Blank for equal-channel corner extrusion

A technology of equal channel corners and blanks, which is applied in the field of channel corner extrusion, can solve the problems of irregular product shape and easy damage of molds, and achieve the effects of reducing punch mold breakage, inhibiting expansion, and reducing grinding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

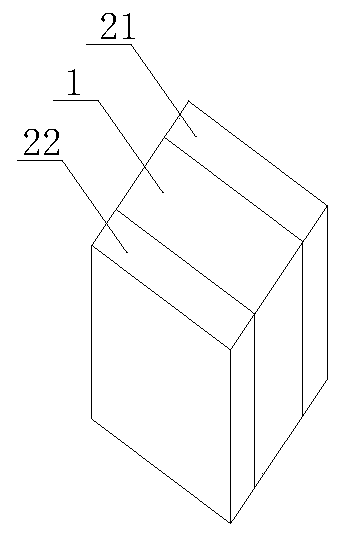

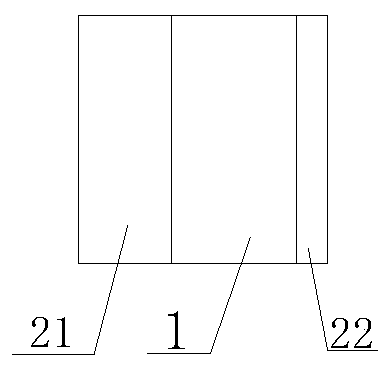

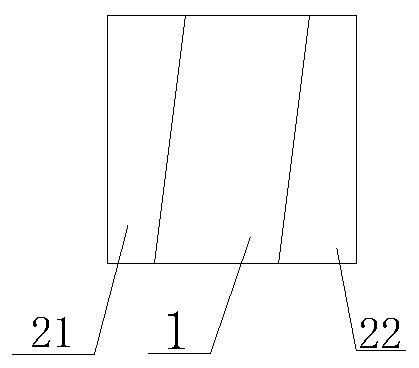

[0065] The cross-section of the green body for equal channel angular extrusion in this embodiment is square, including the sample layer 1 and the modified layer bonded to the side of the sample layer 1, and the hardness of the modified layer is lower than that of the sample layer. The hardness of layer 1, the tensile strength of the modified layer is less than the tensile strength of the sample layer 1; the yield strength of the modified layer is less than the yield strength of the sample layer 1. The sample layer 1 is an iron plate. The modified layer is a polymer sheet, and the polymer sheet is an HDPE sheet. The surface of the green body is provided with a lubricating layer, and the lubricating layer is molybdenum disulfide lubricant.

[0066] Such as figure 1 As shown, the modified layer includes a first modified layer 21 and a second modified layer 22 respectively arranged on a group of opposite sides of the sample layer 1, and the first modified layer 21 and the second...

Embodiment 2

[0069] Compared with Example 1, the green body for equal channel angular extrusion in this example has the difference that: the sample layer 1 is an iron plate. The modified layer is a polymer sheet, and the polymer sheet is a PP sheet.

Embodiment 3

[0071] Compared with Example 1, the green body for equal channel angular extrusion in this example has the difference that: the sample layer 1 is a tantalum plate. The modified layer is a polymer sheet, and the polymer sheet is a PE sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fill height | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com