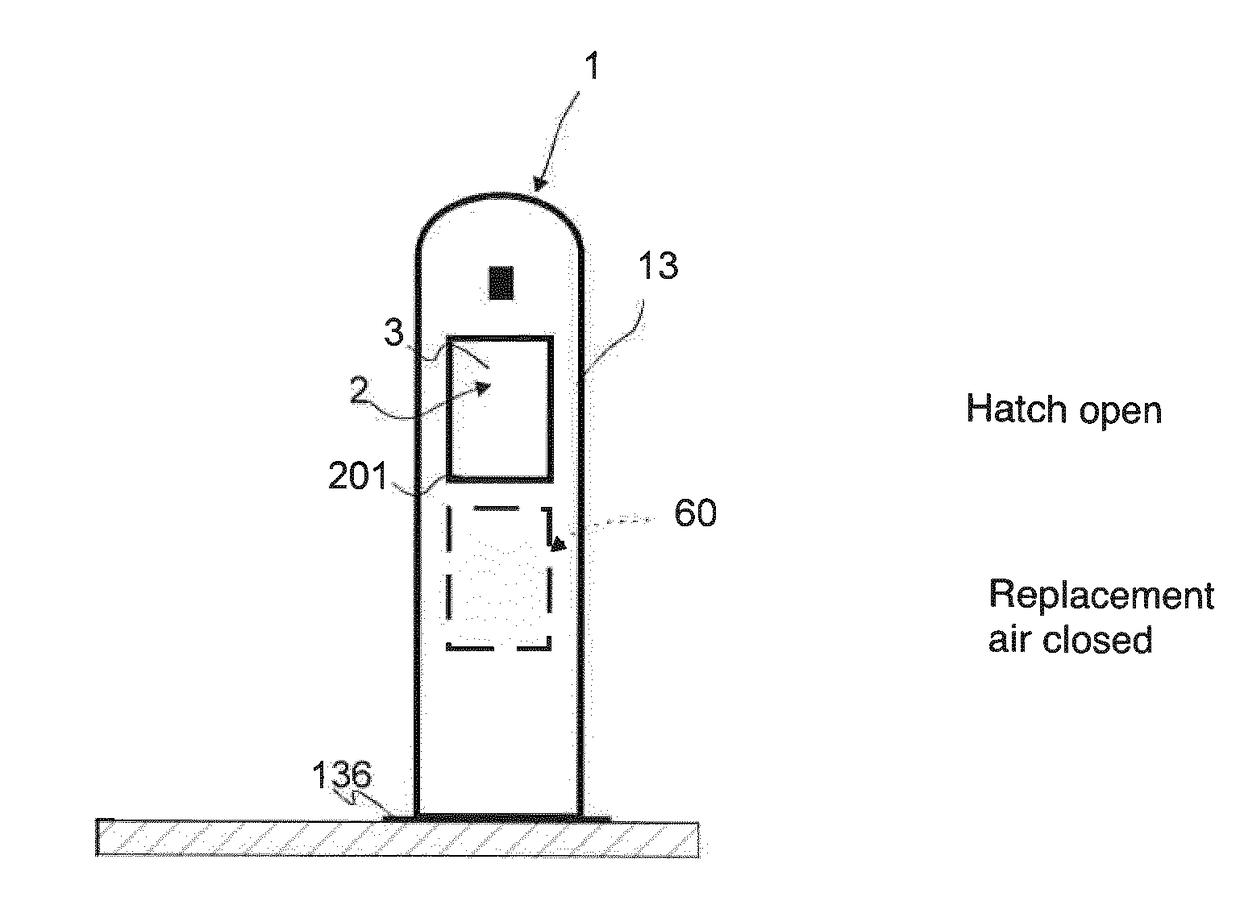

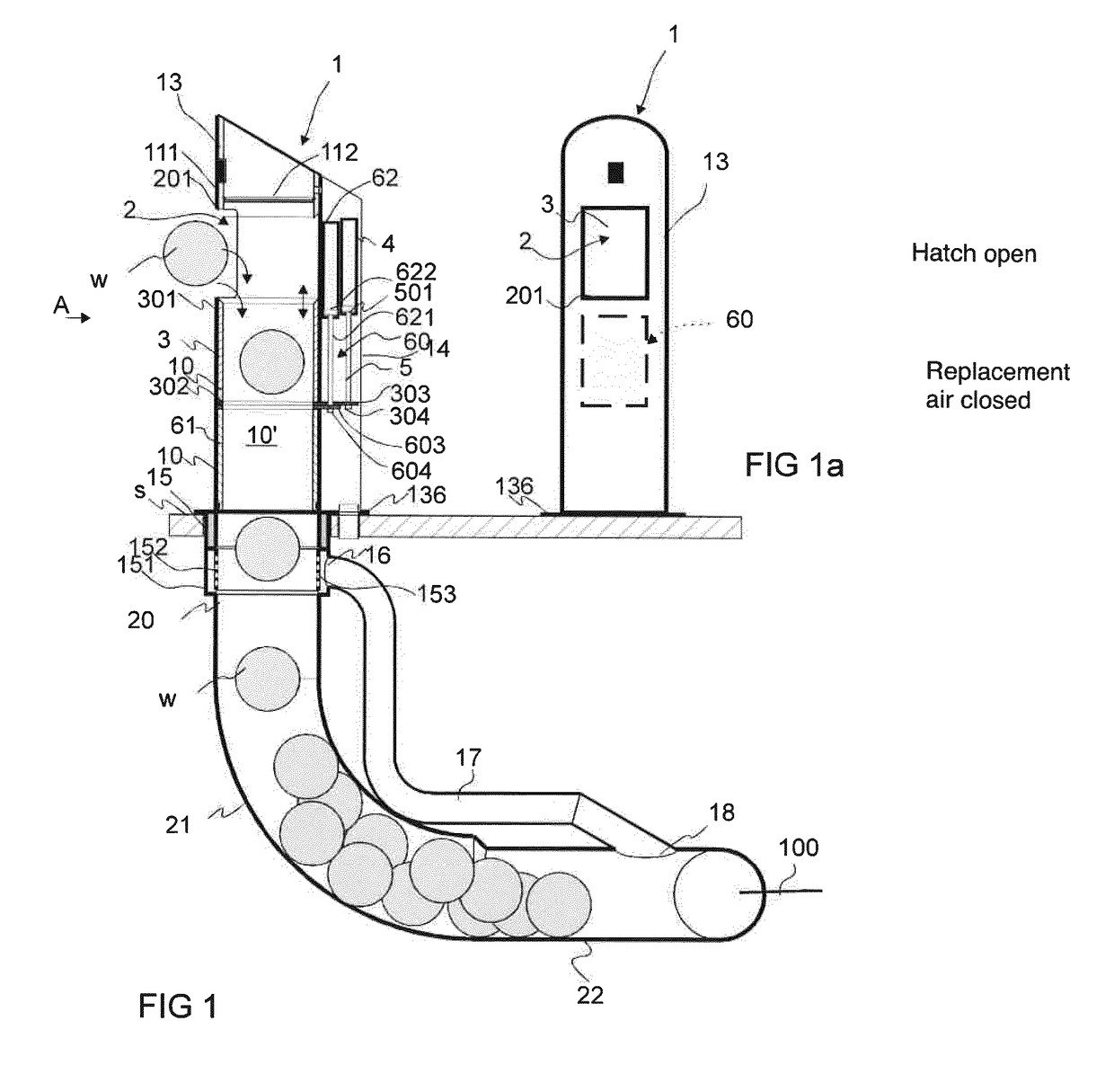

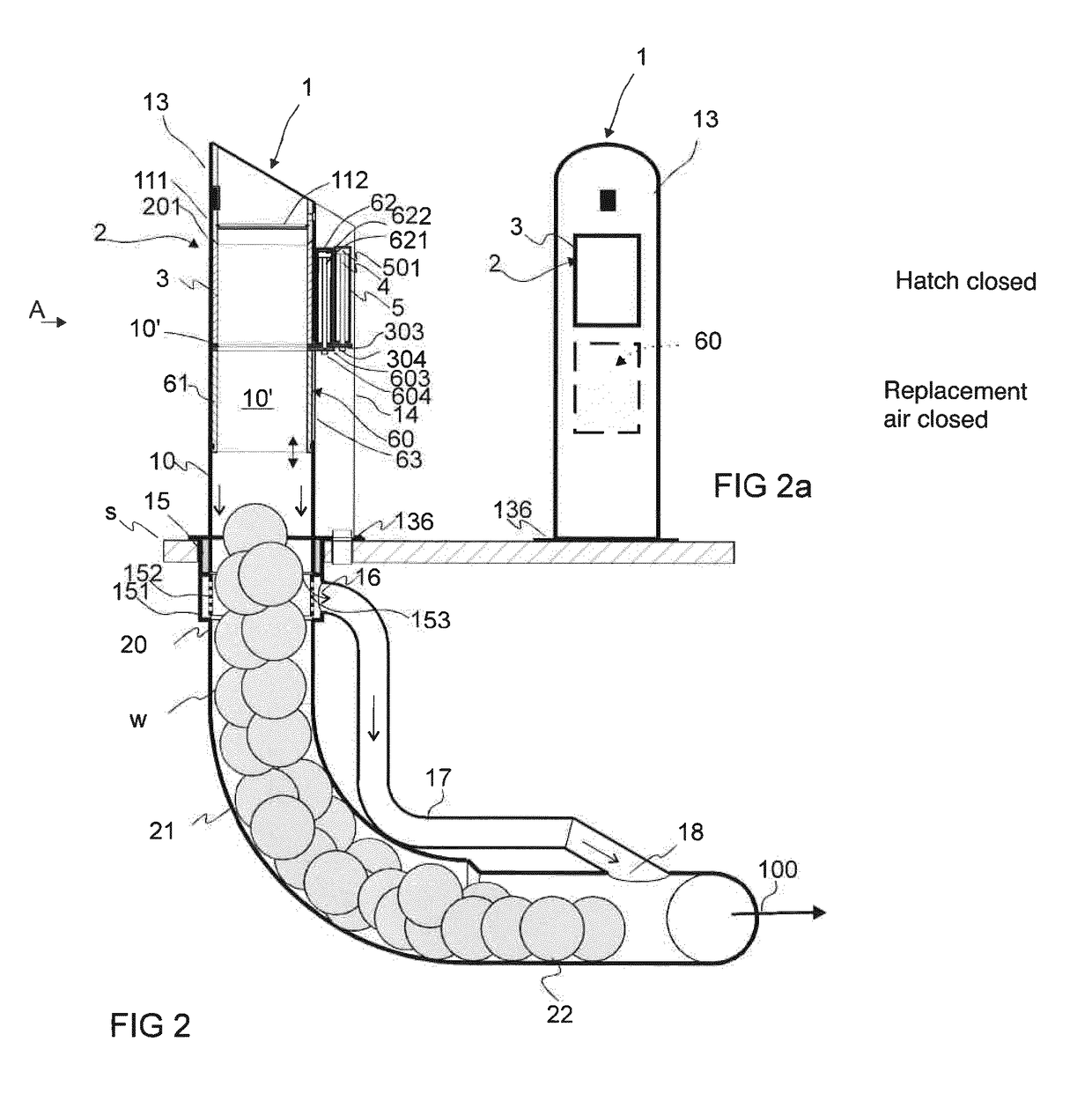

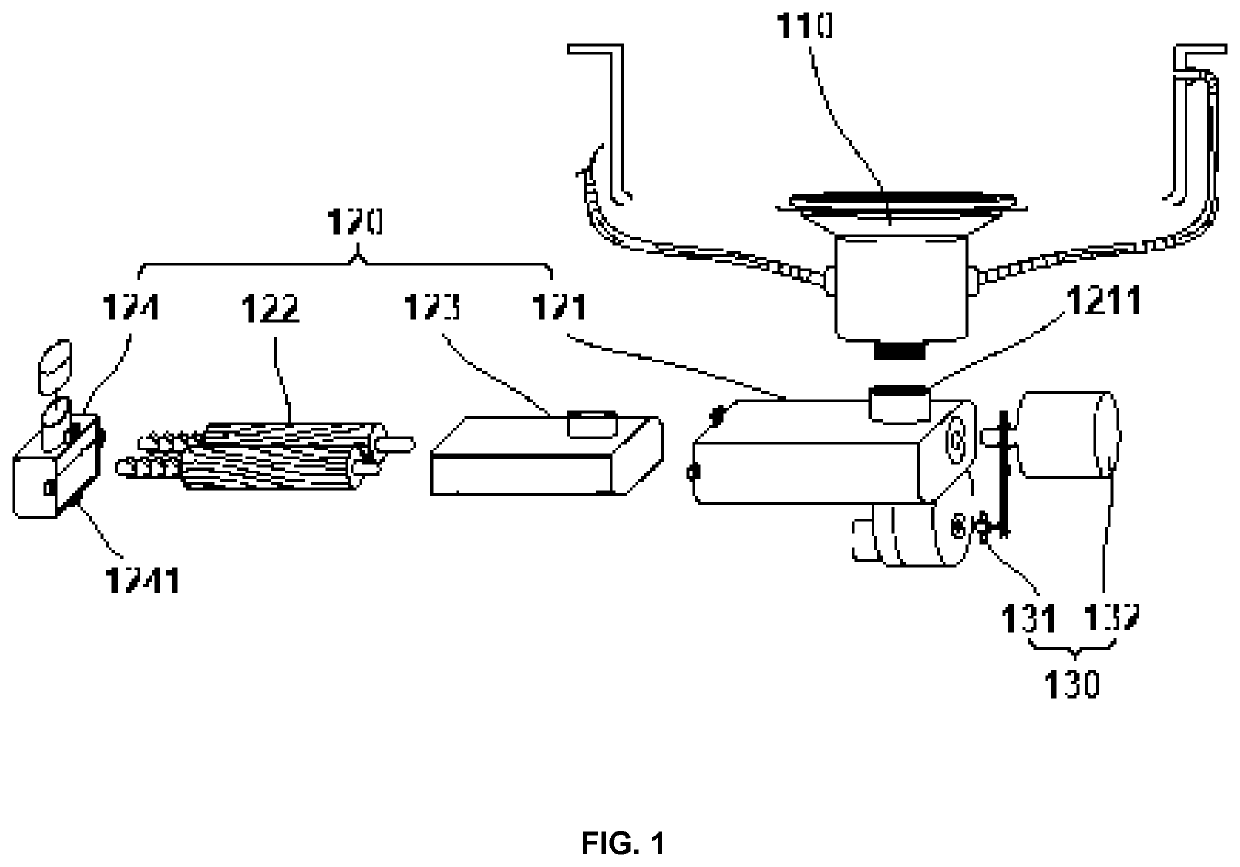

Method and apparatus in a pneumatic pipe transport system for material, and a conveying system for wastes

ActiveUS20180237219A1Compensation changesChange volumeRefuse gatheringBulk conveyorsTransport systemCollection system

Method for compensating a change in volume caused by a pressure difference of the intermediate container of an input point of a pneumatic pipe collection system for material and / or for preventing undesired material displacement from the intermediate container. In the method a bypass channel is arranged in the channel section formed by the intermediate container of an input point for compensating a change in volume resulting from the pressure difference of the pressures of different magnitudes possibly acting on different sides of the material and / or for preventing undesired material displacement from the channel section into the material conveying pipe. The invention also relates to an apparatus and to a wastes conveying system.

Owner:MARICAP OY

Printer device

InactiveUS6130681AThe right amountAvoid flowMeasurement apparatus componentsPrintingEngineeringLiquid surfaces

A printer device for realizing correct representation of the gradation. After oozing a quantitation medium 45 from a quantitation medium nozzle 53, the printer device causes an emission medium 49 from an emission medium nozzle 54 for mixing with the quantitation medium 45 for emitting the resulting mixed liquid. During the time which elapses since emission of the quantitation medium 45 from the quantitation medium nozzle 53 until reversion of the liquid surface of the quantitation medium 45 to the opening end of the quantitation medium nozzle 53, the quantitation medium 53 is pressurized in a direction of pulling the liquid surface of the quantitation medium 45 into the quantitation medium nozzle 53. Also, during the time which elapses since the emission of the emission medium 49 from the emission medium nozzle 54 until reversion of the liquid surface of the emission medium 49 to the opening end of the emission medium nozzle 54, the emission medium 49 is pressurized in a direction of pulling the liquid surface of the emission medium 49 into the emission medium nozzle 54.

