Patents

Literature

34results about How to "Avoid over grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

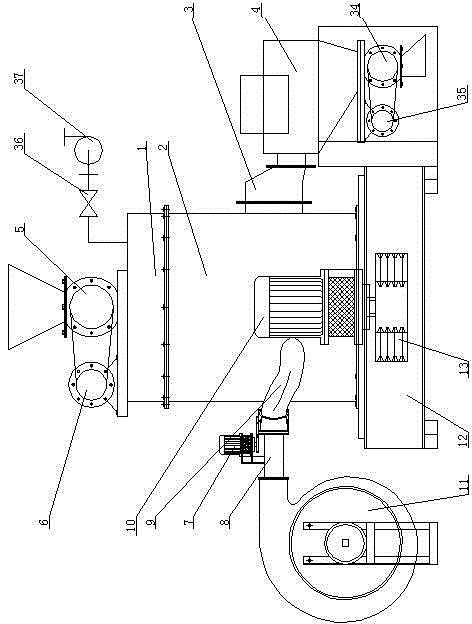

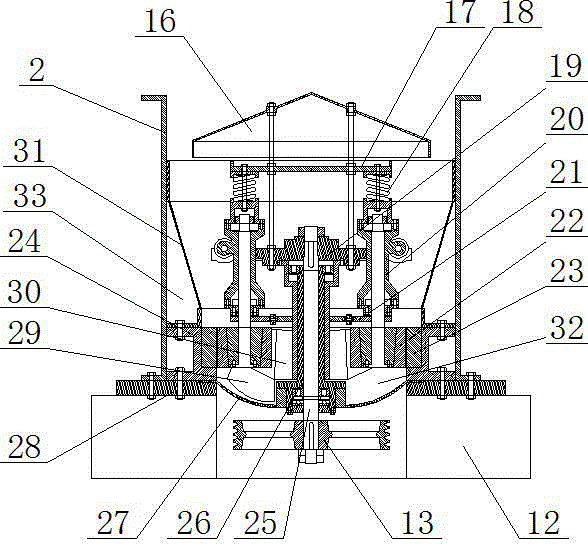

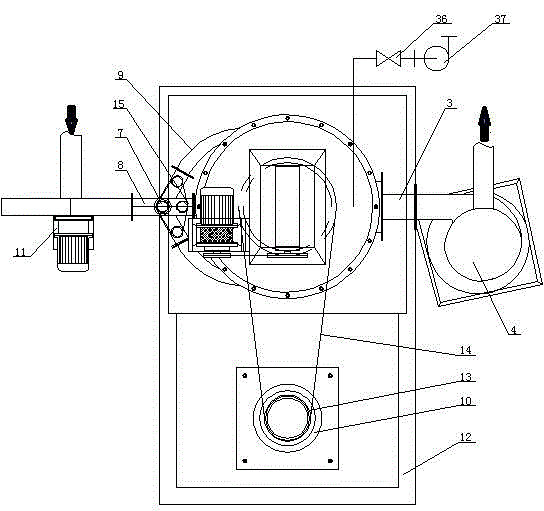

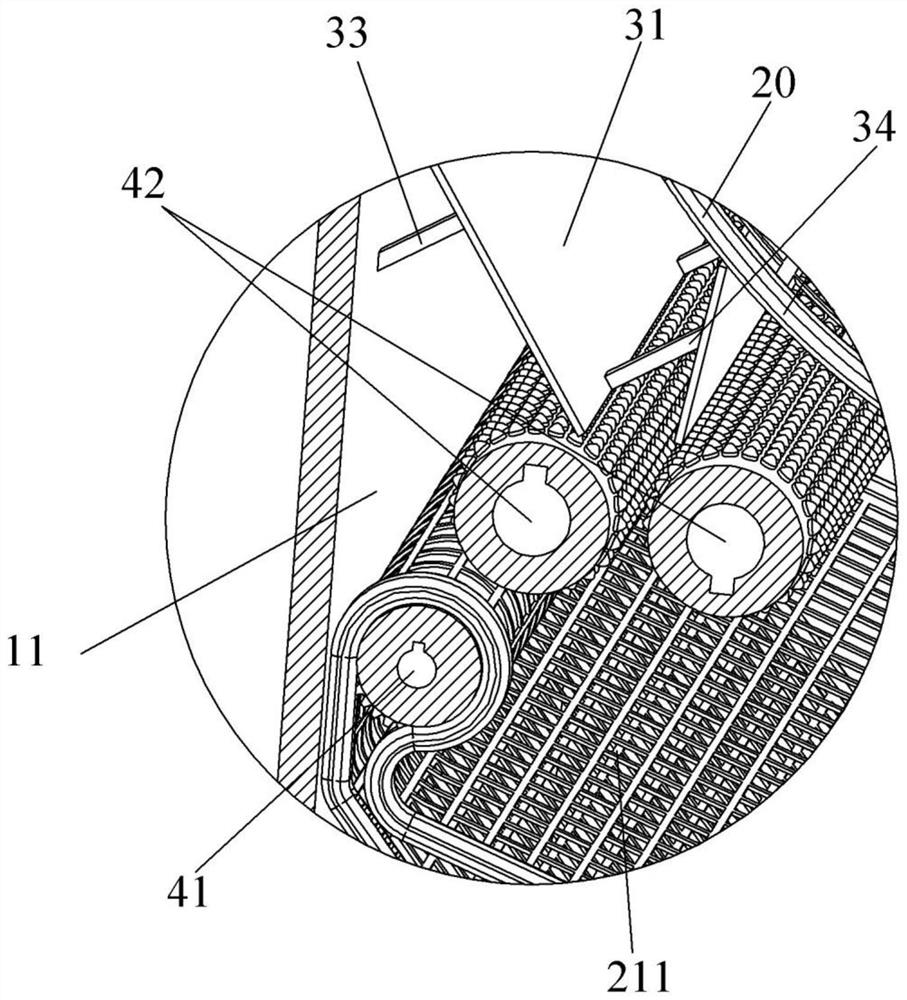

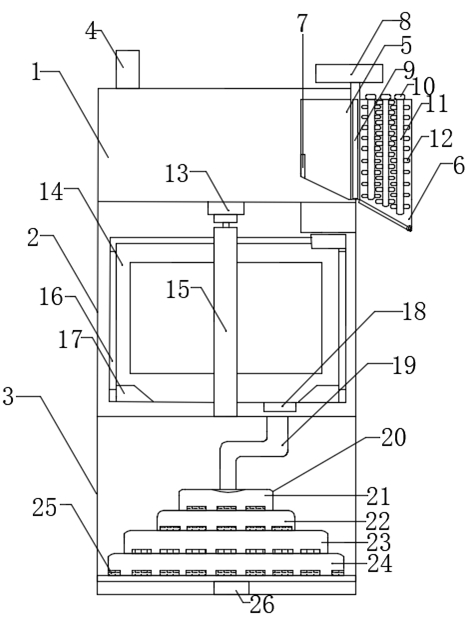

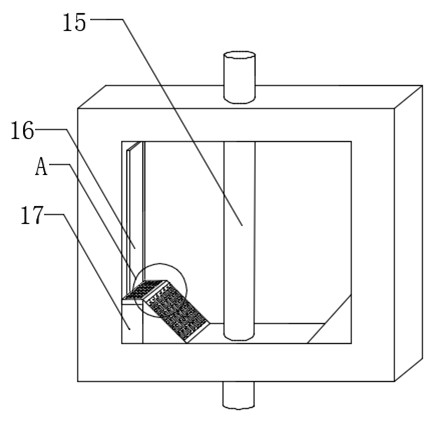

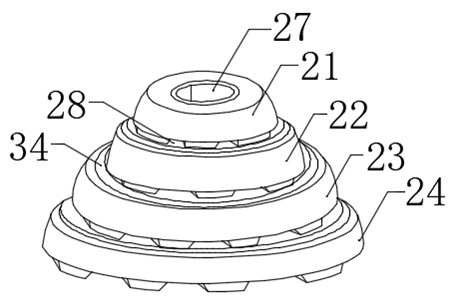

Closed loop balance wheel pulse sand making machine and sand making method

ActiveCN102872944AEfficient sand discharge for finished productsReduce over-grindingGrain treatmentsRiver sandAirflow

The invention provides a closed loop balance wheel pulse sand making machine and a sand making method. A built-in screen cloth barrel is installed, a side-surface aggregate bin is arranged, two direct-connection and side surface airflows of a pulse fan are used for discharging finished product sand so as to avoid overgrinding, and pulverized particles are controlled. The grinding pressure and the pulverization granularity are regulated by a regulation pressure support frame, a grinder roll spring and a grinder roll spacing device. The dry sand making of mountain rock crushed aggregates and the water-flushing wet type sand making of river sand mud crushed aggregates can be realized by the arrangement of a drop guide and a bottom screen cloth. The practical model machine operation effects are as follows: the size of the feeding crushed aggregates is 10-30mm, the finished product sands of superfine sand, fine sand, medium sand and coarse sand can be generated, and the particle range of the finished product is 0.1-6mm.

Owner:程国铭

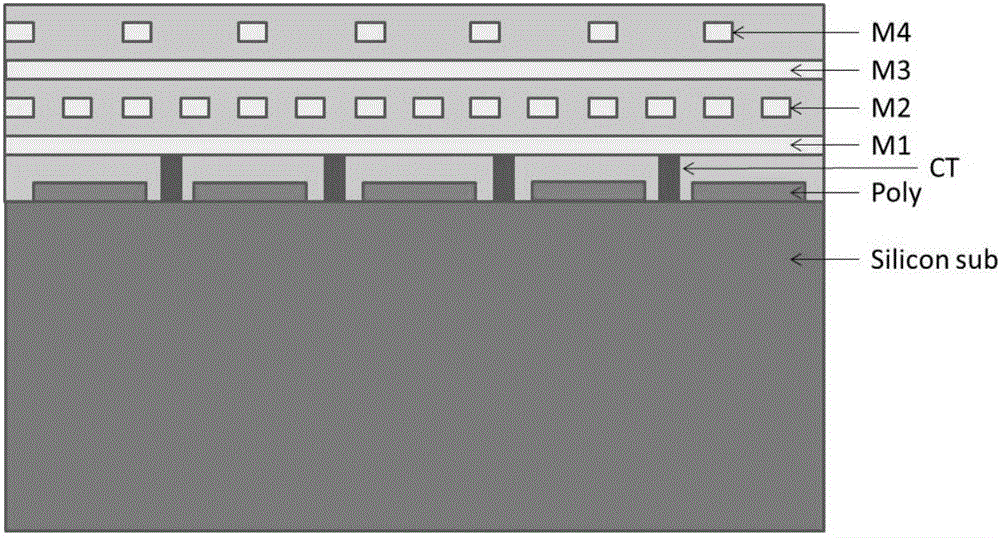

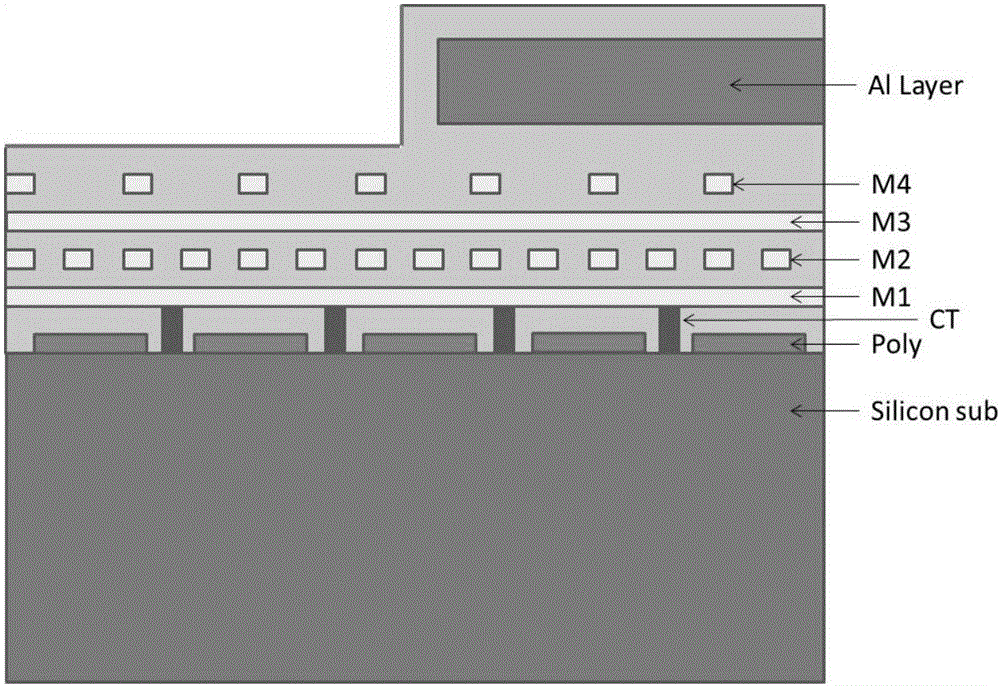

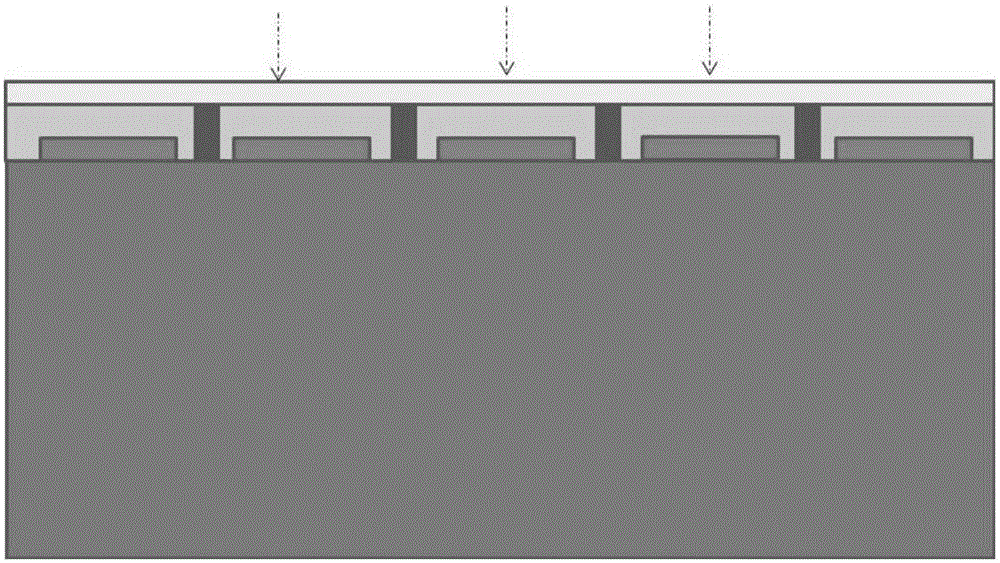

Preparation method for TEM sample

ActiveCN105699698AAvoid processing powerAvoid reactionScanning probe techniquesIon beamCombinatorial chemistry

Disclosed in the invention is a preparation method for a TEM sample. An inclined cutting opening is formed in a chip sample surface by using an ion beam and level removing and TEM sample preparation are carried out on a target area position directly, so that time for TEM sample preparation is substantially shortened; and the position and depth for level removing are controlled precisely, so that the success rate of sample preparation and the quality of the sample are improved. And the chip sample is protected from being damaged.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for making wheat flour for extracting vital gluten

ActiveCN103028457AReduce powder contentGuaranteed qualityGrain huskingGrain polishingProcess engineeringWheat flour

The invention belongs to the processing field of flour production and particularly relates to a method for making wheat flour for extracting vital gluten. The method for making the wheat flour for extracting the vital gluten comprises the following steps of: wheat pre-washing, wheat washing and water adjusting, pure wheat flour grinding, flour mixing and post processing, wherein the pure wheat flour grinding step comprises skin grinding, core grinding, dreg grinding and tail grinding. A skin grinding system comprises a primary skin grinding port and a secondary skin grinding port. The method is characterized in that the speed ratio of the secondary skin grinding port in the skin grinding system is 2:1, namely that the speed ratio of a fast roller to a slow roller is 2:1; and grinding rollers adopted in the core grinding system, the dreg grinding system and the tail grinding system are all matt surface rollers, and the speed ratio of the matt surface rollers is 1.25:1. The wheat flour for the vital gluten, produced by the technical method meets the quality requirement for extracting the vital gluten, few gluten proteins and starch particles are destroyed, gluten is easily formed, and the separating yield rate of the vital gluten is increased by 0.8% more or less. Power consumed by the flour making method is about 5% less than power consumed by a traditional method, so that the energy saving effect is remarkable.

Owner:BINZHOU ZHONGYU FOOD

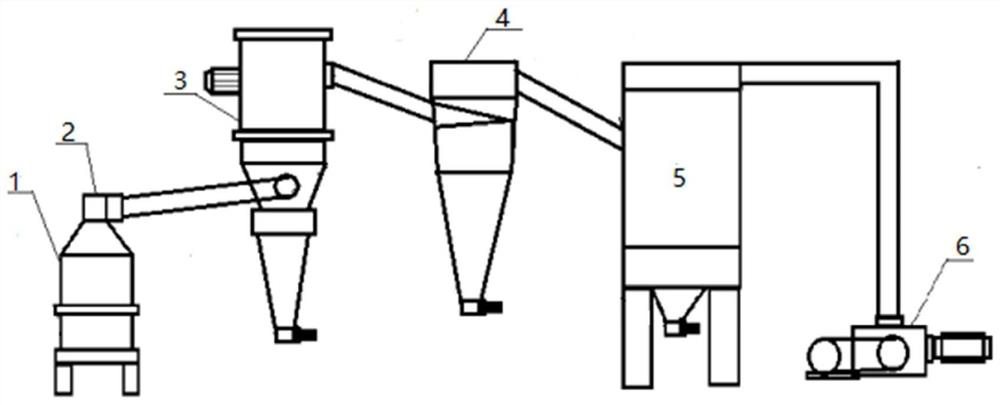

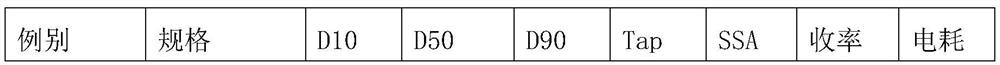

Production method of spheroidized graphite with low specific surface area

ActiveCN114178032AHigh nodularityAvoid over grindingSecondary cellsNegative electrodesCrusherIndustrial engineering

The invention relates to a preparation method of spheroidized graphite. A low-specific-surface-area spheroidized graphite production method uses a steam flow pulverizer, and comprises the following steps: primary pulverizing: adding crystalline flake graphite into the steam flow pulverizer for primary pulverizing until the particle size D50 is 20-30 [mu] m, and rotating a pulverizing disc of a main machine clockwise; second-stage crushing: collecting the materials subjected to the first-stage crushing into one piece, uniformly mixing, repeatedly putting into a crushing machine, crushing for 2-6 times, and counterclockwise rotating a crushing disc of a main machine in the even number of times; shaping: the materials subjected to secondary crushing are collected together and mixed, then the materials are repeatedly put into a crusher with set parameters to be crushed and shaped for 8-12 times, and a main machine crushing disc rotates anticlockwise for the even number of times; and grading is conducted, specifically, the shaped coarse powder material is put into the steam flow pulverizer again to be pulverized, shaped and graded, and operation is repeated for 1-3 times till the particle size and the tap density of the generated coarse powder reach target values. The production method gives consideration to tap density and specific surface area.

Owner:萝北奥星新材料有限公司

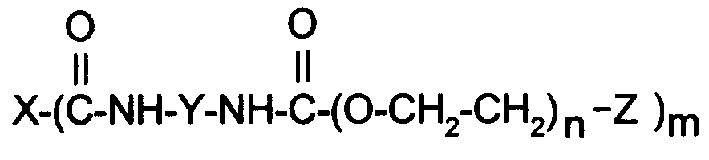

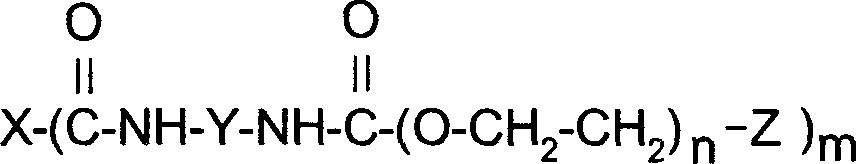

Composite for grinding

A polishing composition that prevents a peripheral portion of the surface of a substrate for a magnetic disk from being excessively polished. A first polishing composition according to the present invention includes a compound, which is represented by the following general formula. <EMI ID=1.1 HE=19 WI=96 LX=437 LY=772 TI=CF> <PC>The letter X represents a residue of polyether polyol. The letter m represents a number equal to the number of hydroxyl groups in one molecule of the polyether polyol. The letter Y represents a divalent hydrocarbon group. The letter Z represents a residue of a monovalent compound, which has an active hydrogen atom. The letter n represents an integer number of at least three. A second polishing composition according to the present invention includes a polymer, which has a monomer unit derived from isoprene sulfonic acid or its salt. These polishing compositions also comprise an abrasive, a polishing accelerator and water.

