Repair method of vehicle bump pavement of bridgehead

A repair method and technology of bridge head jumping, applied in bridge maintenance, bridges, bridge parts, etc., can solve problems such as the difference in settlement velocity between hard soil layers and soft soil layers, achieve short curing time, not easy to crack, and reduce construction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

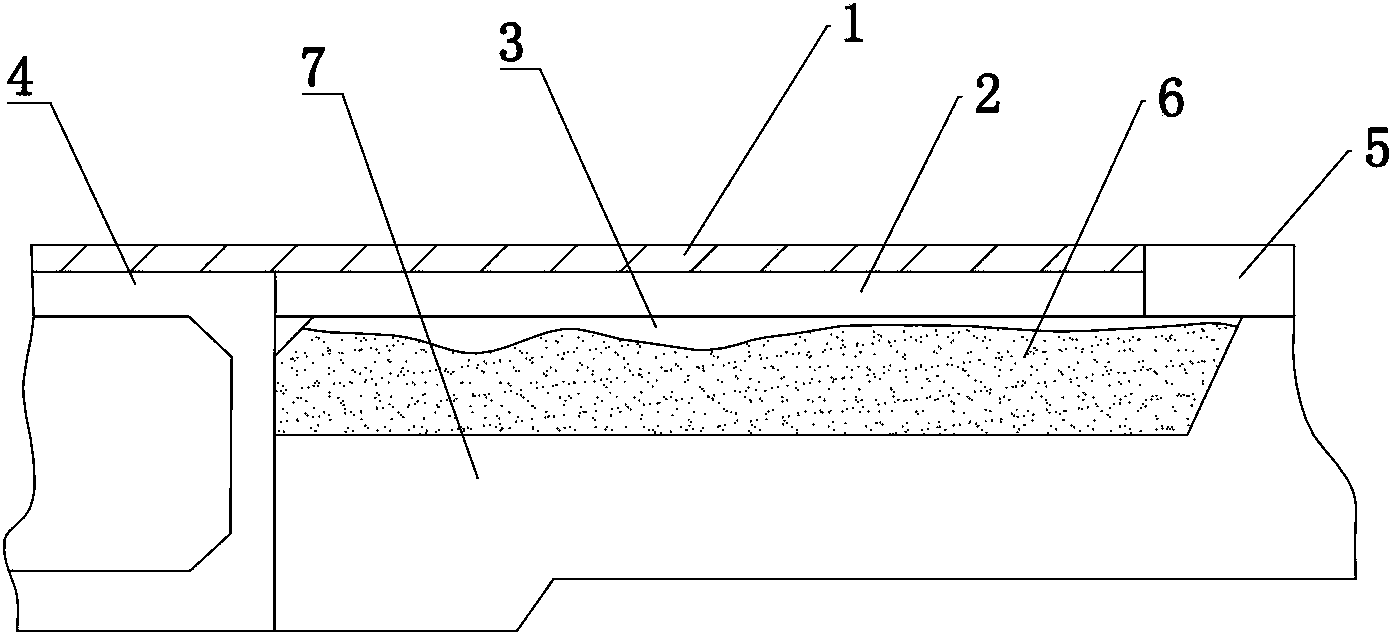

[0035] Such as figure 1 As shown, the damaged bridge generally includes: pavement 1, slab 2, void 3, bridge deck 4, road surface 5, soft soil layer 6, and hard soil layer 7.

[0036] Void generally occurs between the strap 2 and the soft soil layer 6, and the volume of the void will gradually increase with the settlement of the soft soil layer. Since the soft soil layer 6 is higher than the roadbed, it is convenient to drill the soft soil layer 6 from the side. hole.

