Ultra-wideband double-ridge horn antenna for 1-40GHz frequency band

A ridge horn and ultra-wideband technology, which is applied in the field of ultra-wideband double-ridge horn antennas, can solve the problems of poor matching performance in the low frequency band, main lobe splitting gain, and drop, and achieve the effect of improving matching performance and widening bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

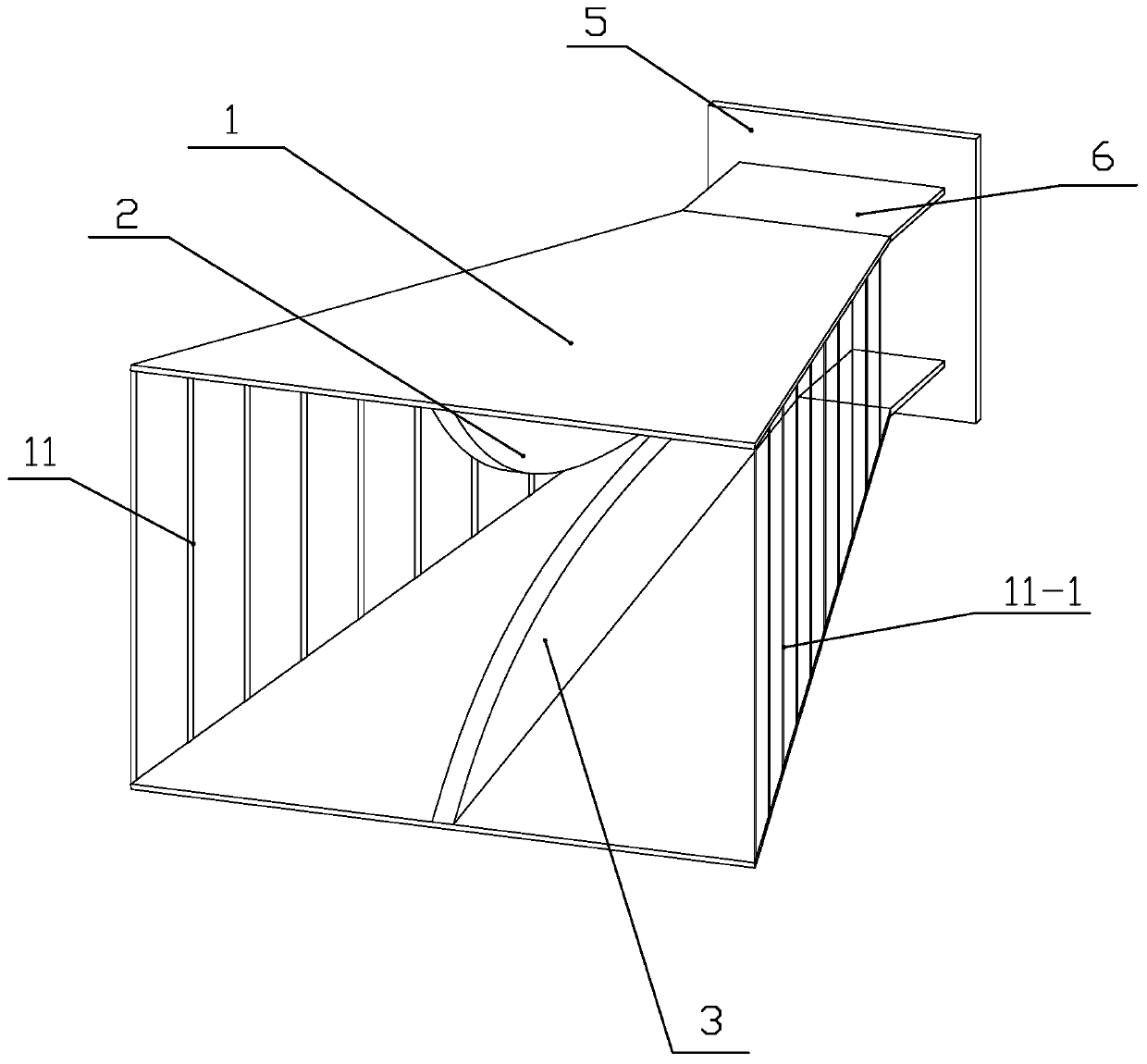

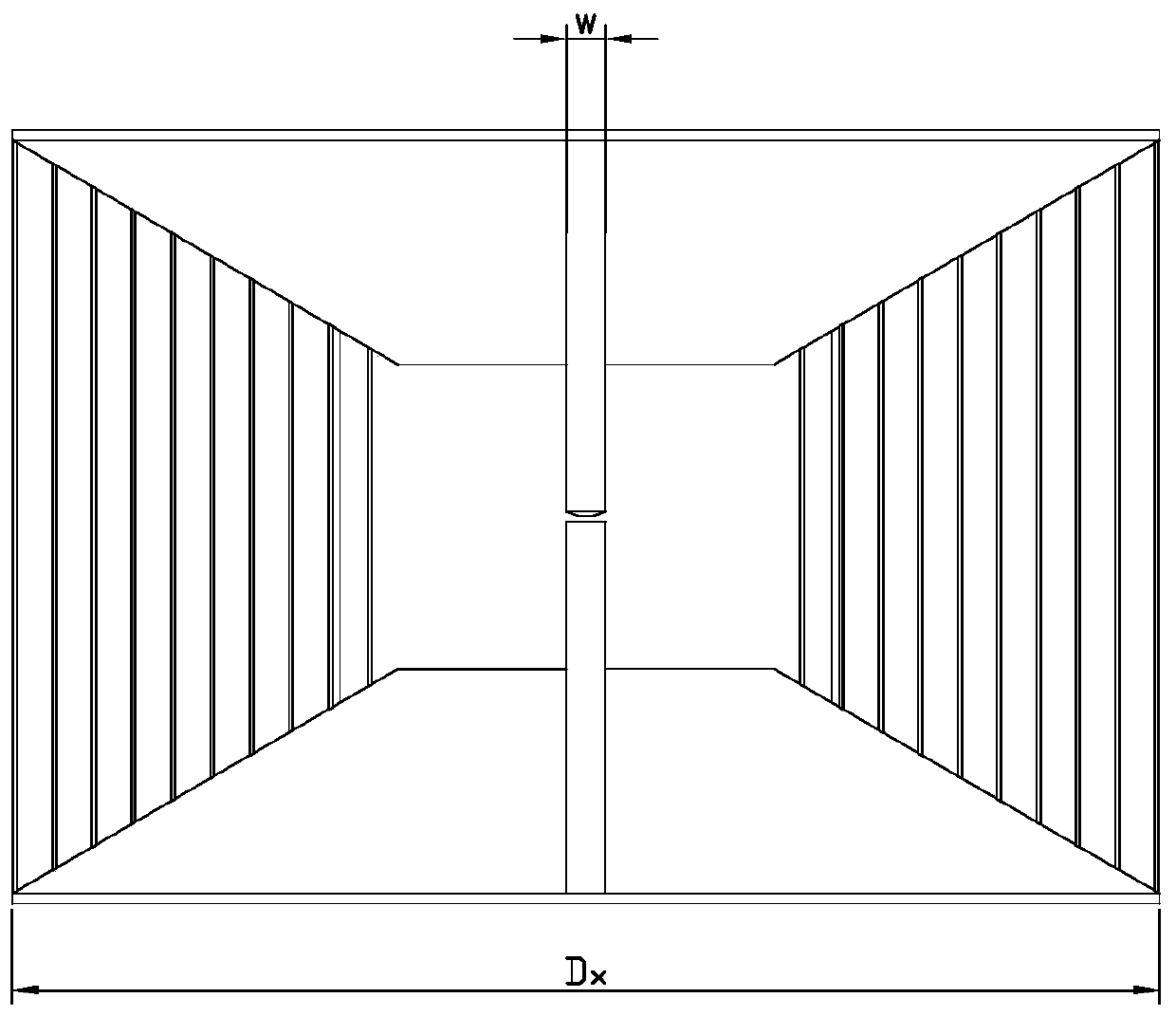

[0034] Specific implementation mode 1: Combination Figure 1~7 To illustrate this embodiment, an ultra-wideband dual-ridged horn antenna for the 1-40 GHz frequency band includes a ridged horn and a feed structure. The ridged horn includes a housing 1, an upper ridge 2 and a lower ridge 3. The casing 1 has a rectangular cone structure, and its left and right side walls are both metal grids 11. The upper ridge 2 and the lower ridge 3 are respectively fixed on the inner side of the upper and lower side walls of the casing 1, and The upper ridge 2 and the lower ridge 3 are arranged symmetrically up and down, and the ridge line of the upper ridge 2 and the ridge line of the lower ridge 3 are both curved;