Owner:SONY CORP

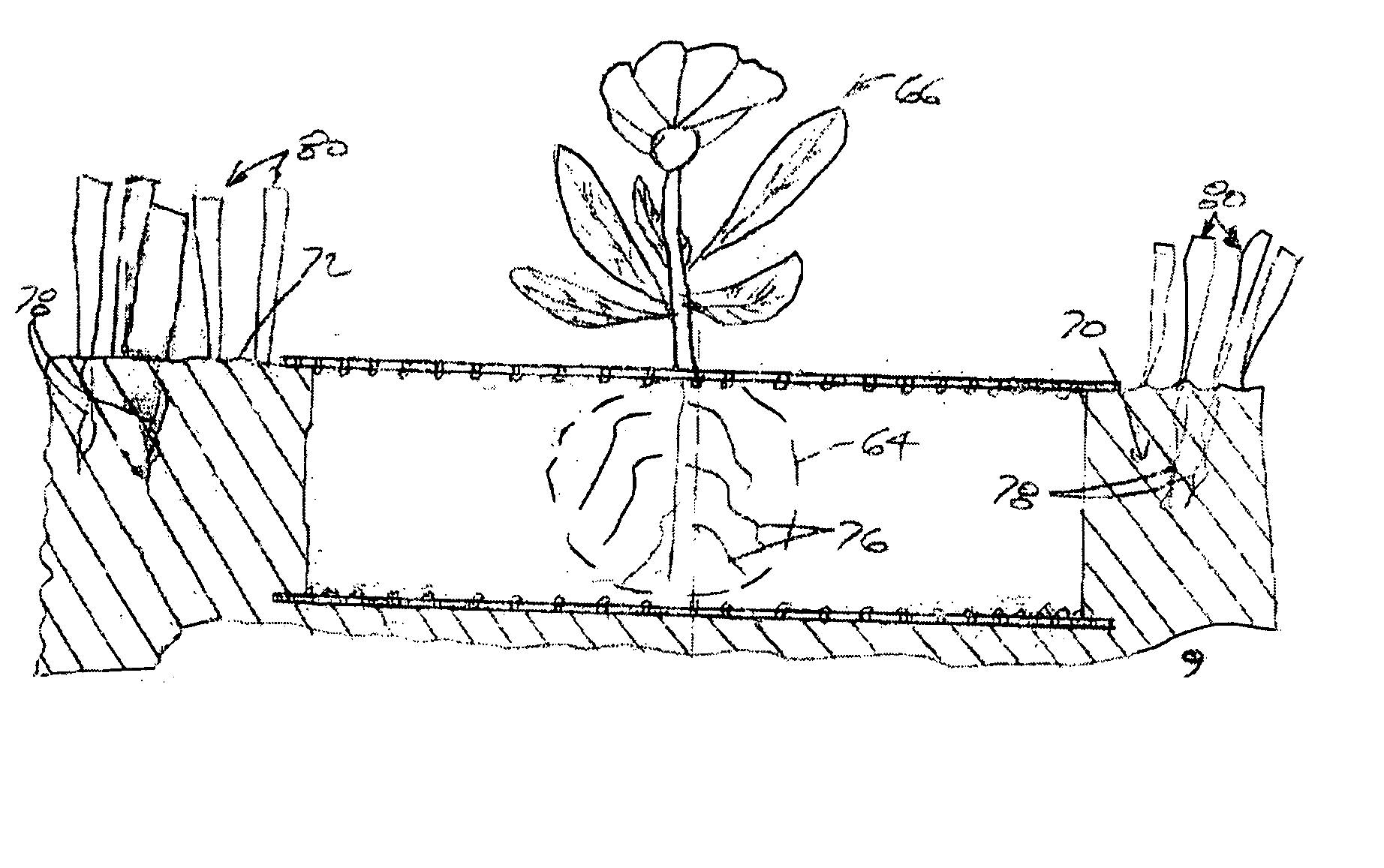

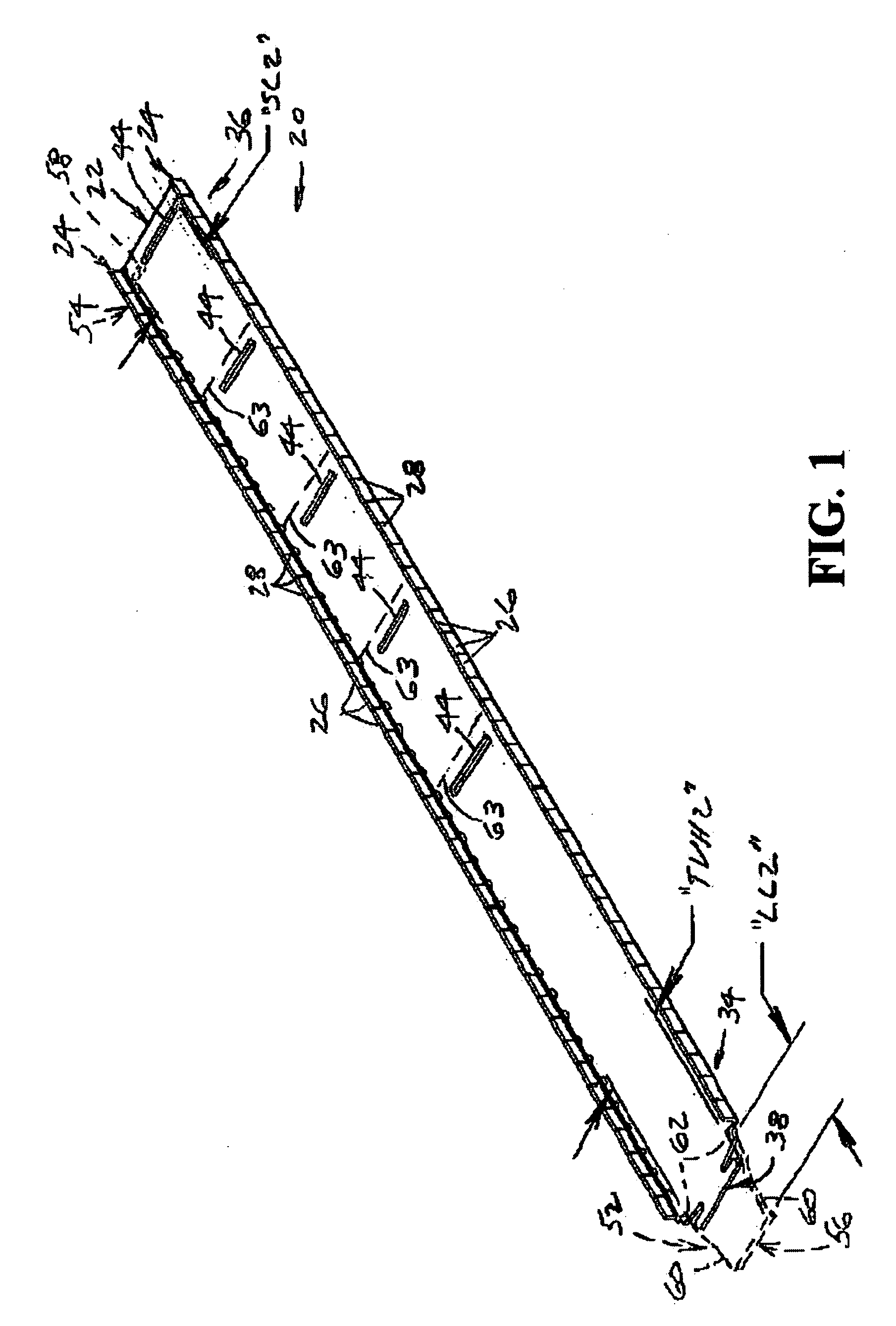

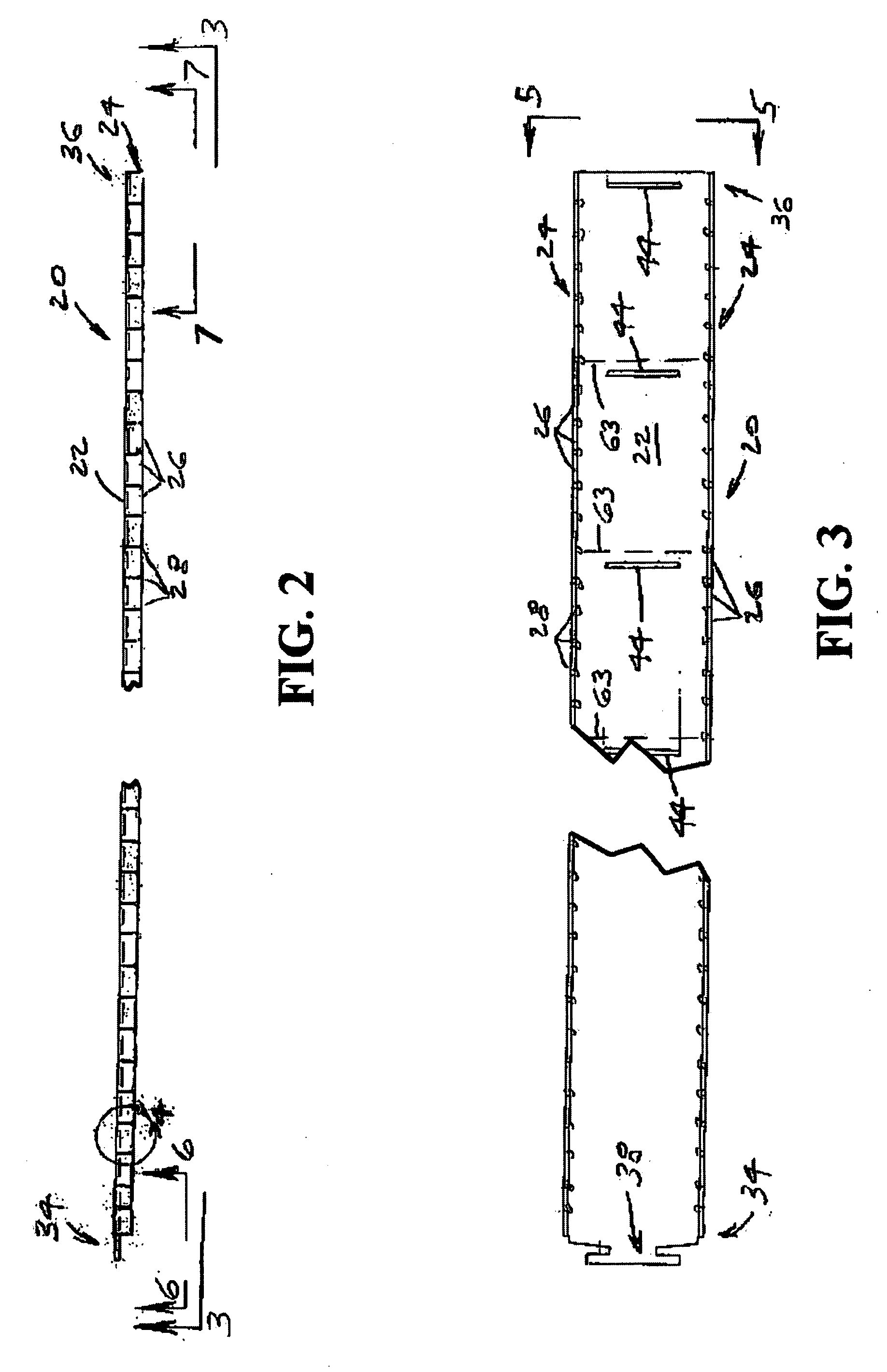

Edge strip for edging plants and making in-ground plant pots

InactiveUS20070107301A1Avoid mixing togetherEasy to bendPlanting bedsEdging using tilesGrowth plantRoot growth

A flexible edge strip for insertion into the ground around plants to prevent roots of the plant and the roots of surrounding plants from mixing together, methods of use and manufacture thereof. The edge strip is of a flexible C-shaped cross-section with an elongate vertical leg having opposite ends which interconnect to form a looped configuration, and top and bottom edges each with a dependent horizontal flange co-extending therealong at substantially a right angle thereto. The horizontal flanges are divided into a plurality of individual tabs separated by respective slots adapted to facilitate bending of the edge strip. The ends of the vertical leg respectively include a retaining tab and a mating vertically disposed retaining slot to receive the retaining tab therethrough to retain the retaining tab therein. The edge strip may be shortened at a plurality of perforated separation lines that extend transversely thereacross. An retaining slot is disposed adjacent each separation line to retain the retaining tab for retention of the shortened edge strip in the looped configuration. The vertical leg obstructs water outflow and root growth when inserted into the ground generally parallel to the ground surface. The horizontal flanges respectively obstruct plant growth above the ground and anchor the edge strip within the ground.

