wet granulation unit

A granulating, wet technology, applied in mixers with rotary stirring devices, transportation and packaging, chemical instruments and methods, etc. separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

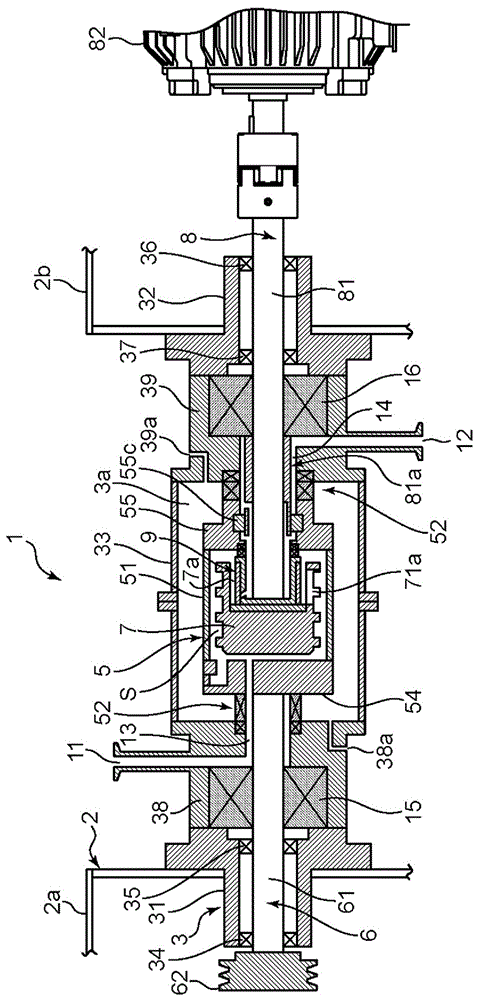

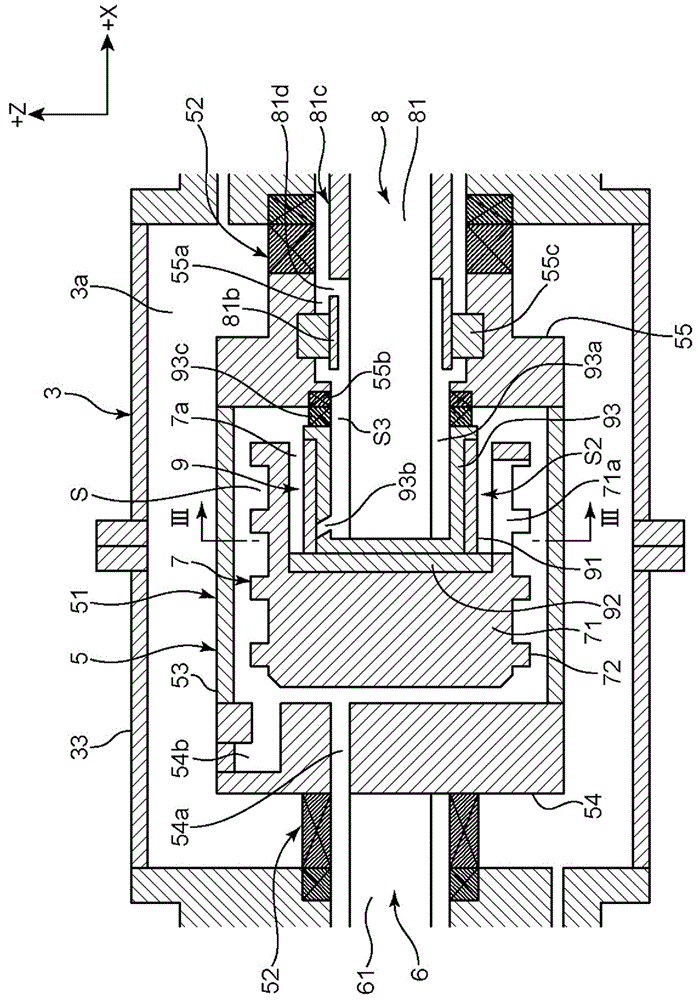

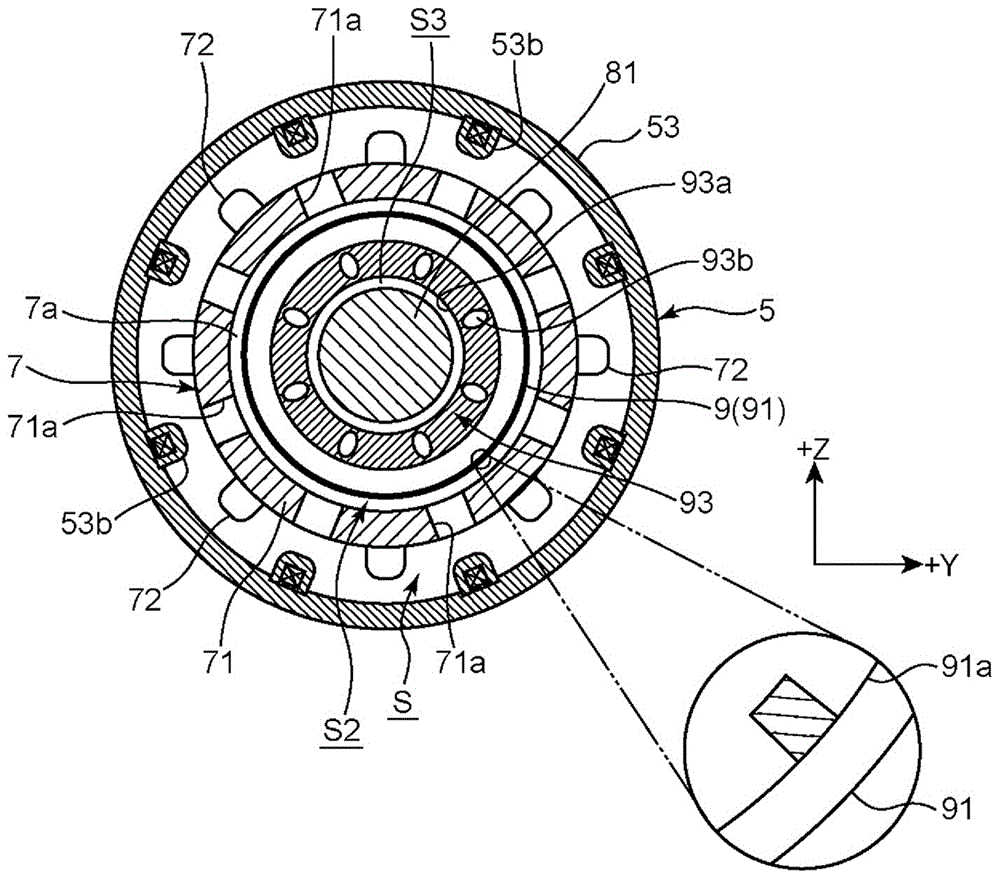

[0028] Hereinafter, one embodiment according to the present invention will be described based on the drawings. In addition, in this embodiment, a ring-type wet continuous dispersing device (more specifically, a continuous dispersing device) that disperses a material to be dispersed (corresponding to a material to be granulated) including an aggregate of primary particles (primary particle) using beads will be described. type bead mill), but the wet granulation device of the present invention can be used not only as a dispersing device, but also as a pulverizing device for pulverizing the material to be granulated finely. In addition, in this embodiment, a horizontal dispersing device in which the rotating shaft of the dispersing rotor described later is arranged in the horizontal direction is described, but the same can be applied to a vertical dispersing device in which the rotating shaft is arranged in the vertical direction and the above-mentioned dispersing device. Dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com