Seat backrest frame structure of vehicle and seat backrest

A technology for seats and vehicles, applied in vehicle seats, seat frames, special positions of vehicles, etc., can solve problems such as unbearable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

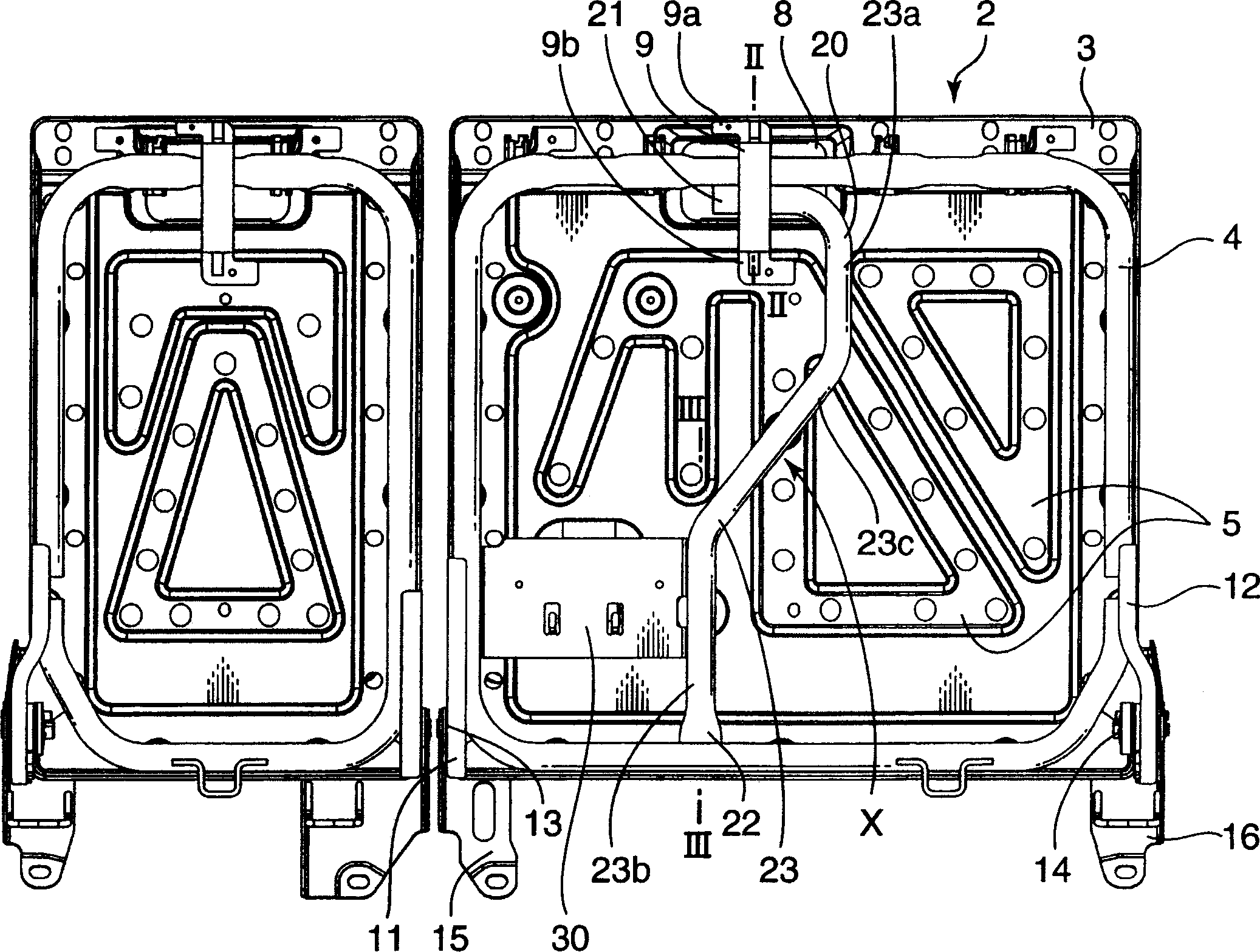

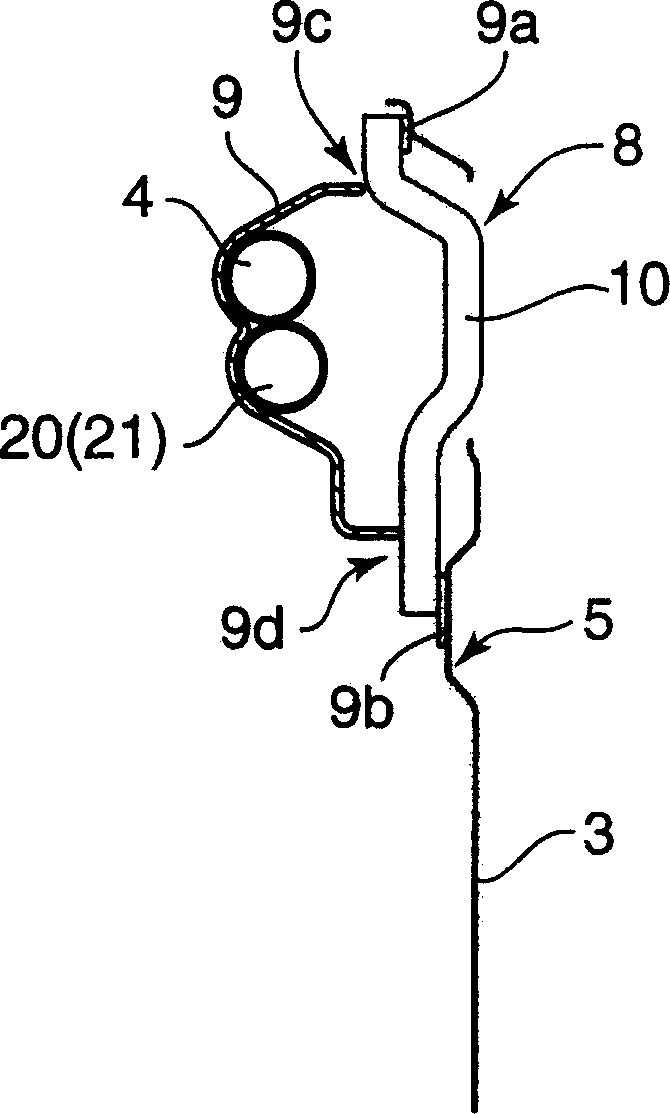

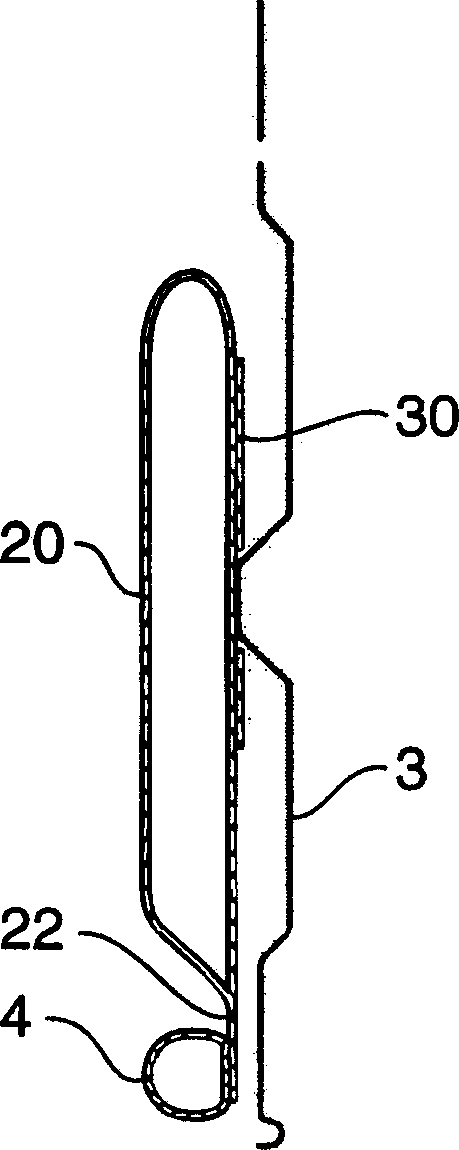

[0024] figure 1 It is a front view showing the structure of a seat back frame for a vehicle in which the present invention is applied to a rear seat divided into two parts of a car. Among them, the seat back with a large area on the right side of the figure is the structure of the vehicle seat back frame according to the first embodiment of the present invention. figure 2 is along figure 1 The sectional view of line II-II, image 3 is along figure 1 Sectional view of line III-III.

[0025] The vehicle seat back frame of the first embodiment includes a seat back bracket 2 and a reinforcing pipe frame 20 as a reinforcing bracket, wherein the seat back bracket has a flat frame 3 and a frame 4, and the two ends of the reinforcing bracket are connected on the upper and lower sides of the frame 4.

[0026] The pallet 3 is made of metal plates such as substantially rectangular steel, and can be partially formed with protrusions 5 protruding to the front side according to a d...

no. 2 Embodiment

[0034] Figure 4 It is a front view showing the structure of the seat back frame for vehicles in which the present invention is applied to the two-part rear seat of a van. The seat back with a large area on the right side of the figure is related to the second embodiment of the present invention. The seat back of the structure of the vehicle seat back frame. Figure 5 is along Figure 4 A cross-sectional view of the V-V line, Image 6 is along Figure 4 Sectional view of line VI-VI. And, with Figure 1~Figure 3 The same reference numerals are attached to the same parts.

[0035] The structure of this vehicle seat back frame is used in the rear seat of a van, and its upper right part is detachably attached to the vehicle body. Although the illustration of the upper right portion of the seat back and the mounting part of the vehicle body is omitted, the structure includes a striker provided on the vehicle body side, and a catch member provided on the seat back bracket 2 si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com