Floor cleaning apparatus employing a combined sweeper and vaccum assembly

a floor cleaning and vaccum assembly technology, applied in the direction of vacuum cleaners, floor sweeping machines, carpet cleaners, etc., can solve the problems of clogging internal vacuum components, noisy prior art apparatus, and insufficient vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

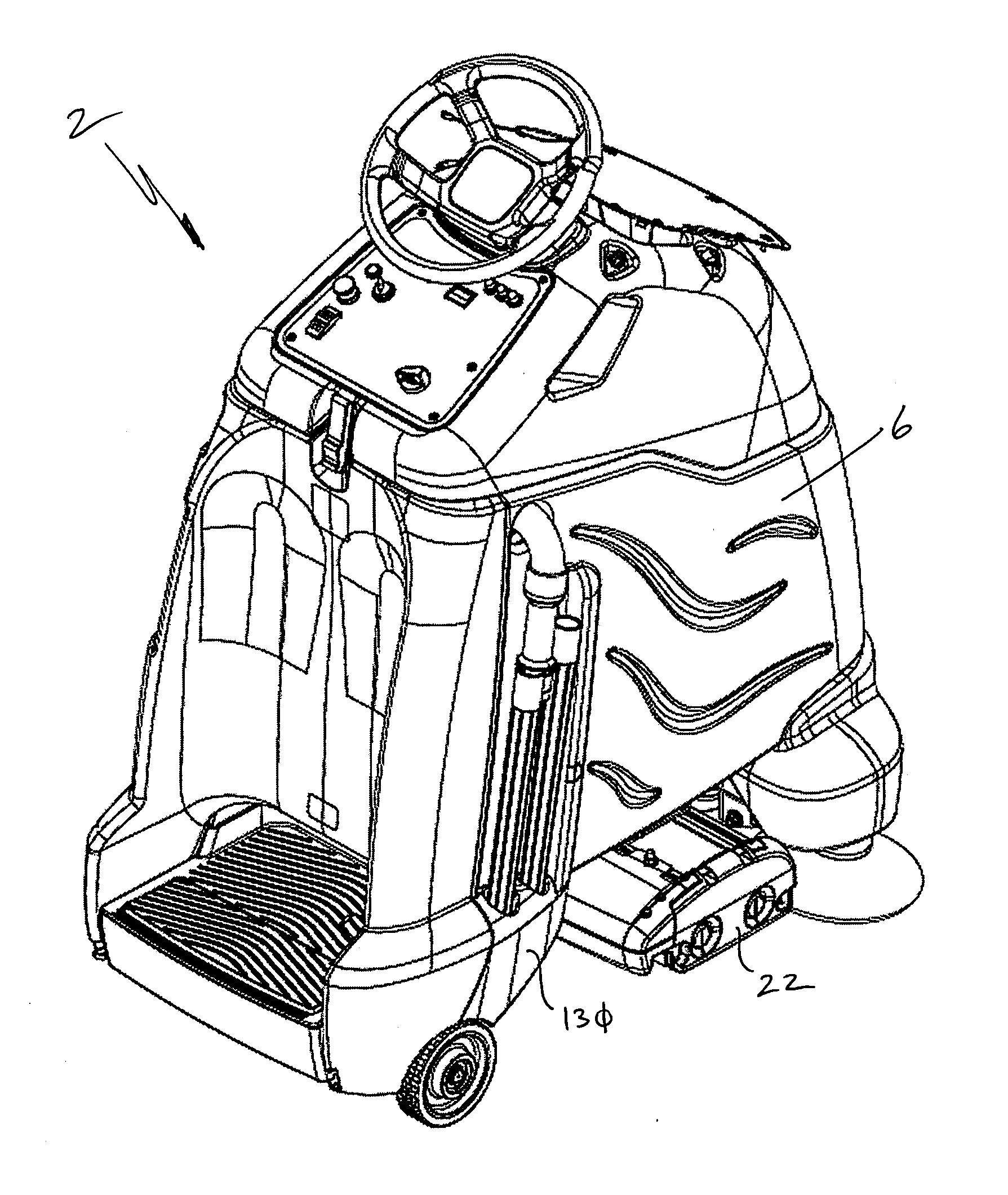

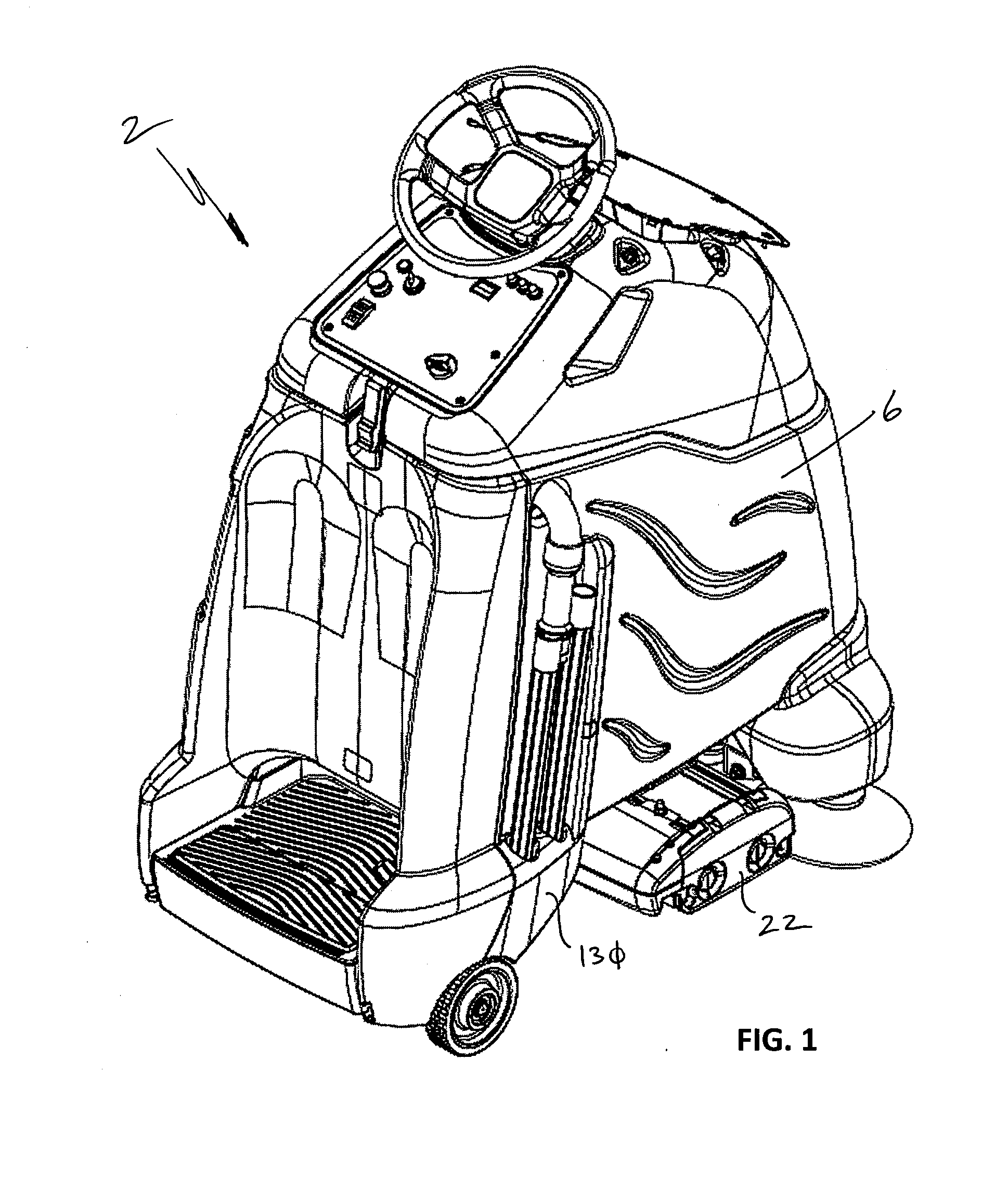

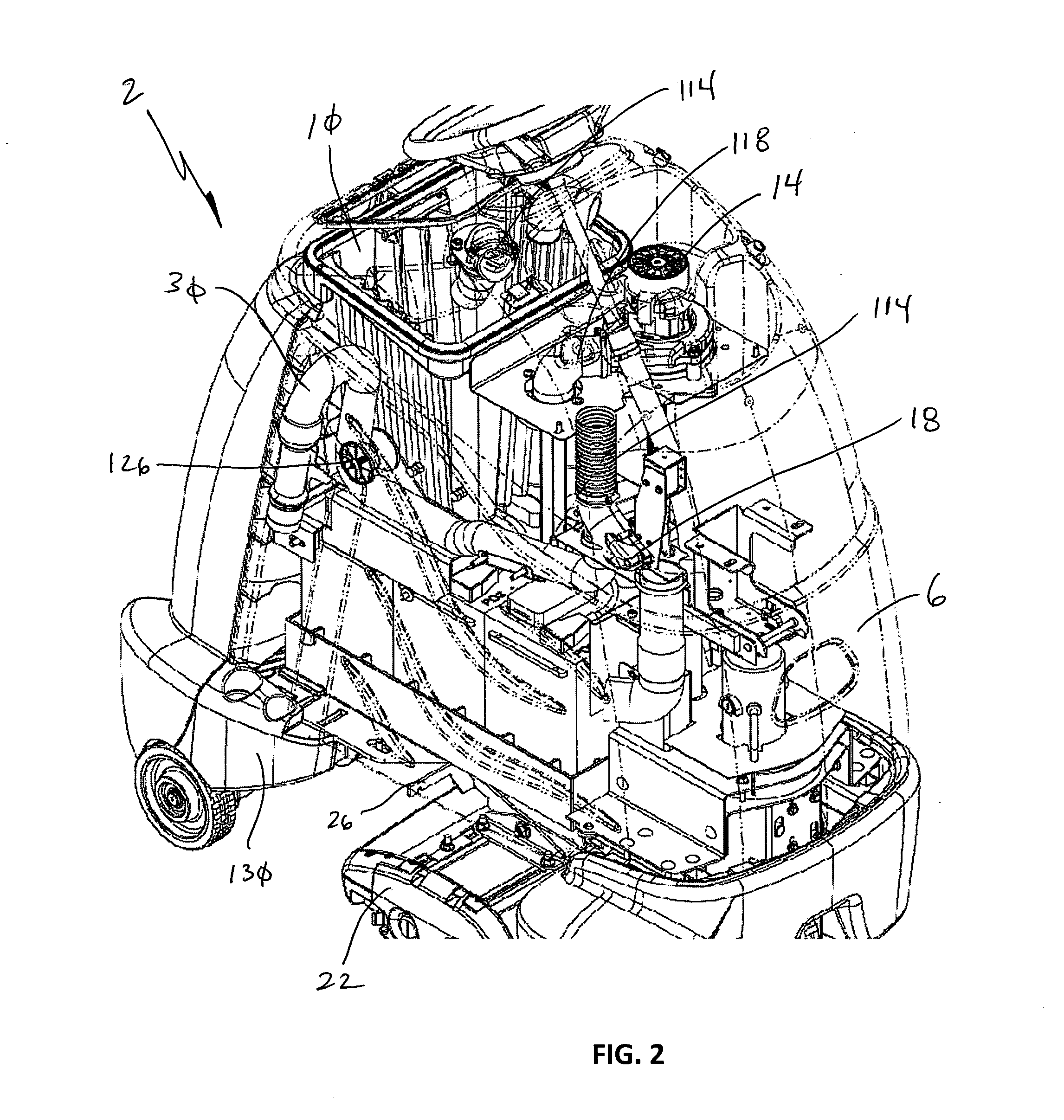

[0040]FIGS. 1-3 show a scrubber / sweeper apparatus 2 (hereinafter “apparatus”) of one embodiment of the present invention that employs a housing 6 that covers a vacuum bag 10, a vacuum motor 14, a valve 18, and other components generally found in floor cleaning apparatus. In addition, the apparatus 2 employs a cleaning assembly 22 that is attached to the housing 6 via a spring to an armature 26, which will be further described below. In operation, dirt, debris, and residue are agitated by the cleaning assembly 22 and suctioned into the vacuum bag 10. In a second mode of operation, a hand-held accessory hose 30 is used to suction debris in hard-to-reach places. The debris suctioned through the accessory hose 30 is also directed to the vacuum bag 10 by the vacuum motor 14.

[0041]Referring now specifically to FIGS. 4-7, the cleaning assembly 22 employed by some embodiments of the present invention is shown that includes a front brush 34 and a rear brush 38. The front brush 34 and rear br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com