A kind of process improvement system for preparing hydroxy ester

A process improvement, hydroxy ester technology, applied in the preparation of carboxylic acid esters, the preparation of organic compounds, the separation/purification of carboxylic acid esters, etc., can solve the problems of improper handling, high cost, environmental pollution, etc., to reduce pollution and avoid The effect of being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technology of the present invention will be further described below in conjunction with the accompanying drawings and specific examples, but the protection scope of the present invention is not limited to the following examples.

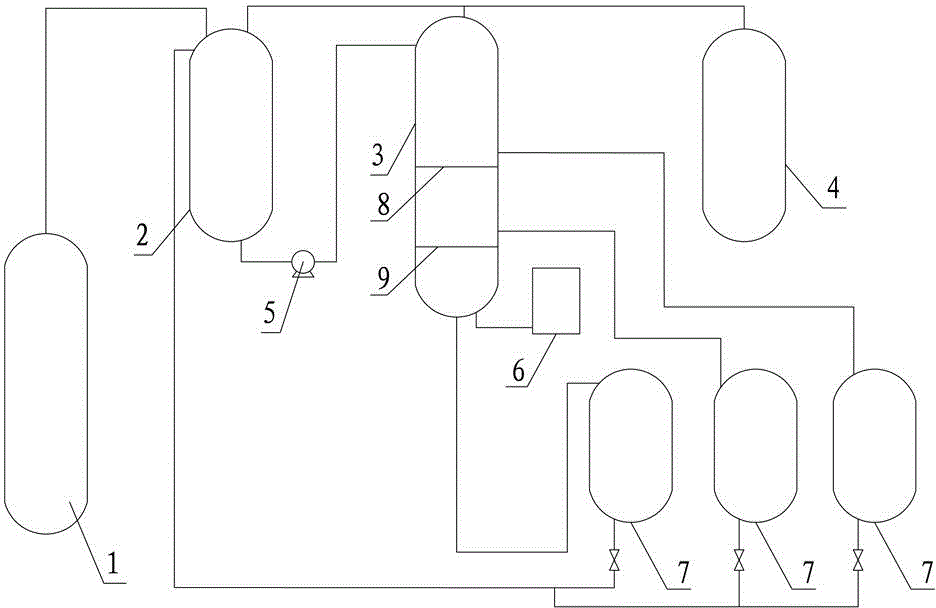

[0011] Such as figure 1 Shown, a kind of process improvement system for preparing hydroxy ester, comprises raw material tank 1, booster pump 5, circulation tank 2, separation tank 3, water tank 4, collecting tank 7, described raw material tank 1 and described The circulation tank 2 is connected by the pressurized pump 5 pipelines, and the upper filter layer 8 and the lower filter layer 9 are set in the described separation tank 3, and the upper filter layer 8 and the lower filter layer 9 separate the separation tank 3 is divided into three cavity parts, and the three cavity parts are respectively connected to the collection tank 7 by pipelines, and there are multiple collection tanks 7.

[0012] The lower end of the separation tank 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com