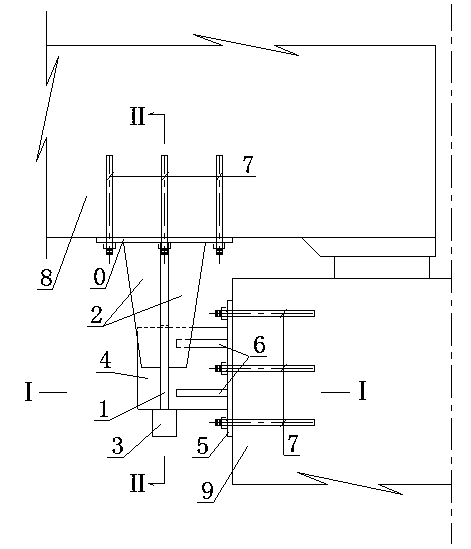

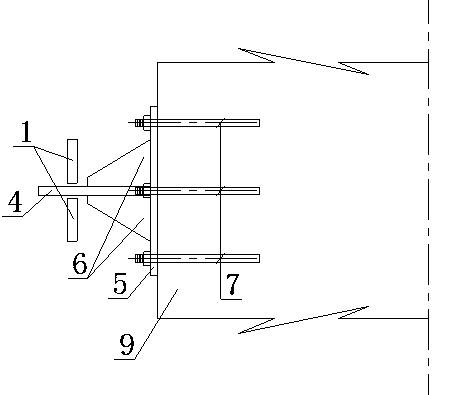

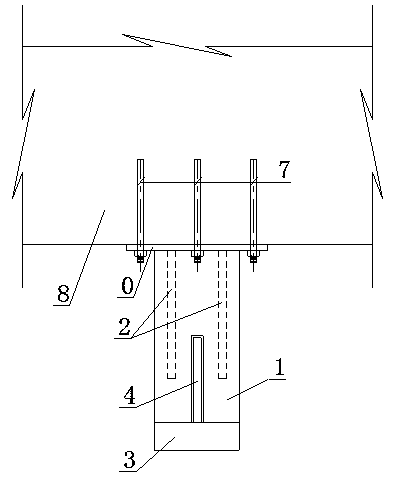

Bridge sliding clamping plate hook lock type box girder overturning prevention mechanism

A technology of sliding clamps and hook locks, which is applied in bridges, bridge parts, bridge construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Construction process:

[0015] The first process: drill connecting bolt holes on the bottom surface of the box girder (8) and the side of the cover beam (9).

[0016] Working steps: 1. Grind and smooth the positions where the box girder sliding pallet hook lock assembly and the cover beam sliding pallet hook lock assembly are to be installed on the bottom surface of the box girder (8) and the side of the cover beam (9);

[0017] 2. Set up and support the box girder sliding pallet hook lock assembly and the cover beam sliding pallet hook lock assembly, find the positions of the bolt holes on the bottom surface of the box girder and the side of the cover beam, and mark them;

[0018] 3. Take off the box girder sliding pallet hook lock assembly and the cover beam sliding pallet hook lock assembly;

[0019] 4. Drill holes at the marks on the bottom surface of the box girder (8) and the side of the cover beam (9), the depth of which meets the requirements for implanting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com