Strain gauge grinding and resistance adjusting system and method

A technology of strain gauge and resistance adjustment, which is applied in the direction of grinding device, grinding machine tool, measuring electrical variables, etc., can solve the problems of not being able to measure the resistance value of strain gauge in real time, increase the labor intensity of staff, increase production cost, etc., and achieve the reduction of labor The effect of increasing the investment, improving the yield rate, and avoiding excessive grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are as follows.

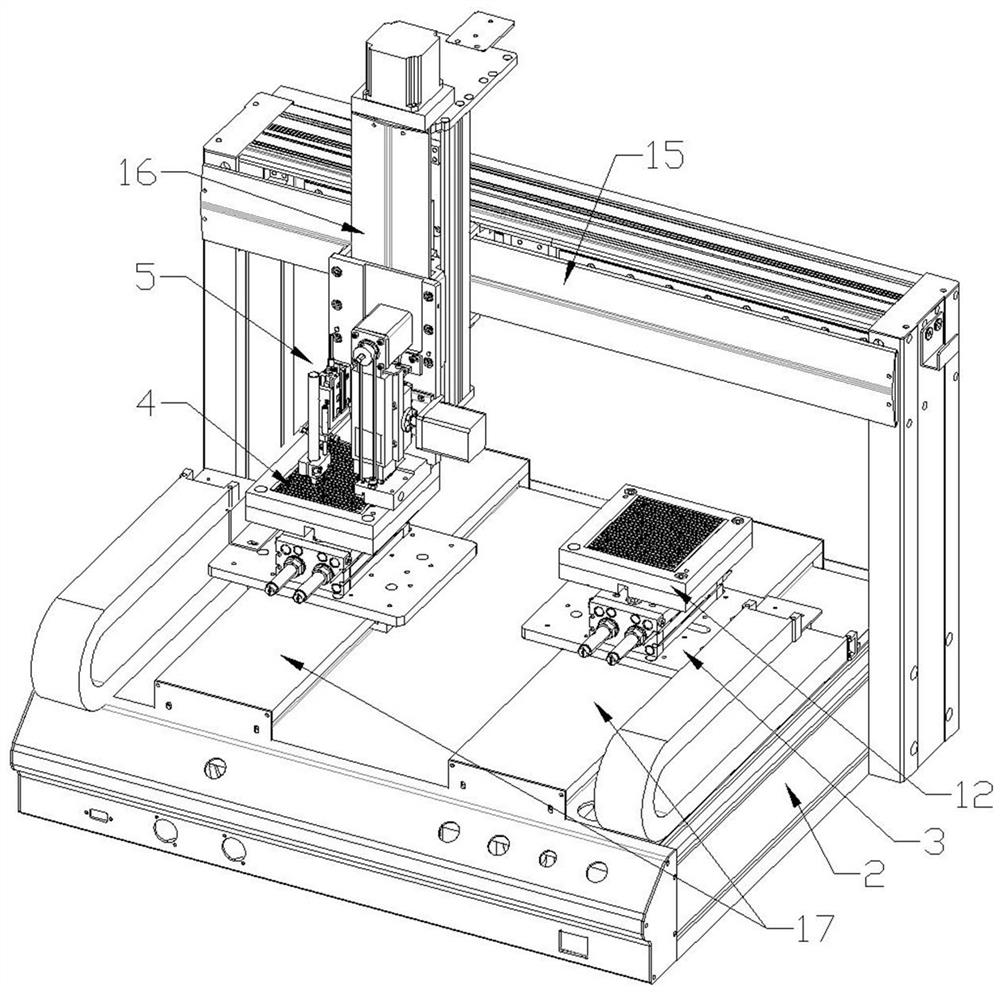

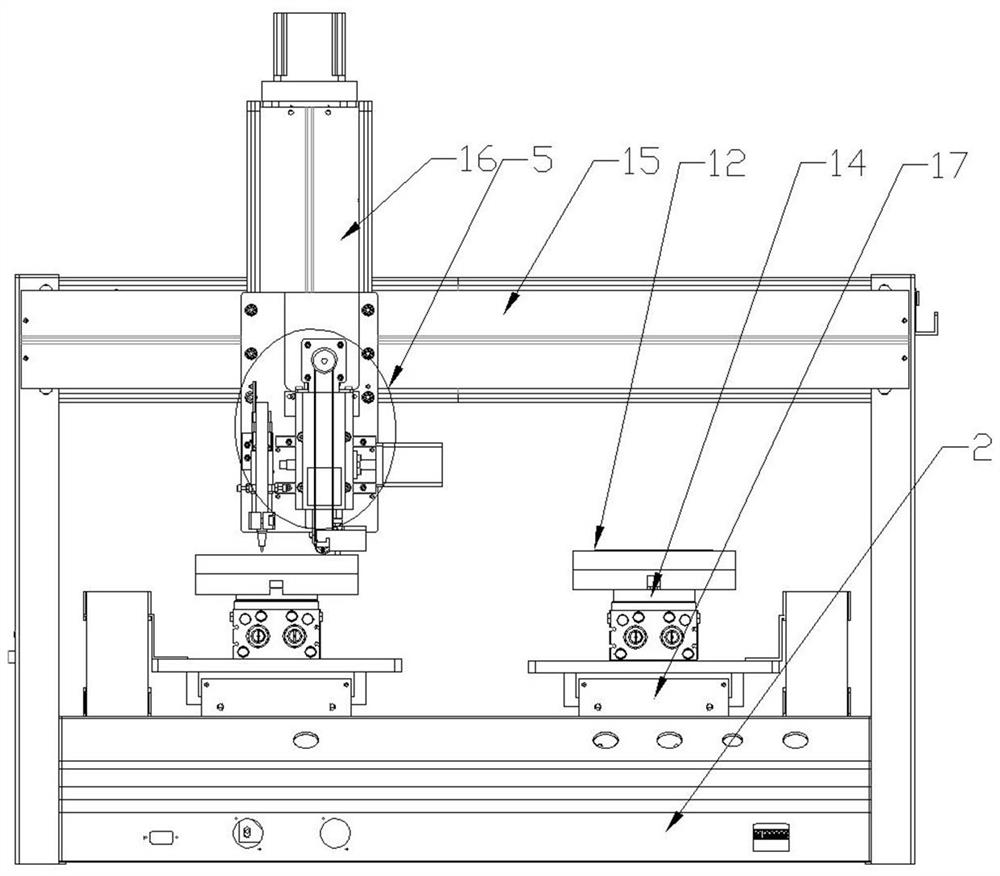

[0039] Such as Figure 1 to Figure 8 As shown, the strain gauge grinding resistance adjustment system of the present invention includes a resistance tester and a machine table 2 containing an XYZ axis moving table, which also includes