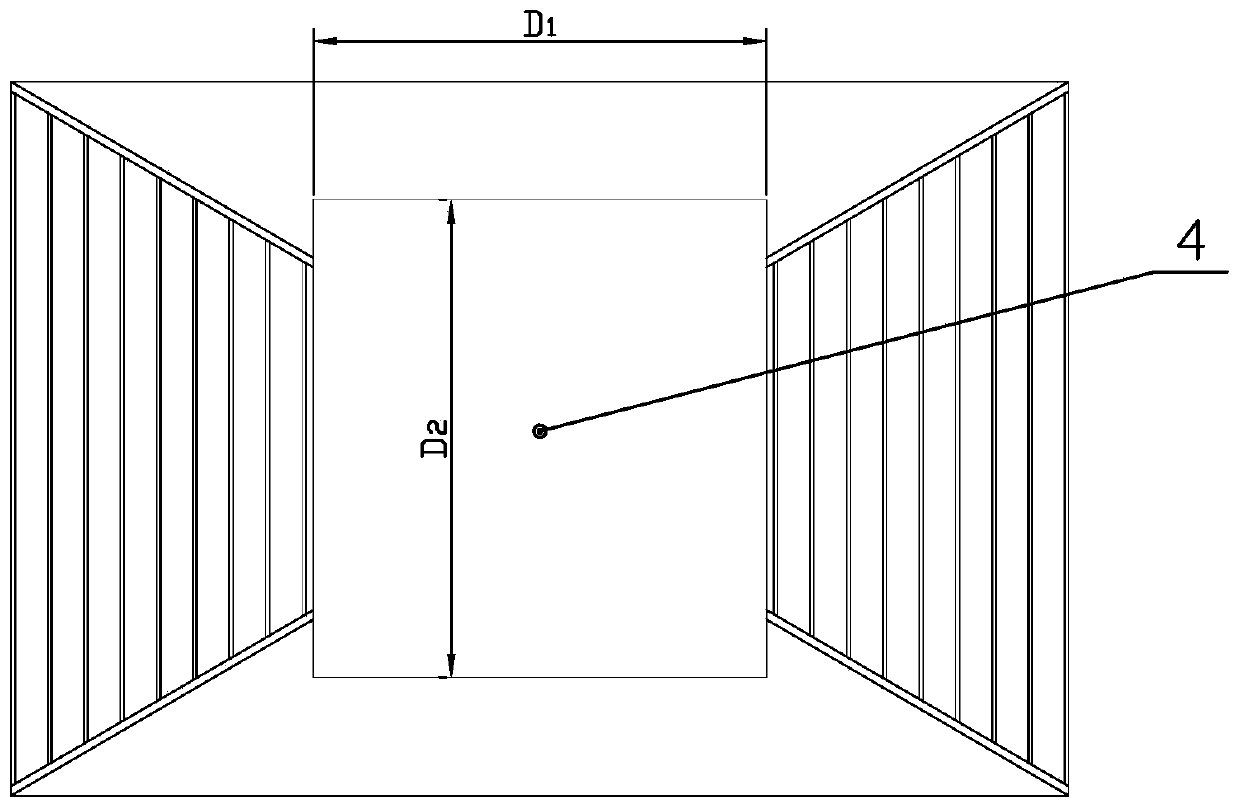

[0035] The feed structure includes a coaxial line 4, a metal floor 5, and a waveguide section 6. The metal floor 5 is arranged vertically, the coaxial line 4 is arranged horizontally, and the coaxial line 4 and the ridged horn pass through the metal floor. 5 and the waveguide sectio...

specific Embodiment approach 2

[0051] Specific implementation manner two: combination Figure 1~13 To illustrate this embodiment, the metal floor 5, the waveguide section 6 and the ridged horn are all made of aluminum. The end of the housing 1 close to the waveguide section 6 is a small end, and its width a 1 Same width as metal floor, where a 1 The value is 44-46mm. The other end of the housing 1 far from the waveguide section 6 is the large end, and its width Dx is 140mm. The upper metal transverse plate 61, the lower metal transverse plate 62, the upper side wall of the housing 1 and the housing The thickness of the lower side wall of 1 is the same, and its thickness is h 1 1.2-1.5mm, the opening angle of the upper and lower side walls of the shell 1 is determined by the ridge line and the length L of the shell 1 0 Decide where L 0 It is 205mm.

[0052] The ridge width w is 4.0-5.0mm, and the height of the end of the ridge close to the waveguide section 6 is h 3 It is 18-20mm, and the ridge line adopts the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com