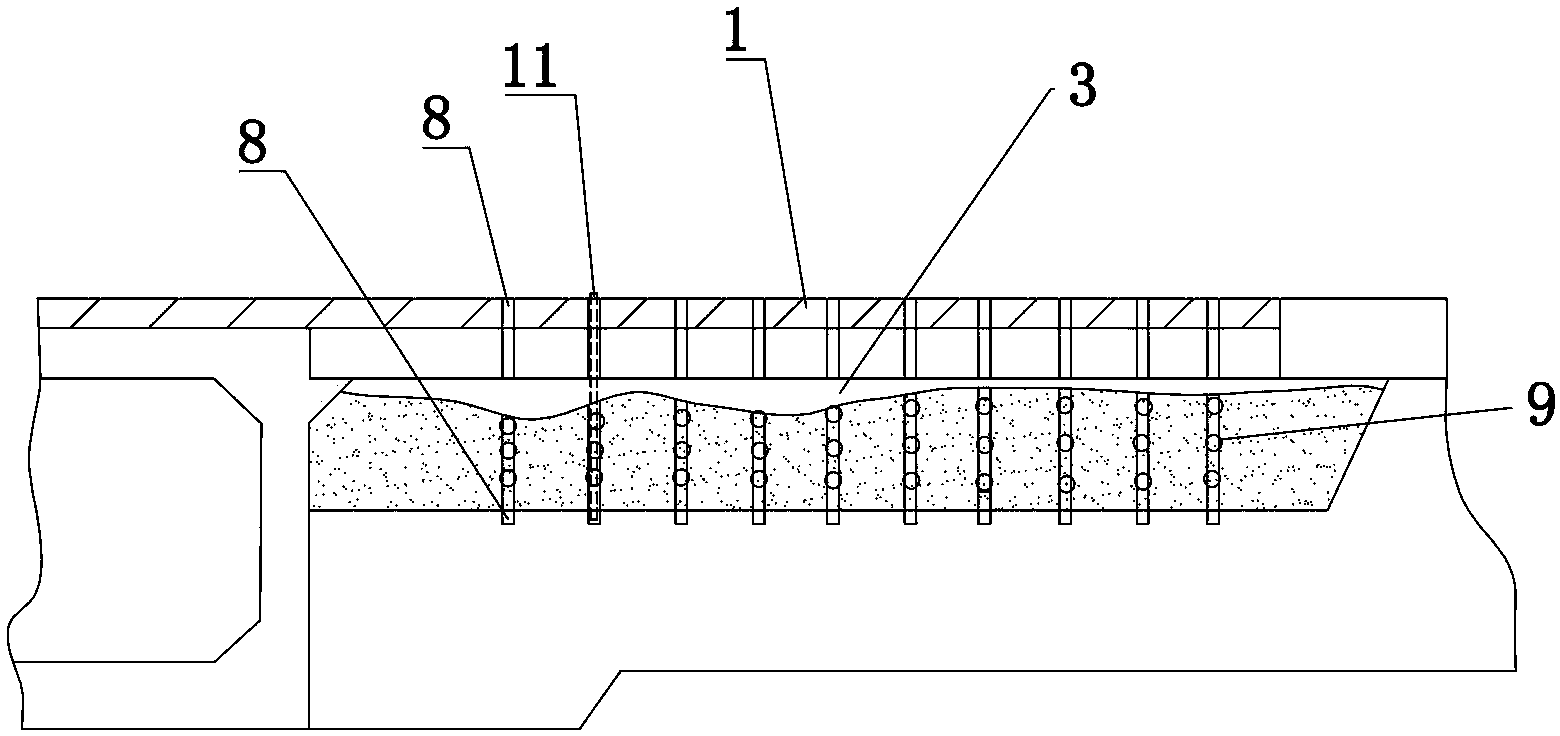

[0037] Such as figure 1 -Shown in 3, the repair method of bridge head jumping road surface of the present invention, comprises the following steps:

[0038] (1) Use the three-dimensional detection radar to detect the position of the void 3 in the slab of the damaged bridge, mark the position of the void 3 on the surface of the slab 2 and measure the depth of the void 3 and the hard soil layer 7;