Owner:MEYERS FRANK J

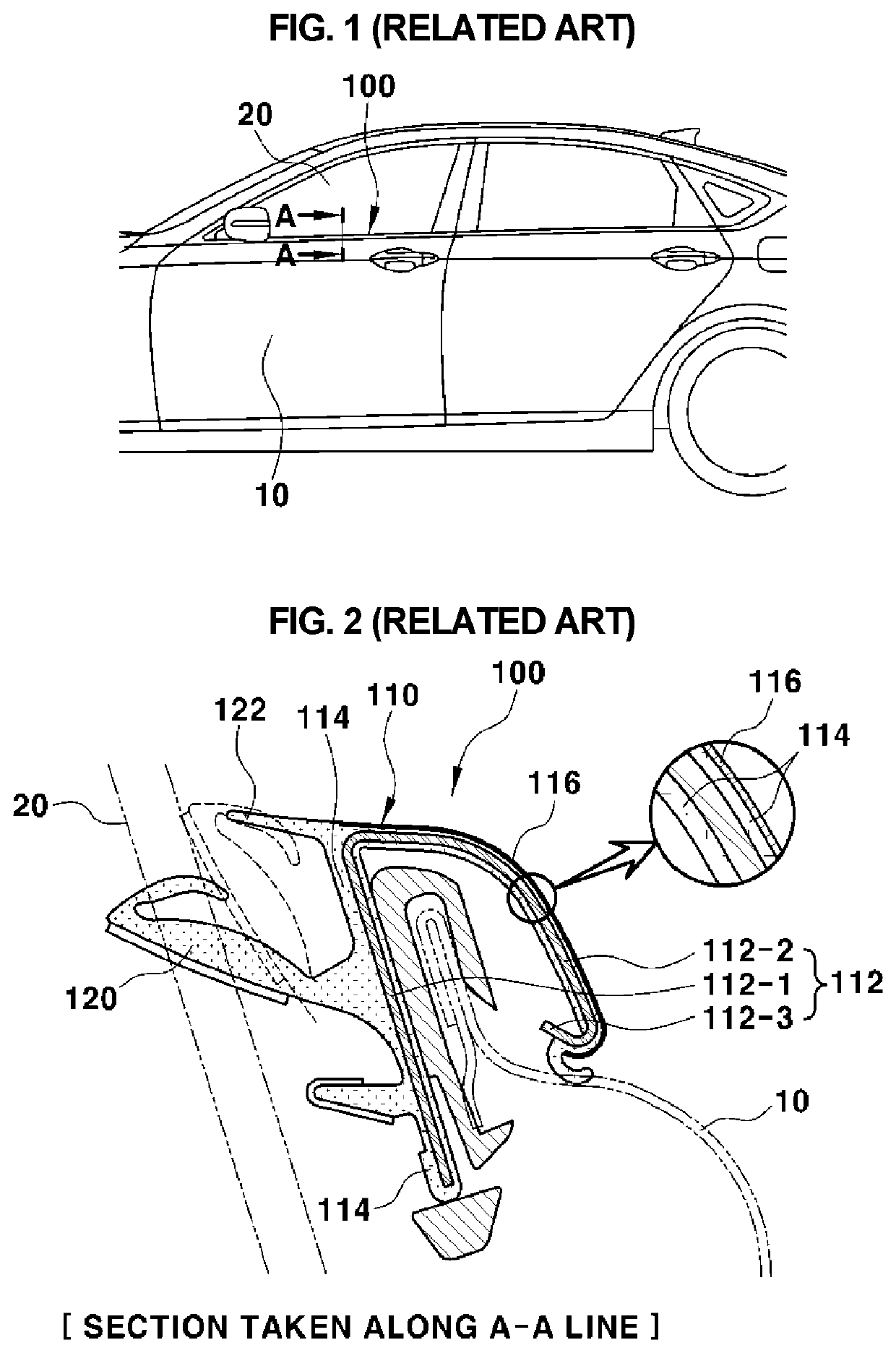

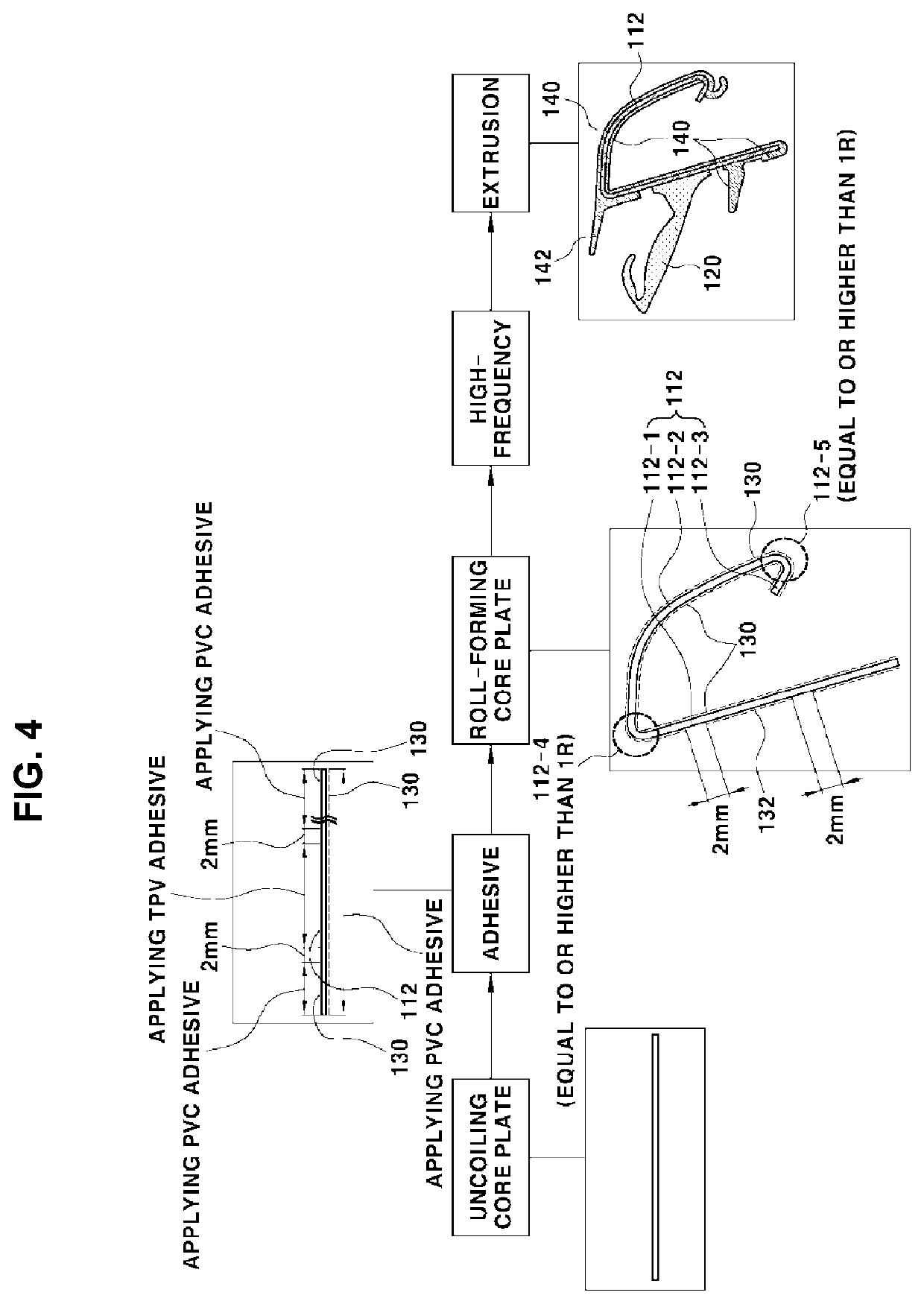

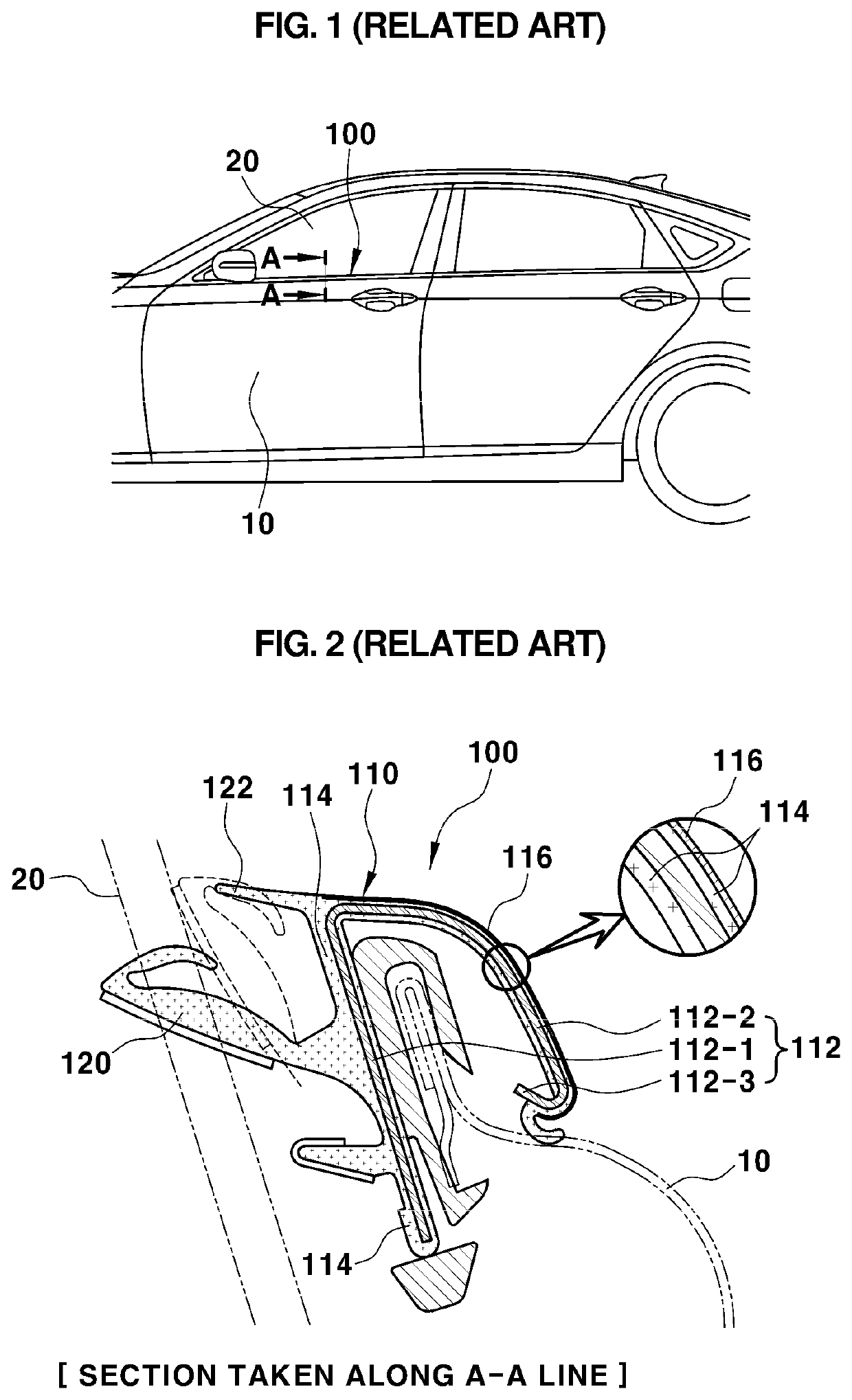

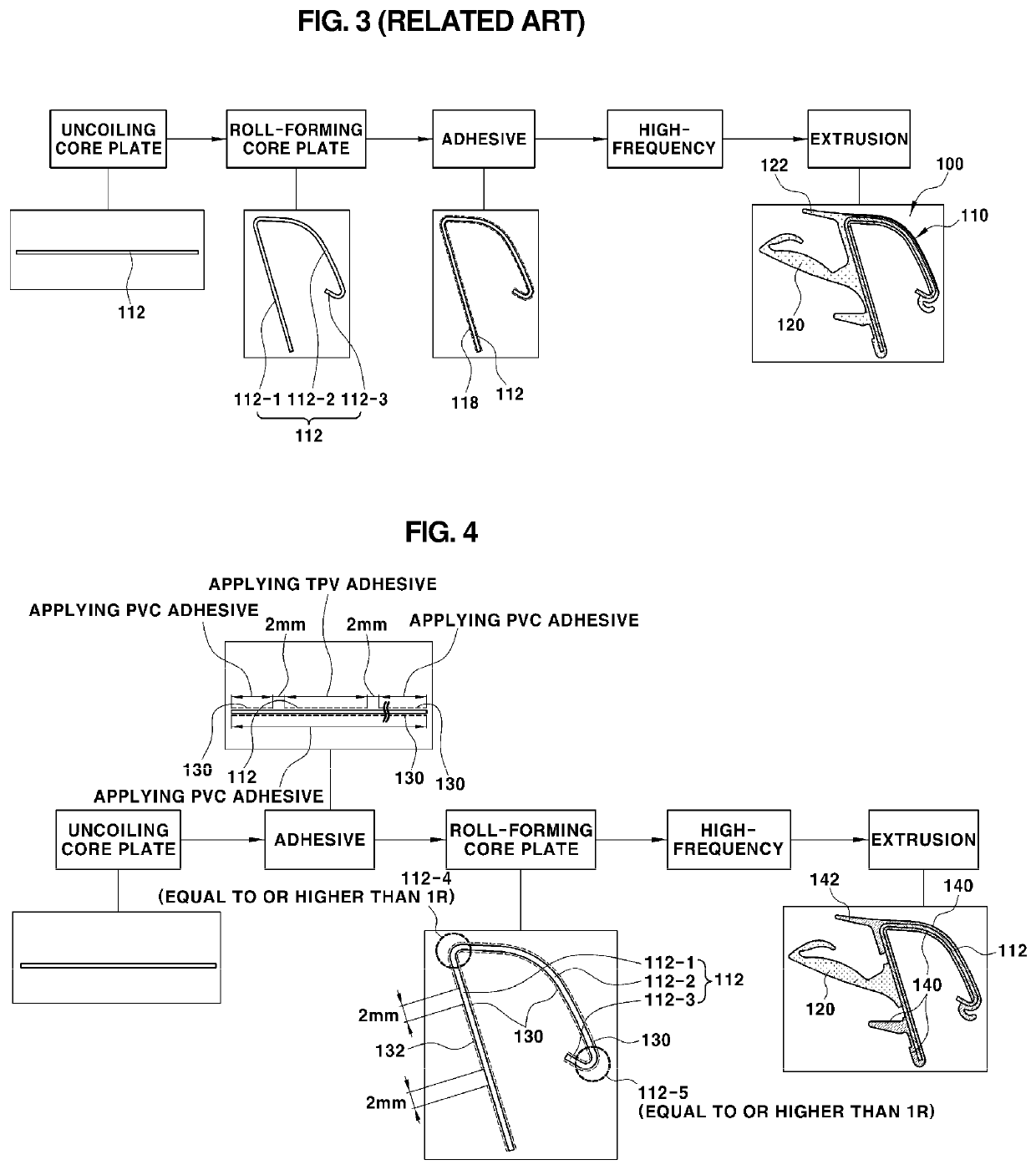

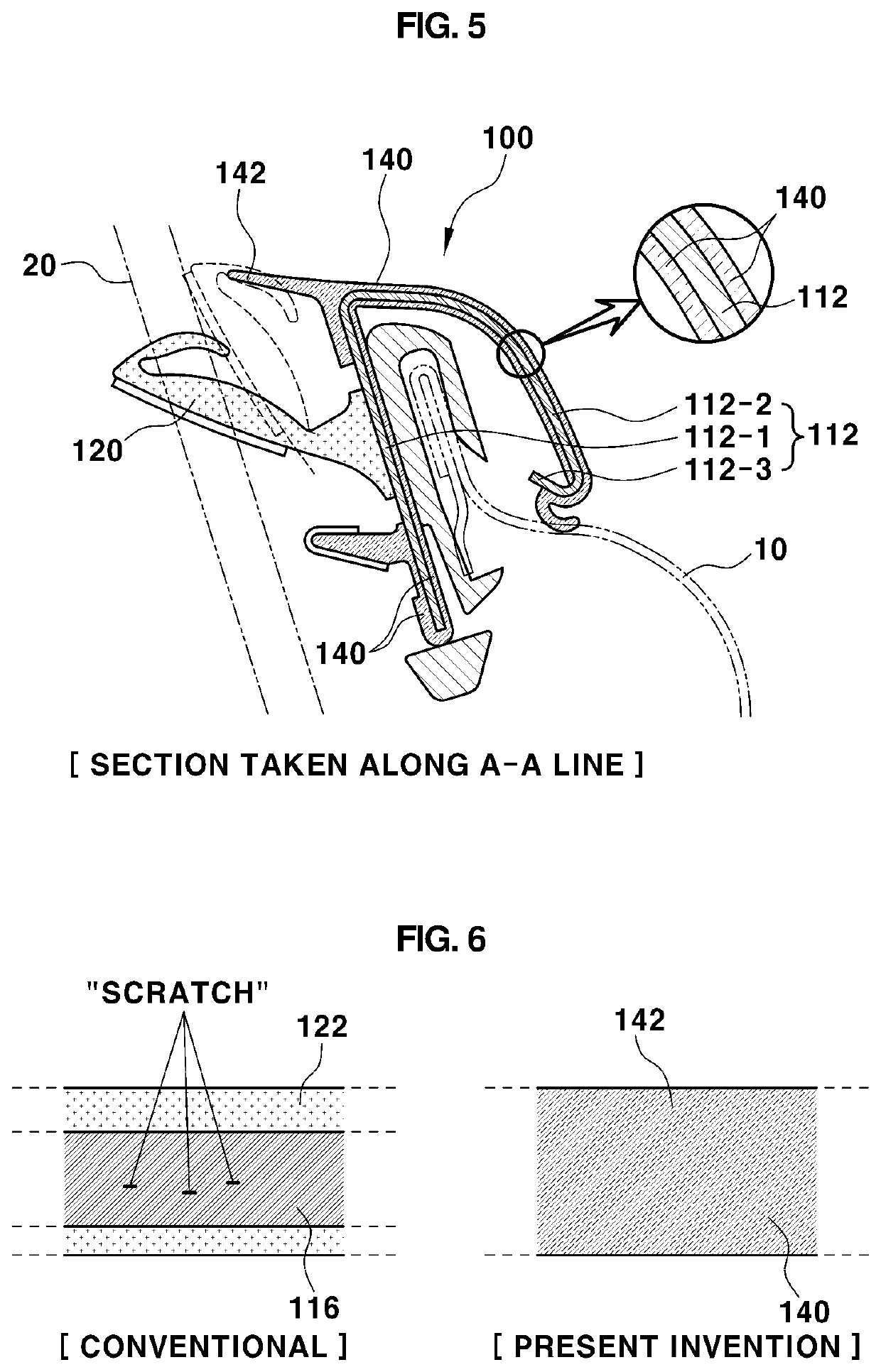

Door outside belt for vehicle

ActiveUS20200338969A1Improve scratch resistanceGood lookingEngine sealsVehicle sealing arrangementsHybrid typeCompression set

A hybrid-type door outside belt for a vehicle utilizes different materials for a skin layer of a skin body that is mounted to an upper end of a door panel and a main wing that is moved by contacting the door glass, the skin layer of the skin body being made of a material having excellent scratch-resistance, and the main wing being made of a material having excellent compression set (deformation).

