Assembly head comprising a stepped-drive rotating rotor and a pneumatic pressure control device

A technology for assembling heads and rotors, applied in electrical components, electrical components, etc., can solve the problems of small pressure difference, unreliable analysis, and reduction of vacuum efficiency of vacuum source 10

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

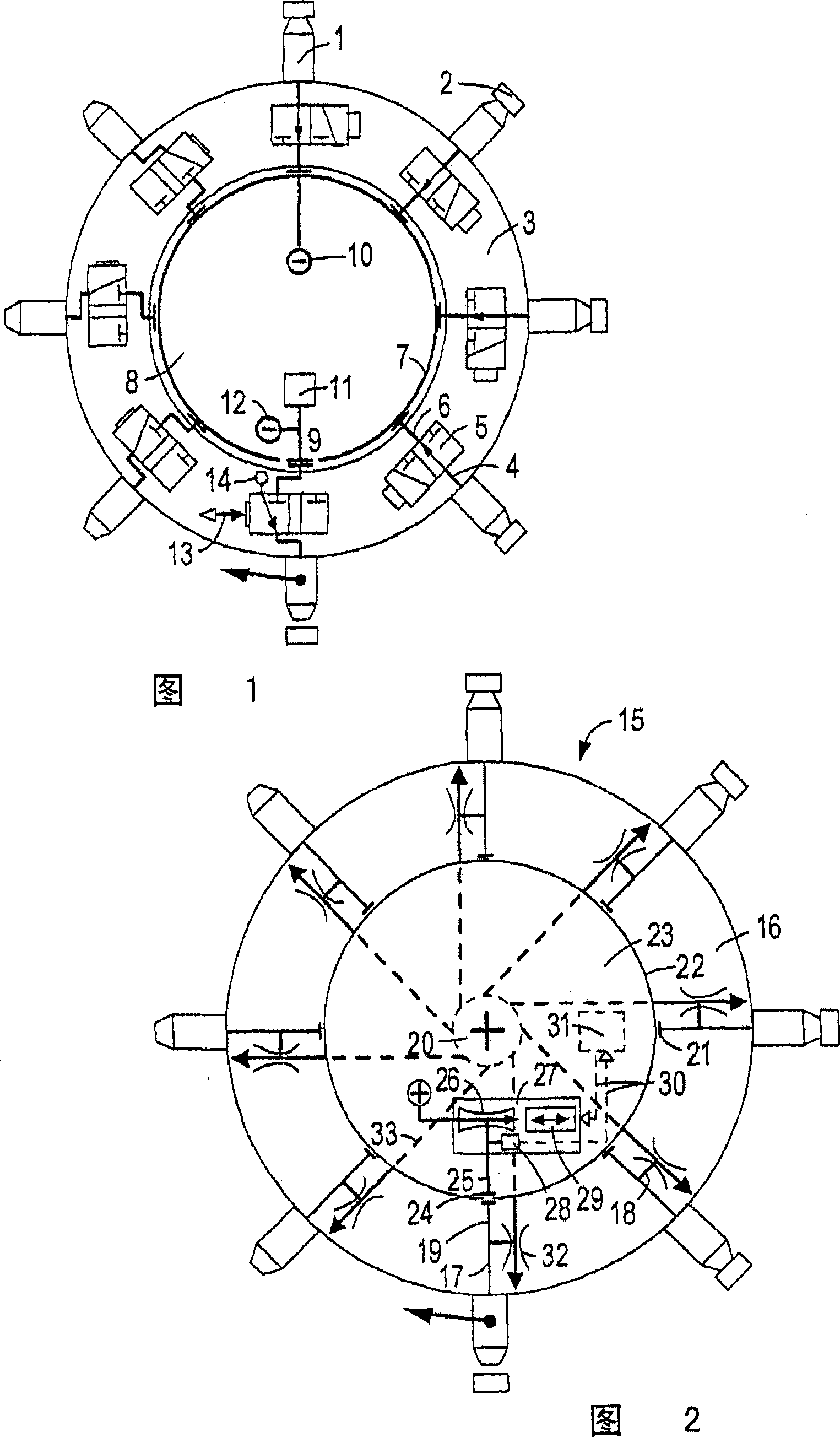

[0022] According to FIG. 2 , an assembly head 15 modified according to the invention likewise has suction pipes 1 spaced apart in a star pattern on a rotor 16 . The suction pipes 1 are connected to respective pneumatic conduits 17 which branch into suction conduits 18 and control conduits 19 . The whole suction pipe 18 is connected with jet pumps 32 which are respectively fixed on the rotors and rotates simultaneously. The jet pumps 32 are permanently and directly connected to the central high-pressure pipe 20 of the rotor 16 through the connection pipes, and generate a permanent vacuum in the suction pipes.

[0023] The control lines 19 lead into respective bores 21 of the rotor 16 which are closed by circular slide valves 22 of the stator 23 . The stator has, at the lower mounting position of the suction pipe 1 , a slide valve opening 24 complementary to the bore 21 , which is passed through a fixed control line 25 and an internal jet pump 26 formed as a flow meter nozzle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com