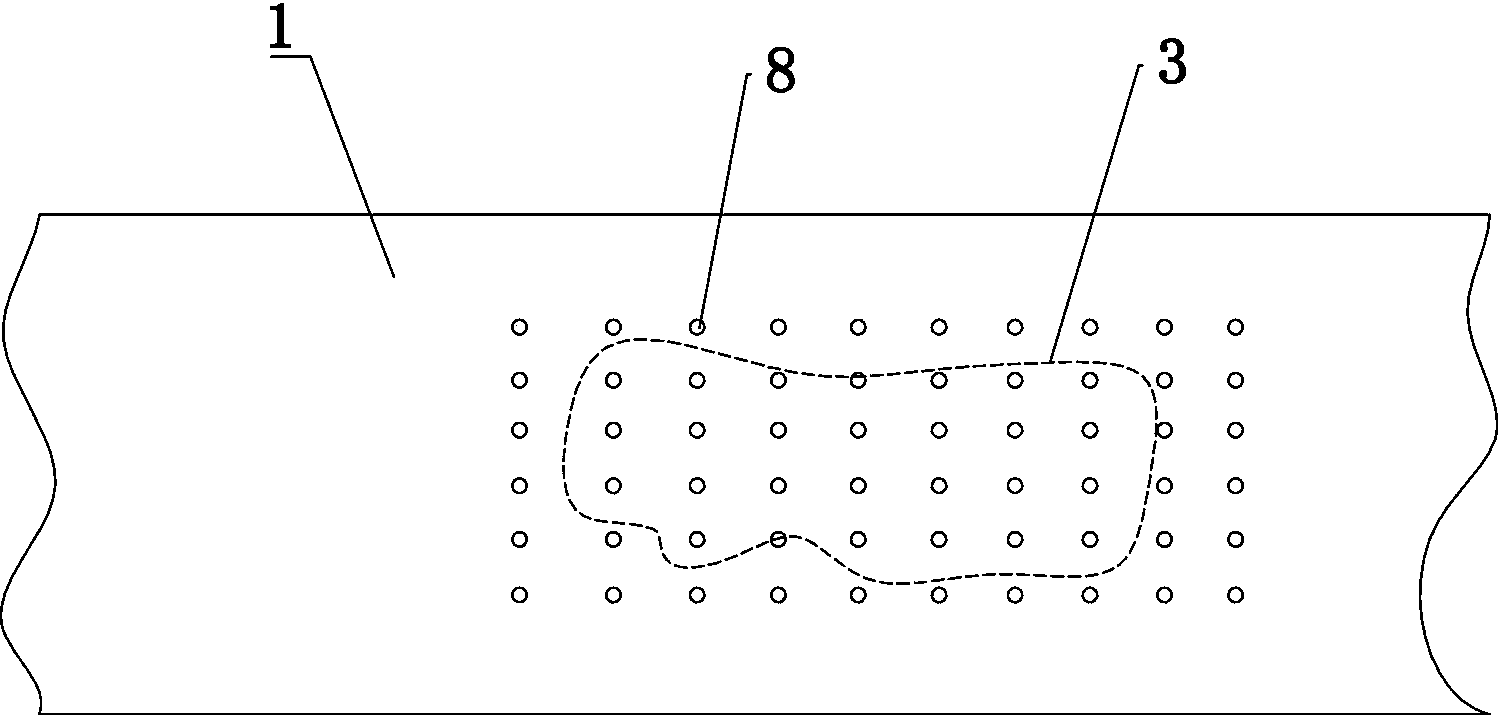

[0039] (2) Mark the position of each grouting hole 8 on the surface of the board 2 above the void 3 and drill the...

Embodiment 2

[0047]The slurry described in the present invention adopts a kind of high-strength foaming resin, and its model is SZ3, and this resin is added in the above-mentioned grouting equipment when grouting, and the resin viscosity (exit machine viscosity) that flows out from this grouting equipment ) is 100±45mPa·s. The volume of the resin slurry increases continuously during the flow, and its permeability is strong. It is suitable for quickly reaching the empty part or entering the gap. The slurry can be filled and voided after 3 minutes of injection, and its final strength can be reached after 10 minutes of injection. The compressive strength is ≥20MPa, and the bending strength is ≥15MPa.

[0048] The slurry has the following characteristics:

[0049] (1) The slurry does not contain water, will not shrink when dry, and can densely fill voids; the slurry is flexible and elastic after curing, and is not prone to cracking. At the same time, the resin material has good impermeability,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com