Owner:HYUNDAI MOTOR CO LTD +1

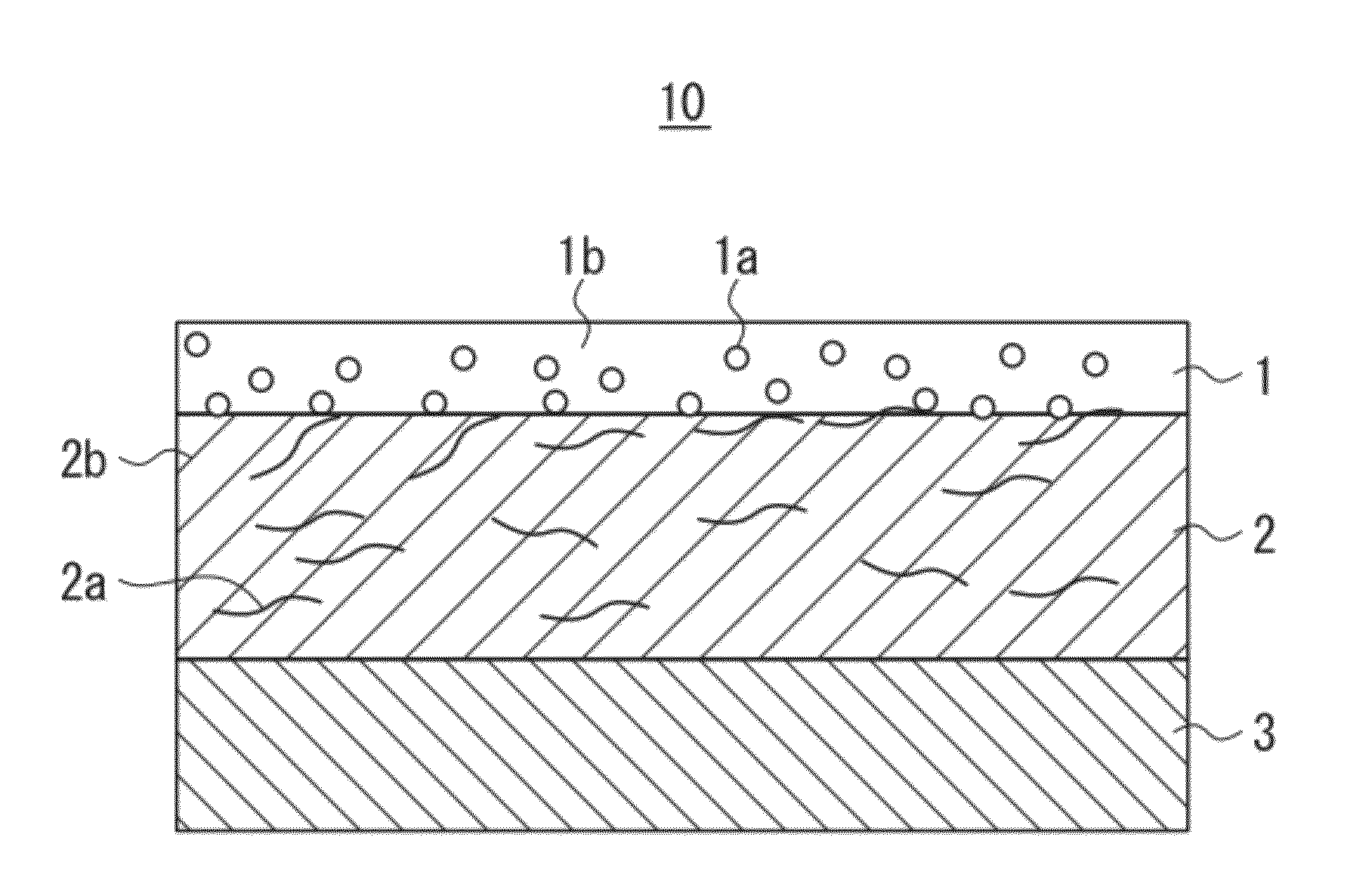

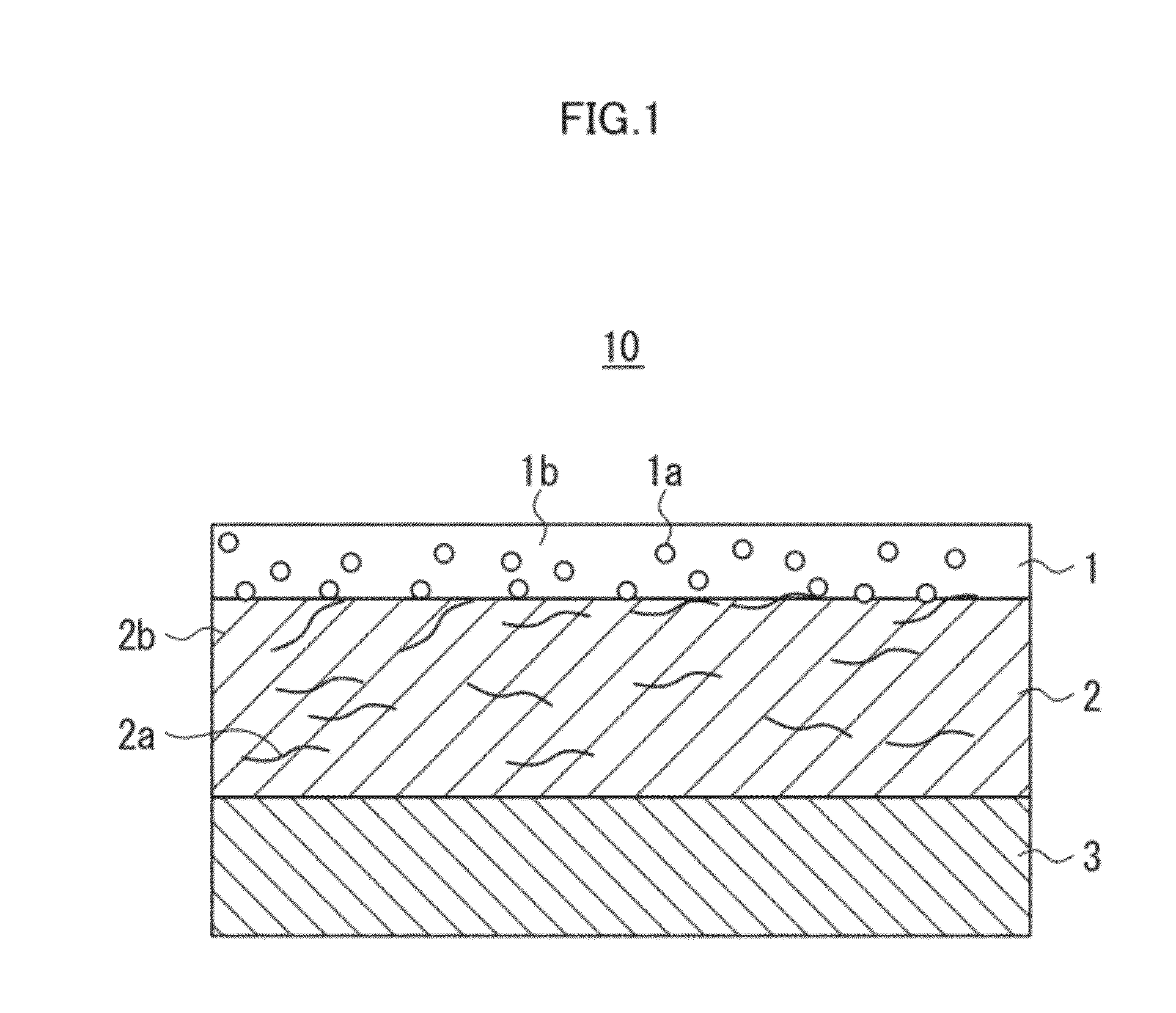

Method for producing laminate film

InactiveUS20120225211A1Reduce concentrationAvoid mixing togetherPretreated surfacesNanoopticsOrganic solventMultiple layer

In a method for producing a laminate film, a first coating fluid containing a first organic solvent in which particles having a first charge are dispersed and a second coating fluid containing a second organic solvent in which a binder having a second charge opposite to the first charge is dissolved are applied on one surface of a running support by wet-on-wet multilayer coating to form a second coating film and a first coating film, and the particles and the binder are gelated by neutralization between the charges to form a gelled layer. This method enables to prevent the first coating fluid and the second coating fluid from being mixed together.

Owner:FUJIFILM CORP

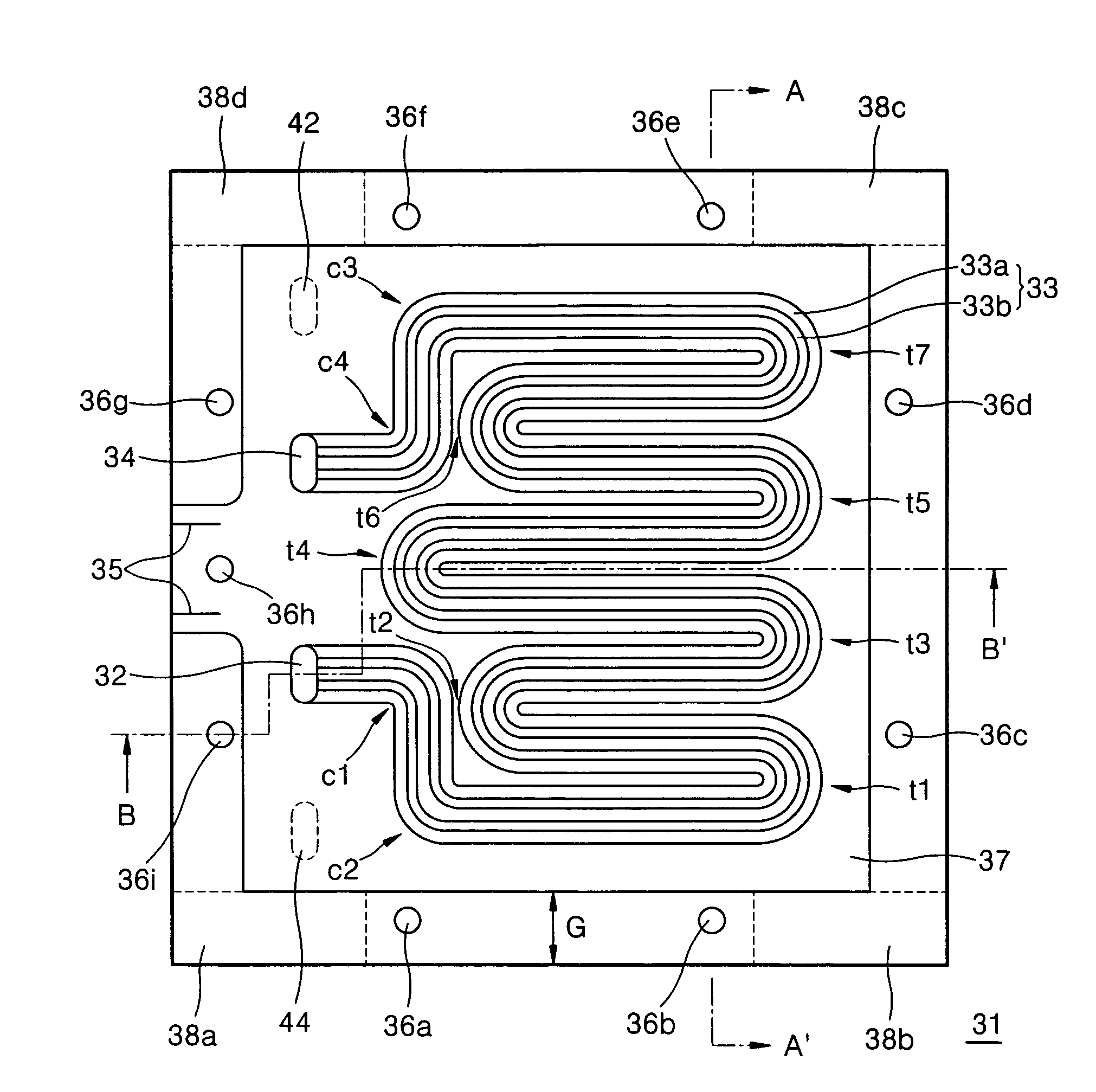

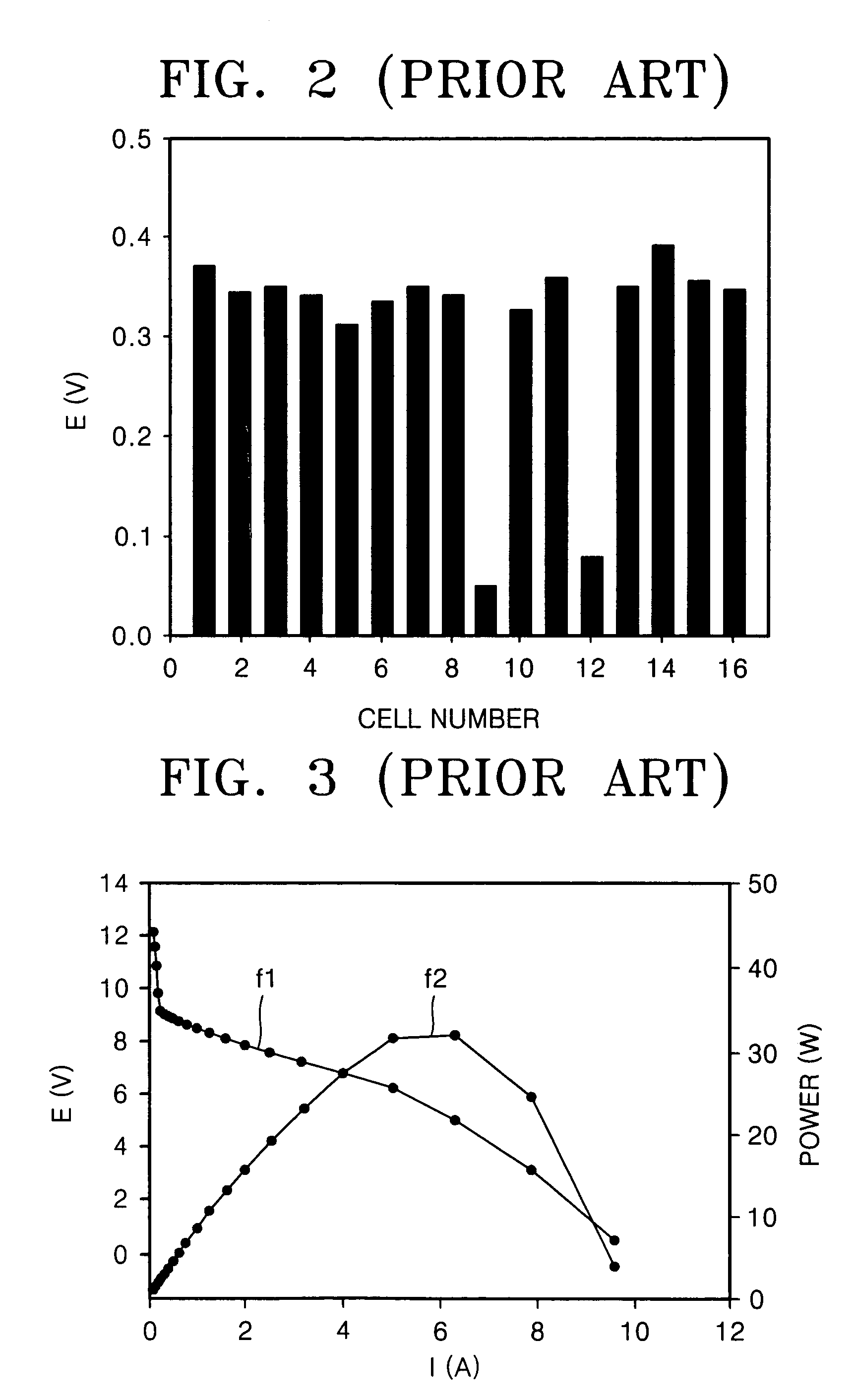

Bipolar plate and fuel cell including the same

InactiveUS7335438B2Reduce variationEasy dischargeCell electrodesFinal product manufactureInternal pressureFuel cells

A bipolar plate and a fuel cell using the same are provided. The bipolar plate includes a flow field that has a length between three and eight times greater than the square of the area of the bipolar plate. The fuel cell includes a first bipolar plate in which a fuel flow field having a length that is between three and eight times greater than the square of the area of the first bipolar plate is formed, and a second bipolar plate in which an air flow field having a length that is between three and eight times greater than the spare of the area of the second bipolar plate is formed. The fuel cell has a lower, uniform internal pressure and can produce a greater power.

