Method for chemical mechanical polishing

A chemical-mechanical, grinding-layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting device performance, excessive grinding, etc., to avoid device performance, avoid excessive grinding, and achieve selective grinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

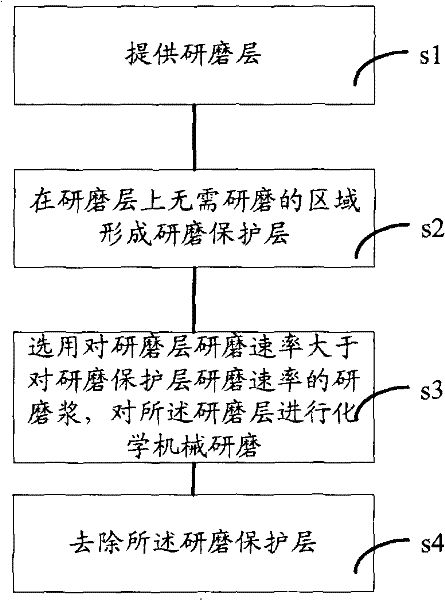

[0013] refer to figure 1 Shown, a kind of embodiment of the method for chemical mechanical polishing of the present invention comprises:

[0014] Step s1, providing a grinding layer;

[0015] Step s2, forming a grinding protective layer on the grinding layer on the area that does not need grinding;

[0016] Step s3, selecting a slurry whose grinding rate for the grinding layer is greater than the grinding rate for the grinding protective layer, and performing chemical mechanical grinding on the grinding layer;

[0017] Step s4, removing the grinding protection layer.

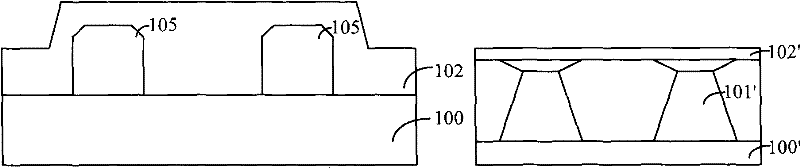

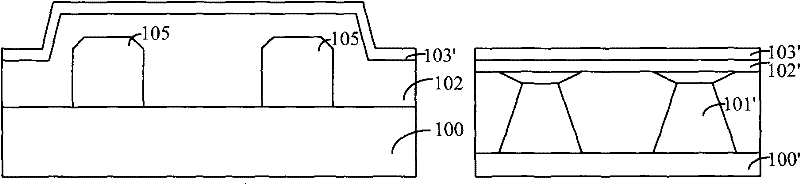

[0018] In a specific embodiment, the grinding layer can be the excess polysilicon layer that needs to be removed during the process of forming the erasing gate and the device gate in the memory process, or it can be the local thickness adjustment or surface smoothing that needs to be performed in other processes Adjusted material layers.

[0019] However, before chemical mechanical polishing, the grinding pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com