Piping structure with inner heat exchanger and refrigeration cycle device having the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

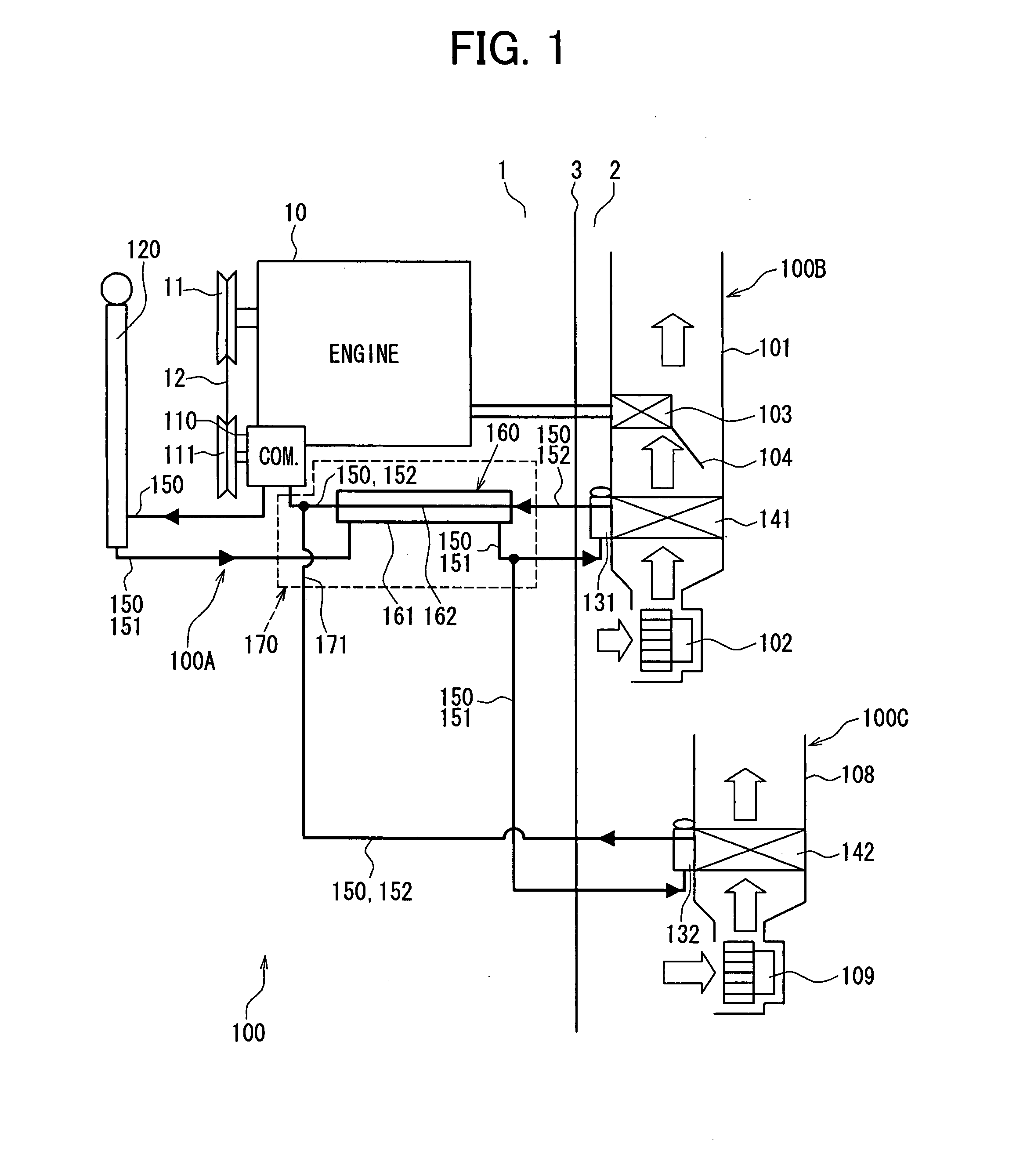

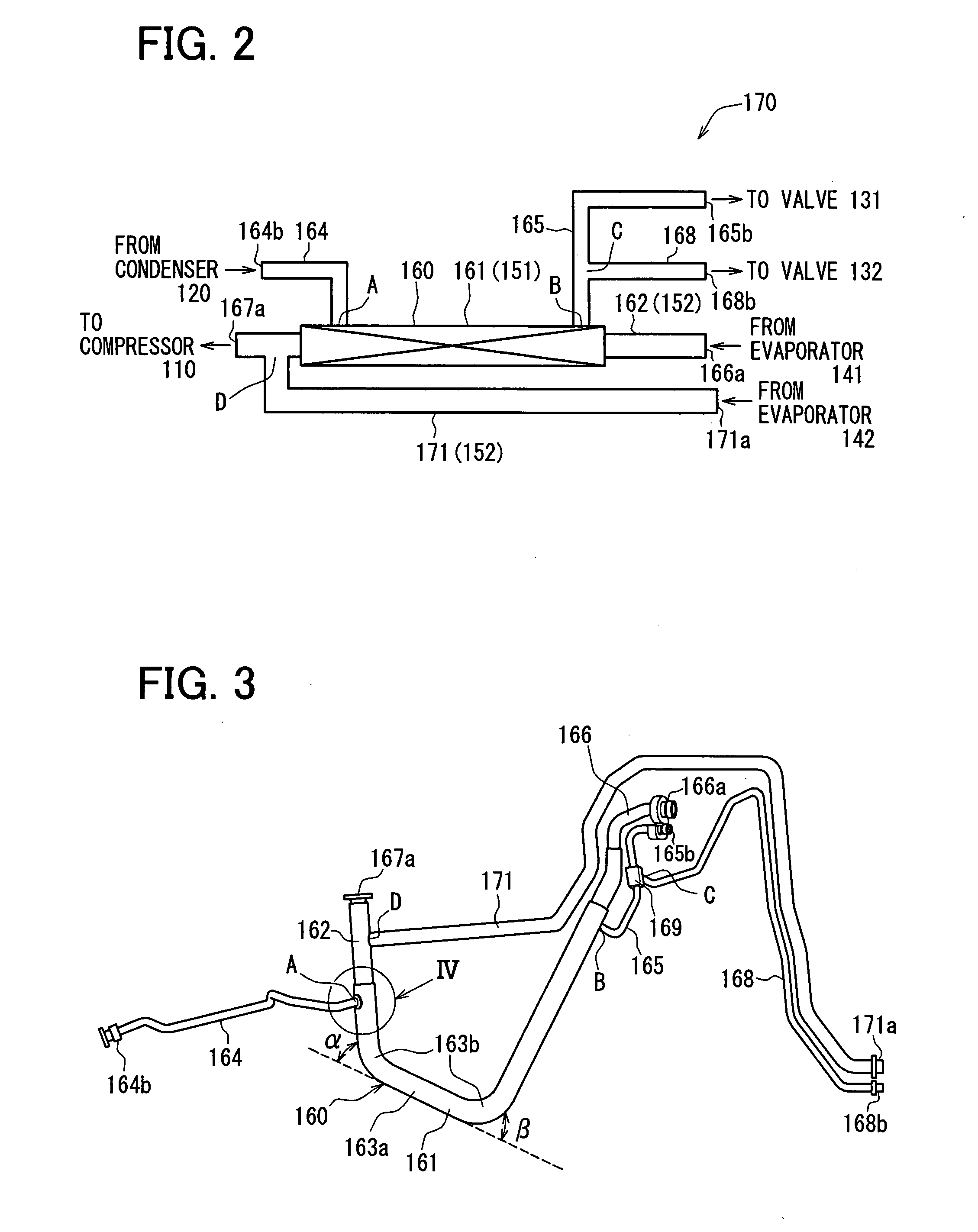

[0026]In this embodiment, a piping structure 170 with an inner heat exchanger in accordance with the present invention and a refrigeration cycle device 100A using the same are typically used for an air conditioner for a vehicle (hereinafter referred to as air conditioner) 100.

[0027]As shown in FIG. 1, a vehicle is partitioned by a dash panel 3 into an engine room 1 in which an engine 10 for a vehicle running is mounted and a vehicle compartment 2 for occupants. Among a refrigeration cycle device 100A and interior units 100B, 100C which construct the air conditioner 100, a part of the refrigeration cycle device 100A (except for expansion valves 131, 132, and evaporators 141, 142 as low-pressure side heat exchangers) is disposed in the engine room 1. The air conditioner 100 in this embodiment is a dual air conditioner provided with two interior units 100B, 100C for the front seat and the rear seat of the vehicle. The interior unit 100B for the front seat is disposed in an instrument p...