Owner:FUJIMI INCORPORATED

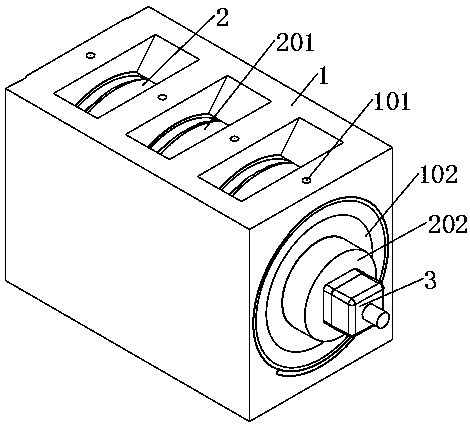

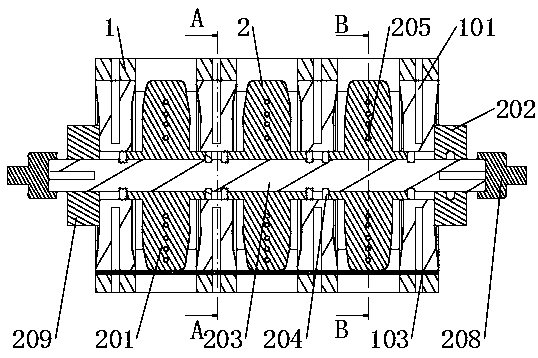

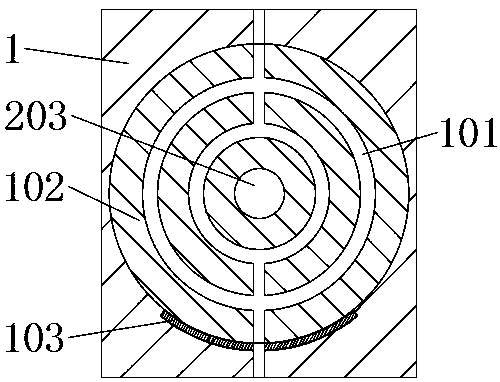

Quick crushing equipment for silicon nitride

The invention discloses quick crushing equipment for silicon nitride. The quick crushing equipment for silicon nitride comprises a fixing part and a rotating part. The fixing part comprises a mountingbody. A plurality of independent grinding cabins are uniformly arranged in the mounting body in a horizontal axis direction. Screens are arranged at openings of the bottoms of the grinding cabins. Through holes are formed between adjacent grinding cabins. Fixed grinding plates are fixedly arranged in the through holes. The rotating part is further arranged in the mounting body. The rotating partcomprises movable grinding plates rotatably mounted in the grinding cabins. The axes of the movable grinding plates and the grinding cabins are superposed, and the circumferential surfaces of the movable grinding plates are in contact with the inner walls of the grinding cabins. The movable grinding plates move in a reciprocating manner in the axis directions. The quick crushing equipment for silicon nitride impacts and grind raw materials simultaneously by means of joint action of the movable grinding plates and the fixed grinding plates combining axial motions with reciprocating motions, andby matched with synchronization effects of the screens, it is ensured that product particles reach a standard.

Owner:河南锐鑫同创高新材料科技有限公司

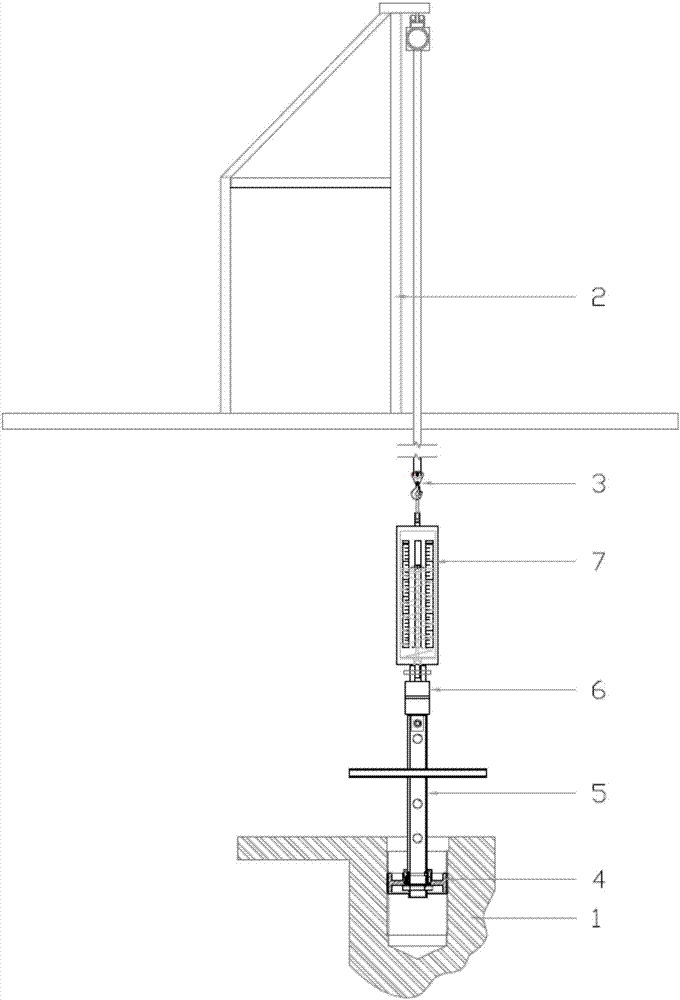

Online repairing method for main screw holes of reactor pressure vessel flanges

The invention relates to an online repairing method for screw holes and threads, in particular to the online repairing method for the main screw hole of reactor pressure vessel flanges. The repairingmethod comprises the following steps of 1, defects of the main screw holes and the threads are inspected and repair preparation is carried out; 2, manually repairing is carried out by a scraper; 3, manual slight grinding is carried out by a metallographic abrasive paper; 4, screw tap repairing method is adopted; and 5, online grinding and repairing are adopted. According to the online repairing method, common defects of the main screw holes and the threads are covered, so that fine, efficient and reliable online repairing is realized.

Owner:SANMEN NUCLEAR POWER CO LTD

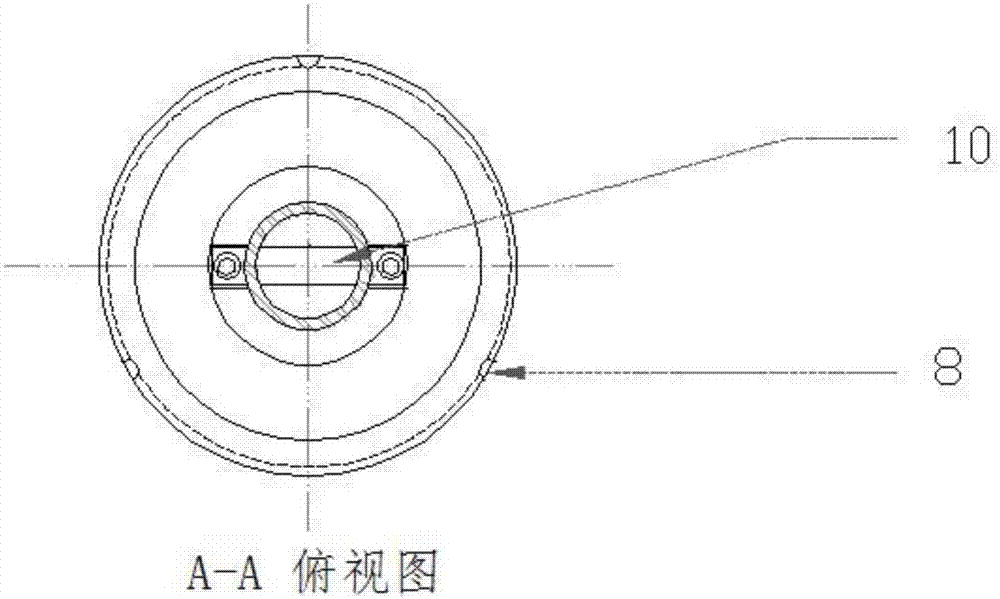

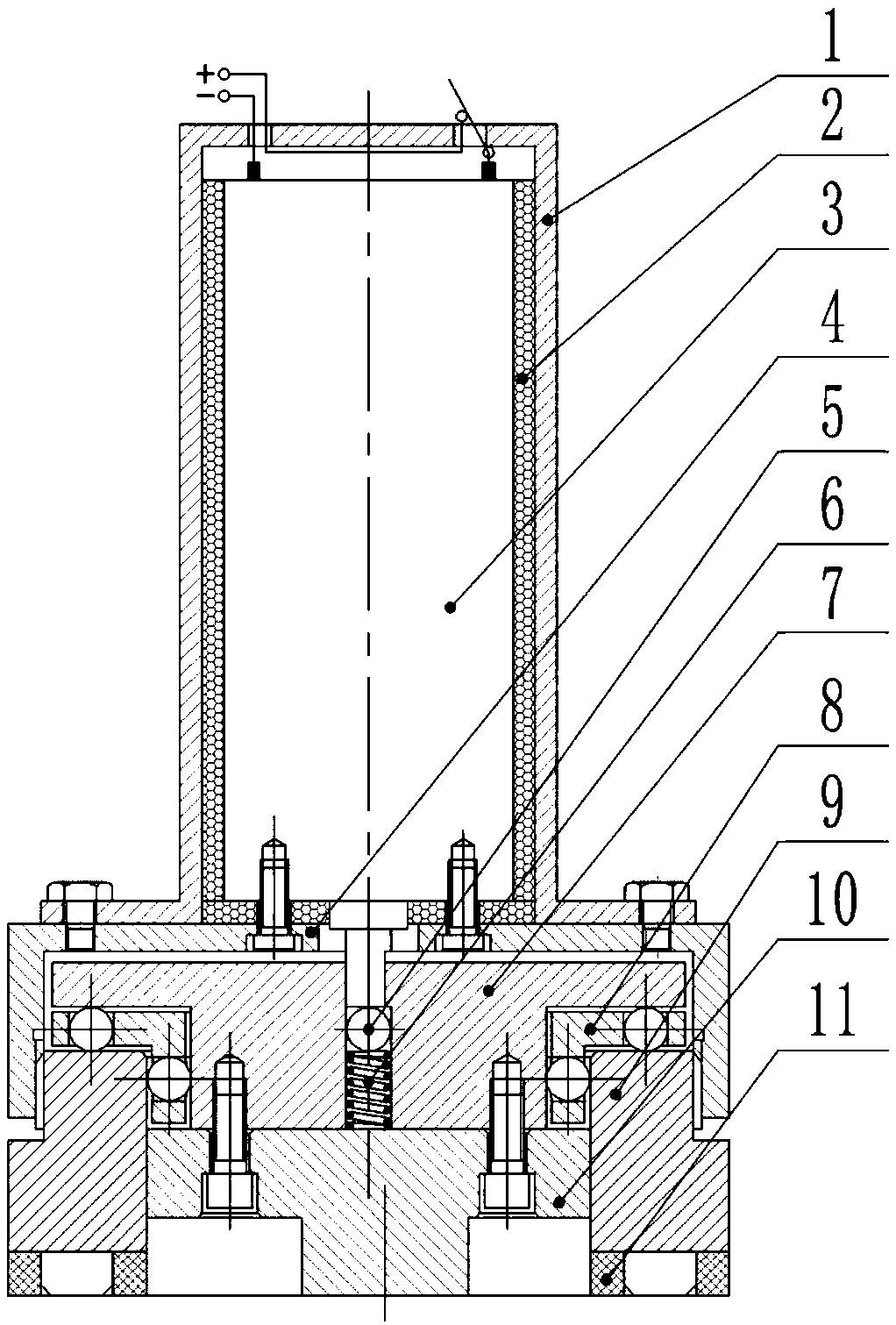

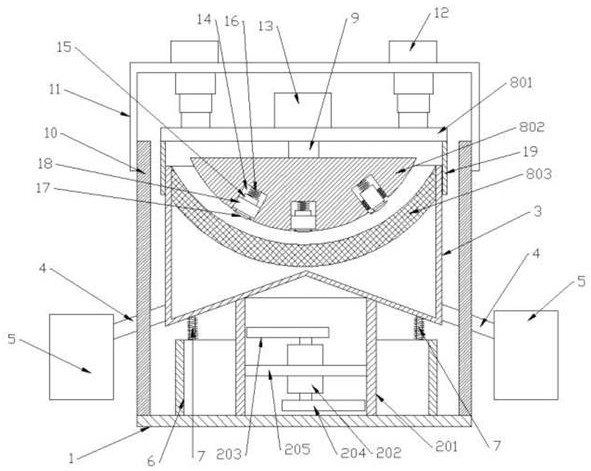

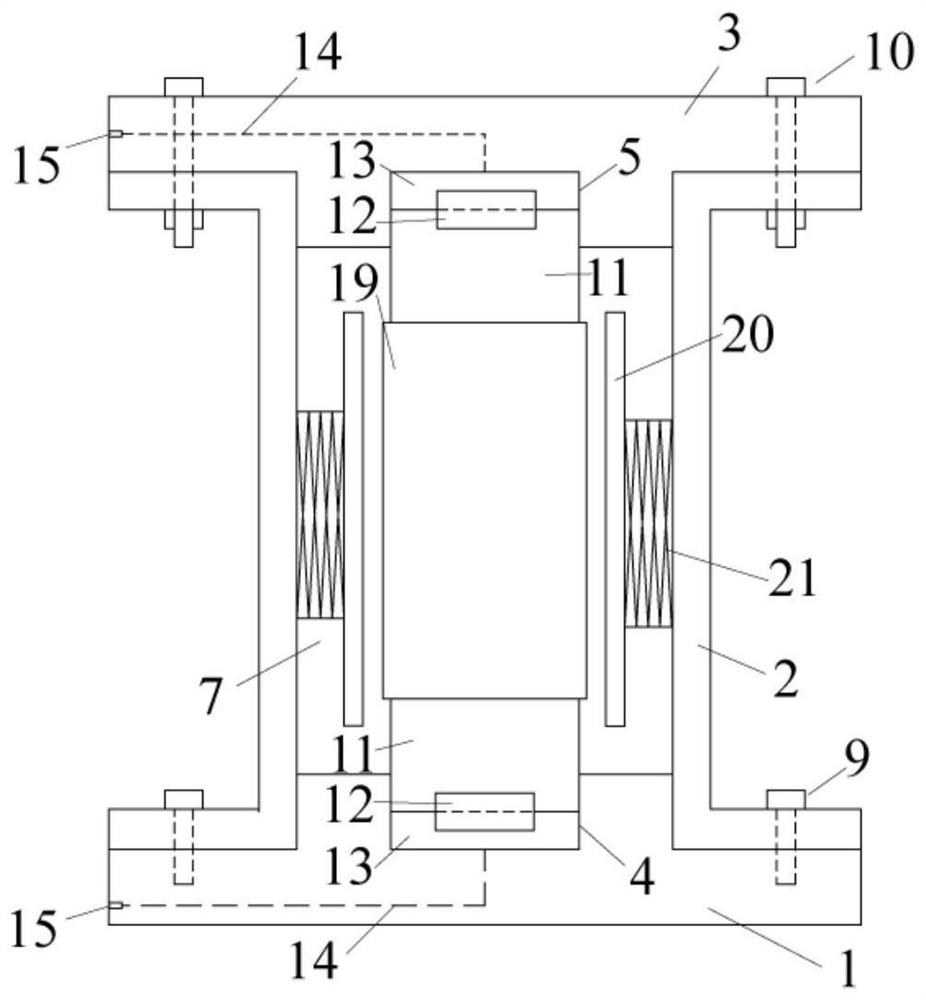

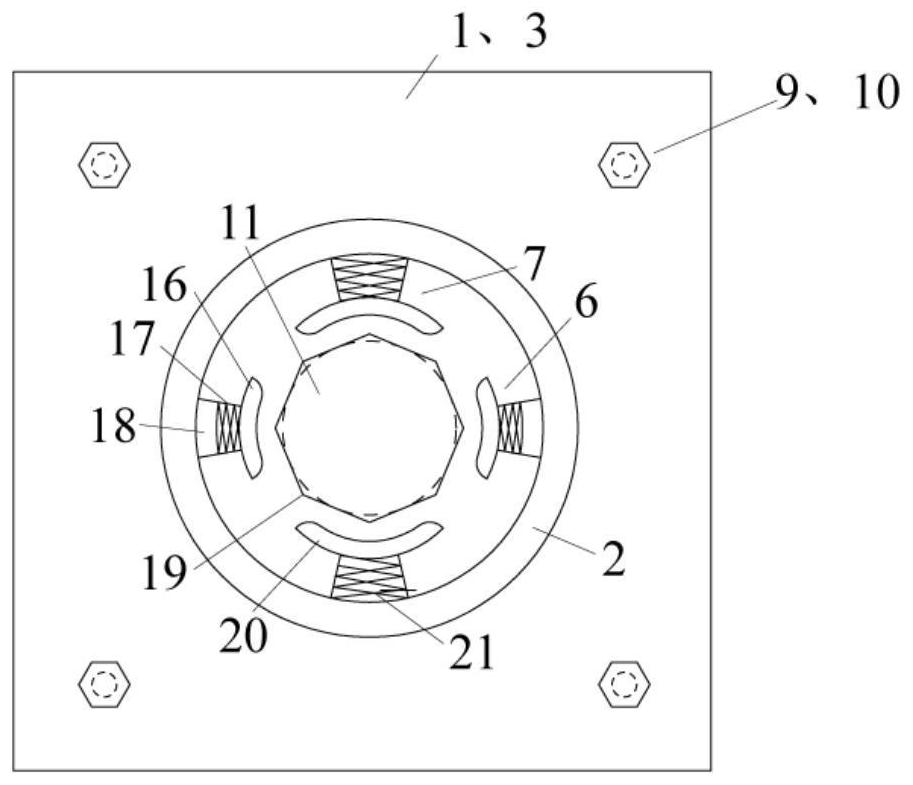

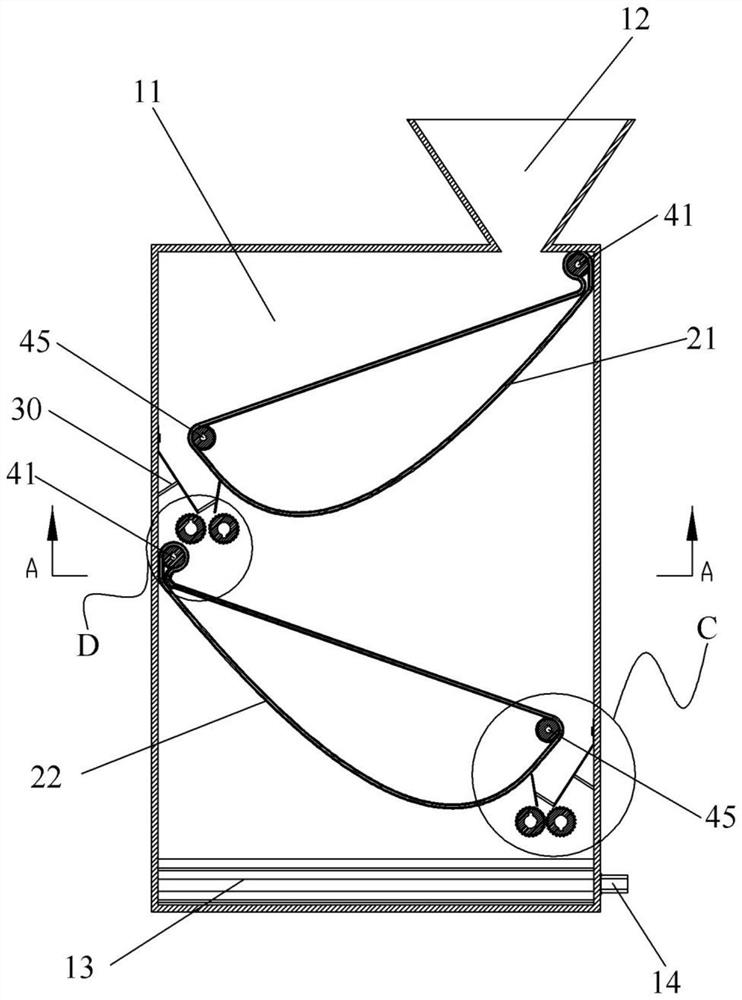

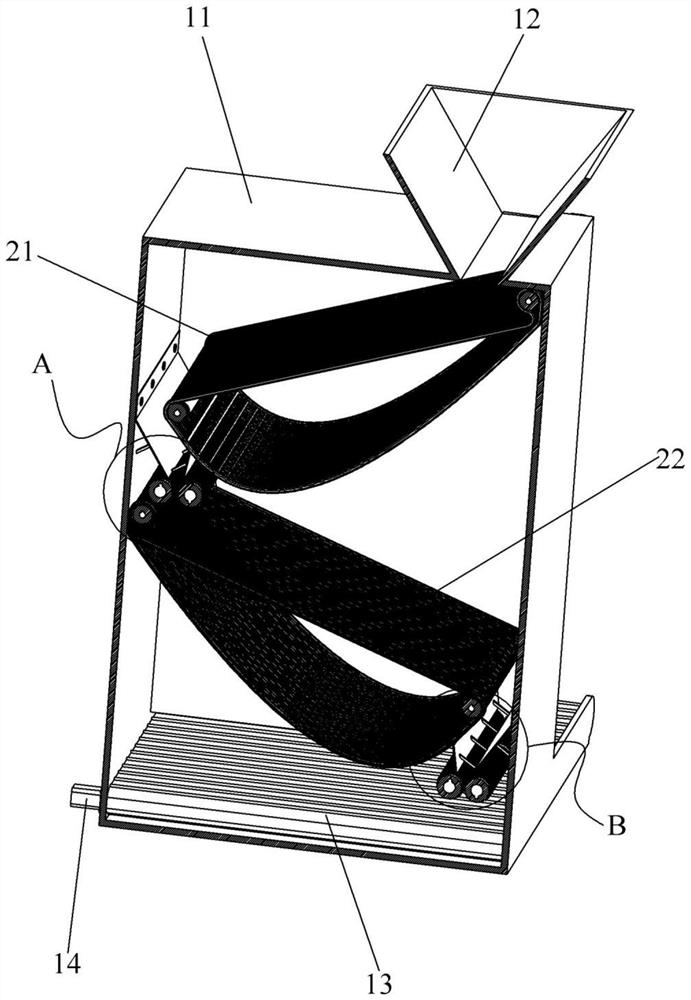

Vertical continuous stirring ball-milling equipment and working method thereof

PendingCN112808393ARealize uninterrupted continuous productionEconomy of productionGrain treatmentsControl systemAir pump