Owner:SAMSUNG SDI CO LTD

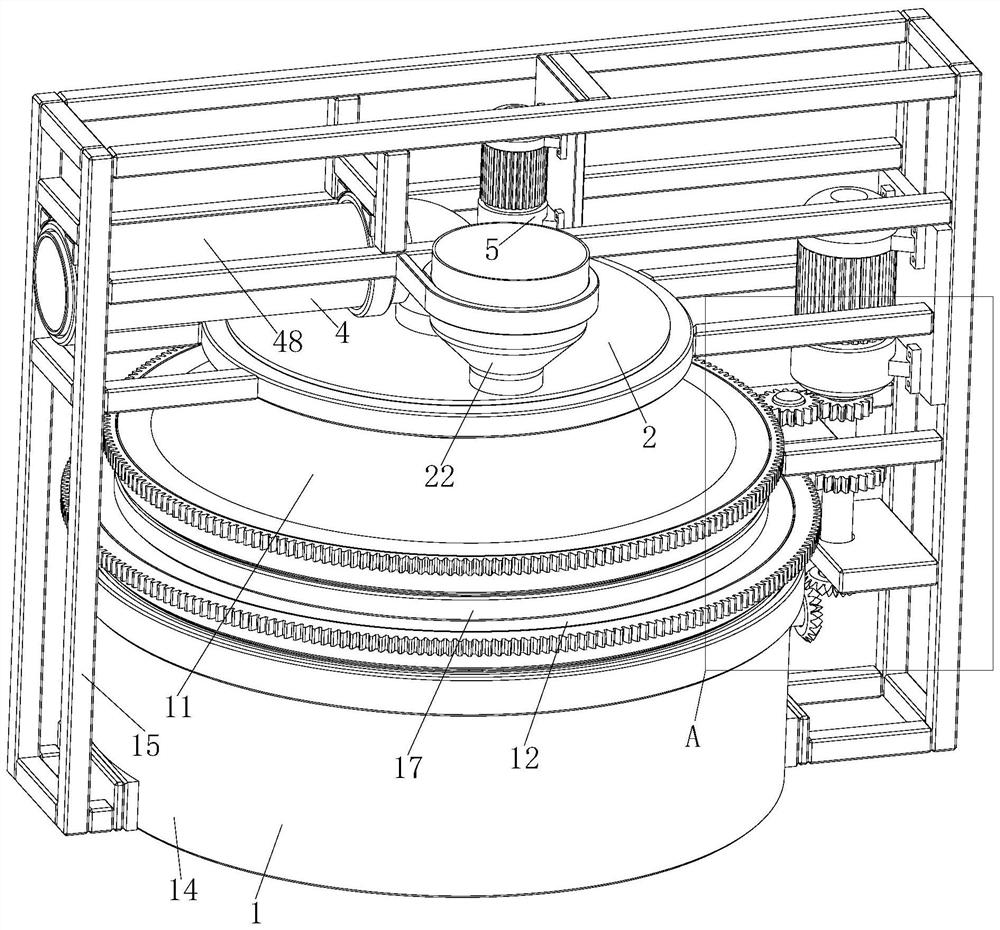

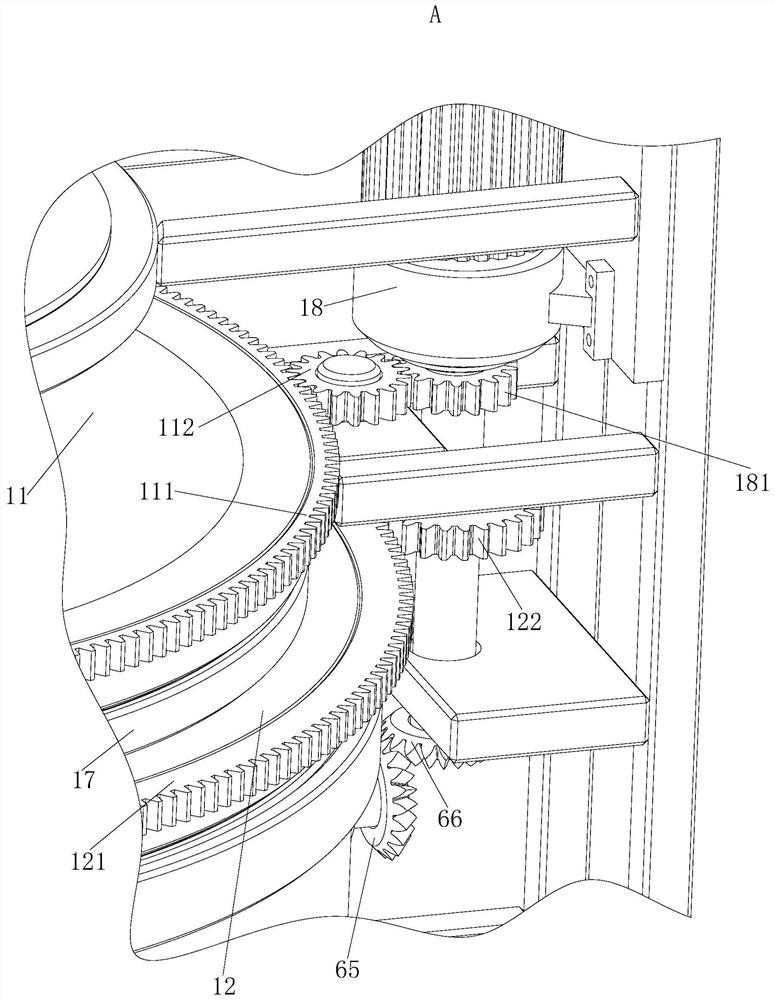

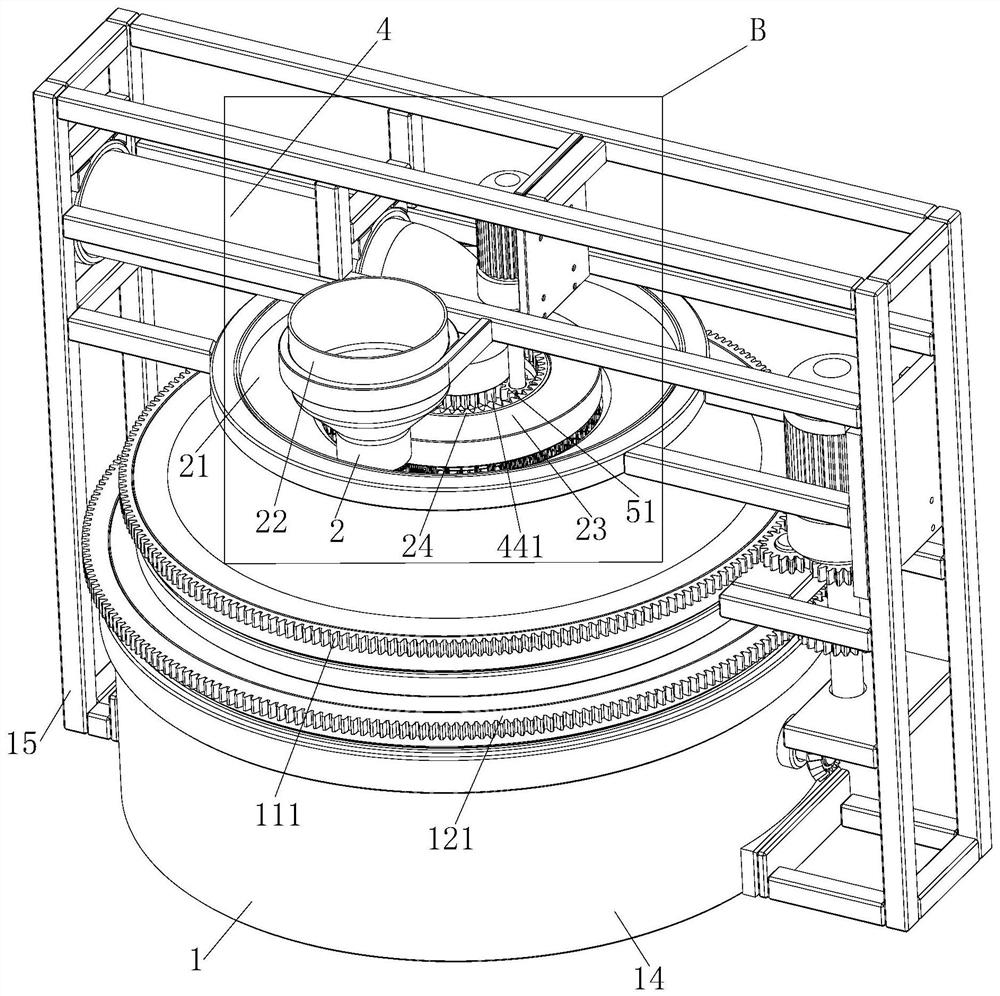

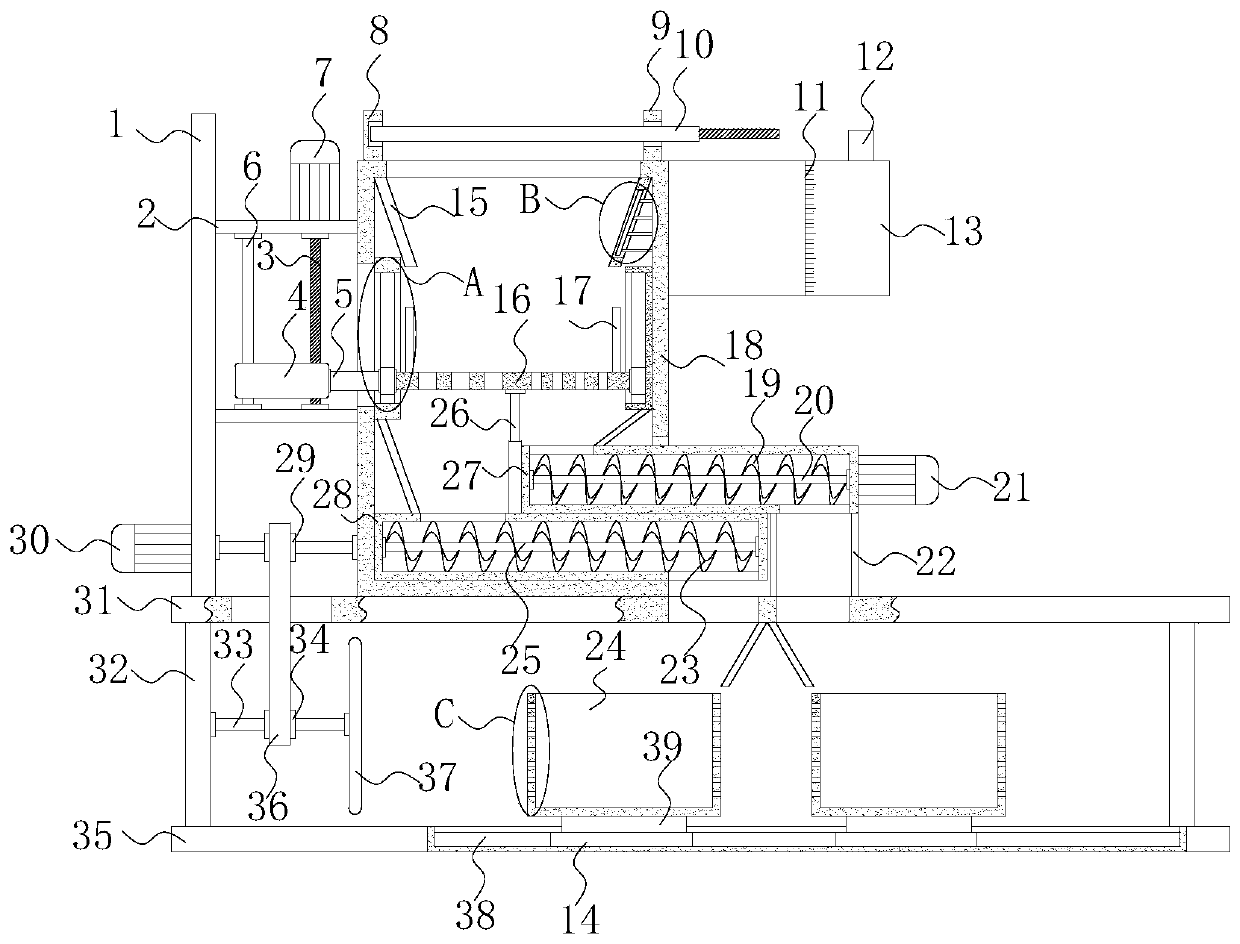

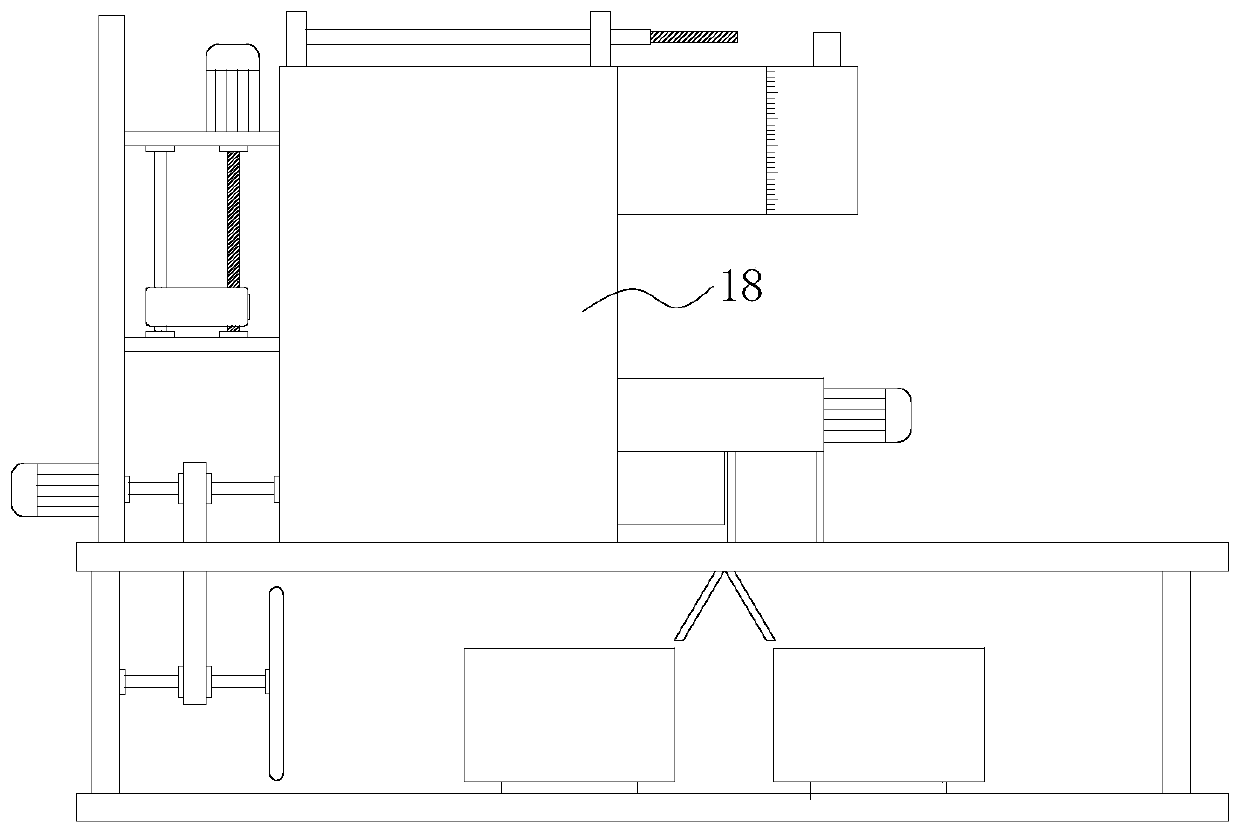

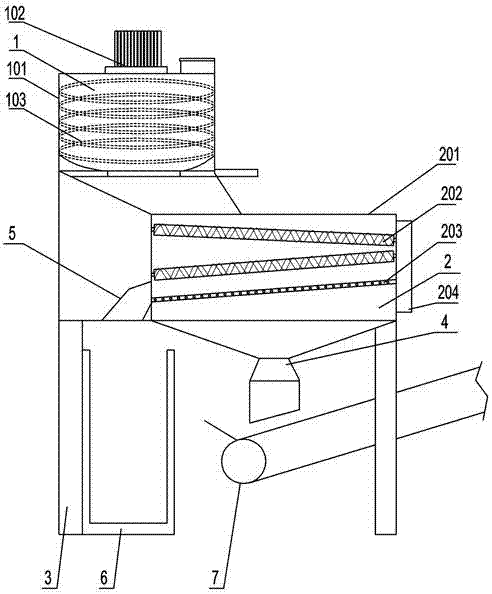

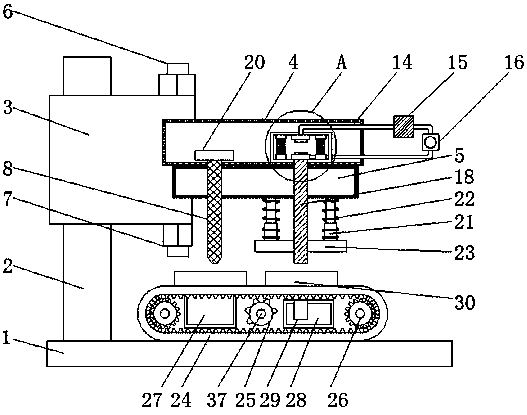

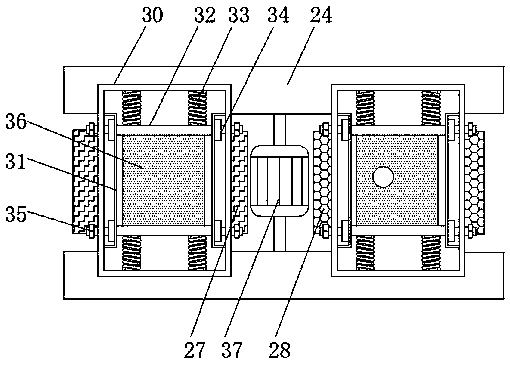

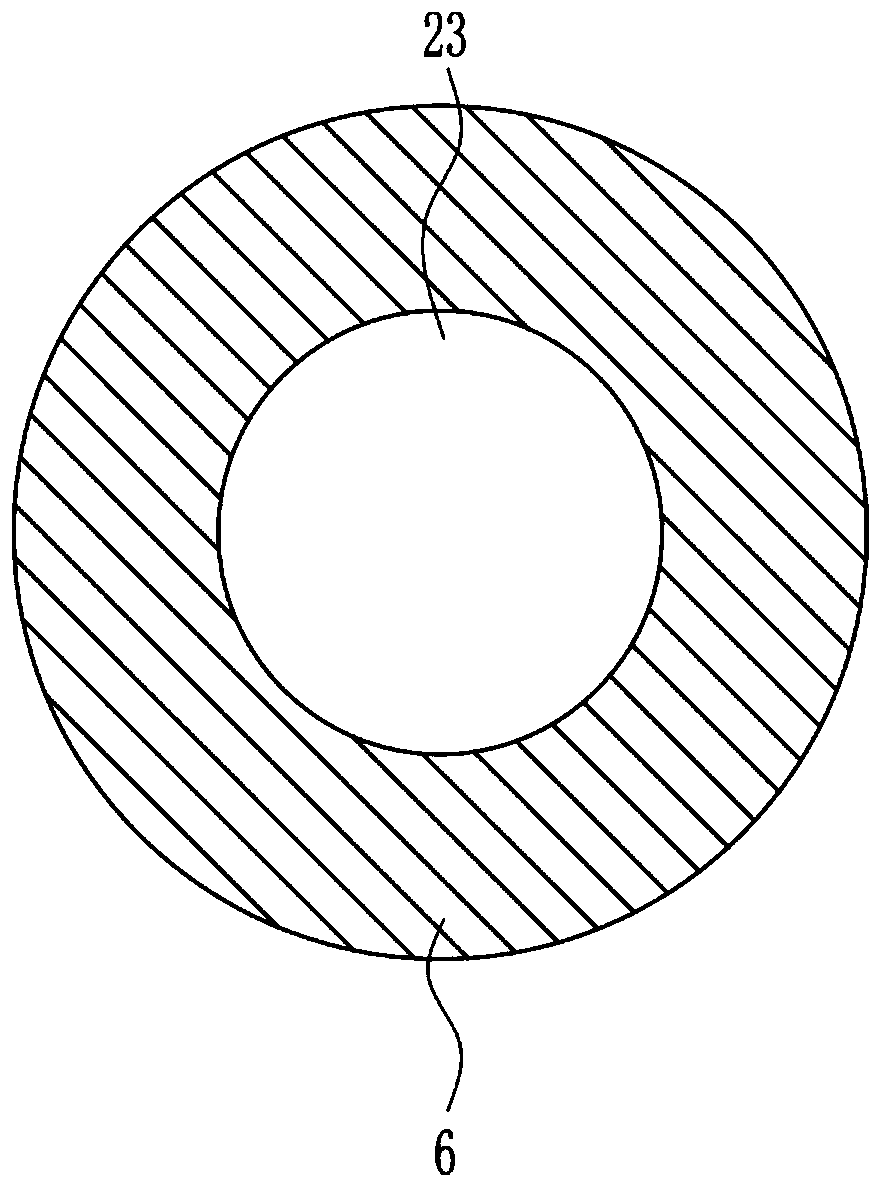

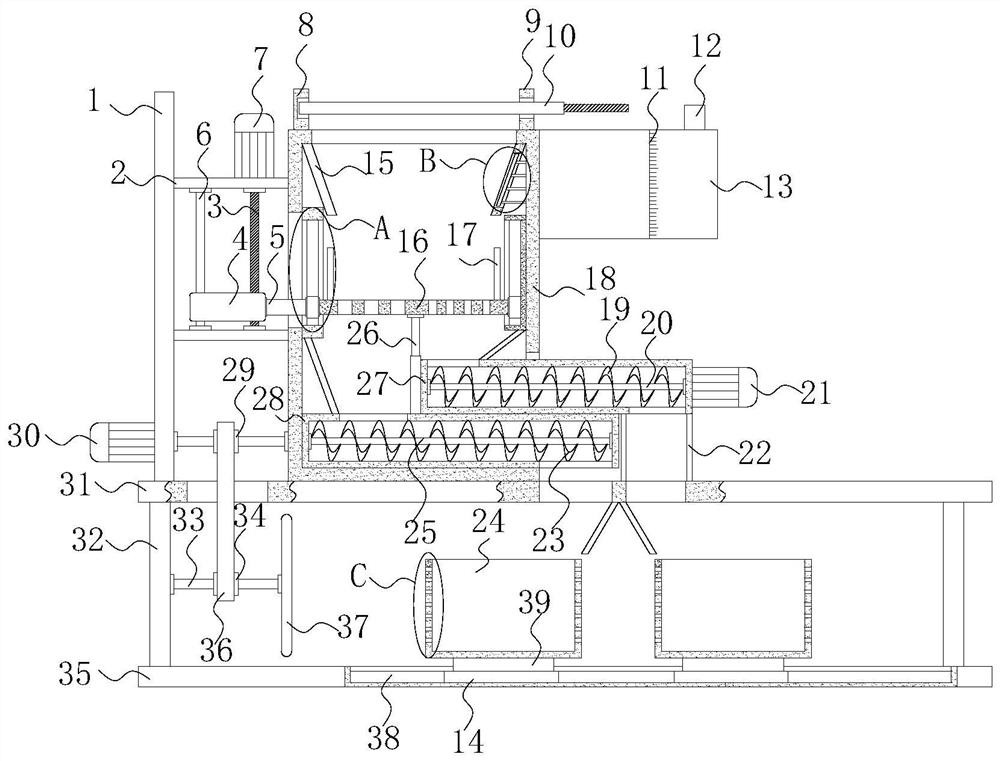

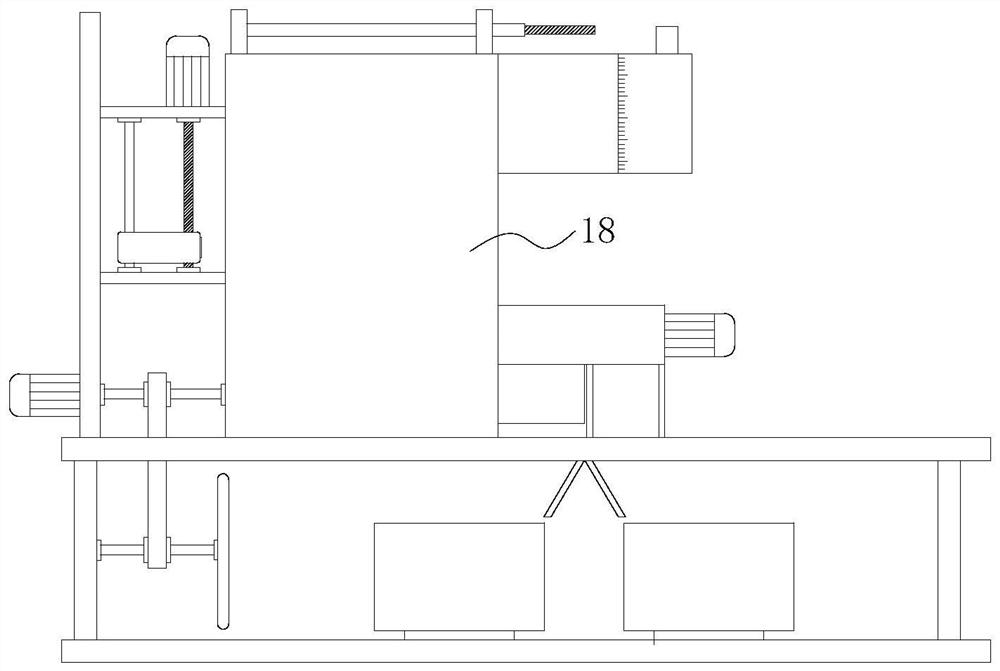

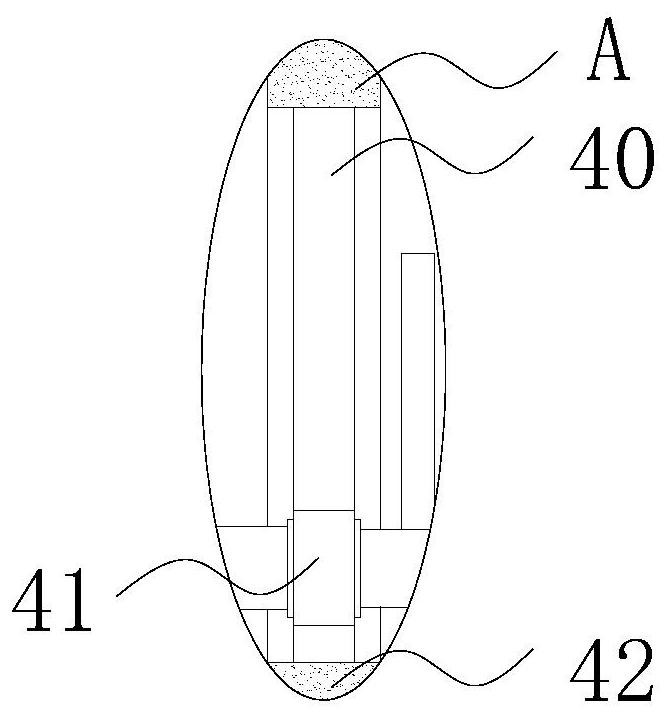

Double-millstone type circulating grinding machine for new material production

InactiveCN112934329AImprove qualityIncrease the speed differenceGrain treatmentsGear wheelElectric machinery

The invention belongs to the technical field of new materials, and particularly relates to a double-millstone type circulating grinding machine for new material production. The double-millstone type circulating grinding machine comprises a grinding component, a feeding component, a conveying component and a separating component. A first motor drives a first gear and a third gear to rotate, a first gear ring and a second gear ring are driven to rotate in the opposite directions, an upper millstone and a lower millstone are driven to rotate in the opposite directions, and then raw materials are ground. The conveying component conveys the ground powder into the separating component, conveys qualified powder out of a grinding machine, and conveys unqualified powder into the grinding component to be ground again. The upper millstone and the lower millstone rotate in the opposite directions to increase the speed difference between the upper surface and the lower surface of the materials, so that the raw materials are fully ground, and the quality of new materials is improved. As the unqualified powder is conveyed into the grinding component to be ground again, the unqualified powder is prevented from being conveyed out of the grinding machine, therefore the qualified rate of the new materials is increased, and the quality of the new materials is further improved.

Owner:邢金丽

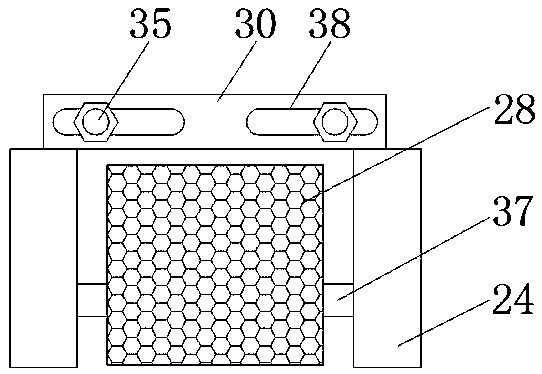

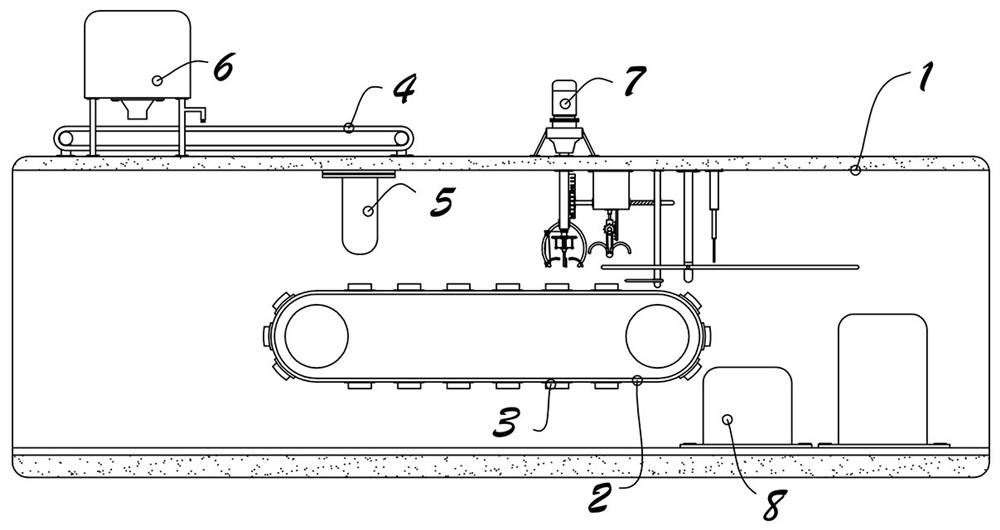

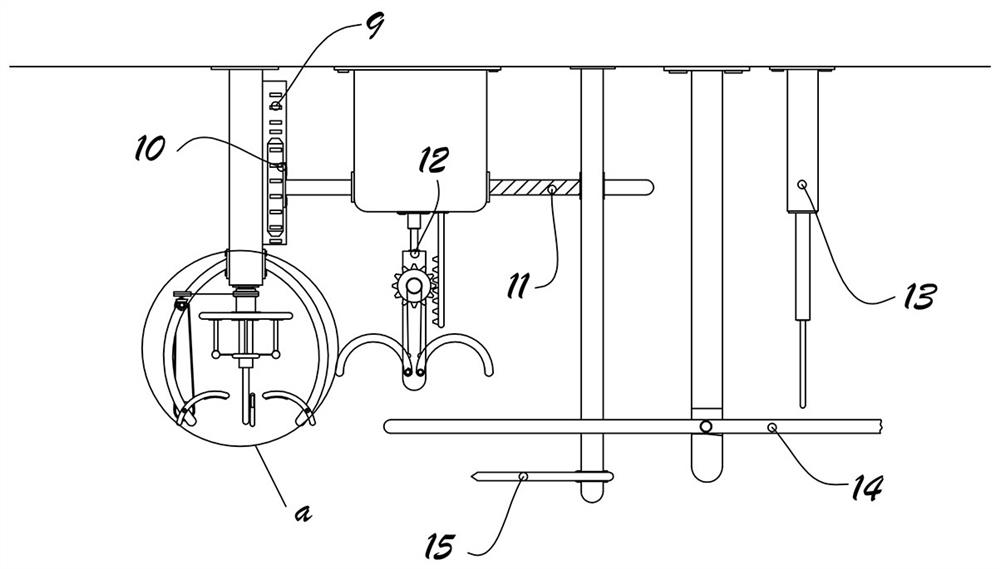

Button screening and sorting device for garment production and machining

ActiveCN110899105AImprove work efficiencyReduce work intensitySievingScreeningElectric machineryStructural engineering

