Bidirectional reverse circulation continuous deslagging drilling tool

A reverse circulation and drilling tool technology, applied in drill pipes, drill pipes, drill bits, etc., can solve problems such as increasing the resistance of drilling tools, increasing the risk of drilling accidents, and increasing drilling costs, reducing pressure loss and improving Slag discharge capacity and slag discharge stability, the effect of increasing suction negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0021] In order to clearly describe the content of the invention, this patent application uses the orientation words "upper" and "lower" to distinguish them. The "upper" and "lower" are determined according to the layout orientation of the above drawings. The name of its location changes accordingly, which cannot be regarded as a limitation on the scope of patent protection.

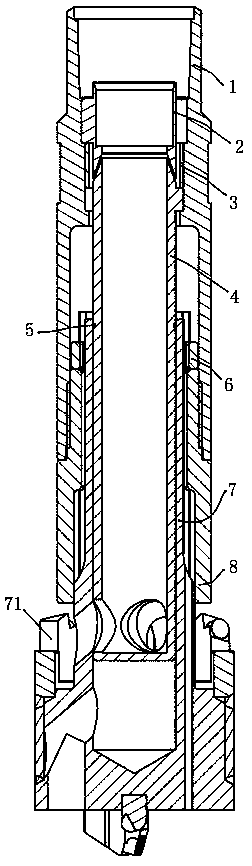

[0022] Such as figure 1 As shown, the present invention includes an outer tube 1, an injection ring 2, a positioning ring 3, a suction core tube 4, a sealing ring 5, a semicircle card 6, a double reverse drill bit body 7 and a spline connection sleeve 8, and the suction core tube 4 Placed inside the outer tube 1, the upper part of the inner wall of the outer tube 1 is provided with a necking step, the radial lugs on the upper part of the suction core tube 4 and the bottom of the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com