The invention discloses vertical continuous stirring ball-milling equipment which comprises a barrel, a plurality of grinding balls, a barrel cover, a stirrer and an air inlet and outlet control system; the barrel is vertically arranged; the plurality of grinding balls are arranged in the barrel; the barrel cover covers a top opening of the barrel in a sealing manner; the stirrer penetrates through the barrel cover, extends into the barrel and can rotate; materials placed in the barrel are ground by the grinding balls under the rotation of the stirrer; the air inlet and outlet control system comprises an air inlet channel and an air outlet; one end of the air inlet channel is arranged on the bottom surface of the barrel and communicated with the inside of the barrel, and the other end is communicated with a pressurized air tank or an air pump outside the barrel; the air outlet is formed in the barrel cover; the air inlet and outlet control system further comprises a spherical crown type cover plate, and the spherical crown type cover plate is arranged in the barrel, covers a port of the air inlet channel and is connected with the bottom face of the barrel through an elastic piece; and a feeding hole penetrating through the inside and the outside of the barrel is formed in the barrel cover. The vertical continuous stirring ball-milling equipment has the advantages of continuous processing, accurate product particle size control, high efficiency, energy saving and the like.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

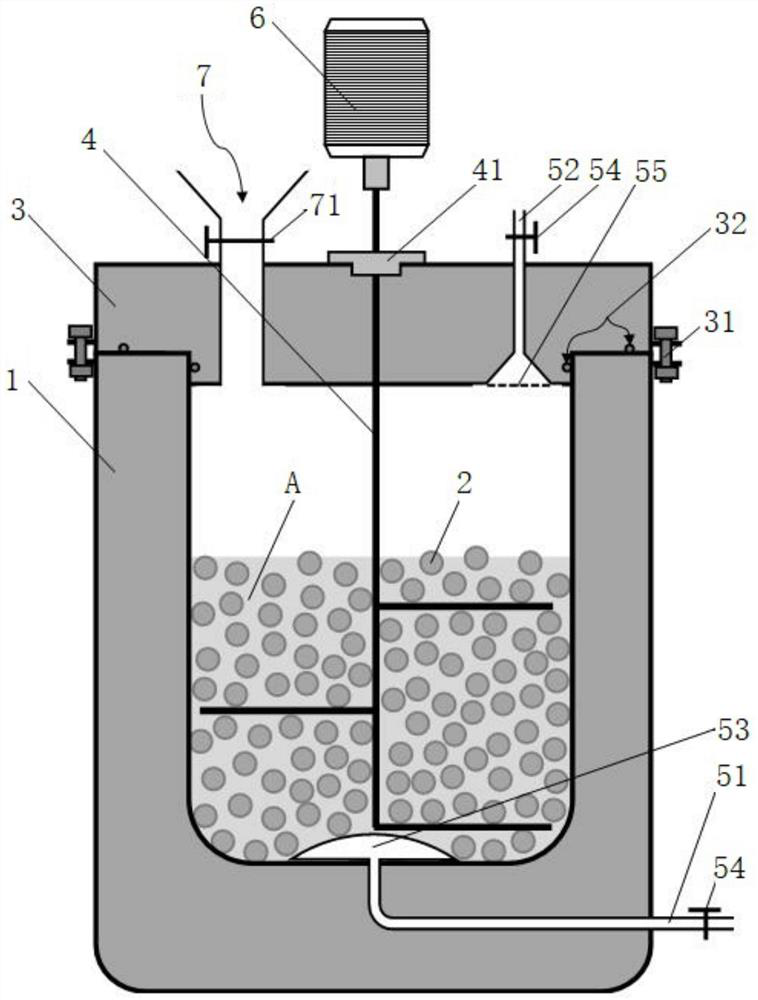

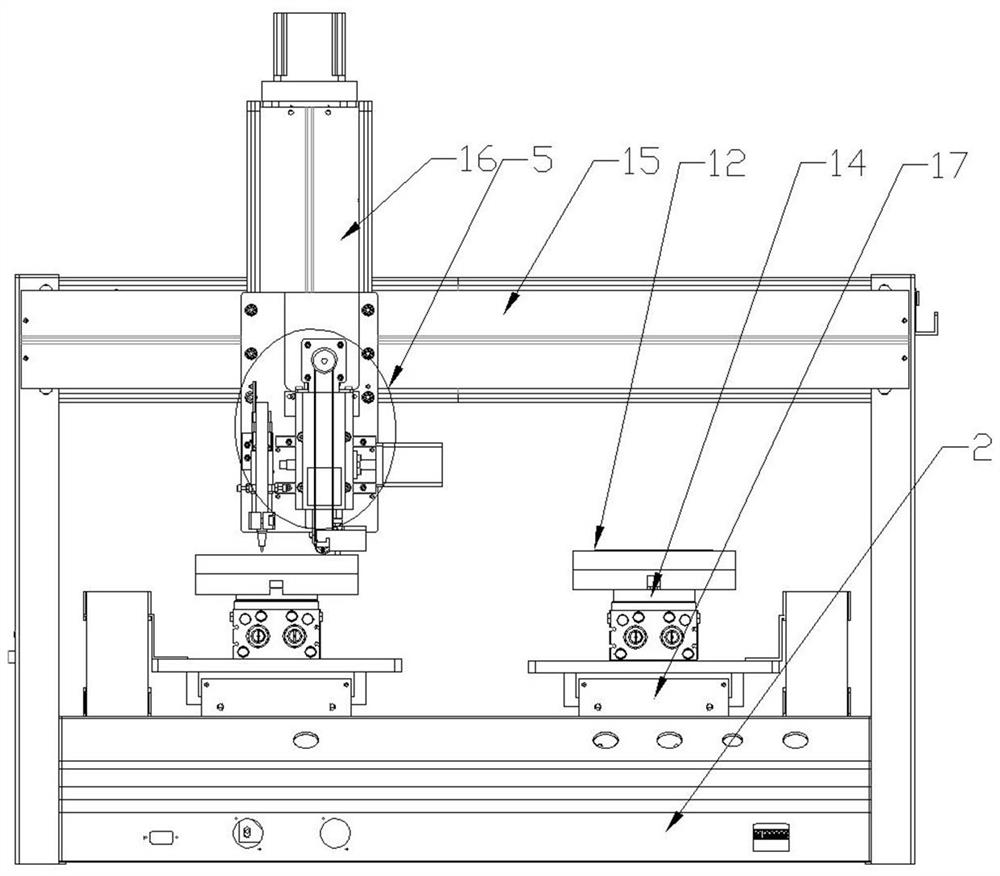

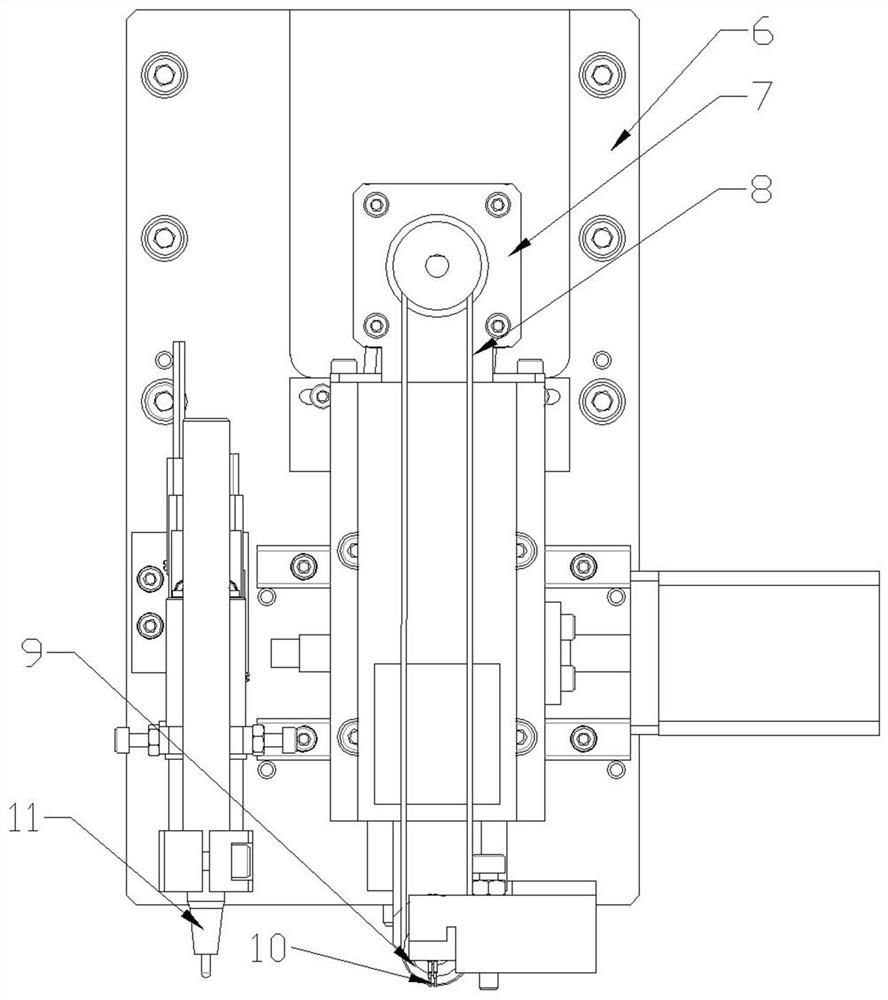

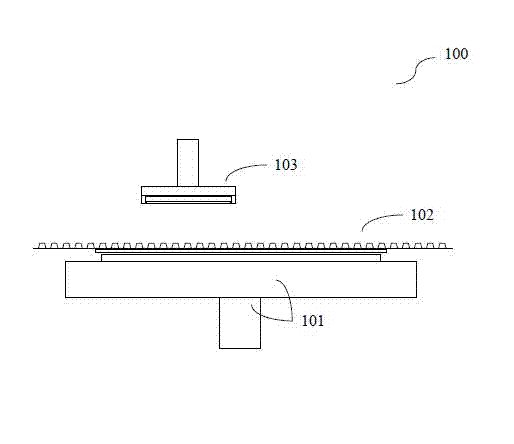

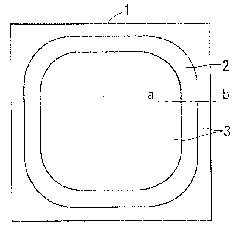

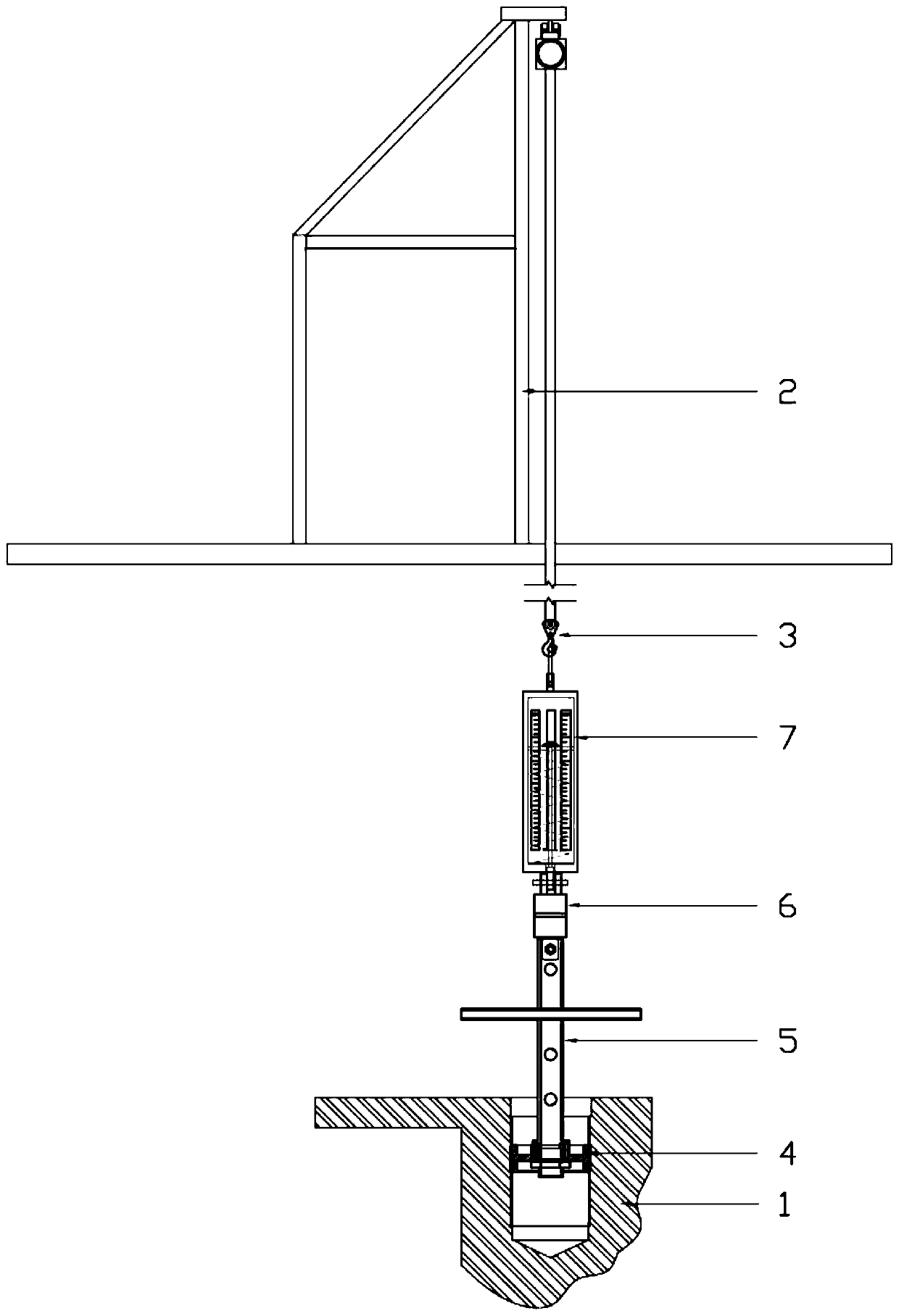

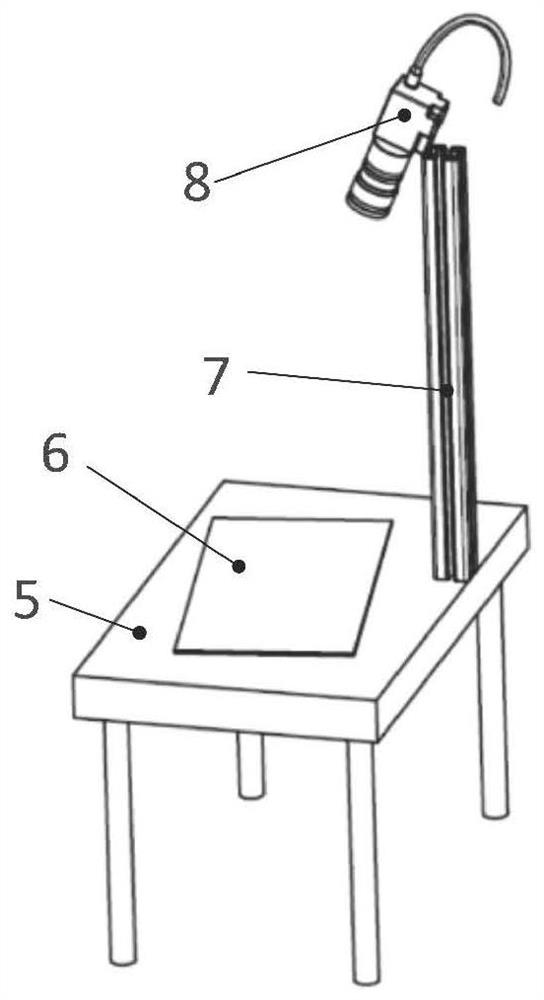

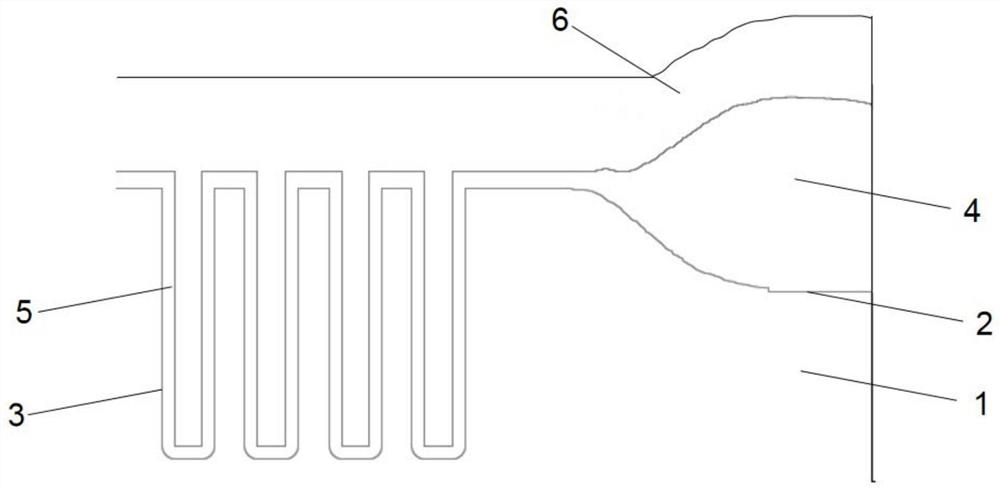

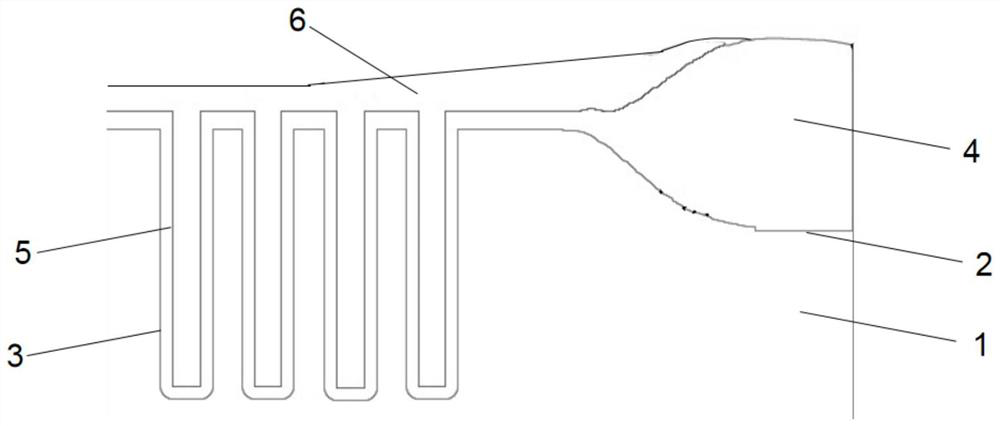

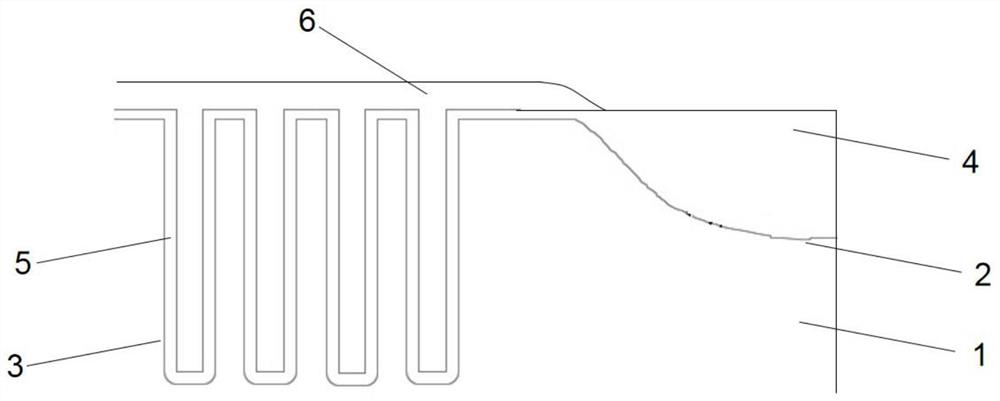

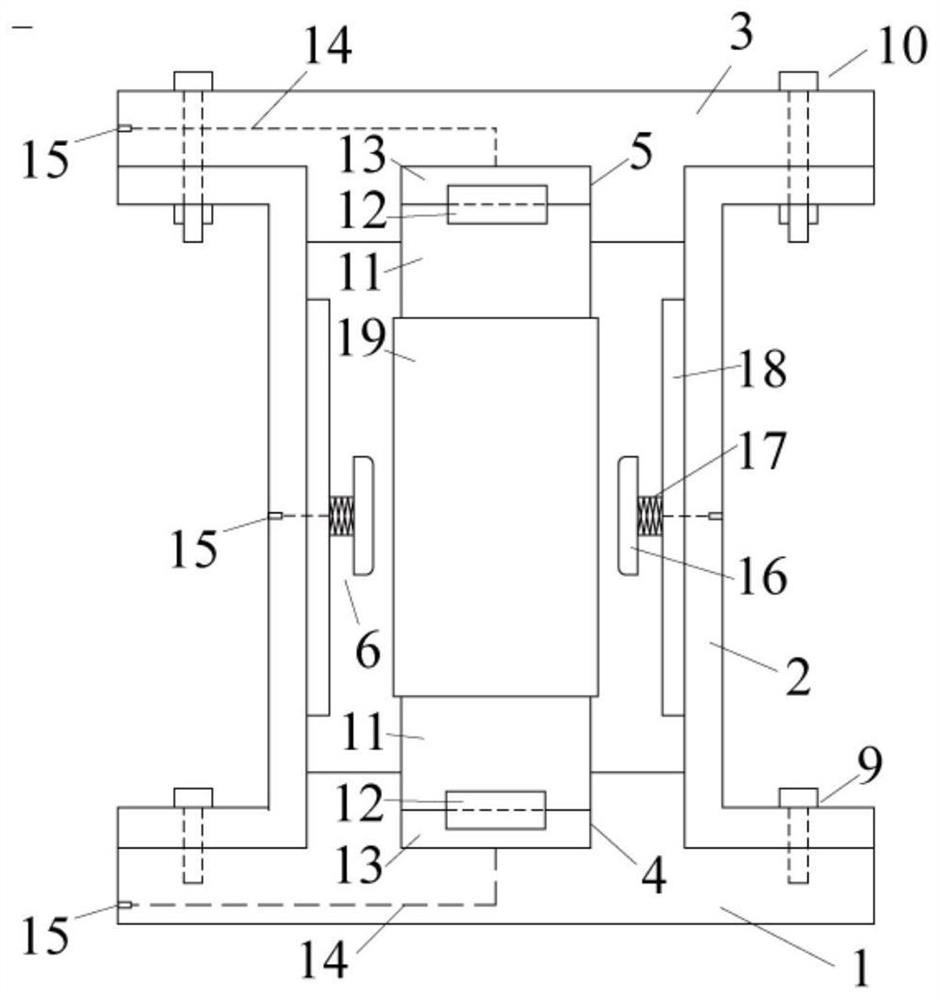

Strain gauge grinding and resistance adjusting system and method

PendingCN114167139AReduce investmentReduce grinding speedResistance/reactance/impedenceLapping machinesTester deviceEngineering

The strain gauge grinding and resistance adjusting system provided by the invention is high in automation degree, ensures the detection precision and high yield, and can effectively reduce the cost. The system comprises a resistance tester and a machine table (2) containing an XYZ-axis moving table, and further comprises at least one strain gauge placement table (3) and a grinding and testing integrated assembly (5), and the grinding and testing integrated assembly comprises an assembly substrate (6), a grinding module and a testing module; under the action of the XYZ-axis moving table, the grinding and testing integrated assembly moves to the strain gauge placement table to grind a resistance-adjusting strain gauge (4) to be tested and measure the resistance value in real time, the measured resistance value is fed back to the resistance tester and the control table located in the machine table in real time, whether the resistance-adjusting strain gauge to be tested needs grinding and resistance adjusting or not is judged according to the tested resistance value, and then the resistance-adjusting strain gauge to be tested needs grinding and resistance adjusting. And if not, the product is a qualified product or an NG product. The method can be applied to the field of intelligent equipment.