The invention discloses a button screening and sorting device for garment production and machining, and relates to the technical field of button screening. The button screening and sorting device forthe garment production and machining comprises a base, wherein two supporting bases are fixedly mounted on the outer surface of the top of the base, a a top plate is fixedly mounted at the tops of thesupporting bases, a side machine frame and a working box are fixedly mounted on the outer surface of the top of the top plate, fixing plates are fixedly mounted on the outer wall of one side of the side machine frame, first motors are fixedly mounted on the fixing plates, screw rods are rotatably mounted on the adjacent inner walls of the fixing plates, sliding rods are fixedly mounted on the adjacent inner walls of the fixing plates, output shafts of the first motors penetrate through the fixing plates and are fixedly connected with the screw rods, moving blocks are arranged between the screw rods and the sliding rods, and the moving blocks are in sliding connection with the sliding rods. According to the button screening and sorting device, a traditional manual screening and sorting button mode is replaced, the working efficiency of workers is improved, and the situation that buttons of different specifications are doped together is avoided.

Owner:湖州百源创意产业有限公司

Method for ejecting liquid material, method for manufacturing organic electroluminescense device, and method for manufacturing color filter

ActiveUS7662423B2High positioning accuracyPrecise positioningSolid-state devicesPower drive mechanismsEngineeringOrganic electroluminescence

A method for ejecting a liquid material includes classifying the plurality of nozzles of a head into a plurality of nozzle groups having different landing position accuracies for droplets; and performing ejection includes main scanning for ejecting droplets of the liquid material through selected nozzles while generating relative movement in a main-scanning direction between the head and a target substrate, and sub-scanning for generating relative movement between the head and the target substrate in a sub-scanning direction orthogonal to the main-scanning direction. The main scanning and the sub-scanning are performed separately for each of the plurality of nozzle groups. During the sub-scanning, relative movement is generated in accordance with correction information for the corresponding nozzle group for correcting landing positions of the droplet. During the main scanning, a droplet is ejected through at least one nozzle selected from the corresponding nozzle group.

