Air total heat exchanger for changing runner to improve efficiency

A technology of total heat exchanger and total heat exchange core, applied in the field of air total heat exchanger, can solve the problems of localized air distribution concentration, thinness, and affecting the heat exchange efficiency of total heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. It should be noted that the content of the present invention is not limited to these specific embodiments. On the premise of not departing from the background and spirit of the present invention, those skilled in the art can make equivalent replacements and modifications on the basis of reading the content of the present invention, and the content is also included in the scope of protection of the present invention.

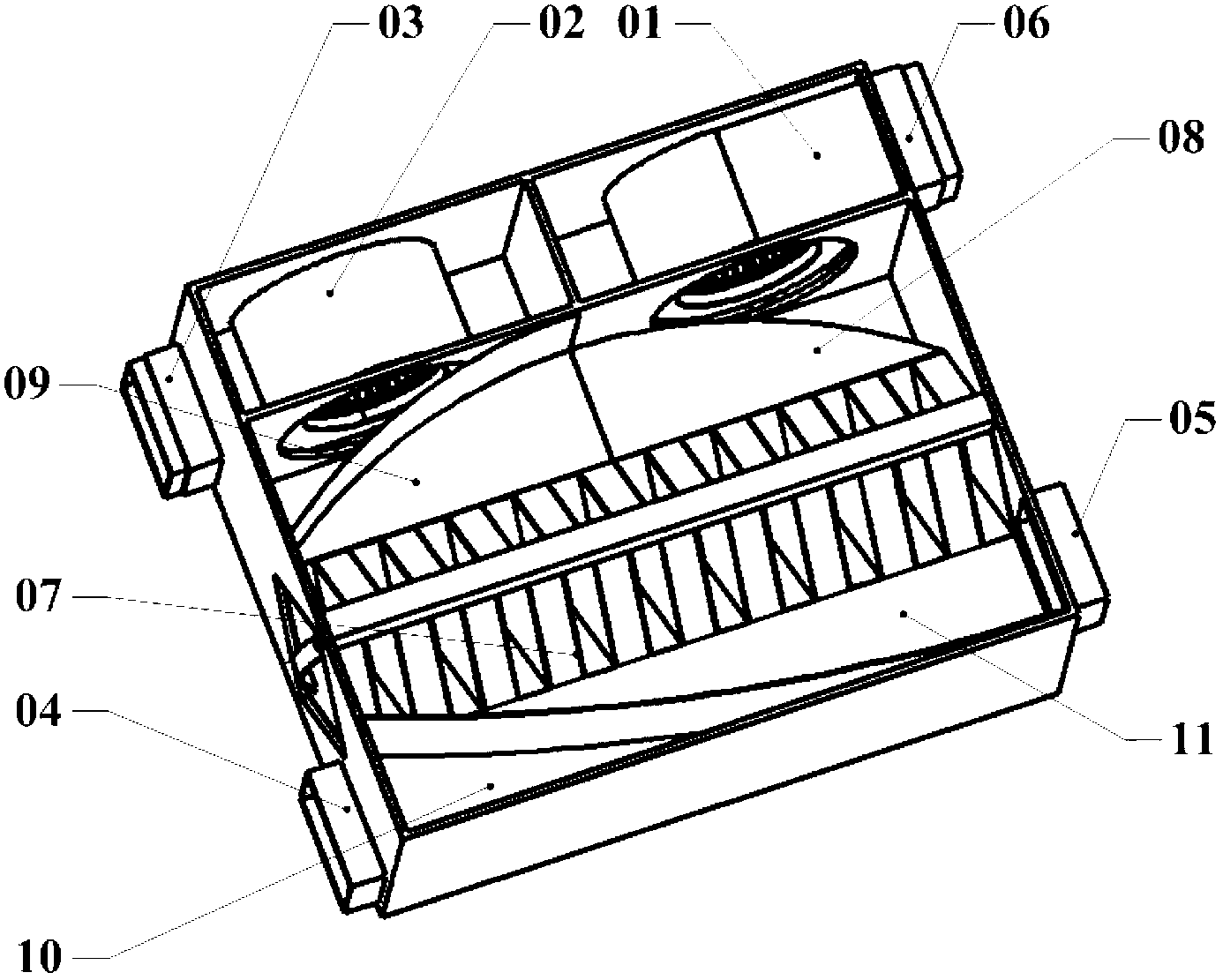

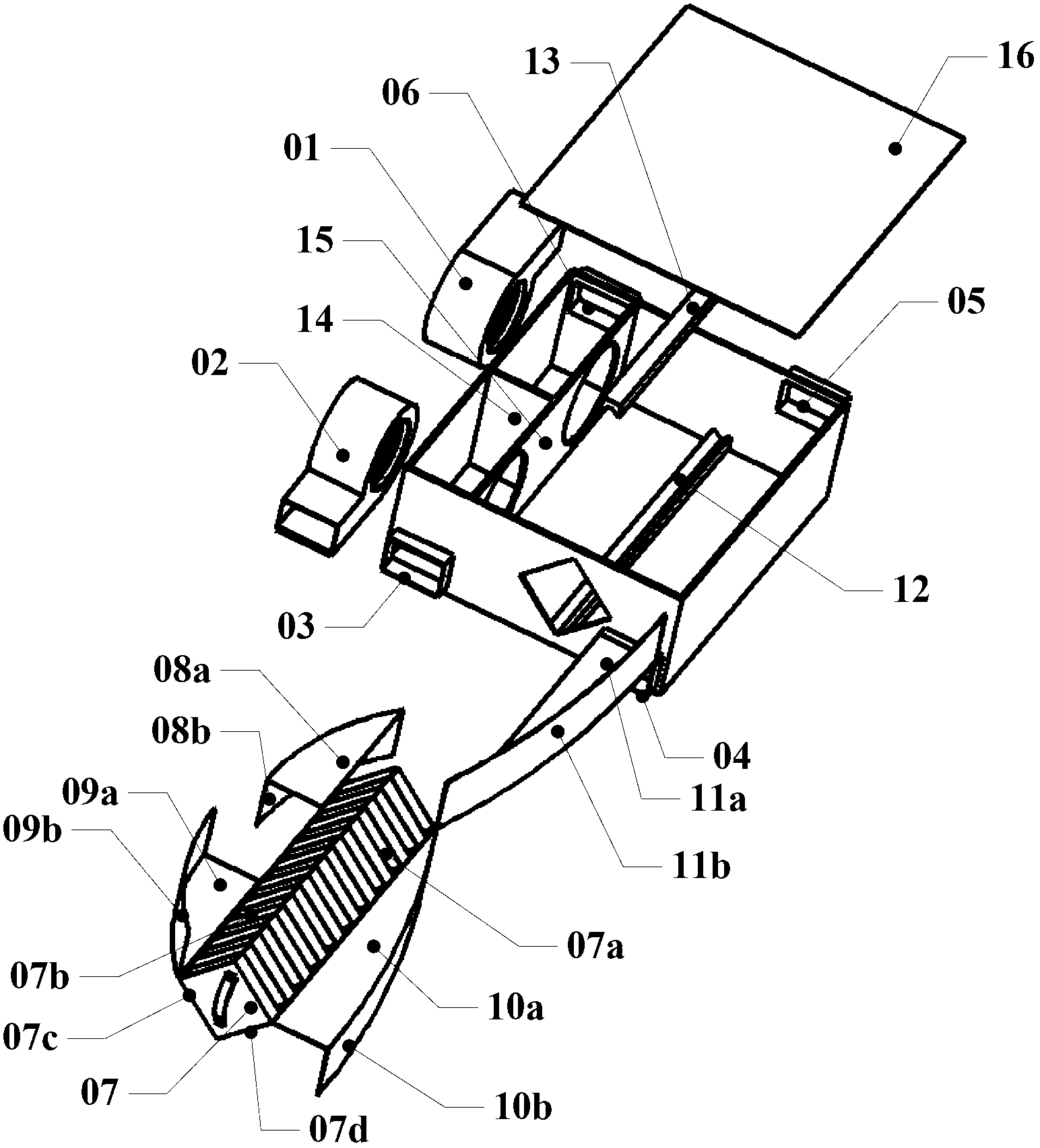

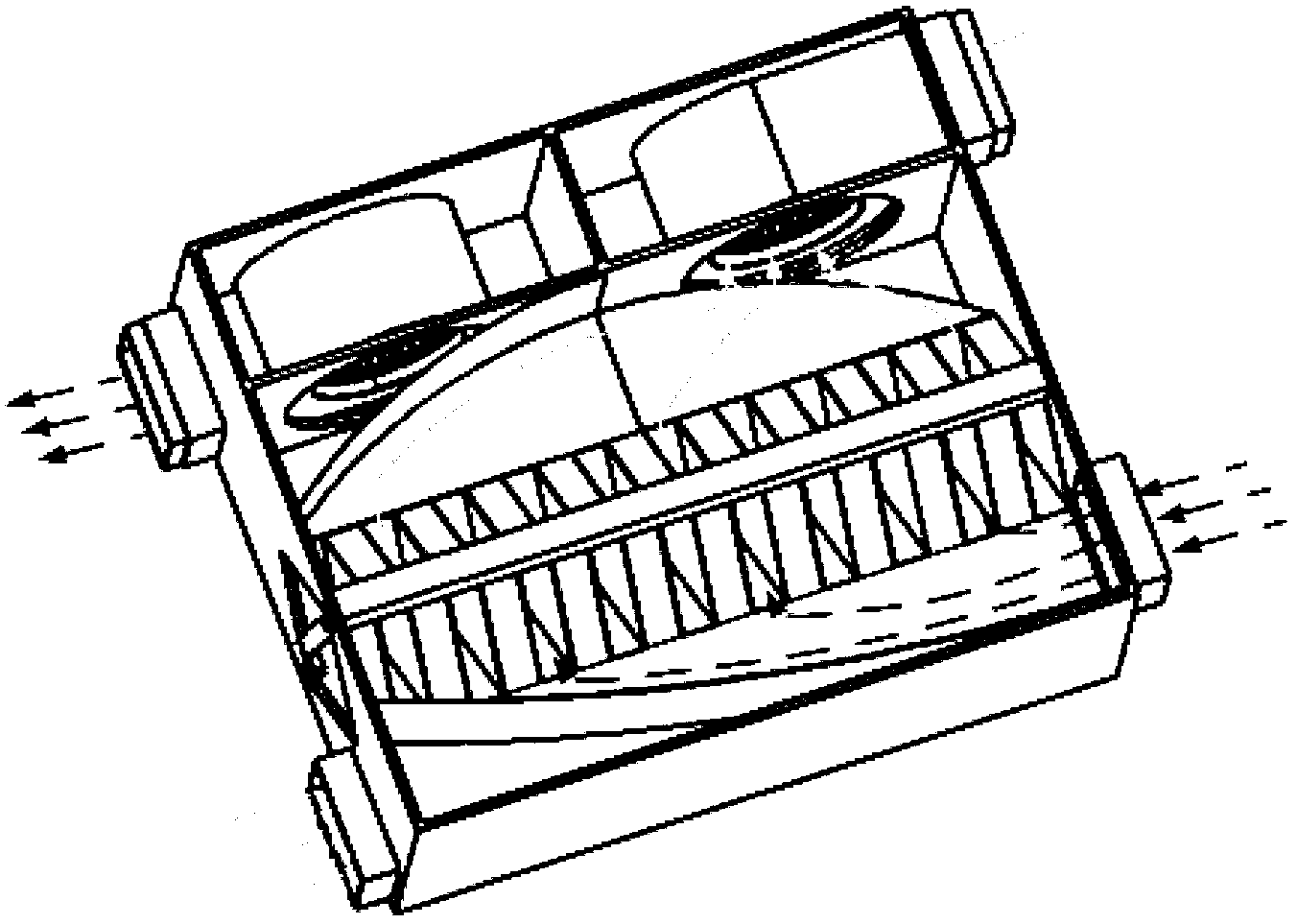

[0075] Such as figure 1 , as shown in 2, the total heat exchanger can be divided into three parts: the fresh air flow path, the exhaust air flow path and the heat exchange core according to the different flow paths:

[0076] 1. The fresh air passage of the total heat exchanger consists of fresh air inlet 04, fresh air outlet horizontal partition 09a, fresh air outlet side diversion partition 09b, fresh air inlet horizontal partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com