Owner:珠海立众科技有限公司

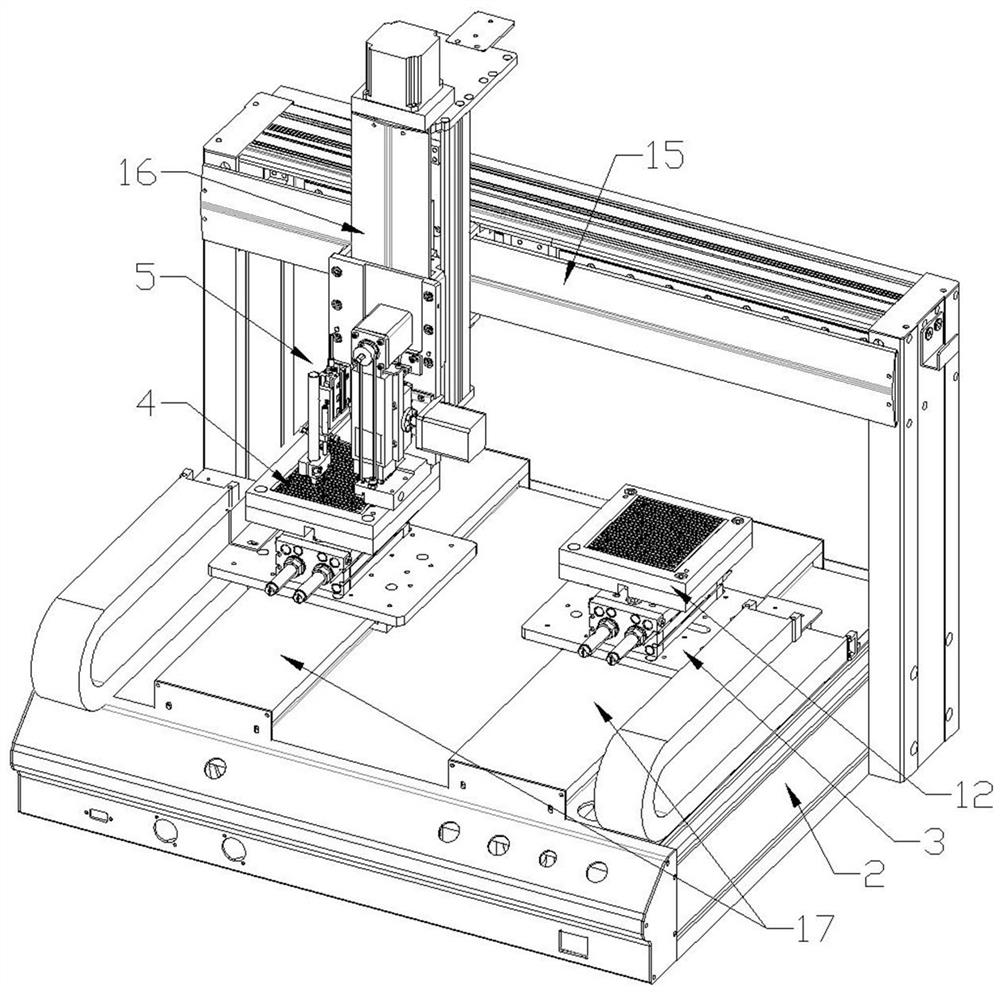

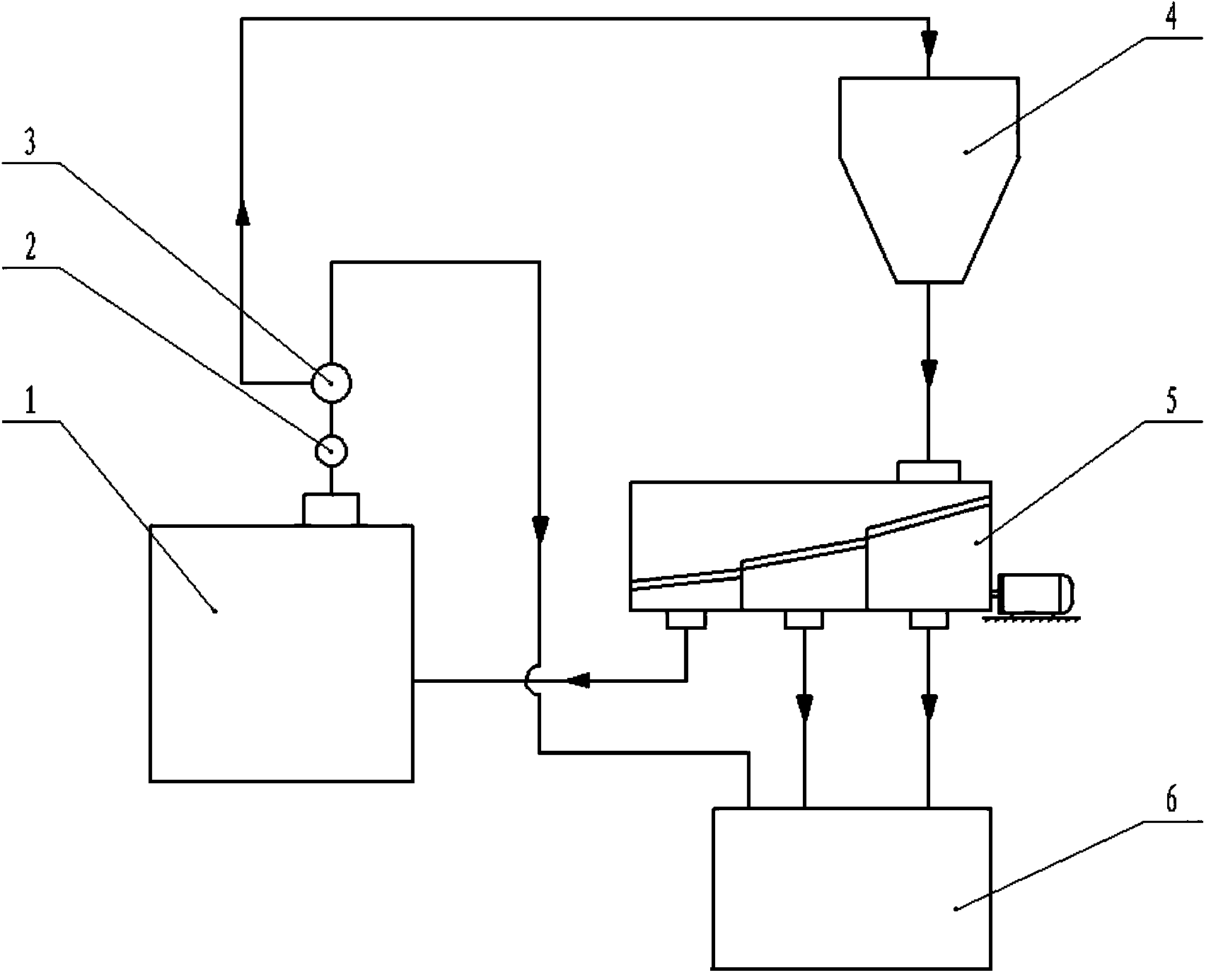

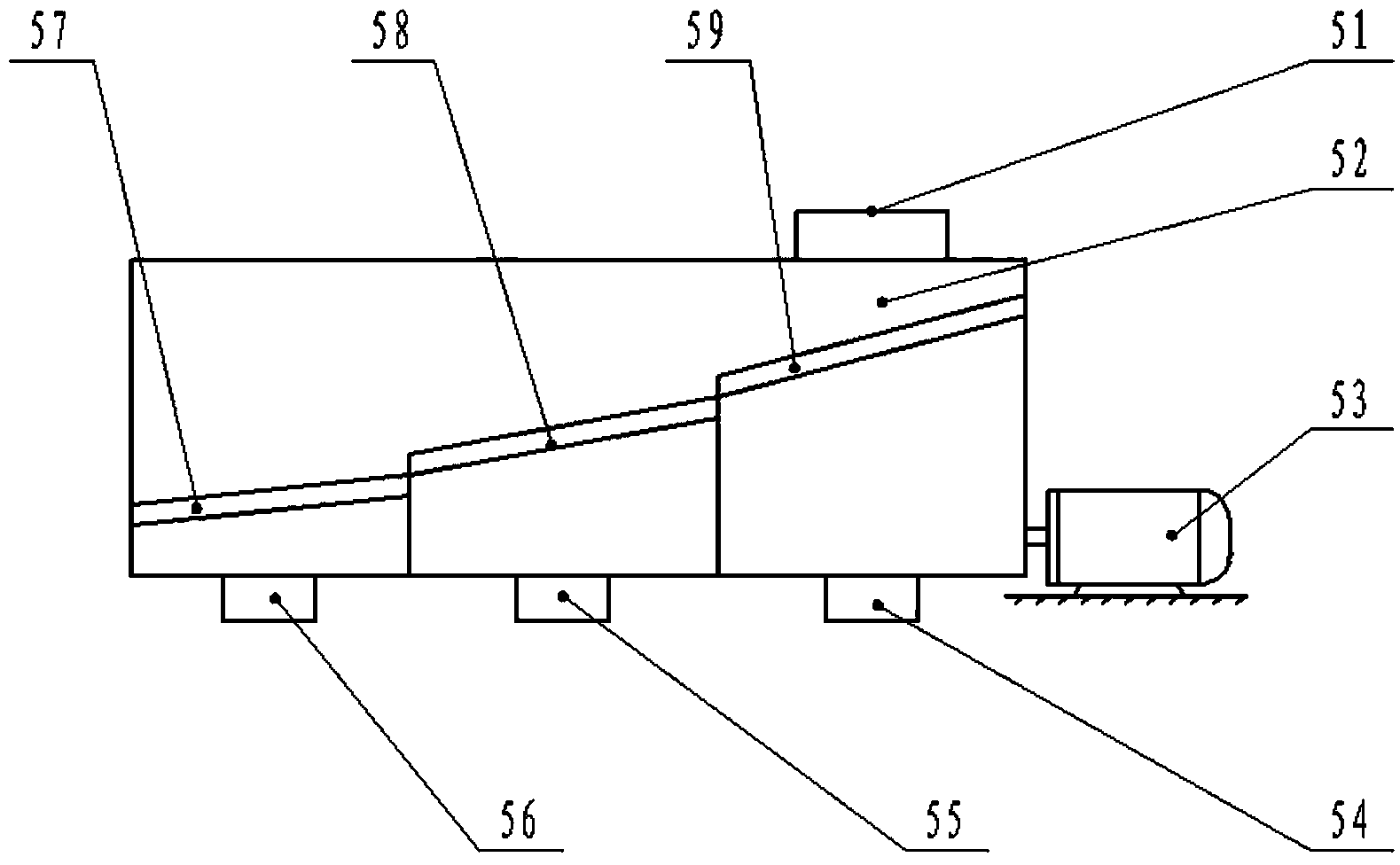

Electrolytic manganese dioxide screening equipment

InactiveCN103537358AAvoid over grindingReduce the burden onSievingScreeningElectrolysisEconomic benefits

The invention provides electrolytic manganese dioxide screening equipment comprising a grinding machine, a cyclone separator, a vibrating screen classifier and a storage bin. The electrolytic manganese dioxide screening equipment is characterized in that an online analysis sampling instrument is arranged on the discharge opening of the grinding machine, and a tee valve is arranged above the online analysis sampling instrument; one path of the tee valve is connected with the storage bin, the other path of the tee valve is connected with the inlet of the cyclone separator, and the discharge opening of the cyclone separator is connected with the vibrating screen classifier. The electrolytic manganese dioxide screening equipment provided by the invention avoids the excessive grinding of the qualified manganese dioxide particles, improves the uniformity of the particle diameters of materials, reduces the load of the grinding machine and realizes automation; and the electrolytic manganese dioxide screening equipment provided by the invention is simple and compact in structure, small in occupation area, convenient to operation and suitable for generalization and application, thereby having a good economic benefit.

Owner:GUANGXI GUILIU CHEM CO LTD

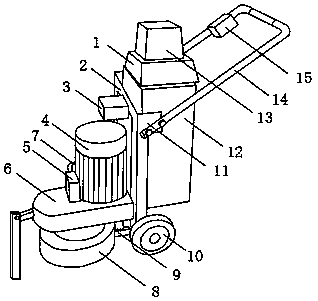

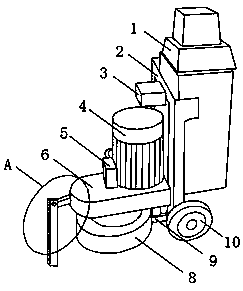

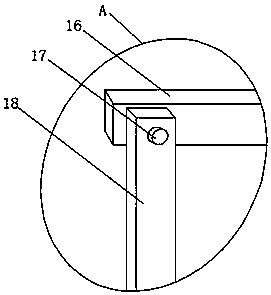

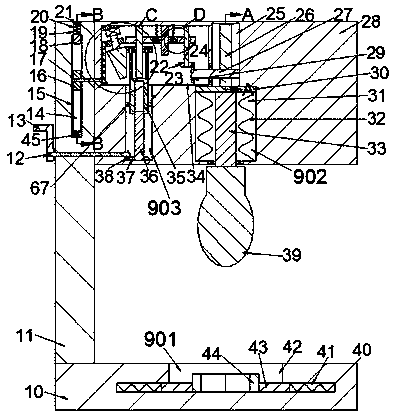

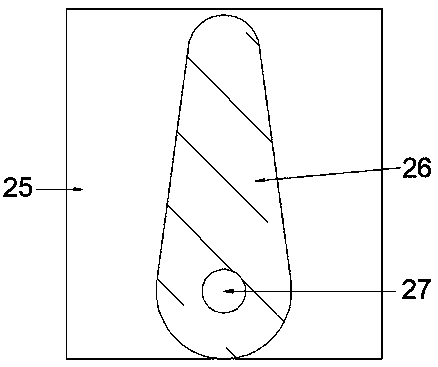

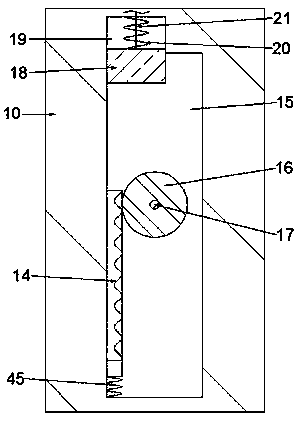

Reciprocating stone grinding machine

InactiveCN108436644ASimple structureEasy to operateGrinding carriagesGrinding drivesArchitectural engineeringWater tanks

The invention discloses a reciprocating stone grinding machine. The reciprocating stone grinding machine comprises a main body bracket; a base and a cooling water tank are riveted to the outer surfaceof the front end of the main body bracket; moving wheels are fixedly installed on the outer surface of one side of the main body bracket; a grinding disc and a telescopic shaft shell are fixedly installed on the outer surface of the lower end of the base; a telescopic shaft is movably connected into the telescopic shaft shell, the outer surface of one side of the telescopic shaft shell is fixedlyconnected with a second fastening bolt, and the outer surface of the lower end of the telescopic shaft is fixedly connected with a limiting disc; and a fixed rod is welded to the outer surface of oneside of the base, and the outer surface of one side of the fixed rod is movably connected with a protective rod. The reciprocating stone grinding machine is provided with the limiting disc, the protective rod and the cooling water tank, over grinding of the grinding machine can be prevented, the grinding disc can be prevented from being damaged in the moving process, in addition, the temperaturecan be quickly lowered, and the better using prospects can be brought.

