Chemical mechanical lapping method

A grinding method and chemical mechanical technology, which is applied in the direction of grinding devices, grinding machine tools, electrical components, etc., can solve the problems of reducing the stability of devices and small metal resistance, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

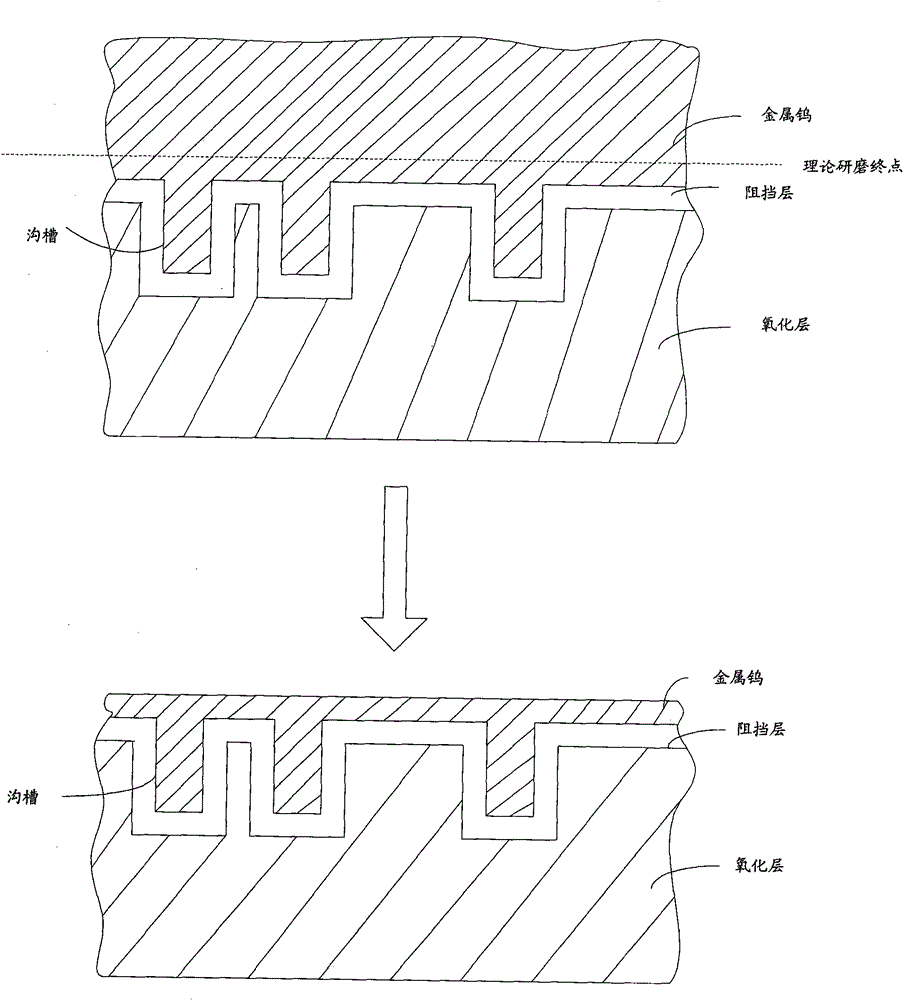

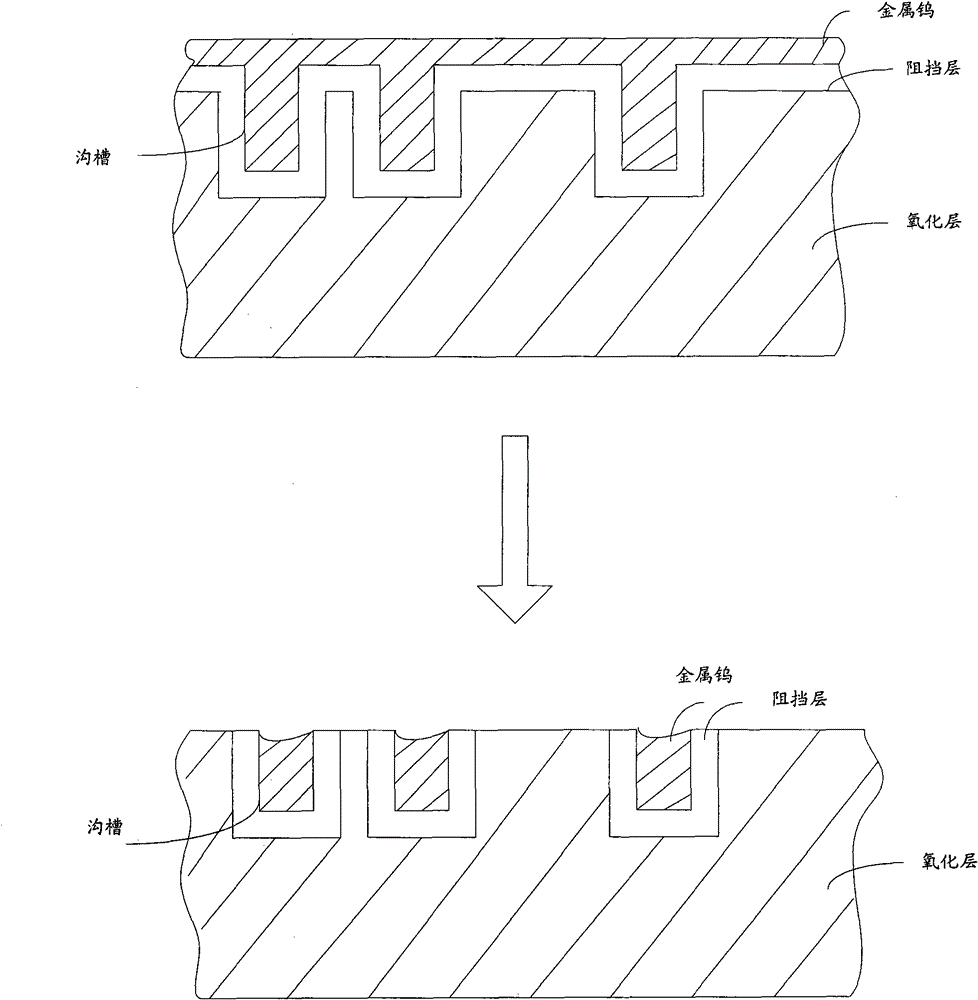

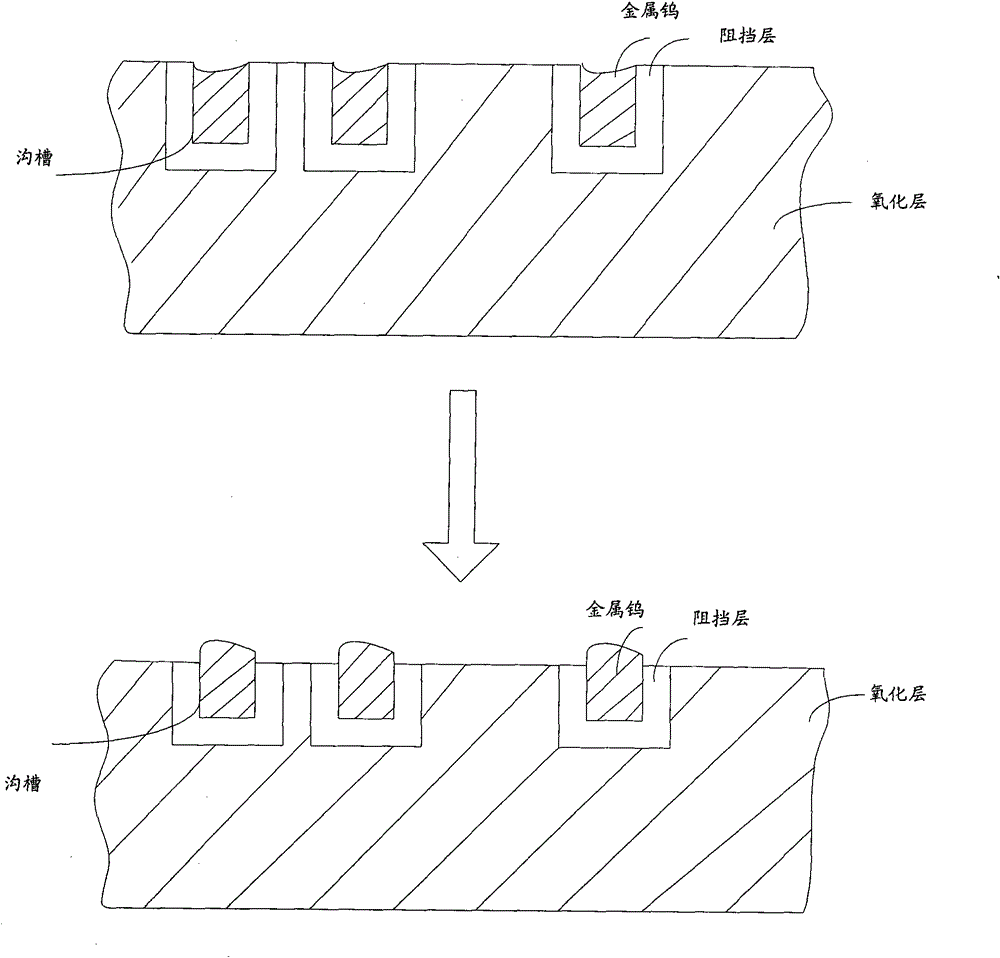

[0019] The core idea of the present invention is: when performing the first process, detect the theoretical grinding end point in real time, when the theoretical grinding end point is detected, end the first process and execute the second process, which can ensure that when the metal layer is ground to a point close to the theoretical The second process is performed immediately when the position of the end point is ground, and after the first process and the second process are completed, the entire oxide layer and the metal in the trench can be prevented from being over-grinded.

[0020] Figure 4 It is a flowchart of an embodiment of a chemical mechanical polishing method provided by the present invention. Such as Figure 4 As shown, the method in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com