Polishing method and grinding fluid

A technology of lapping fluid and abrasive particles, which is applied in the directions of lapping devices, lapping machine tools, polishing compositions, etc., can solve the problems of difficulty in obtaining in-plane uniformity, difficulty in sufficiently suppressing scratches, and difficulty in suppressing dents, etc., and achieves less scratches. , The effect of suppressing dents and reducing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

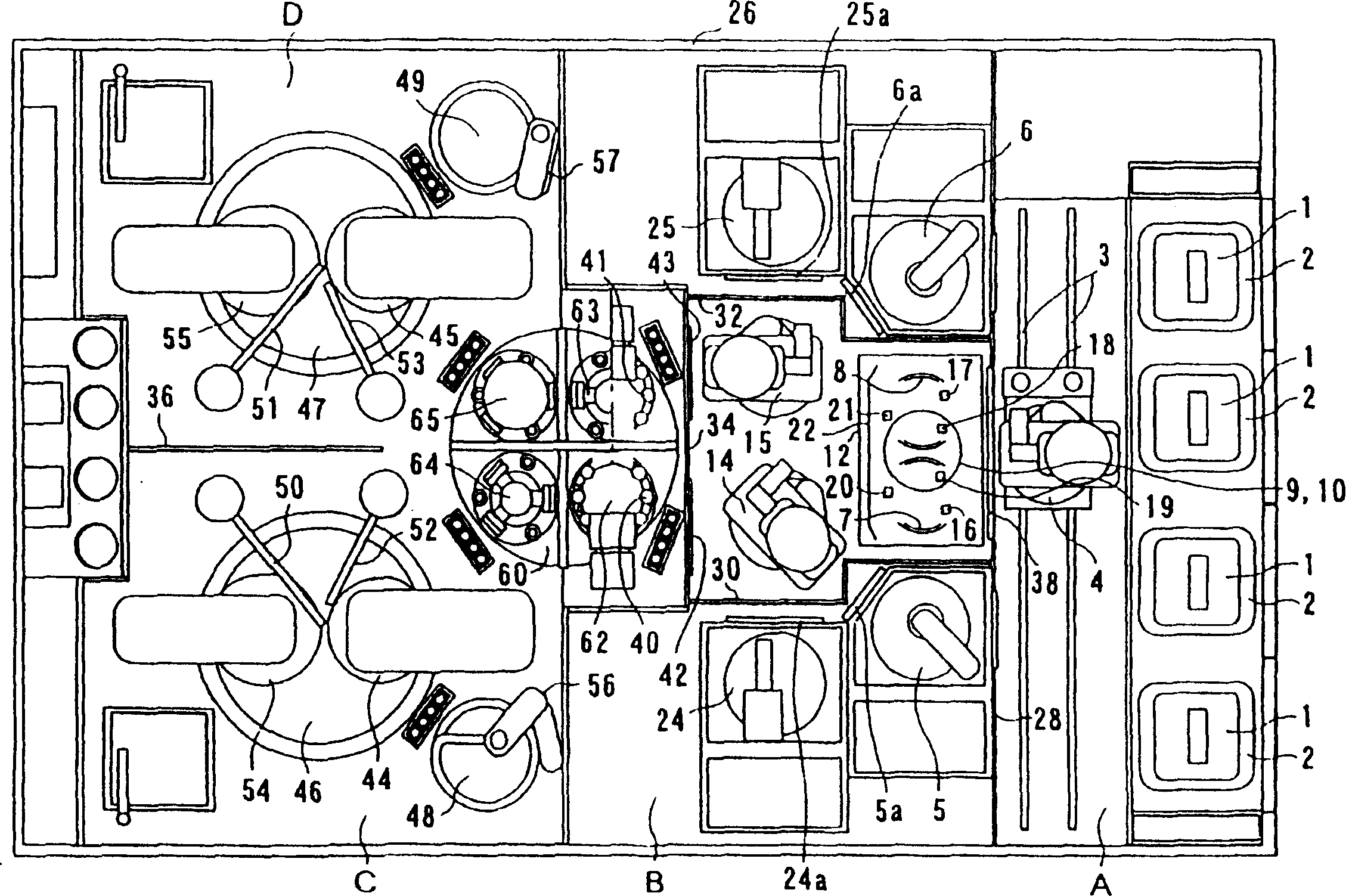

[0025] Hereinafter, embodiments of the polishing apparatus according to the present invention will be described in detail with reference to the drawings. figure 1 is a plan view showing the overall structure of a polishing apparatus according to one embodiment of the present invention.

[0026] Such as figure 1 As shown, the polishing apparatus in this embodiment includes four loading / unloading tables 2 for loading wafer cassettes 1 stacked with a plurality of semiconductor wafers. The loading / unloading table 2 can also have a mechanism that can be raised and lowered. In order to be able to reach each wafer cassette 1 on the loading / unloading station 2 , a transfer robot (transfer robot) 4 is arranged on the moving mechanism 3 .

[0027] The transfer robot 4 is equipped with two hands up and down. Of the two hands of the transfer robot 4 , the lower hand is a suction-type hand that vacuum-suctions wafers, and is used only to receive semiconductor wafers from the wafer cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com