Owner:KATEEVA

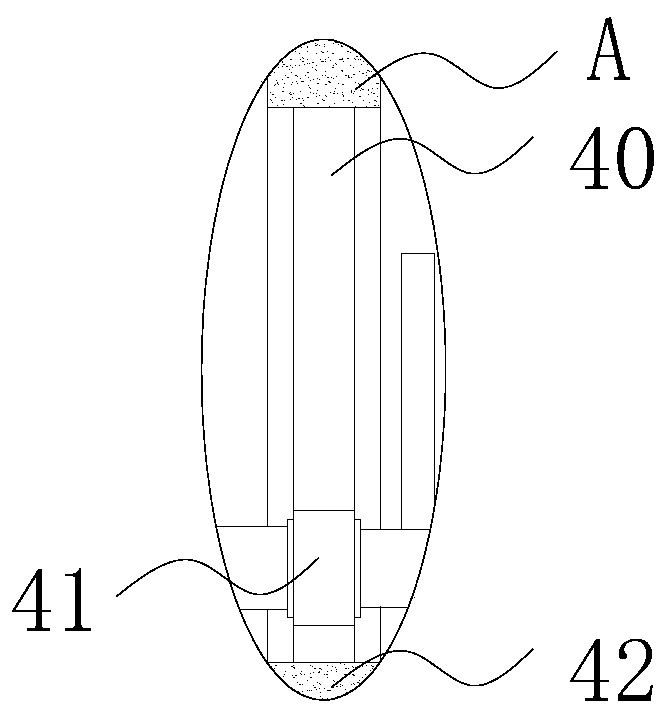

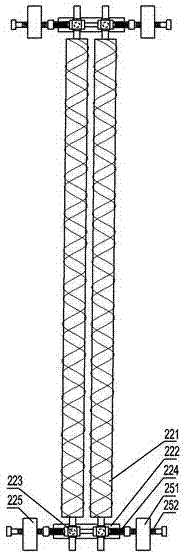

Automatic shelling device of camellia oleifera fruits

InactiveCN107411109APrevent ruptureQuality improvementFatty-oils/fats productionHuskingEngineeringCamellia oleifera

The invention relates to the technical field of processing of camellia oleifera, in particular to an automatic shelling device of camellia oleifera fruits. The automatic shelling device comprises a heating mechanism, a shelling mechanism and a supporting frame, wherein the heating mechanism is fixedly arranged above the shelling mechanism; a discharge end of the heating mechanism communicates with an inner chamber of the shelling mechanism; a discharge opening is formed below the shelling mechanism; the supporting frame is fixedly arranged at the bottom of the shelling mechanism; the shelling mechanism comprises a shelling box body, shelling double-roll mechanisms, a multi-aperture screen mesh and a power mechanism; incline directions of the adjacent two groups of shelling double-roll mechanisms are opposite; the multi-aperture screen mesh is fixedly and obliquely arranged in the shelling box below the bottommost shelling double-roll mechanism; and the power mechanism drives the shelling double-roll mechanisms to rotate. According to the automatic shelling device of camellia oleifera fruits disclosed by the invention, when the camellia oleifera fruits are squeezed out, camellia oleifera seeds cannot burst, so that burst of camellia oleifera seeds during the shelling process of the camellia oleifera fruits can be effectively avoided, and the quality of camellia oleifera products can be greatly improved.

Owner:HUNAN SHENNONG CAMELLIA OLEIFERA TECH DEV

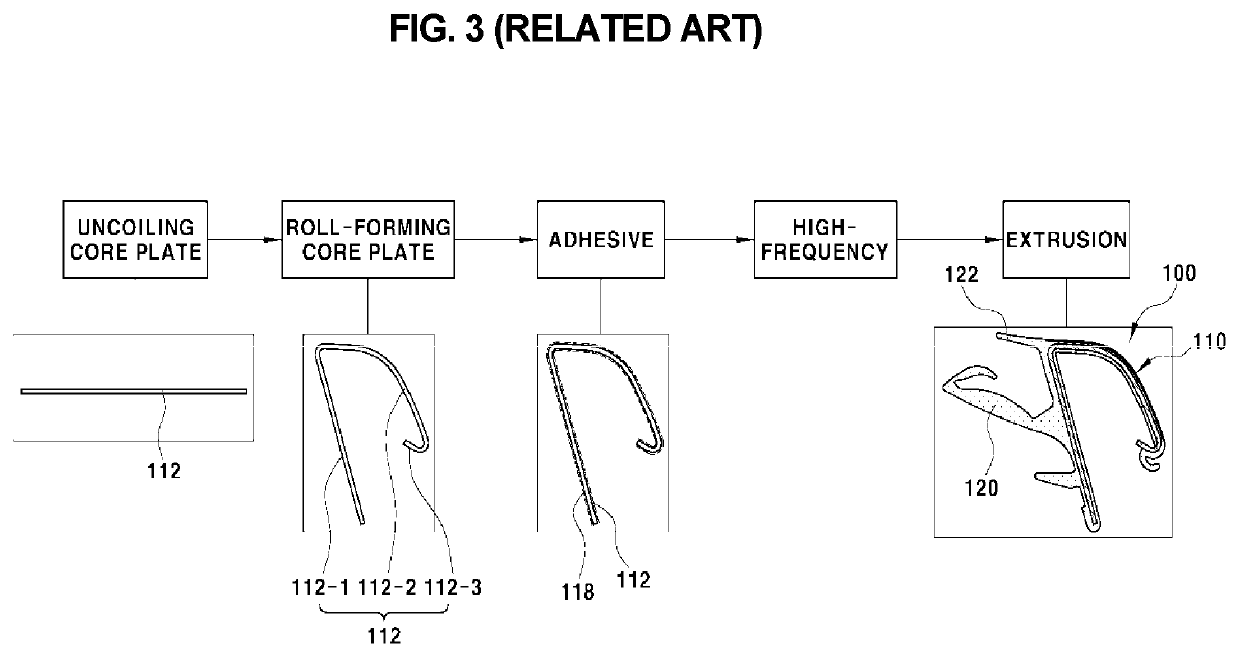

Method for manufacturing door outside belt of vehicle

ActiveUS20200338970A1Improve scratch resistanceGood lookingEngine sealsVehicle sealing arrangementsHybrid typeCompression set

A method for manufacturing a hybrid-type door outside belt of a vehicle utilizes different materials for a skin layer of a skin body that is mounted to an upper end of a door panel and a main wing that is moved by contacting the door glass, the skin layer of the skin body being made of a material having excellent scratch-resistance, and the main wing being made of a material having an excellent compression set (permanent deformation).

Owner:HYUNDAI MOTOR CO LTD +1

Novel continuous mold detection device

InactiveCN108043954ARealize automatic feedingGuaranteed accuracyShaping toolsMetal-working feeding devicesPunchingEngineering

The invention relates to the technical field of continuous molds, and discloses a novel continuous mold detection device, which comprises a base. A hydraulic rod is fixedly arranged on the left side of the top part of the base; a clamped fixing block is fixedly sleeved on the top part of the hydraulic rod; an upper module top plate and an upper module base plate are sequentially and fixedly connected to the right side of the clamped fixing block from top to bottom through a fixing rod; a fixing plate and a detection box are sequentially and fixedly arranged on an inner cavity of the upper module top plate from left to right; and a fixing block is fixedly arranged on the top part of an inner cavity of the detection box. According to the novel continuous mold detection device, through arranging a detection rod, when punching is incomplete, the detection rod cannot penetrates through a mold to enter a limiting slot so as to move upwards, so that a first conductive block and a second conductive block are electrically connected, then an indicator light is powered to emit light, operating personnel can immediately find failed products, defective goods can be clearly seen, the problem that the defective goods and quality goods are mixed is avoided, and the practicability of the device is greatly improved.

Owner:云和县华翎工业设计有限公司

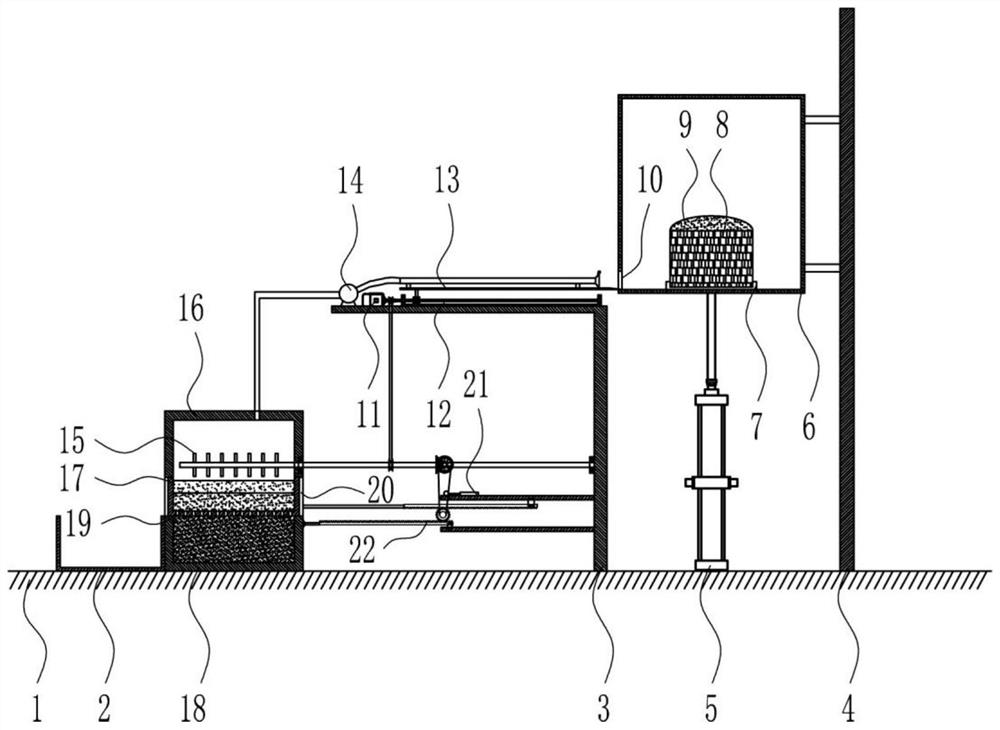

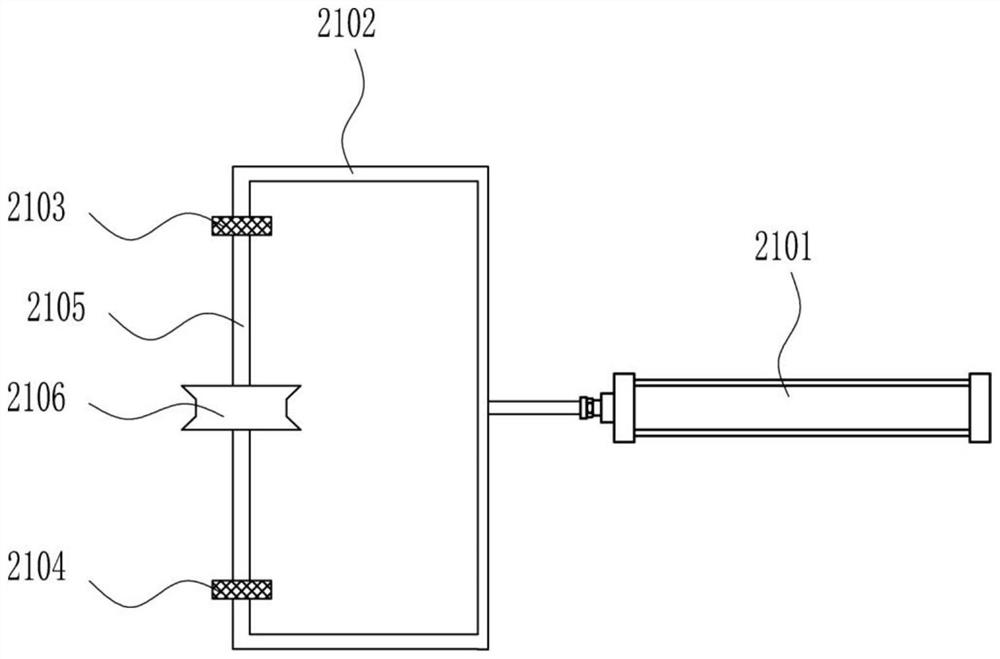

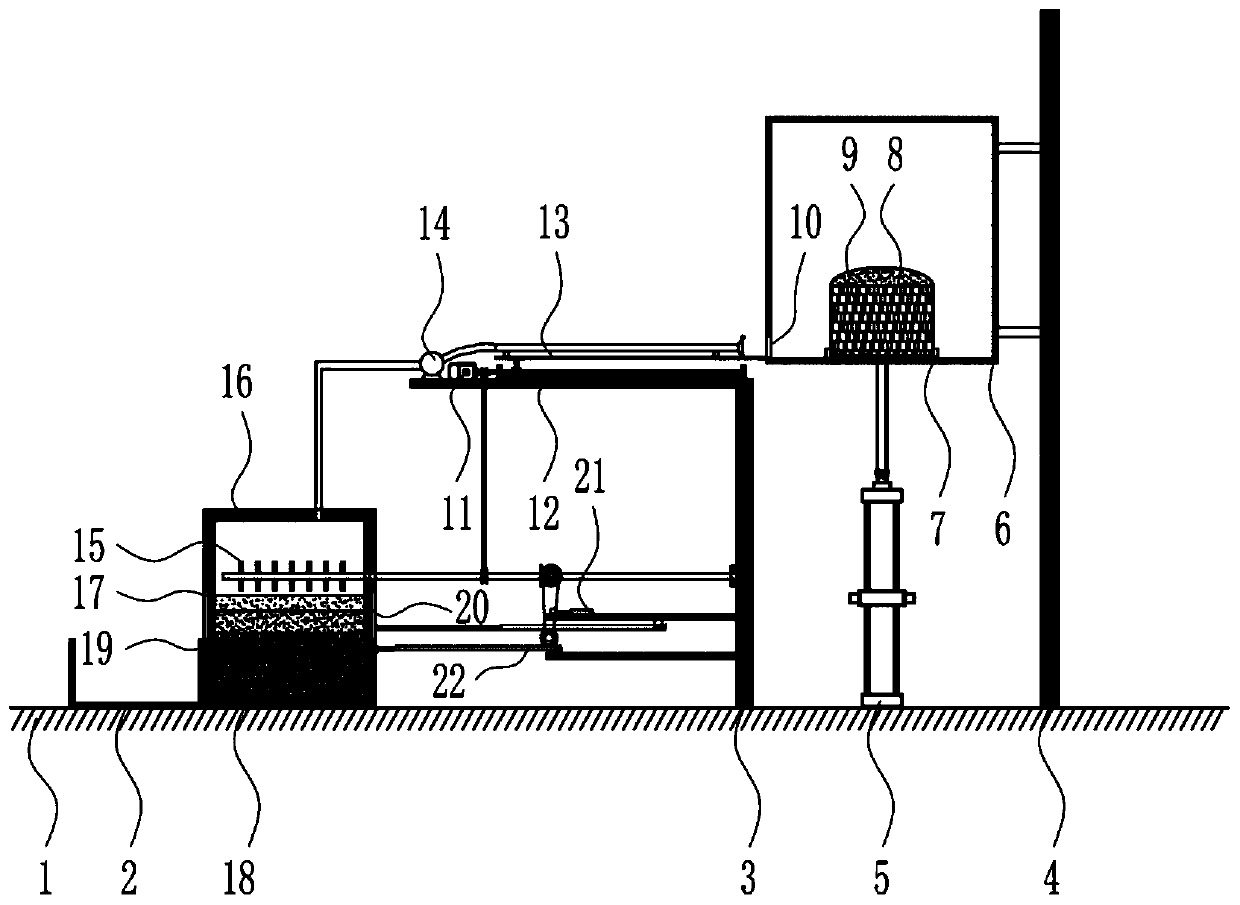

A microbial recovery device

ActiveCN109913370BNot easy to polluteEasy to recycleBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismHydraulic cylinder

The invention belongs to the technical field of microorganisms, and in particular relates to a microorganism recovery device. The technical problem to be solved by the present invention is to provide a microorganism recovery device capable of recovering excrement, saving power and not easily polluting the culture medium. In order to solve the above technical problems, the present invention provides such a microorganism recovery equipment, including a recovery tank, a first rack, a second rack, a hydraulic cylinder, a constant temperature incubator, a placing tray, a rebound door, a motor, and a moving mechanism , slicing, suction mechanism, breaking mechanism, recovery reaction box, first loading tank, second loading tank, tensioning mechanism and push-pull mechanism; the ground is sequentially fixed with a first frame, a hydraulic cylinder and a second Rack, a recovery reaction box is placed on the ground near the first rack. The invention achieves the effects of being able to recover the excrement, saving power, not easily polluting the culture medium, and easily recovering the microorganisms in the excrement.