Owner:JIANGSU KERUIXIN MACHINERY

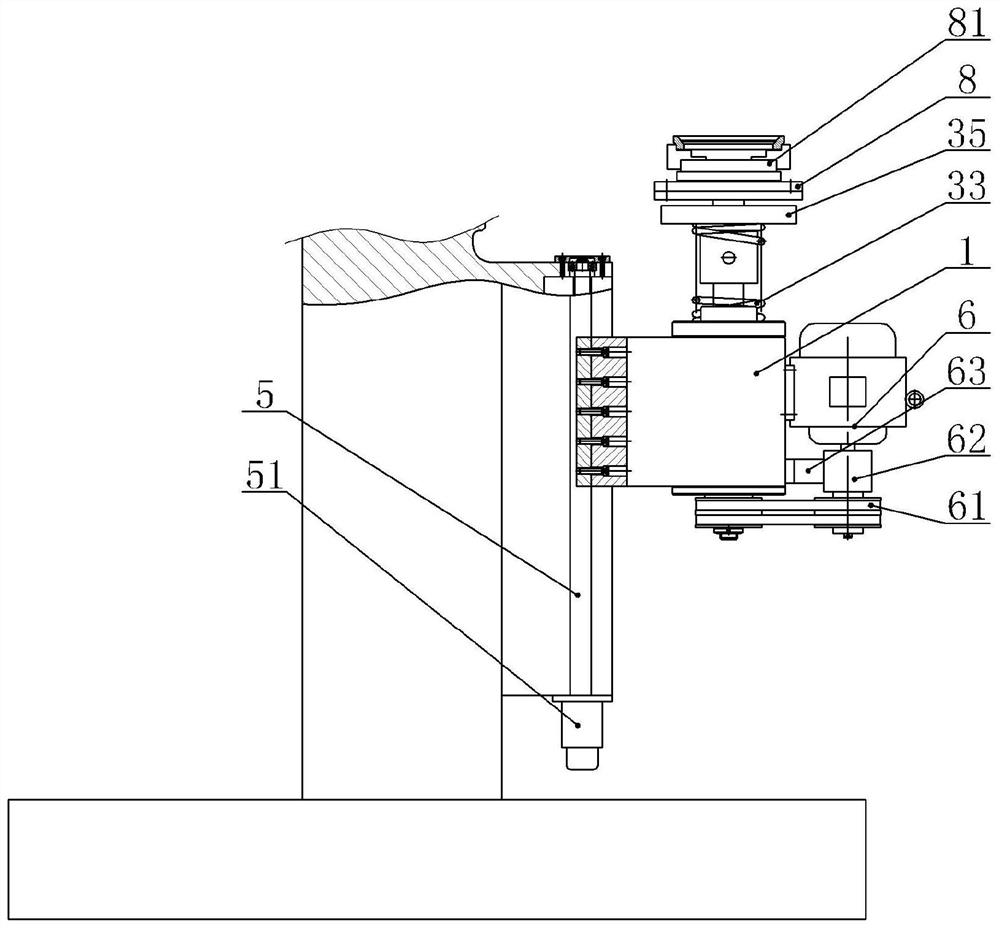

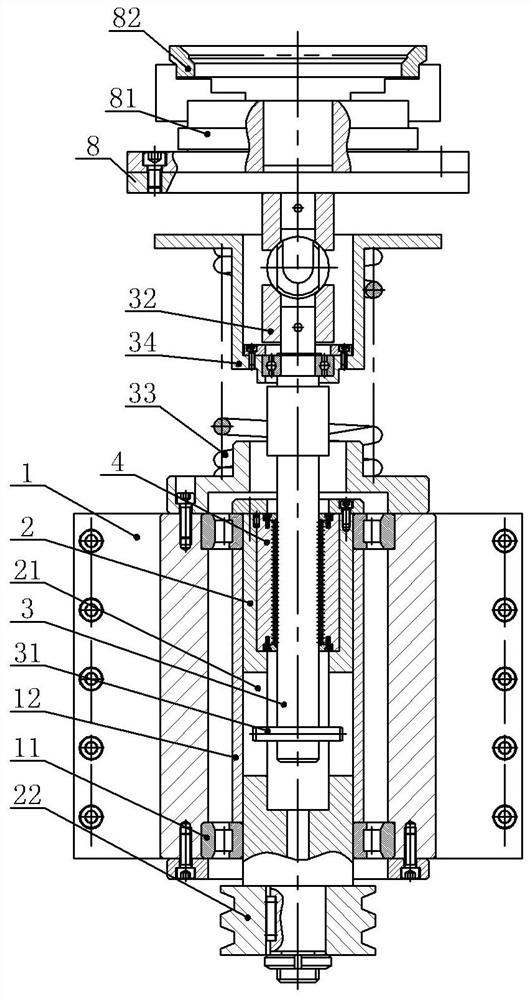

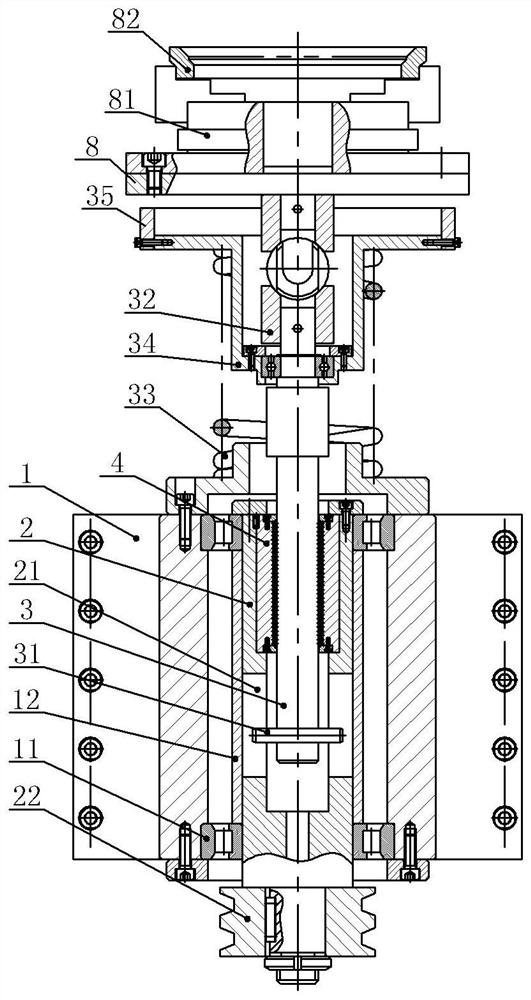

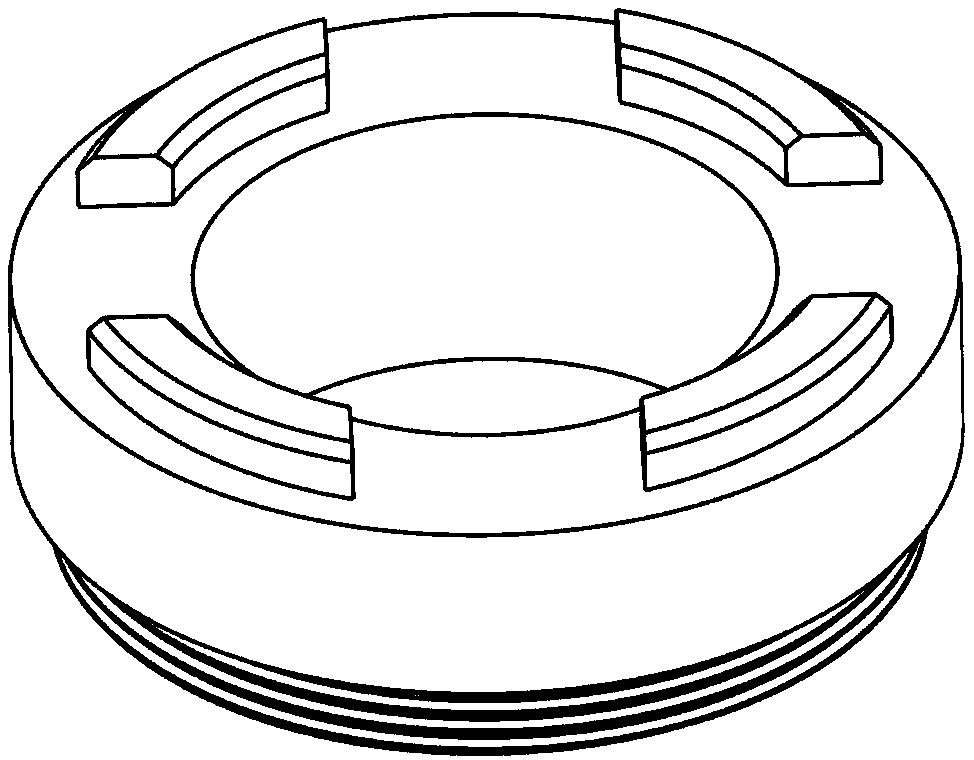

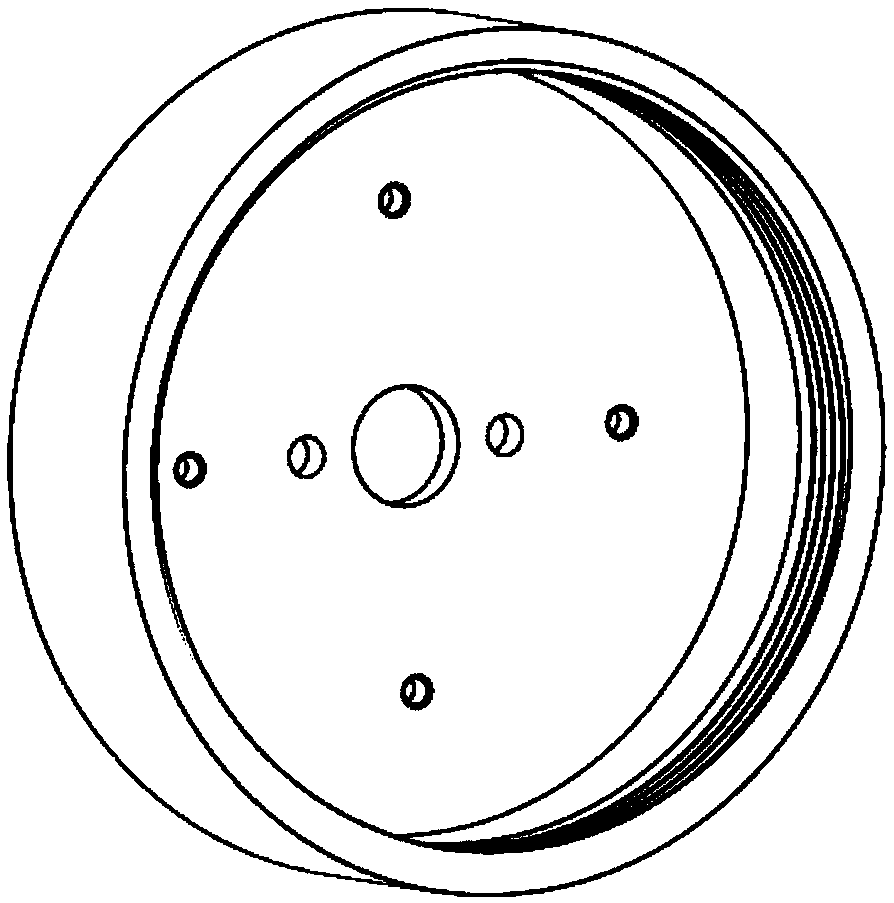

Valve seat grinding, clamping and moving device

PendingCN112157528ASlide fastReduce workloadGrinding drivesSeat surface grinding machinesDrive shaftMachining

The invention relates to the field of valve machining, in particular to a valve seat grinding, clamping and moving device. The device comprises a lathe bed, a valve seat clamping mechanism and a valveseat clamping and moving mechanism, wherein the valve seat clamping mechanism comprises a transmission main shaft, a transmission shaft, a clamping mechanism base and a spring; the transmission mainshaft penetrates through the clamping mechanism base, a fixing groove is formed in the transmission main shaft, the transmission shaft is coaxial with the transmission main shaft, and a rectangular linear bearing is arranged between the transmission shaft and the transmission main shaft; the upper end of the transmission shaft is connected with a self-centering chuck; the spring is positioned between the transmission main shaft and the self-centering chuck; the valve seat clamping and moving mechanism comprises a lead screw, and the lead screw penetrates through the clamping mechanism base andthe lathe bed and is in threaded fit with the clamping mechanism base; a guide groove is formed in the lathe bed in the axial direction of the transmission shaft; and the clamping mechanism base is connected with the guide groove in a sliding manner. The valve seat grinding, clamping and moving device disclosed by the invention can drive a valve seat to move, so that the workload of workers is reduced, and the machining efficiency is improved.

Owner:CHONGQING CHUANYI CONTROL VALVE

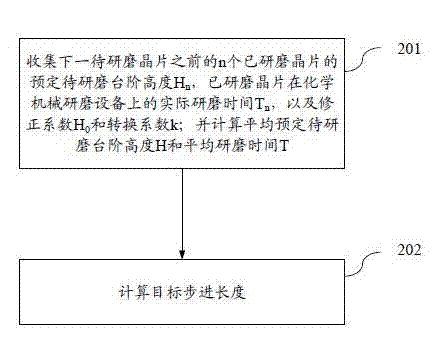

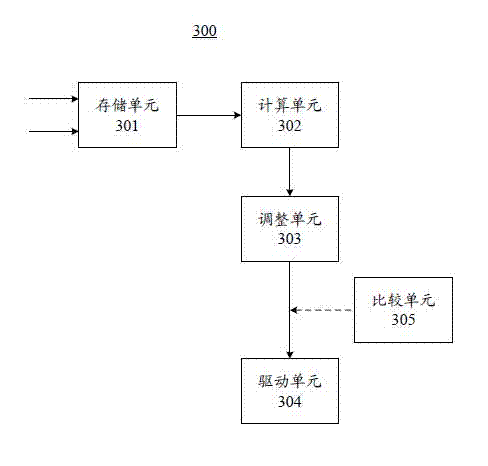

Method for reducing memory effect of chemical mechanical grinding equipment of fixed abrasive particles

ActiveCN102452040AReduce memory effectImprove use valueSemiconductor/solid-state device manufacturingLapping machinesMemory effectConversion coefficients

The invention relates to a method for reducing the memory effect of chemical mechanical grinding equipment of fixed abrasive particles. The method comprises the following steps of: a) collecting the preset to-be-ground step height Hn of n ground wafers before the next to-be-ground wafer, the actual grinding time Tn, a correction coefficient H0 and a conversion coefficient k; and calculating the average preset to-be-ground step height H and average grinding time T of the ground wafers respectively; and b) calculating a target stepping length IR of the next to-be-ground wafer by a grinding pad according to the following calculation model: IR=k.T(H0+H) / 103. The method provided by the invention avoids the conditions of insufficient grinding of the next to-be-ground wafer due to the insufficient abrasive particles on the grinding pad or excessive grinding and waste caused by excessive abrasive particles, and thus reduces the memory effect of chemical mechanical grinding of the fixed abrasive particles, and improves the grinding rate and consistency of wafers with the wafer thickness.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

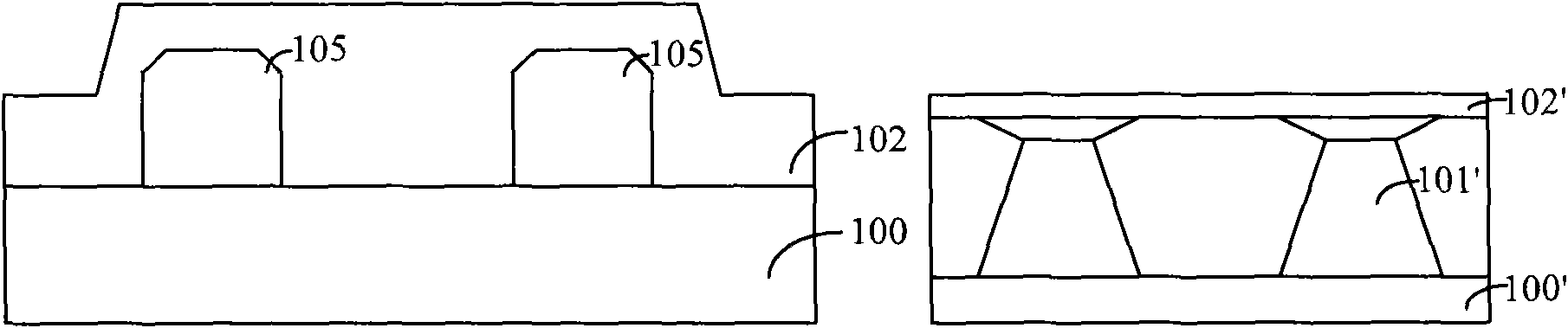

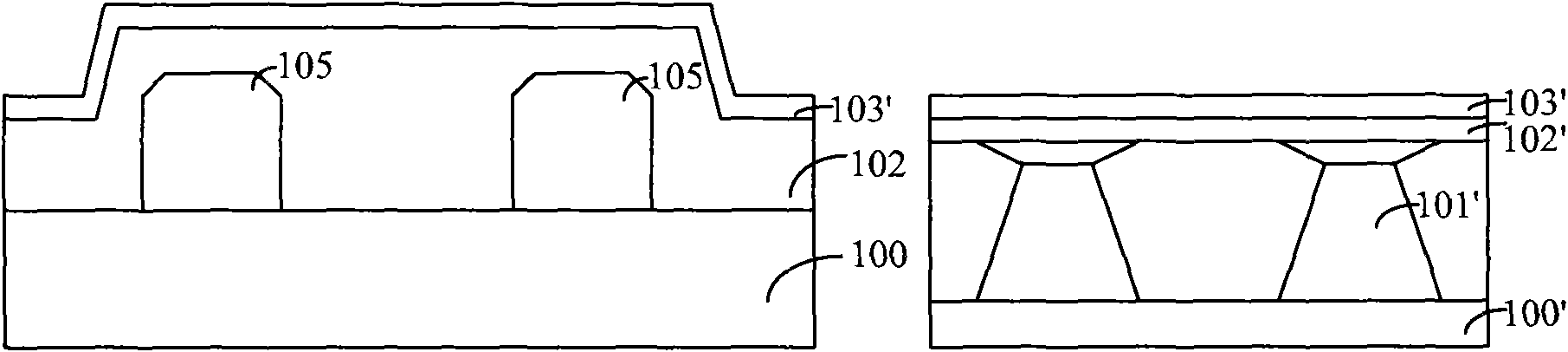

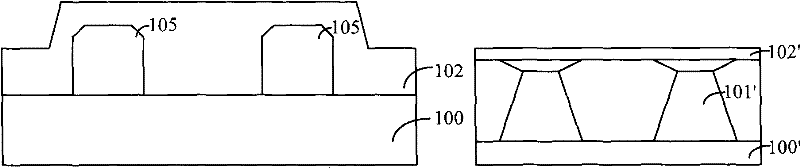

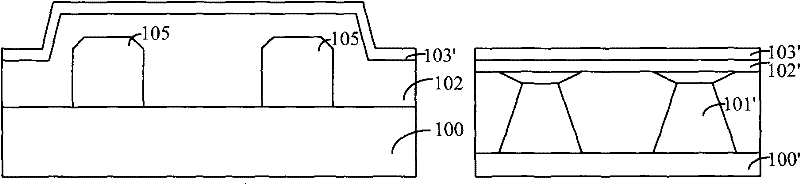

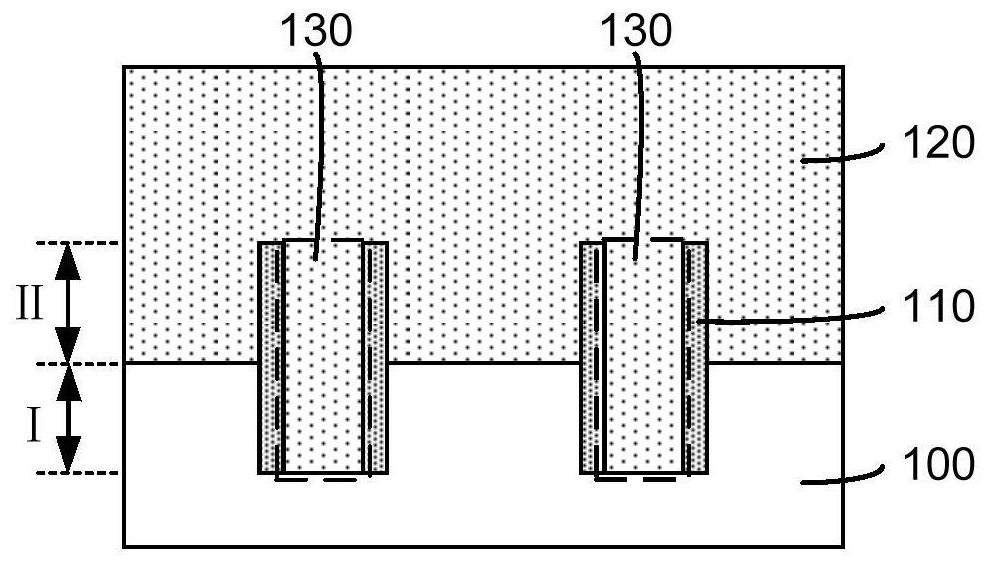

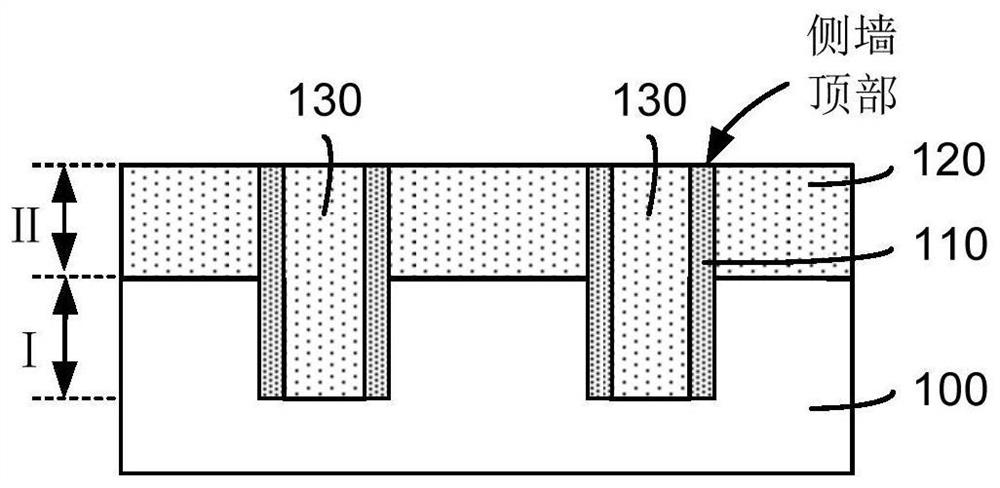

Power semiconductor device and method of manufacturing the same

ActiveCN102194688AAvoid over grindingSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceSilicon oxide

The present invention provides a method of manufacturing a power semiconductor device capable of forming a RESURF structure by burying an insulating film in a semiconductor substrate without causing a variation of the thickness of the insulating film and damage to the substrate, and also to provide a power semiconductor device manufactured by the manufacturing method. The method of manufacturing the power semiconductor device according to the present invention includes the steps of: (a) forming a silicon nitride film on a semiconductor substrate; (b) after the step (a), forming a ring-shaped trench along a peripheral portion of the semiconductor substrate 6; (c) forming a first silicon oxide film on an inner surface of the trench; (d) after the step (c), forming a second silicon oxide film on an entire surface of the semiconductor substrate to bury the trench; (e) planarizing the second silicon oxide film by using the silicon nitride film as a stopper; and (f) forming a third silicon oxide film in a region in which the silicon nitride film is removed.