second embodiment

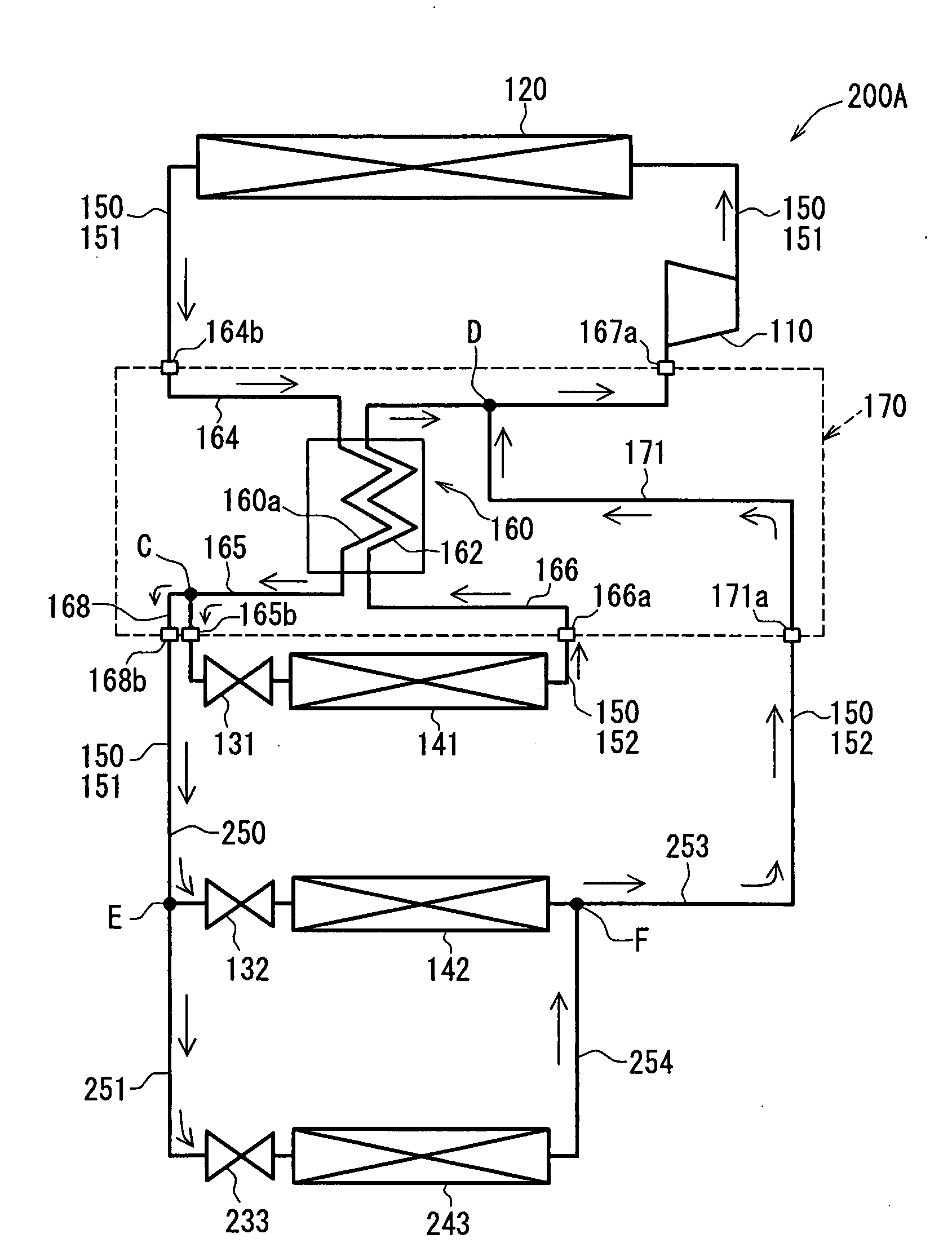

[0056]A second embodiment of the present invention will be described with reference to FIG. 9. In the above-described first embodiment, the piping structure 170 with the inner heat exchanger is applied to the refrigeration cycle device 100A of the dual air conditioner 100 that are provided with the two evaporators 141, 142 for the front seat and the rear seat. In contrast to this, in this embodiment, the piping structure 170 with the inner heat exchanger of the present invention is applied to a refrigeration cycle device 200A of an air conditioner for a vehicle (triple air conditioner) provided with three evaporators 141, 142, and 243 for the front seat, the rear seat, and a cool box.

[0057]The piping structure 170 with the inner heat exchanger in this embodiment has the same construction as in the first embodiment shown in FIG. 2 to FIG. 4, and the condenser 120, the compressor 110, the front expansion valve 131, the front evaporator 141 are connected to the joints 164b, 167a, 165b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com