Owner:郭聃洋

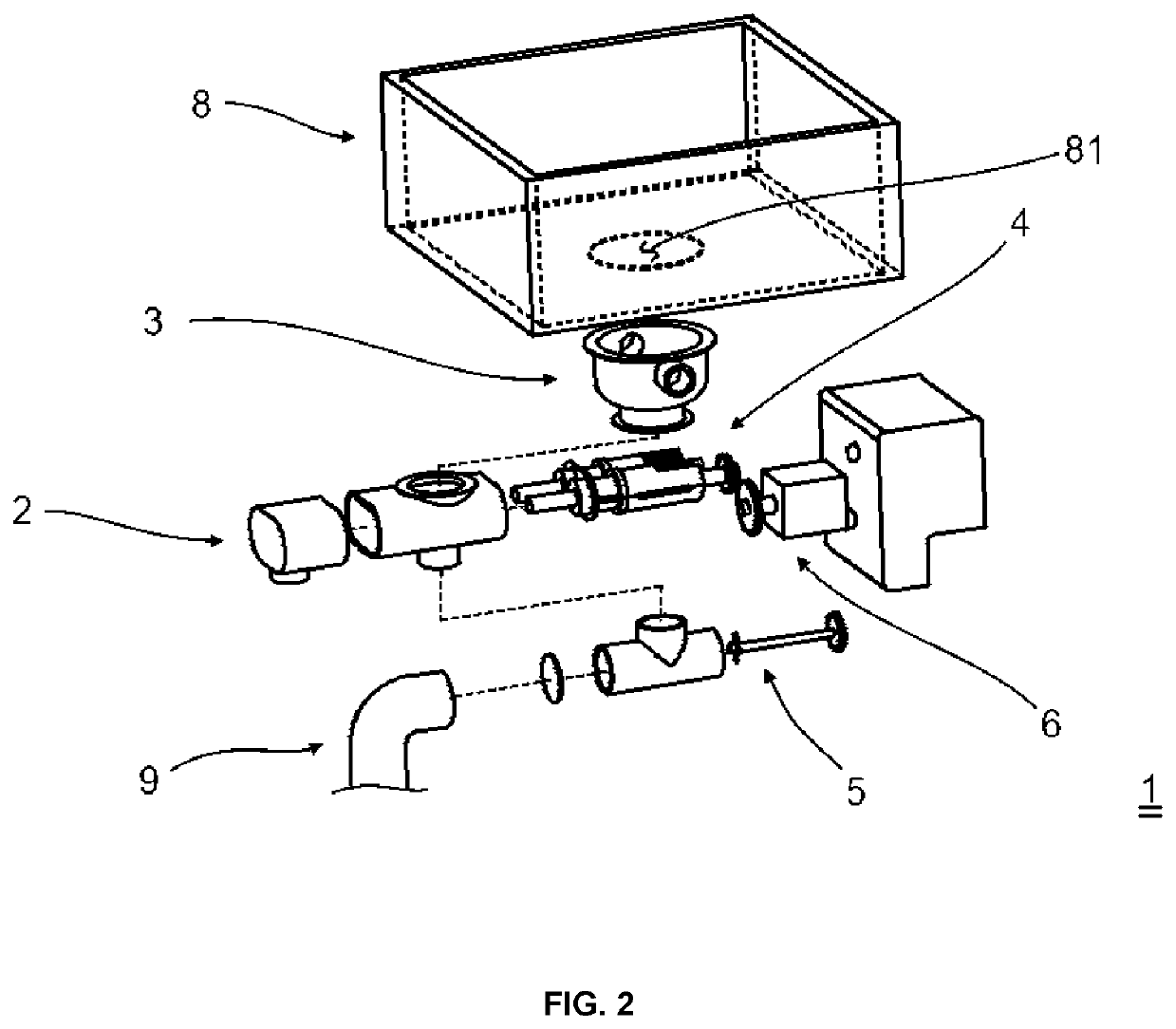

Food waste disposal device

PendingUS20210164209A1Avoid damagePreventing bad smellDomestic plumbingGrain treatmentsGear wheelElectric machinery

The present invention relates to a food waste disposer that is configured to allow an opening and closing plate adapted to open and close a drain pipe to be open only when a motor operates, so that normally, the drain pipe from which water is discharged is closed, thereby preventing bad smell and sewage from flowing backward from the drain pipe, to allow a propeller adapted to forcedly discharge the water from a casing to the drain pipe to be driven reversely and to thus close the opening and closing plate if the motor is driven reversely, so that gears inside a pulverizing part rotate to circulate the water in the casing and thus to automatically clean the casing, without any separation of the casing, and to allow a magnetic material to be built in a hopper so that if iron introduced into the hopper is sensed by sensors, the pulverizing part stops working and is thus prevented from being damaged by the iron.

Owner:WARM DREAM CO LTD

Printing apparatus and control method of printing apparatus

ActiveUS9665806B2Low costAppropriate performanceVisual presentation using printersOther printing apparatusPrinting inkInformation acquisition

Owner:SEIKO EPSON CORP

Microbial recycling equipment

ActiveCN109913370ANot easy to polluteEasy to recycleBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismHydraulic cylinder

The invention belongs to the technical field of microorganisms, and particularly relates to microbial recycling equipment which can recycle excreta and save power and is less prone to contaminating culture media. The microbial recycling equipment comprises a recycling tank, a first rack, a second rack, a hydraulic cylinder, a constant-temperature culture box, a placement tray, a rebound door, a motor, a moving mechanism, a slice, a suction mechanism, a scattering mechanism, a recycling reaction box, a first loading tank, a second loading tank, a tensioning mechanism and a push-pull mechanism,the first rack, the hydraulic cylinder and the second rack are fixedly connected on the ground sequentially, and the recycling reaction box is placed on the ground close to the first rack. The microbial recycling equipment has the advantages of being capable of recycling the excreta and saving power, less prone to contaminating the culture media and easy in recycling microorganisms in the excreta.

Owner:郭聃洋

A button screening and sorting device for garment production and processing

ActiveCN110899105BImprove work efficiencyReduce work intensitySievingScreeningElectric machineryEngineering

The invention discloses a button screening and sorting device for garment production and processing, and relates to the technical field of button screening. The button screening and sorting device for clothing production and processing includes a base, the top outer surface of the base is fixedly installed with support seats, the number of support seats is two, the top of the support seats is fixedly installed with a top plate, and the top outer surface of the top plate is fixedly installed There are side frame and work box, one side outer wall of the side frame is fixedly installed with a fixed plate, the number of fixed plates is two, the first motor is fixedly installed on the fixed plate, and the adjacent inner wall of the fixed plate is rotatably installed with a screw rod and A sliding rod is fixedly installed, the output shaft of the first motor runs through the fixed plate and is fixedly connected with the screw rod, a moving block is arranged between the screw rod and the sliding rod, and the moving block is slidably connected with the sliding rod. The invention replaces the traditional way of manually screening and sorting buttons, improves the work efficiency of staff, and avoids the situation that buttons of different specifications are mixed together.

Owner:湖州爆米花信息科技有限公司

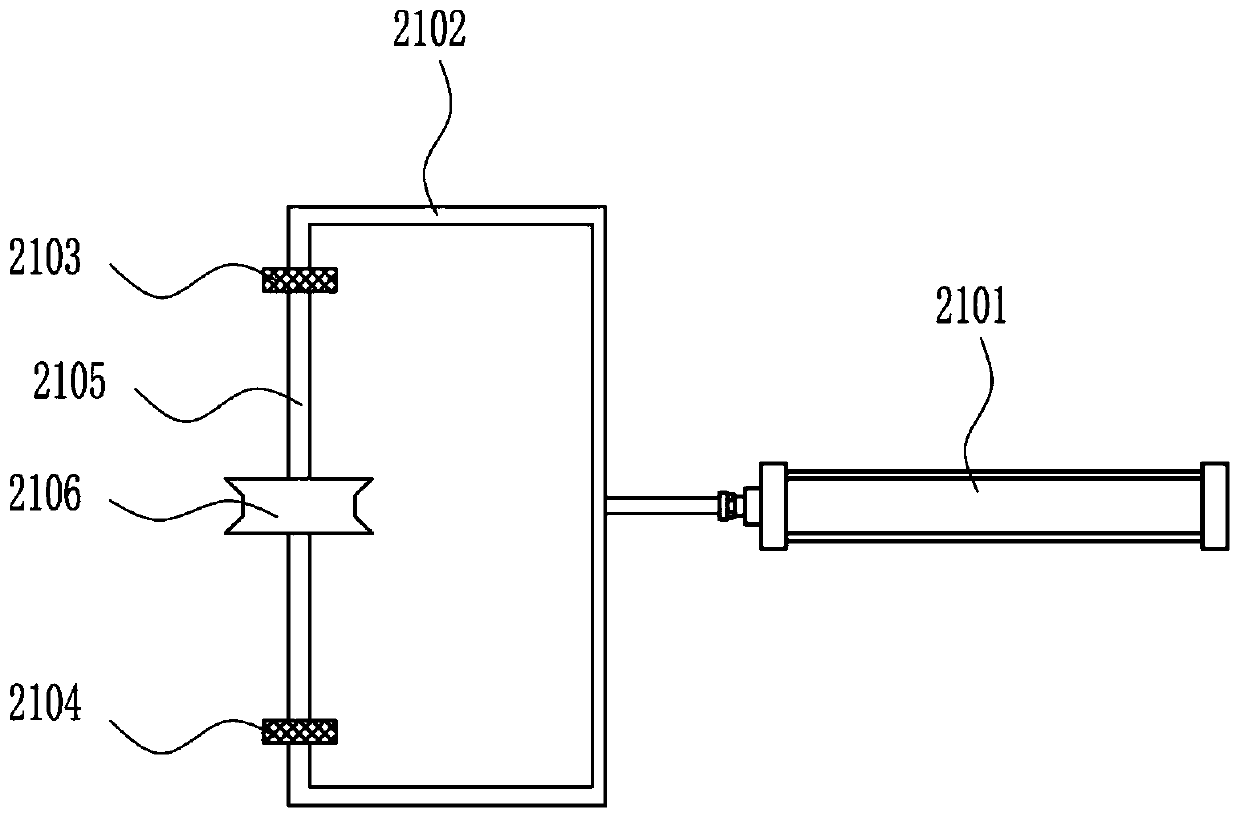

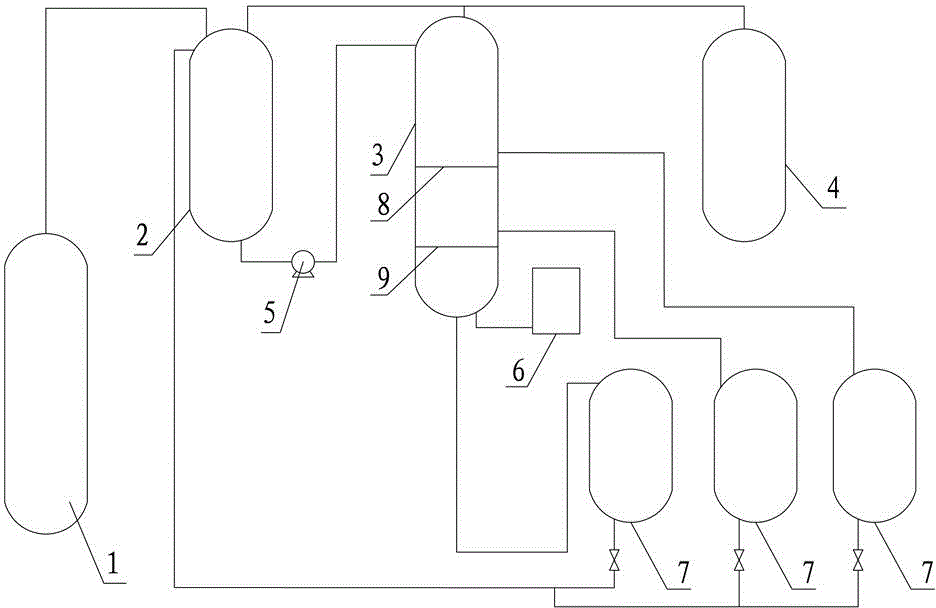

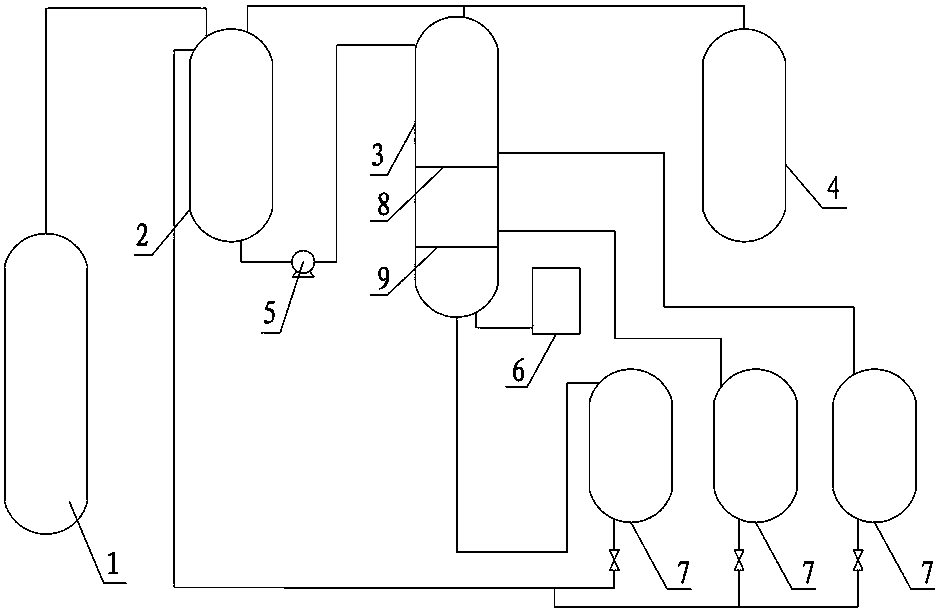

A kind of process improvement system for preparing hydroxy ester

ActiveCN103936584BAvoid mixing togetherAvoid cloggingOrganic compound preparationCarboxylic acid esters separation/purificationProcess systemsPharmaceutical industry

The invention relates to an improved process system for preparing hydroxyl esters. The improved process system comprises a raw material tank, a pressure pump, a circulation tank, a separation tank, a water tank and a collection tank, wherein the raw material tank is connected with the circulation tank by virtue of the pressure pump pipe, an upper filtering layer and a lower filtering layer are arranged in the separation tank, and the separation tank is divided into three cavities by the upper and lower filtering layers. The process system is applicable to the production in chemical and pharmaceutical industries.

Owner:JIANGSU CHENGXIN PHARMA

Improved process system for preparing hydroxyl esters

ActiveCN103936584AAvoid mixing togetherAvoid cloggingOrganic compound preparationCarboxylic acid esters separation/purificationProcess systemsPharmaceutical industry

The invention relates to an improved process system for preparing hydroxyl esters. The improved process system comprises a raw material tank, a pressure pump, a circulation tank, a separation tank, a water tank and a collection tank, wherein the raw material tank is connected with the circulation tank by virtue of the pressure pump pipe, an upper filtering layer and a lower filtering layer are arranged in the separation tank, and the separation tank is divided into three cavities by the upper and lower filtering layers. The process system is applicable to the production in chemical and pharmaceutical industries.

Owner:JIANGSU CHENGXIN PHARMA

Internal pounding type orange peel separating device for orange juicing

PendingCN114403465AReduce usagePrevent discolorationConveyorsVegetable peelingOrange juiceStructural engineering

The invention discloses an internal smashing type orange peel separating device for orange juicing. A conveying belt facilitating orange moving is arranged in the middle of a support. The limiting columns are arranged on the periphery of the conveying belt, and the interiors of the limiting columns are of concave structures; the collecting frame is arranged on the right side in the support; comprising a conveying pipe installed at the upper left corner of a support, and an upper belt wheel used for conveying oranges is arranged at the upper left corner of the support; and the hydraulic cylinder is arranged in the middle of the upper portion of the support, the lower end of the hydraulic cylinder is provided with a pounding rod for treating the centers of the oranges, and a rotating rotary disc penetrates through the upper portion of the pounding rod. According to the internal pounding type orange peel separation device for orange juicing, orange pulp is prevented from being treated, use of oranges is reduced, orange juice is prevented from splashing, the internal surface of the device is prevented from containing sugar, the device is kept clean, the clamping rods rotate and move, the orange pulp is taken, orange peel separation is thoroughly achieved, and the device is simple in structure, convenient to use and high in practicability. And subsequent manual processing is not needed.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com