[0040]At least one strain gauge storage platform 3, the strain gauge storage platform 3 is arranged on the machine platform 2, and the resistance adjustment strain gauge 4 to be measured is positioned on the strain gauge storage platform 3;

[0041] and a grinding and measuring integrated assembly 5, the grinding and measuring integrated assembly 5 is arranged on the XYZ axis moving table;

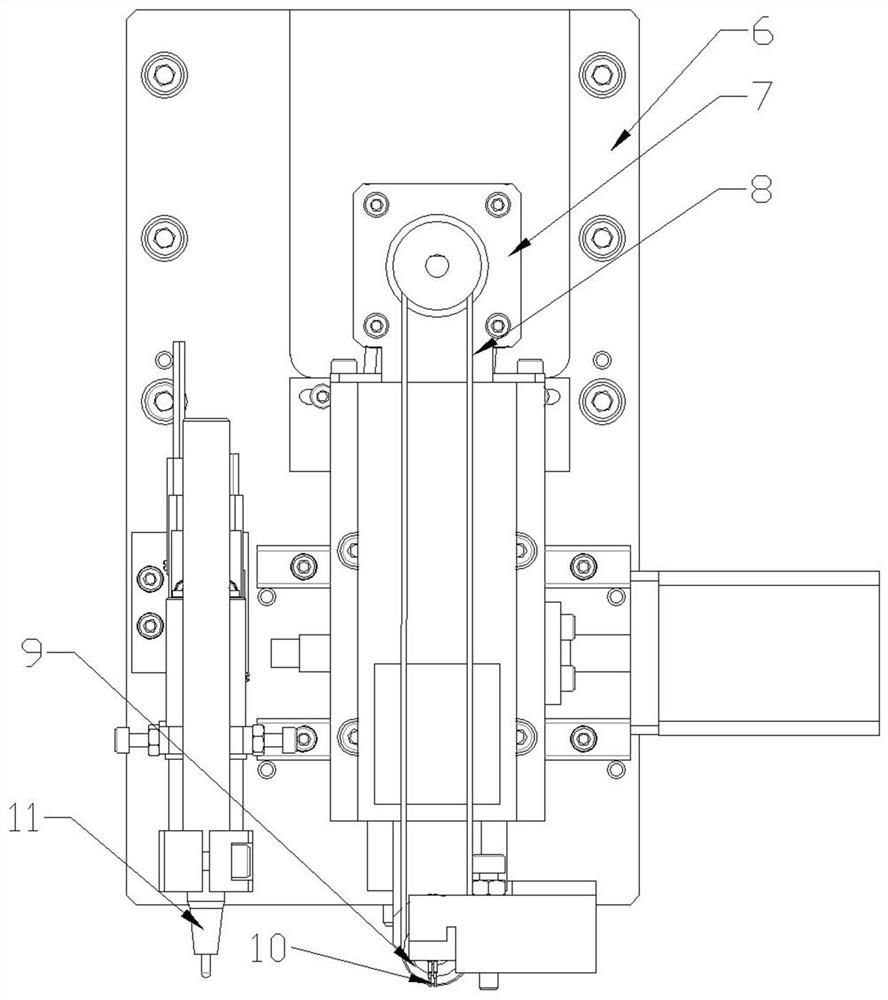

[0042] The integrated grinding and measuring assembly 5 includes

[0043] Assembly substrate 6,

[0044] A grinding module, the grinding module is arranged on the assembly substrate 6, and is composed of a grinding motor 7, a grinding belt 8 and a driven grinding wheel 9 in cooperation with ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com