Owner:MITSUBISHI ELECTRIC CORP

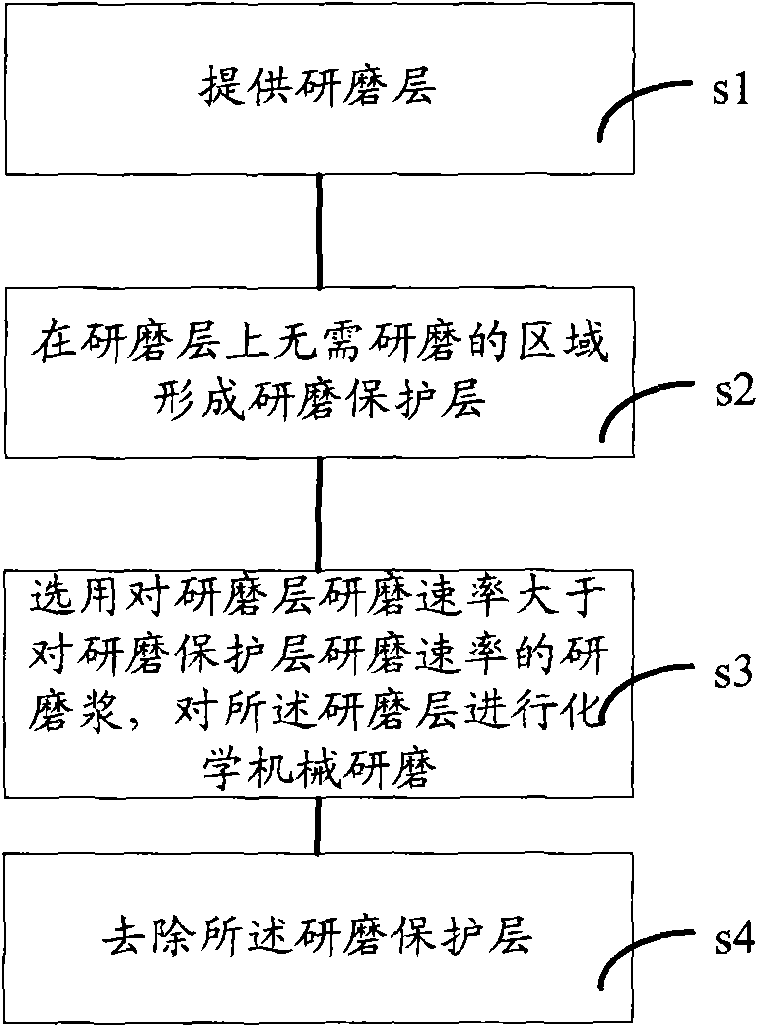

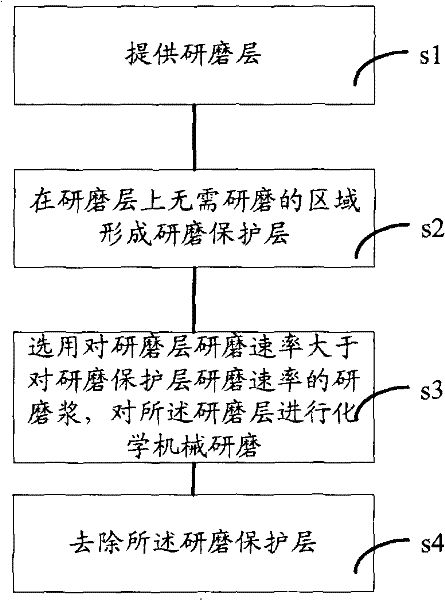

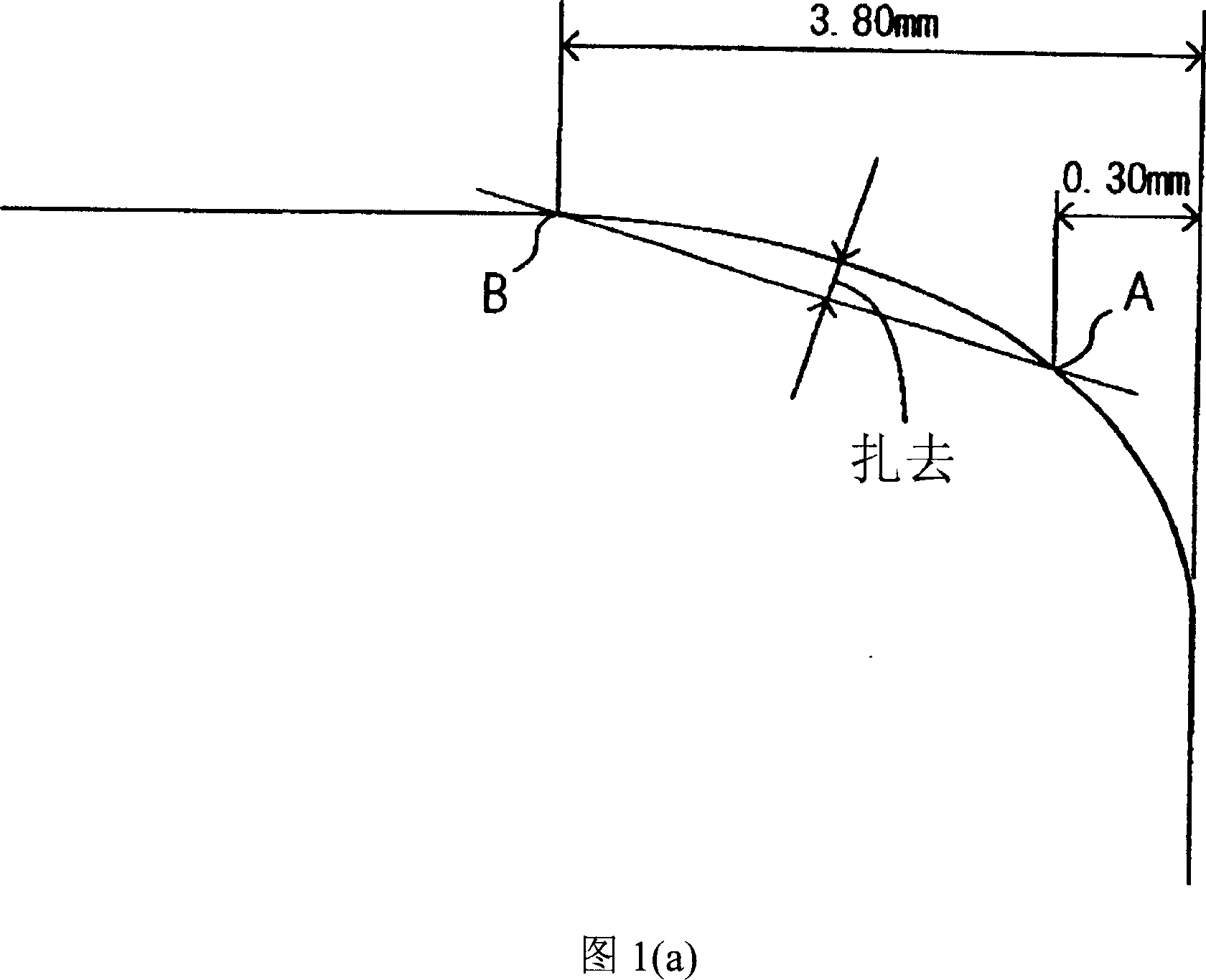

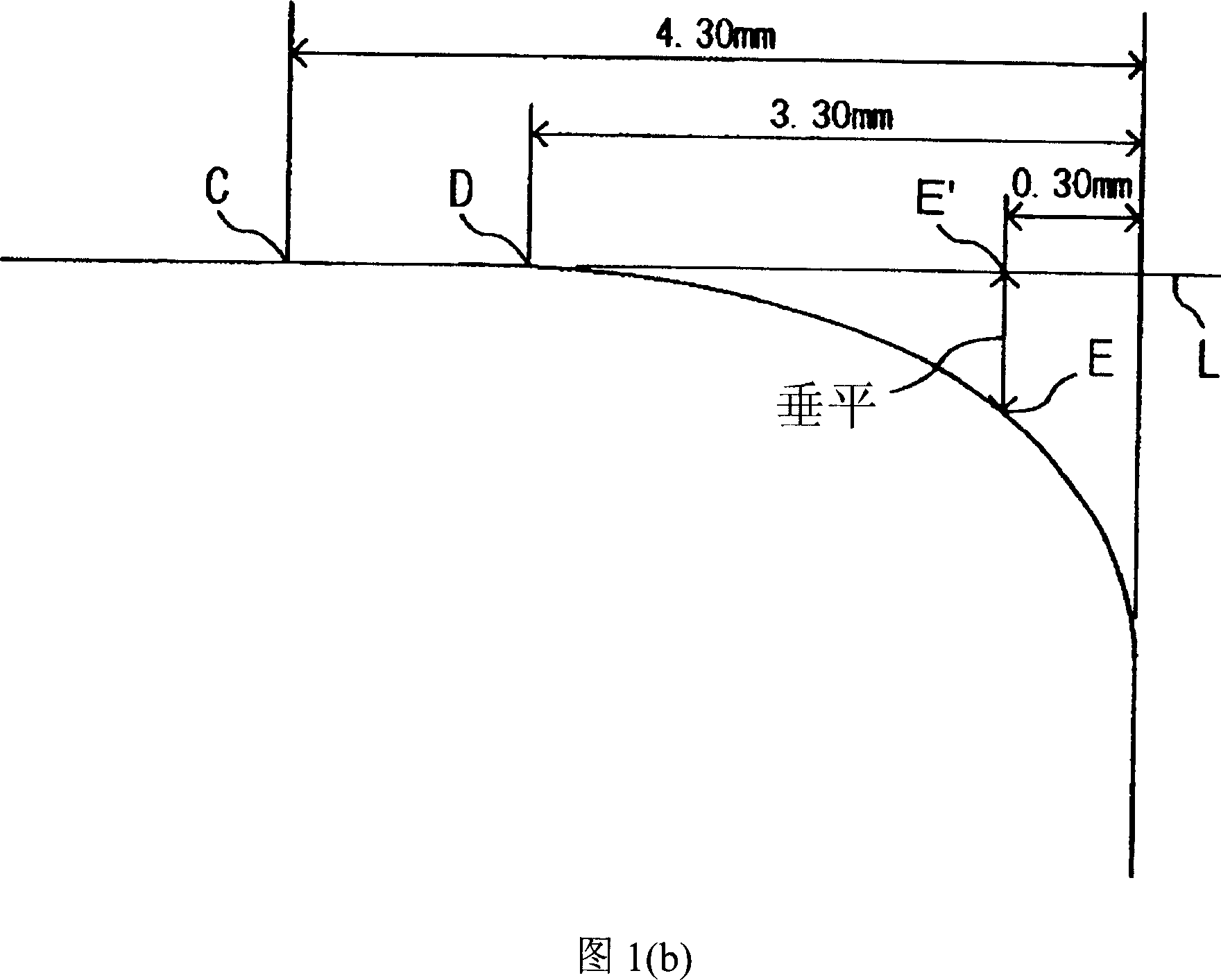

Method for chemical mechanical polishing

ActiveCN101656209AAvoid over grindingAffect performanceSemiconductor/solid-state device manufacturingMetallurgyCompound (substance)

The invention relates to a method for chemical mechanical polishing, which comprises the following steps: forming a polishing protective layer in an area without needing to be polished on a polishinglayer; and selecting a polishing paddle which has a higher polishing speed on the polishing layer than the polishing speed on the polishing protective layer to perform chemical mechanical polishing ofthe polishing layer. The method for the chemical mechanical polishing avoids the over-polishing on the area without needing to be polished, thereby preventing a polishing process from influencing thedevice performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Traditional Chinese medicine grinding equipment with adjustable grinding frequency

InactiveCN111437194AHigh degree of automationAvoid over grindingPharmaceutical product form changeGrain treatmentsProcess engineeringChinese herbology

The invention discloses traditional Chinese medicine grinding equipment with adjustable grinding frequency. The traditional Chinese medicine grinding equipment with adjustable grinding frequency comprises a substrate and a placement cavity which is located in the substrate and provided with an upward opening, wherein connection cavities which are located in the left and right sides of the placement cavity and communicate with the placement cavity are formed in the substrate, a clamping device which can clamp a traditional Chinese medicine tank with a to-be-ground traditional Chinese medicine is arranged in the connection cavities and the placement cavity, and the rotating speed of a grinding device can be adjusted by a frequency adjusting device so that the traditional Chinese medicine canbe ground into medicine powder with corresponding particle size according to the practical requirements. The clamping device of the traditional Chinese medicine grinding equipment with adjustable grinding frequency can clamp the grinding tank (traditional Chinese medicine tank) with the traditional Chinese medicine in need of grinding, the grinding tank does not need to be held by people manually, only by clamping the grinding tank into the clamping device and conducting adjustment to obtain required frequency before starting, the traditional Chinese medicine can be automatically ground intothe medicine powder, and the traditional Chinese medicine grinding equipment with adjustable grinding frequency is high in automation degree, and has a timing function, so that overgrinding due to forgetting of a user is prevented.

Owner:台州椒江路行医疗科技有限公司

An online repair method for the main screw hole of the reactor pressure vessel flange

The invention relates to an online repairing method for screw holes and threads, in particular to the online repairing method for the main screw hole of reactor pressure vessel flanges. The repairingmethod comprises the following steps of 1, defects of the main screw holes and the threads are inspected and repair preparation is carried out; 2, manually repairing is carried out by a scraper; 3, manual slight grinding is carried out by a metallographic abrasive paper; 4, screw tap repairing method is adopted; and 5, online grinding and repairing are adopted. According to the online repairing method, common defects of the main screw holes and the threads are covered, so that fine, efficient and reliable online repairing is realized.

Owner:SANMEN NUCLEAR POWER CO LTD

Grinding method of grinding system and grinding system

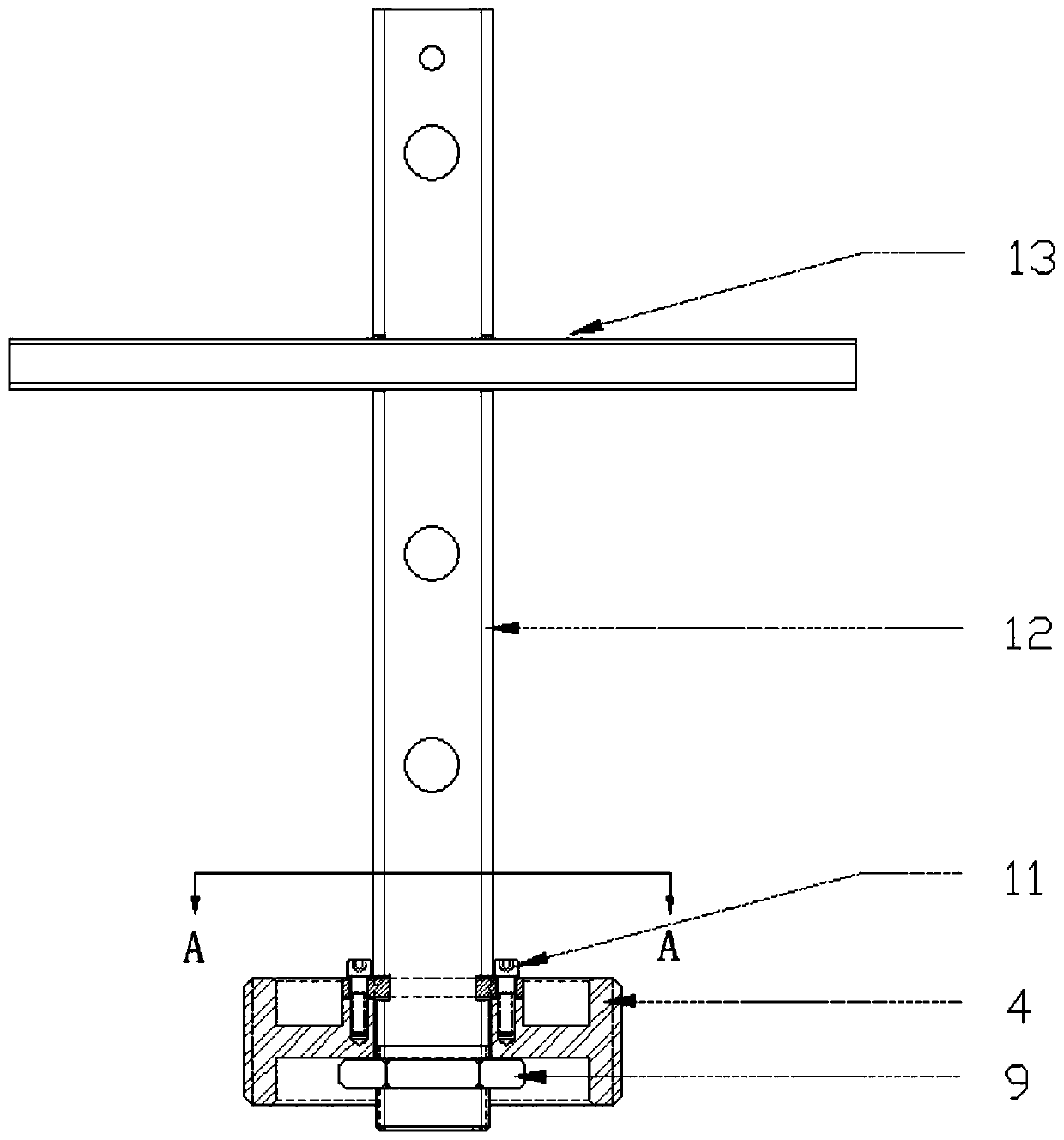

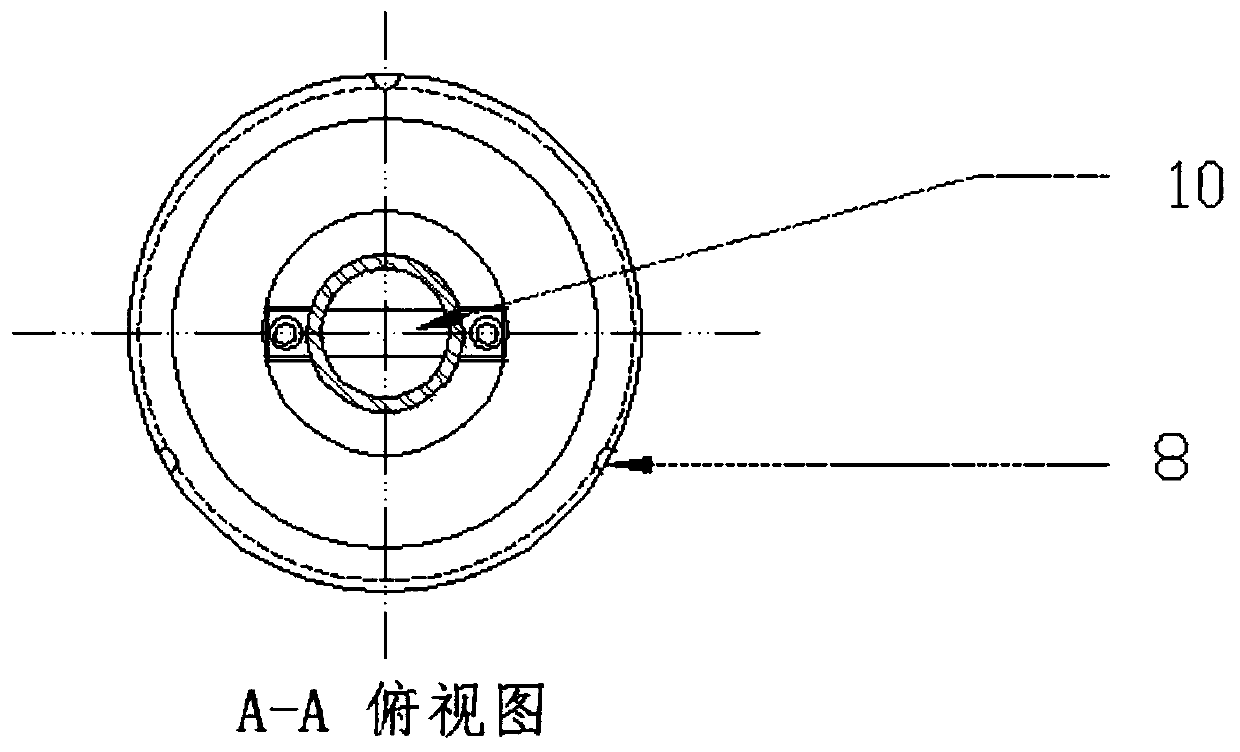

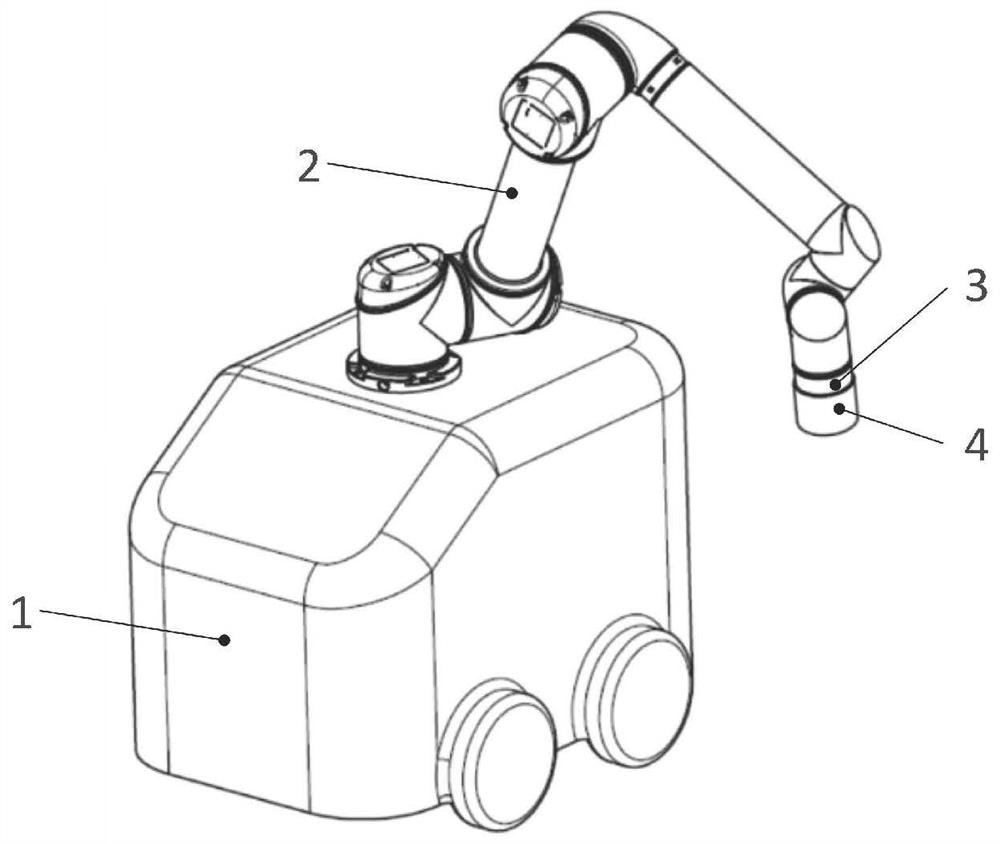

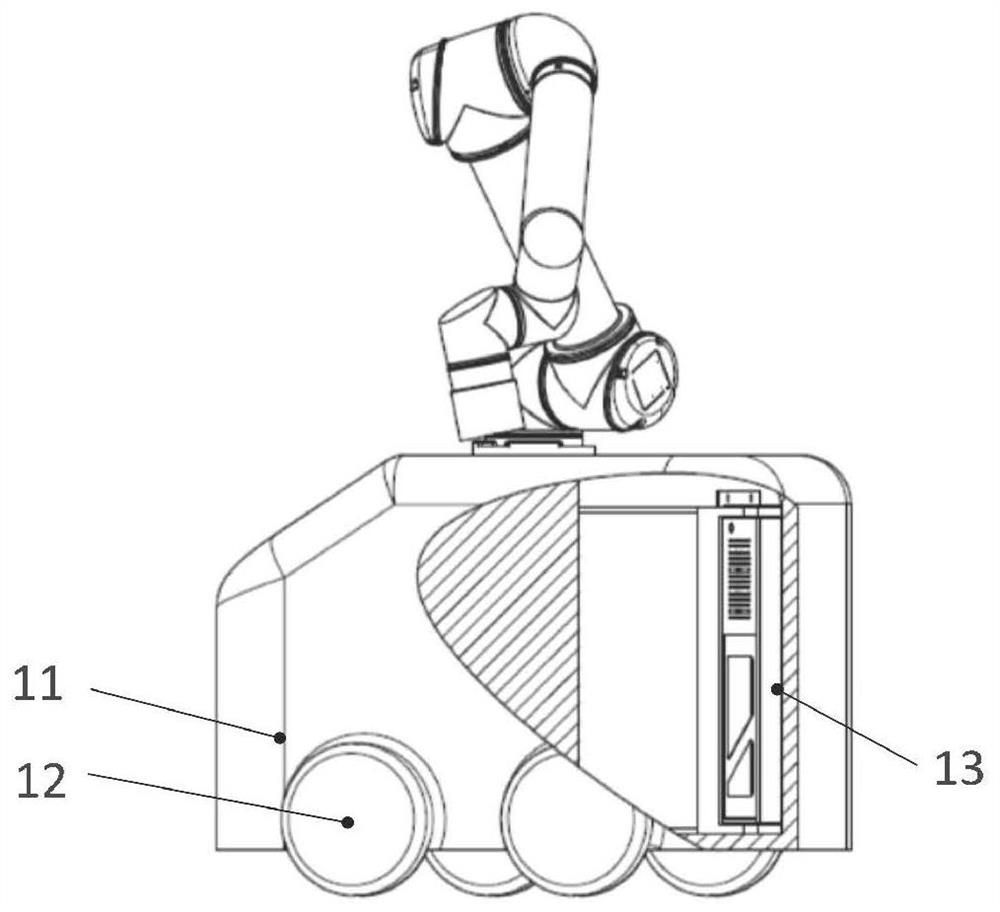

PendingCN113787382AGood grinding effectImprove grinding effectGrinding feed controlGrinding machinesGrinding processVisual perception

The invention relates to the technical field of grinding, and discloses a grinding method of a grinding system and the grinding system. The grinding method of the grinding system comprises the following steps that a visual device of the grinding system obtains information of a workpiece so as to obtain a grinding path according to the information of the workpiece; a grinding tool of the grinding system grinds the workpiece along the grinding path, and in the grinding process, the visual device detects the grinding effect of a ground area; and if the grinding effect does not meet the requirement, the grinding system re-plans the grinding path so as to re-grind the area where the grinding effect does not meet the requirement, and grinding force corresponding to the grinding effect is matched for grinding during grinding. By means of the grinding method, the grinding effect of the finally for ground workpiece is good; and during grinding, grinding force corresponding to the grinding effect is matched for grinding, and the over-grinding phenomenon is avoided. The grinding system conducts grinding through the grinding method of the grinding system, and the grinding effect can be guaranteed.

Owner:SHANGHAI AIRCRAFT MFG

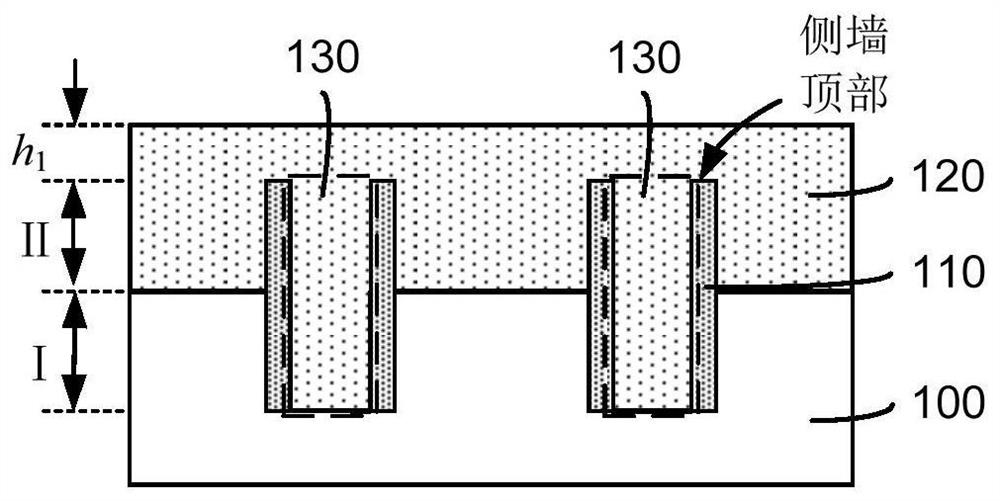

Planarization method of IGBT device

PendingCN112086354AAvoid overpolishing and undergrindingFlush on the upper surfaceSemiconductor/solid-state device manufacturingSemiconductor devicesInsulated-gate bipolar transistorPolycrystalline silicon

The invention provides a planarization method of an IGBT (Insulated Gate Bipolar Transistor) device. The method comprises the following steps of firstly, removing part of polycrystalline silicon through first grinding to expose a first insulating layer, and then, mainly removing part of the first insulating layer through second grinding to be flush with the upper surface of a second insulating layer, then, polycrystalline silicon on the upper surface of the second insulating layer being mainly removed through third grinding to expose the second insulating layer, that is, targeted grinding being achieved in each grinding process, meanwhile, each grinding process being matched with an online end point detection method to achieve control over each grinding end point, situations of over-polishing and insufficient grinding are avoided, and production efficiency is improved. Therefore, it is guaranteed that the upper surfaces of the first insulating layer and the second insulating layer obtained after planarization processing are flush, and accurate control over the uniformity of the surface morphology of the wafer is achieved.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

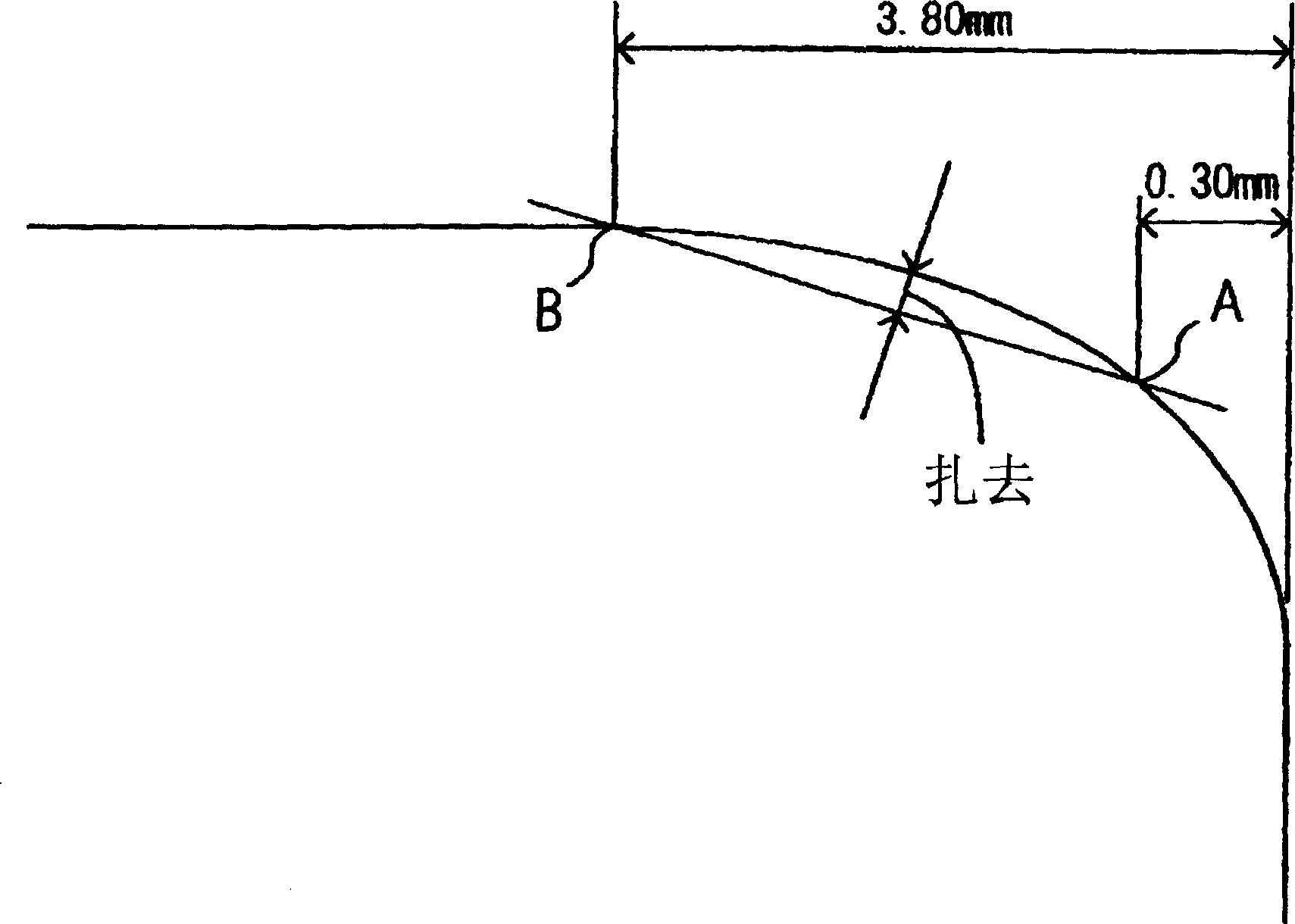

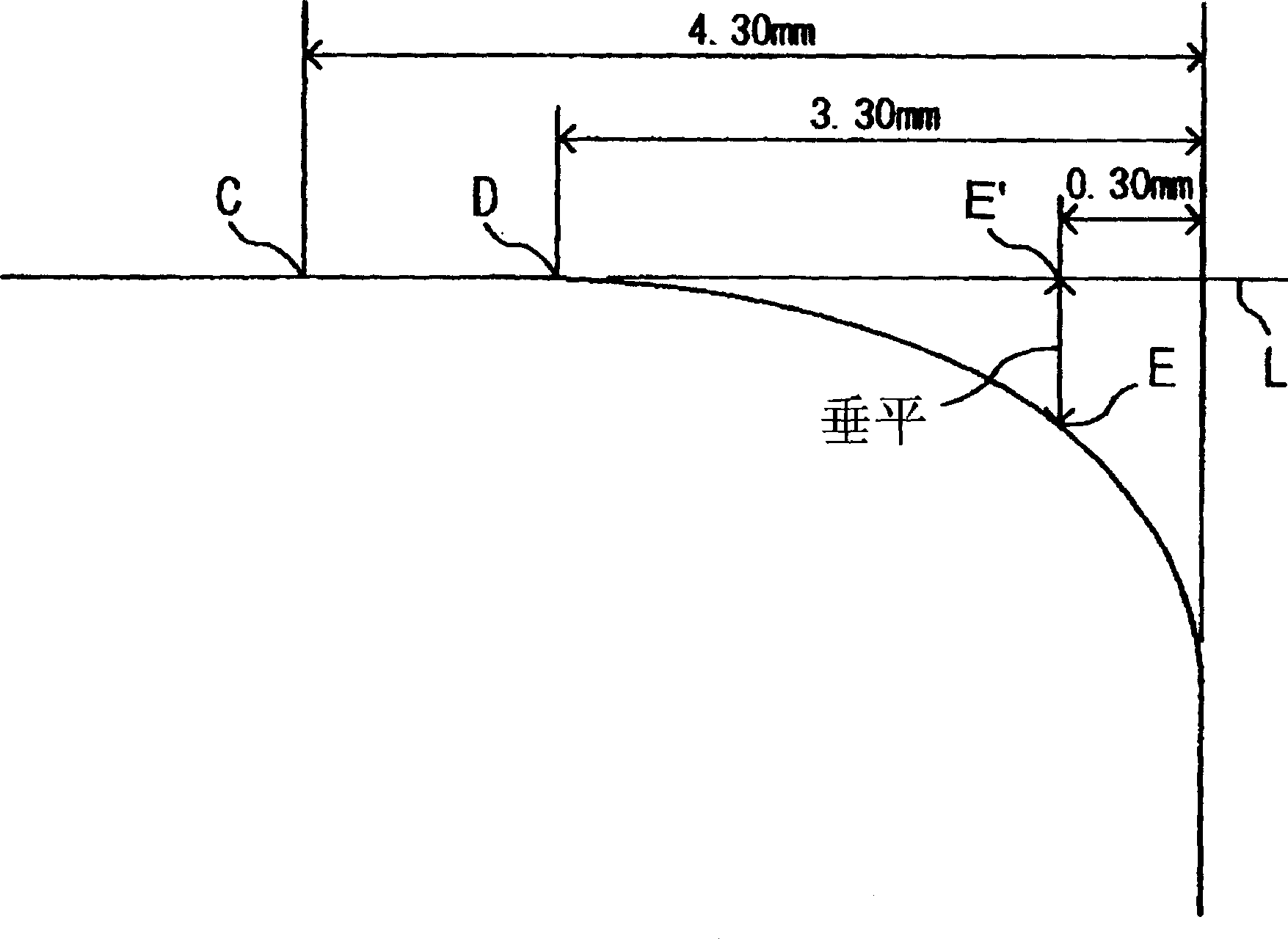

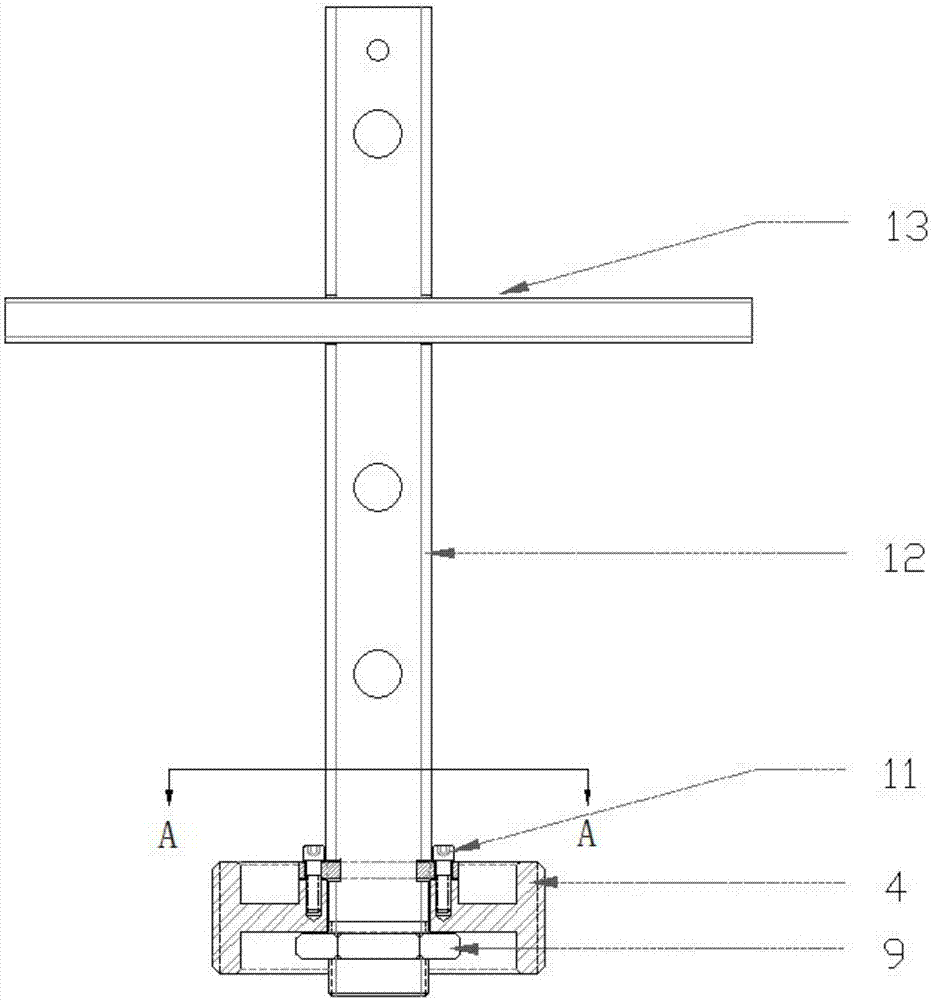

A precision grinding device and parameter determination method for plane local high point removal

ActiveCN107150286BImprove grinding precisionMeet grinding needsLapping machinesBall bearingSteel ball

The invention belongs to the technical field of precise machining and relates to a precise grinding device for the local plane high areas and a parameter determining method. The device comprises a motor shell, a damping washer, a motor, a connecting block, a transmission block, a dense ball bearing, a reference block, an eccentric grinding block, a wool felt seal ring, a precise steel ball and a pressure spring. According to the precise plane grinding device provided by the invention, the flat area around the high points on the surface of a workpiece is used as the reference, and the high points are removed through the grinding process. In the grinding device, the eccentric grinding block is used as a grinding head, non-uniform abrasion of the grinding block is reduced, and the precision of the working surface of the grinding block is improved; a bearing structure composed of a T-shaped dense ball shaft sleeve is adopted, and through the high-precision rotation and the axial limiting function of the eccentric grinding block, excessive grinding of the high point areas is prevented; and the device has the advantages of being simple in structure, convenient to operate and high in grinding accuracy and has the advantage that the eccentric grinding block can be replaced, and the device can meet the requirement for ultra-high precision plane grinding and is good in market application prospect and popularization value.

Owner:金齿传动科技(大连)有限公司

Method for chemical mechanical polishing

ActiveCN101656209BAvoid over grindingAffect performanceSemiconductor/solid-state device manufacturingMetallurgyMaterials science

The invention relates to a method for chemical mechanical polishing, which comprises the following steps: forming a polishing protective layer in an area without needing to be polished on a polishing layer; and selecting a polishing paddle which has a higher polishing speed on the polishing layer than the polishing speed on the polishing protective layer to perform chemical mechanical polishing of the polishing layer. The method for the chemical mechanical polishing avoids the over-polishing on the area without needing to be polished, thereby preventing a polishing process from influencing the device performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

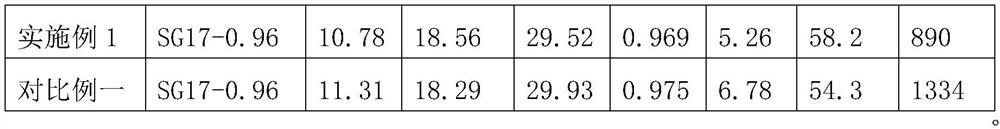

Polishing composition

A polishing composition that prevents a peripheral portion of the surface of a substrate for a magnetic disk from being excessively polished. A first polishing composition according to the present invention includes a compound, which is represented by the following general formula. The letter X represents a residue of polyether polyol. The letter m represents a number equal to the number of hydroxyl groups in one molecule of the polyether polyol. The letter Y represents a divalent hydrocarbon group. The letter Z represents a residue of a monovalent compound, which has an active hydrogen atom. The letter n represents an integer number of at least three. A second polishing composition according to the present invention includes a polymer, which has a monomer unit derived from isoprene sulfonic acid or its salt.

Owner:FUJIMI INCORPORATED

A water-based polyurethane matting resin grinding device

The invention provides a water-based polyurethane matting resin grinding device, comprising a base, a vibrating assembly is arranged on the base, a collecting box is installed on the vibrating assembly; a grinding part is arranged above the collecting box; the grinding part includes a sealing plate, Grinding head and grinding groove; the top surface of the grinding head is connected with a connecting shaft, and the top of the connecting shaft passes through the sealing plate and is located above the sealing plate; the grinding groove is an arc-shaped groove made of a mesh plate; the grinding end of the grinding head The surface shape matches the inner side of the grinding tank; the opening end of the grinding tank is connected to the inner side of the collection box; a flexible curtain is installed under the sealing plate, and the inner side of the flexible curtain is attached to the outer side of the collection box. Using the grinding device to grind resin can effectively reduce the phenomenon of excessive grinding or insufficient grinding of raw materials, improve the qualified rate of raw materials after grinding, and increase the utilization rate of raw materials; in addition, during use, it can avoid dust pollution to the environment and reduce Raw material loss.

Owner:烟台道成化学有限公司

Flattening process method

ActiveCN110729185BAvoid over grindingFacilitate subsequent processingSemiconductor/solid-state device manufacturingMetallic materialsEngineering physics

A planarization process method includes: providing a semiconductor substrate and a metal material layer, the metal material layer is arranged above the semiconductor substrate, a metal gate and a sidewall are formed in the semiconductor substrate and the metal material layer, and the sidewall is formed on the metal The two side walls of the gate, the first part of the metal gate is formed in the semiconductor substrate, and the second part of the metal gate is formed in the metal material layer; the first grinding process is used to grind the metal material layer, or grind part of the sidewall, the second part of the metal gate, so that the second part of the remaining metal gate has a first height; and performing a second grinding process on the remaining metal gate and the sidewall spacers, exposing the semiconductor substrate, the first grinding process and the second grinding process The grinding process has a grinding rate ratio for the metal material layer or metal gate and for the sidewall spacer, respectively. Grinding the second portion of the metal gate in a two-step process allows for fine control over the height dimension of the final metal gate structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

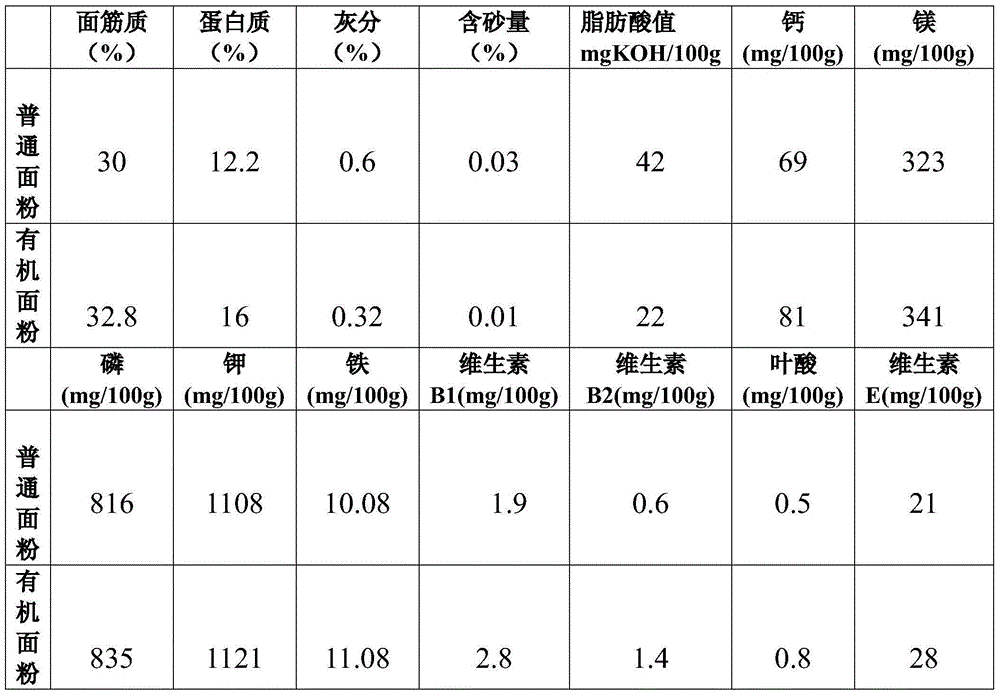

Low-temperature organic flour processing method

The invention discloses a low-temperature organic flour processing method. The low-temperature organic flour processing method comprises the three processing steps of checking unprocessed grains, cleaning the unprocessed grains and pulverizing the unprocessed grains; the process of checking the unprocessed grains comprises the sub-step of carrying out conventional check and activity check on the unprocessed grains; the process of cleaning the unprocessed grains comprises the sub-step of removing impurities in the qualified unprocessed grains by using common screening equipment and a special colour selector for wheat; and the process of pulverizing the unprocessed grains comprises the sub-step of grinding and pulverizing the unprocessed grains without impurities in a low-temperature production environment, and finally, packaging prepared flour by using a freshness protection bag. The whole course of the flour processing technology is carried out at low temperature; and furthermore, wheat is prevented from being grinded excessively by extending the length of a flour grinding path, and therefore, the reserving ratio of nutritional ingredients of wheat and the reserving ratio of original wheat flavour of wheat flour are greatly increased.

Owner:孟景华

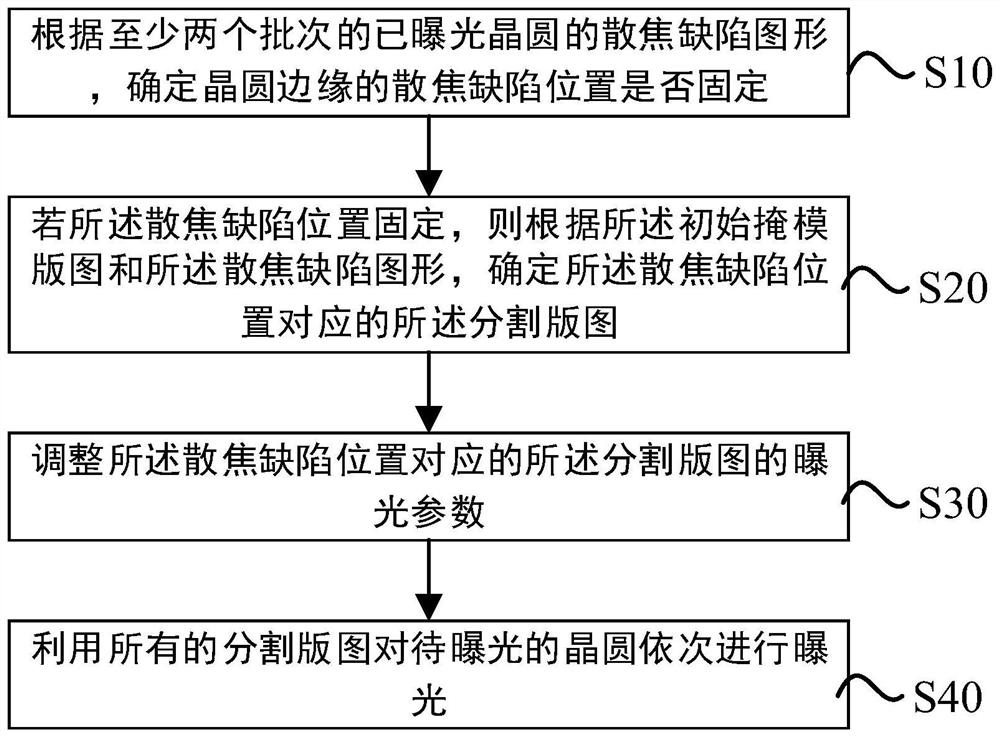

Photoetching method

PendingCN114675504AImprove yieldAvoid over grindingPhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsExposure

The photoetching method comprises the following steps: determining whether the position of a defocusing defect on the surface of a wafer is fixed or not according to a defocusing defect pattern; if the position of the defocusing defect is fixed, determining a segmentation layout corresponding to the position of the defocusing defect according to the initial mask plate graph and the defocusing defect graph; adjusting exposure parameters of the segmented layout corresponding to the defocusing defect position; and sequentially exposing the wafer by using all the segmentation layouts. According to the method, the position of the defocus defect is fixed, and the segmentation layout corresponding to the position of the defocus defect is determined by using the initial mask plate graph and the defocus defect graph, so that the exposure parameter of the segmentation layout corresponding to the position of the defocus defect is adjusted; therefore, the position of the mask pattern transferred to the wafer is adjusted in advance in the photoetching process, the problem that a partial region on the wafer is over-ground or insufficiently ground due to a load effect generated on the surface of the wafer when the surface of the wafer is chemically and mechanically ground is avoided, and the yield of a device is improved.

Owner:HUA HONG SEMICON WUXI LTD +1

Dry-type sampling method and device for easily-hydrolyzed brittle soft rock standard test piece

PendingCN114674631AReduce manufacturing costOvercoming the Direct Drill StereotypePreparing sample for investigationMechanical engineeringClassical mechanics

The invention relates to the technical field of rock mechanics, in particular to a dry-type sampling device and method for an easily-hydrolyzed brittle soft rock standard test piece, and the dry-type sampling device comprises a base and a top module which are connected with a processing chamber, a lower rotating module for supporting and fixing the bottom surface of a sample of an octagonal-prism-shaped soft rock block, and a friction assembly arranged on the side surface of the sample, the control assembly is electrically connected with the lower rotating module and the friction assembly and controls the lower rotating module and the friction assembly to move. The characteristics of low hardness and easy polishing of soft rock are utilized, low-strength cutting and polishing are adopted, no cooling water participates in and is not influenced in the whole process, and the defects that a soft rock sample is easy to crack, the physical and mechanical properties of the sample are changed and the like due to stress concentration caused by a traditional sampling method are avoided to the greatest extent; the integrity and the accuracy of physical and mechanical parameters of the soft rock sample are ensured to the greatest extent, and meanwhile, the sampling success rate of on-site rock blocks is improved.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

An energy-saving and environment-friendly crushing device for construction engineering

ActiveCN112138768BAvoid over-grindingImprove filtering effectGrain treatmentsConstruction engineeringStructural engineering

The invention relates to the technical field of crushing, in particular to an energy-saving and environment-friendly crushing device for construction engineering. It includes a shell, a first endless filter belt, a first crushing assembly, a second endless filter belt, a second crushing assembly, and a discharge belt. The shell is provided with a first transmission device and a second transmission device arranged up and down. Driven by the transmission device, the two filter belts rotate in opposite directions, and the upper part of the two filter belts is tensioned, while the lower part is loose, and they are arranged obliquely in opposite directions. In the present invention, the material is sieved through the first annular filter belt first, and then enters the first crushing assembly for primary crushing; after coarse sieving and primary crushing, the material is sieved by the second annular filter belt, and then Enter the second crushing component for secondary crushing; through the crushing process combined with screening, crushing and graded crushing, the over-grinding phenomenon caused by re-crushing the qualified materials is avoided, and the screening effect and the rational use of equipment are improved. rate, energy saving and environmental protection.

Owner:HUANGHUAI UNIV

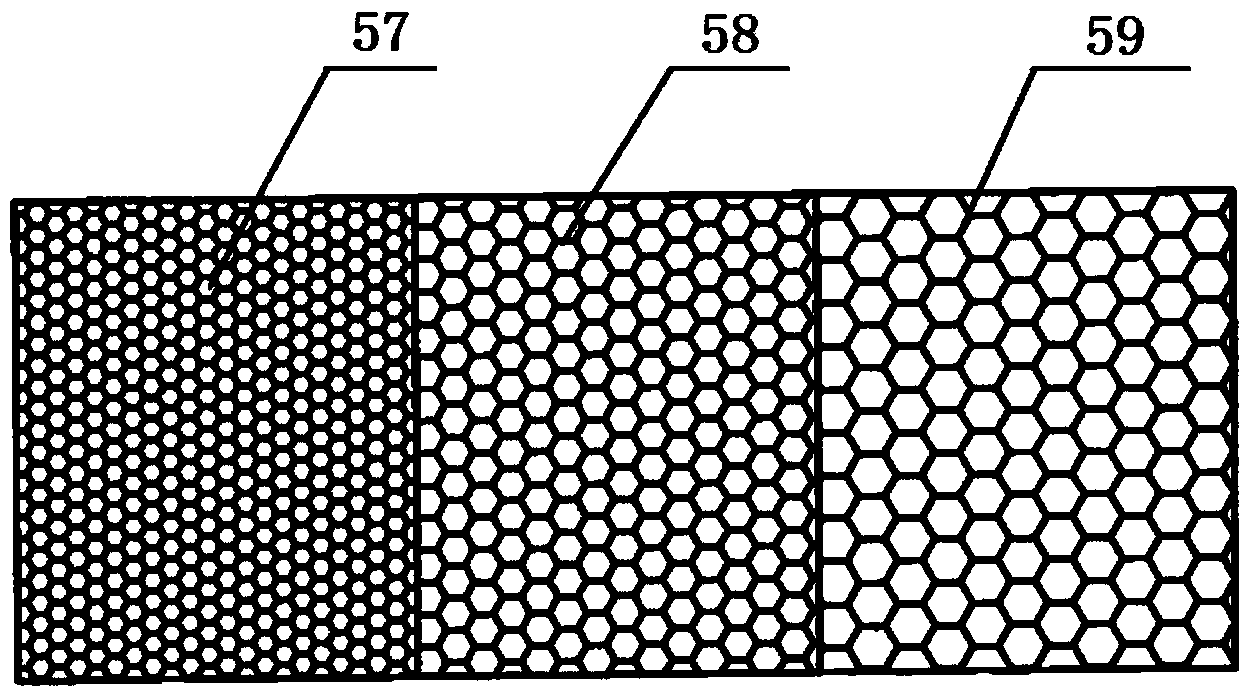

Wheat bran removing device for preparing wheat flour and use method of wheat bran removing device

ActiveCN114471790AEasy to filterHigh precisionGrain huskingGrain polishingAgricultural engineeringWheat Brans

The wheat bran removing device comprises a placing box, an electrode box and a grinding box, the placing box is located at the top of the electrode box, the electrode box is located at the top of the grinding box, a screening part is arranged in the grinding box, and the screening part is located at the top of the electrode box. The screening piece is sequentially provided with a first ring layer, a second ring layer, a third ring layer and a fourth ring layer from top to bottom. According to the bran removing device for wheat flour and the use method of the bran removing device, flour particles needing to be ground can be ground through the first ring layer, the second ring layer, the third ring layer and the fourth ring layer, and flour is sequentially ground layer by layer from the first ring layer to the fourth ring layer from top to bottom; the grinding precision can be improved, wheat particles can be ground for the first time conveniently through an electric rotating plate and a smashing plate, the wheat particles are screened for the first time, and the wheat particles and wheat bran can be separated for the first time.

Owner:石家庄市藁城区立峰面业有限公司

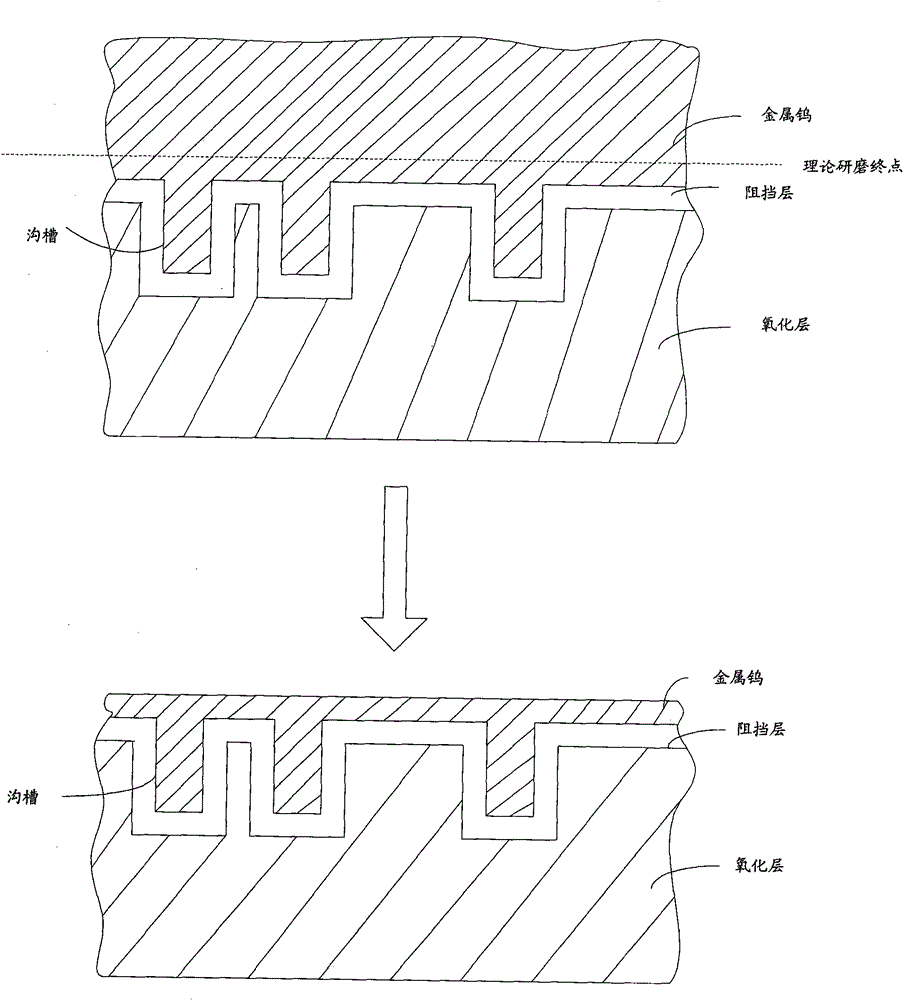

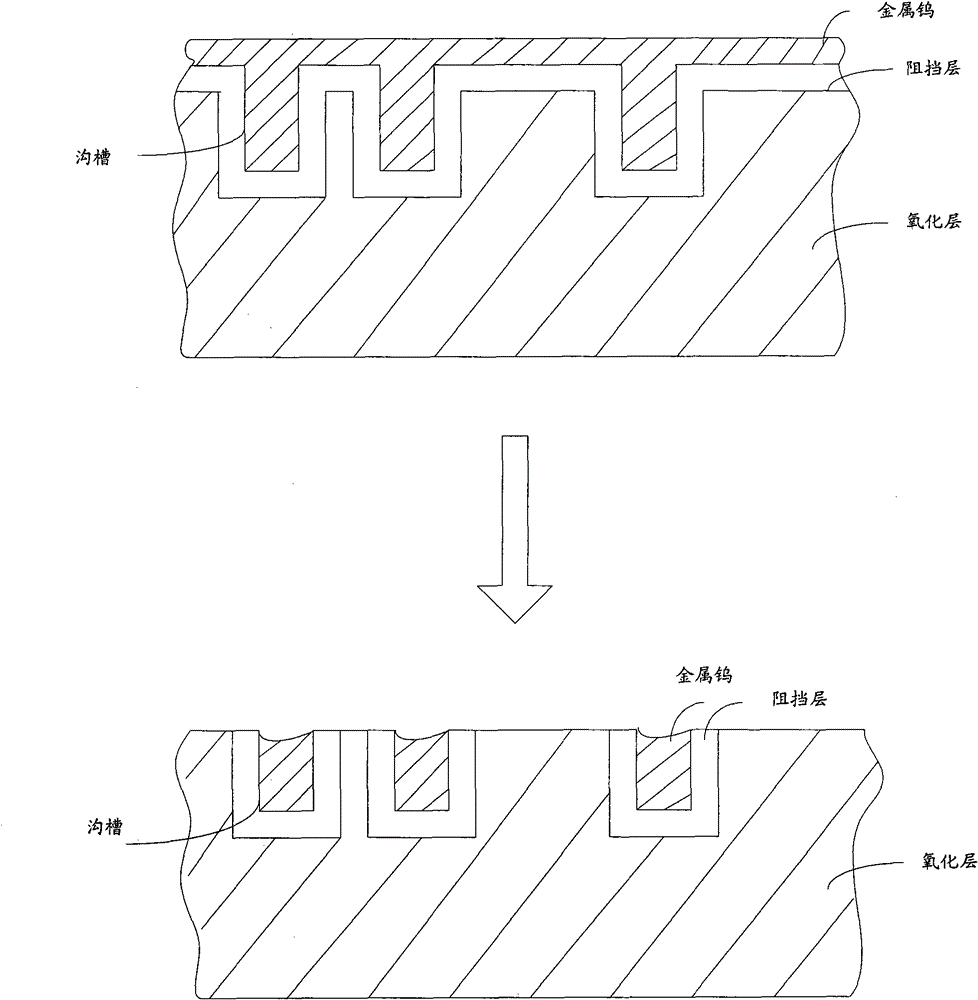

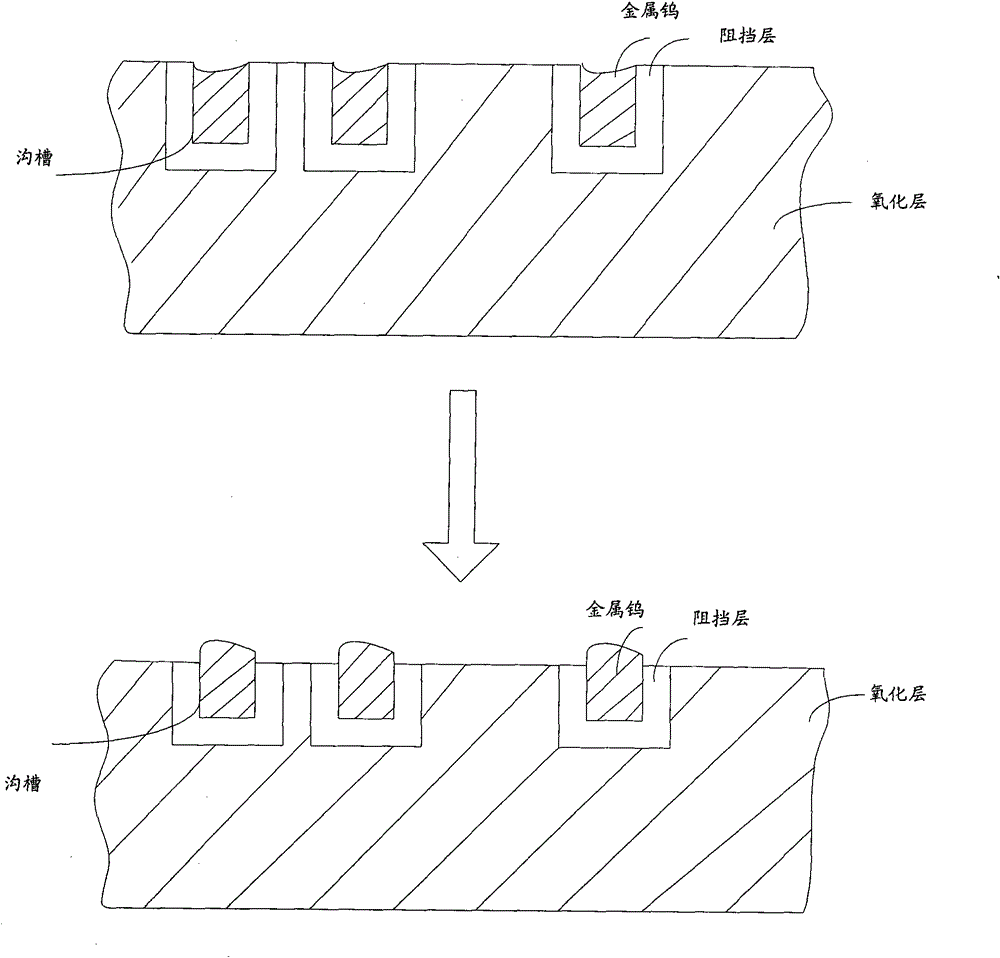

Chemical mechanical lapping method

ActiveCN101966687BAvoid over grindingImprove stabilitySemiconductor/solid-state device manufacturingLapping machinesCompound (substance)Blocking layer

The invention discloses a chemical mechanical lapping method which comprises the following steps: when carrying out lapping on metals, detecting a theoretic lapping end point in real time, and when the theoretic lapping end point is detected, lapping the surplus metals outside a blocking layer, an oxidation layer and a groove; and continuing to carry out lapping on the oxidation layer, wherein the lapping time of the oxidation layer is a preset fixed value. By using the method, the stability of devices can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com